If you encounter a failure in automatic filament loading and unloading when using CFS, in addition to scanning the QR code in the error code pop-up window to find the corresponding troubleshooting Wiki, we have also prepared these general troubleshooting steps. When facing filament loading/unloading issues, you can directly follow this troubleshooting document, which will help you resume printing as quickly as possible.

Before you start troubleshooting CFS filament loading and unloading issues, we recommend that you first read this Wiki: Intro of CFS Main Function and Worklfow to understand the main functions of CFS, such as filament pre-feeding, filament loading detection (RFID reading), and the working principles of automatic filament loading and unloading, to facilitate subsequent troubleshooting.

¶ 1. Fault prevention

- The filament path is relatively long if you use CFS for filament feeding and unloading. Our recommended CFS placement method and PTFE tube length can effectively reduce the failure. If you need to change the CFS placement position, please ensure that the PTFE tube does not have any sharp bends.

- Layer compression can also cause filament loading and unloading issues. If you notice layer compression, please address this issue first. Refer to this Wiki page:Troubleshooting for Layer Compression

- The condition of the filament spool also affects. Be careful not to use damaged or deformed filament spools, or spools that are too small or too large, as these can cause the spool to rotate poorly inside the CFS, resulting in feeding and unloading failures. For more details, please refer to Wiki page: CFS Filament Compatibility Description

- Due to friction between the filament and filament tube, and the limited service life of PTFE tubes, regular maintenance can prevent failures in advance. Refer to this Wiki page: K2 Plus Periodic Maintenance Tips

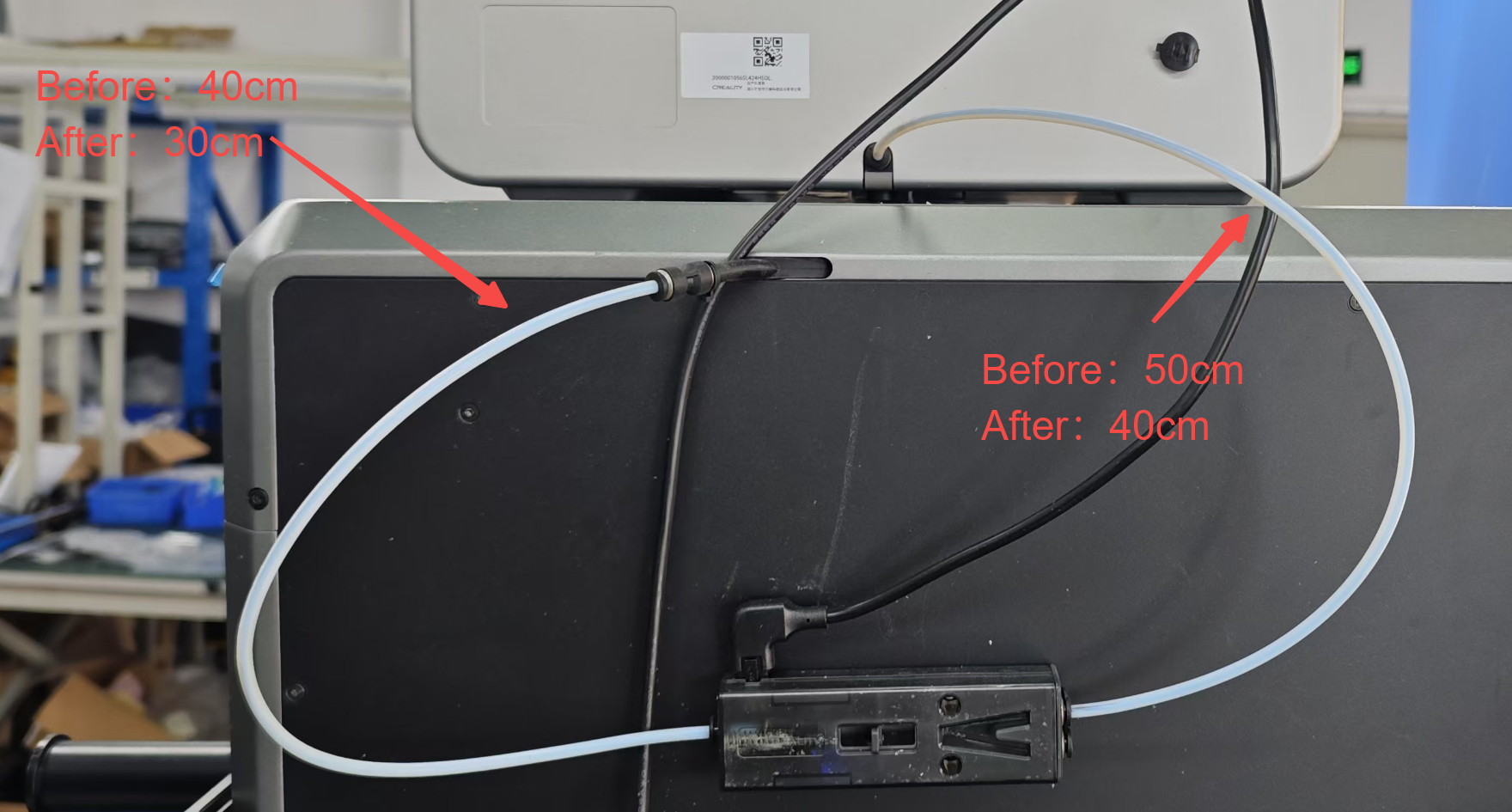

- The initial version of the printer has two PTFE tubes at the back of the CFS (from buffer to CFS and from buffer to machine), with lengths of 40cm and 50cm respectively in the package. After long-term verification, we found that adjusting them to 30cm and 40cm can effectively reduce the failure rate. If you are using the longer version of PTFE tubes and experiencing frequent feeding and unloading issues, it is recommended to cut them shorter before use.

¶ 2. Troubleshooting

We have provided illustrations to help you troubleshoot issues based on the machine's status, along with Wiki links to potential solutions below each illustration, allowing you to quickly resolve problems.

¶ 2.1 Automatic Filament Feeding Failure

CFS enables automatic filament feeding, which occurs in the following situations:

①During filament pre-feeding;

②During filament insertion detection;

③During manual filament feeding;

④At the start of printing;

⑤During filament replacement in multi-color printing;

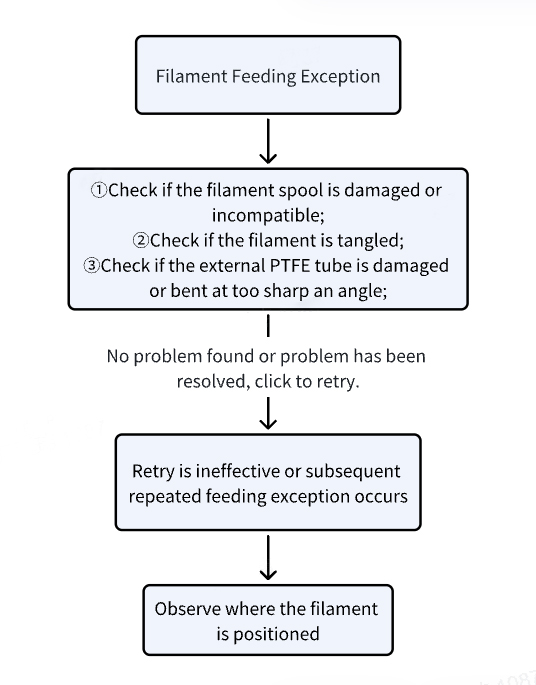

¶ If CFS automatic filament feeding fails, please follow these steps to troubleshoot:

Wiki Pages:

CFS Filament Compatibility Description

Filament entangling Solution: FB2847

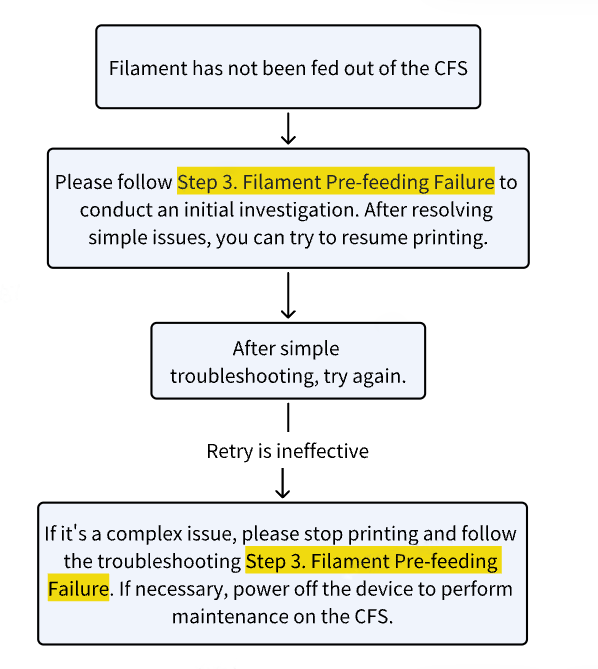

¶ Filament has not been fed out of the CFS

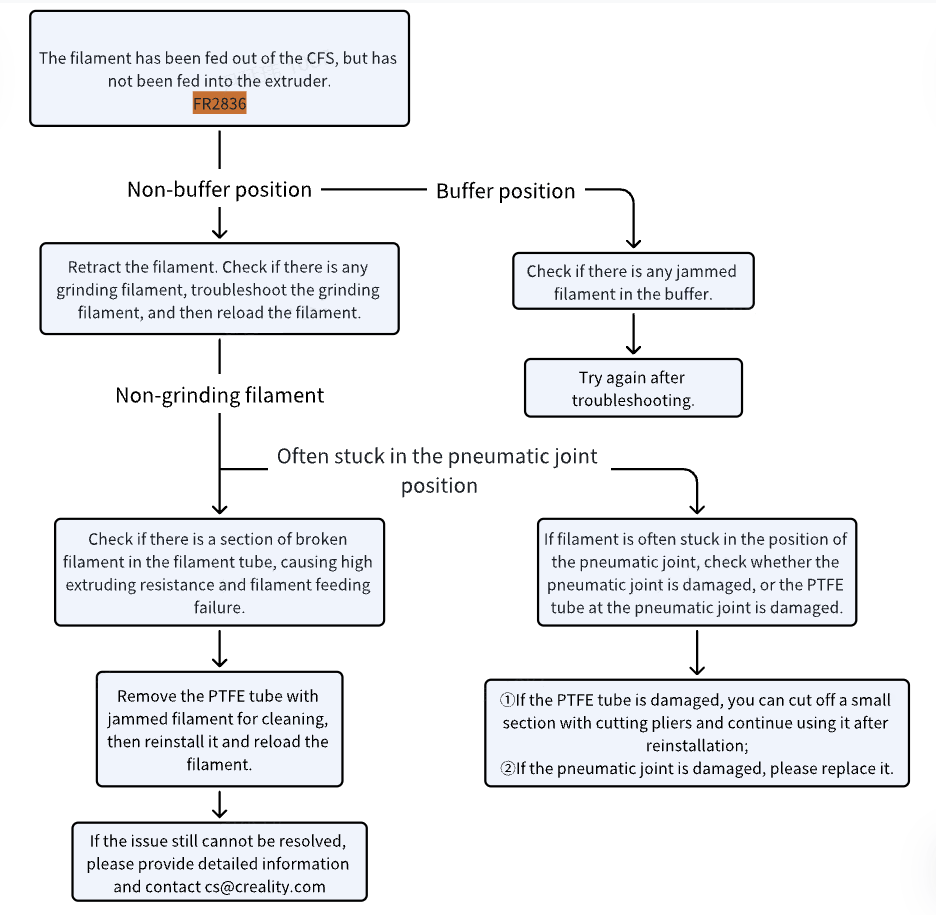

¶ The filament has been fed out of the CFS, but has not been fed into the extruder.

Wiki Pages:

Troubleshooting for Grinding Filament

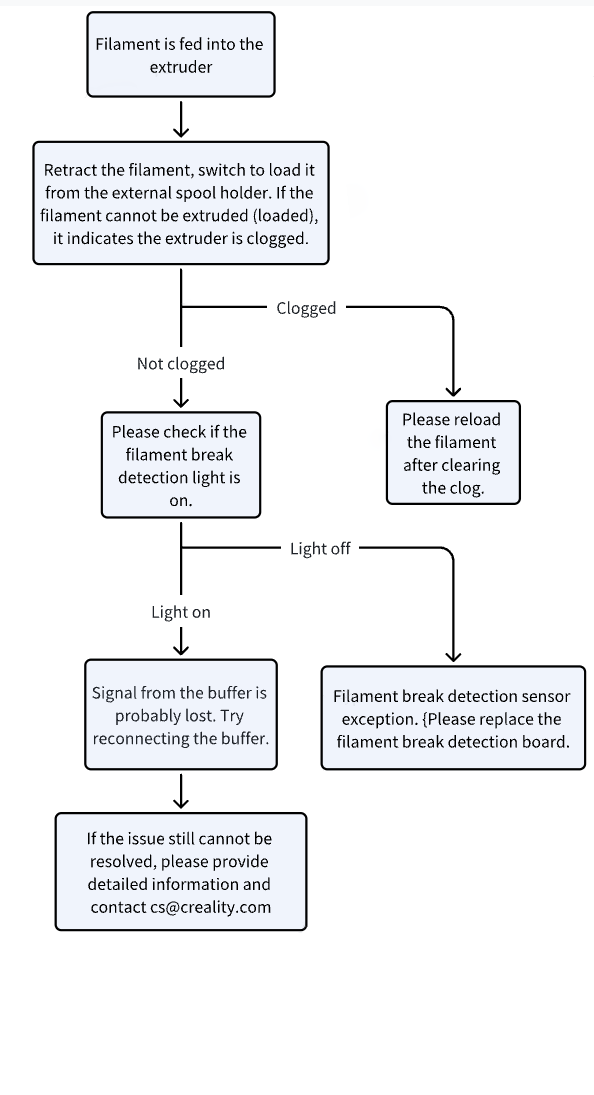

¶ Filament is fed into the extruder

Wiki Pages:

Troubleshooting for K2 Plus Jammed Filament

Replace K2 Plus Filament Break Detection

¶ 2.2 Automatic Filament Retraction Failure

CFS enables automatic filament unloading, which occurs in the following situations:

①During filament pre-feeding process, filament is rewinding and auto-tensioning;

②After RFID reading, filament is rewinding;

③During manual filament unloading;

④During filament replacement in multi-color printing;

⑤At the end of printing;

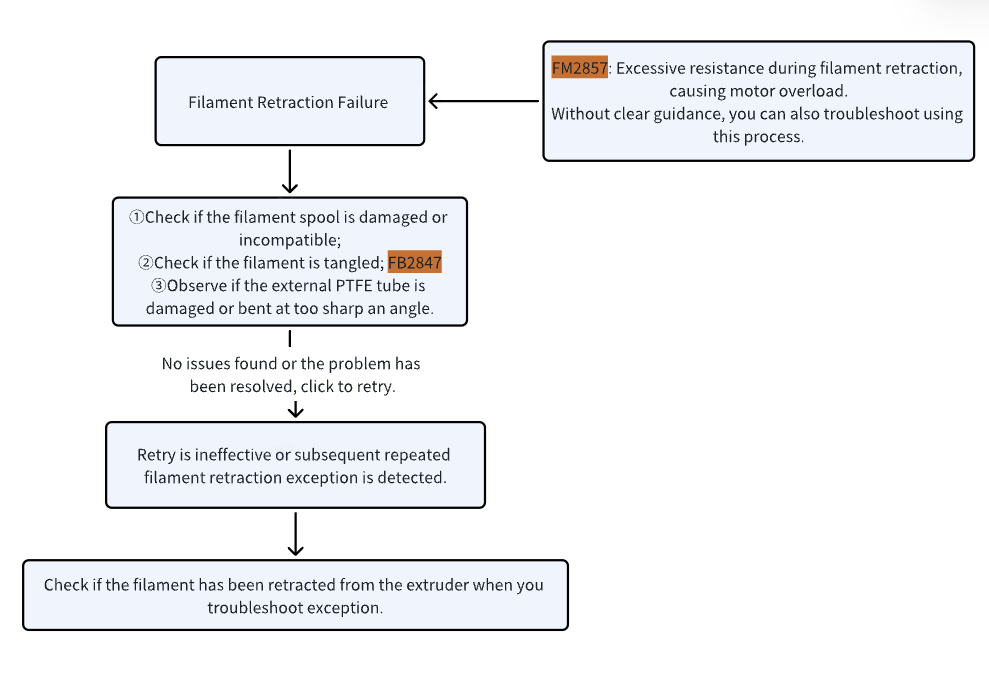

If CFS automatic filament unloading fails, please follow these steps to troubleshoot:

Wiki Pages:

CFS Filament Compatibility Description

Filament entangling Solution: FB2847

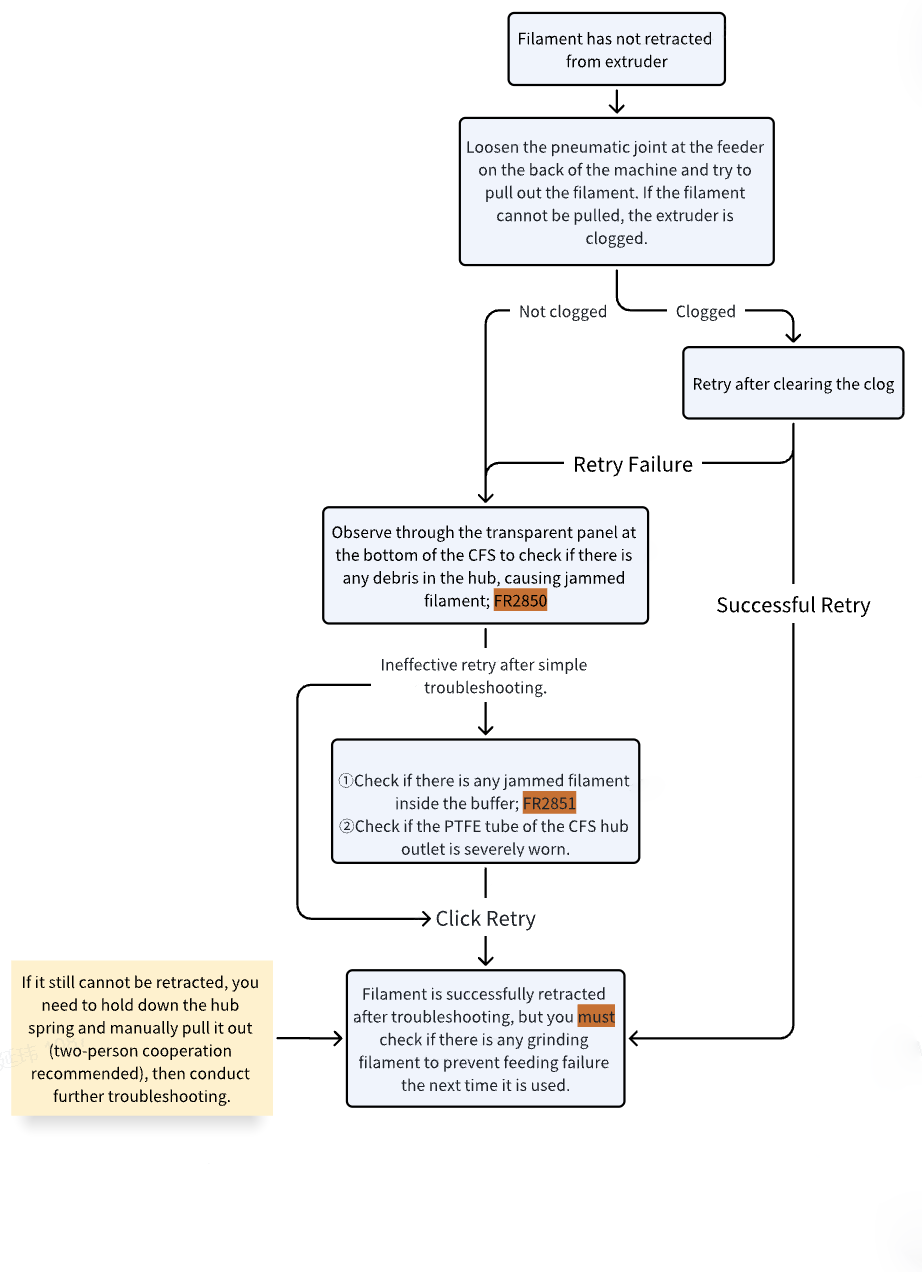

¶ Filament has not retracted from extruder

Wiki Pages:

Troubleshooting for K2 Plus Jammed Filament

Troubleshooting for CFS hub filament clogged

Troubleshooting for Grinding Filament

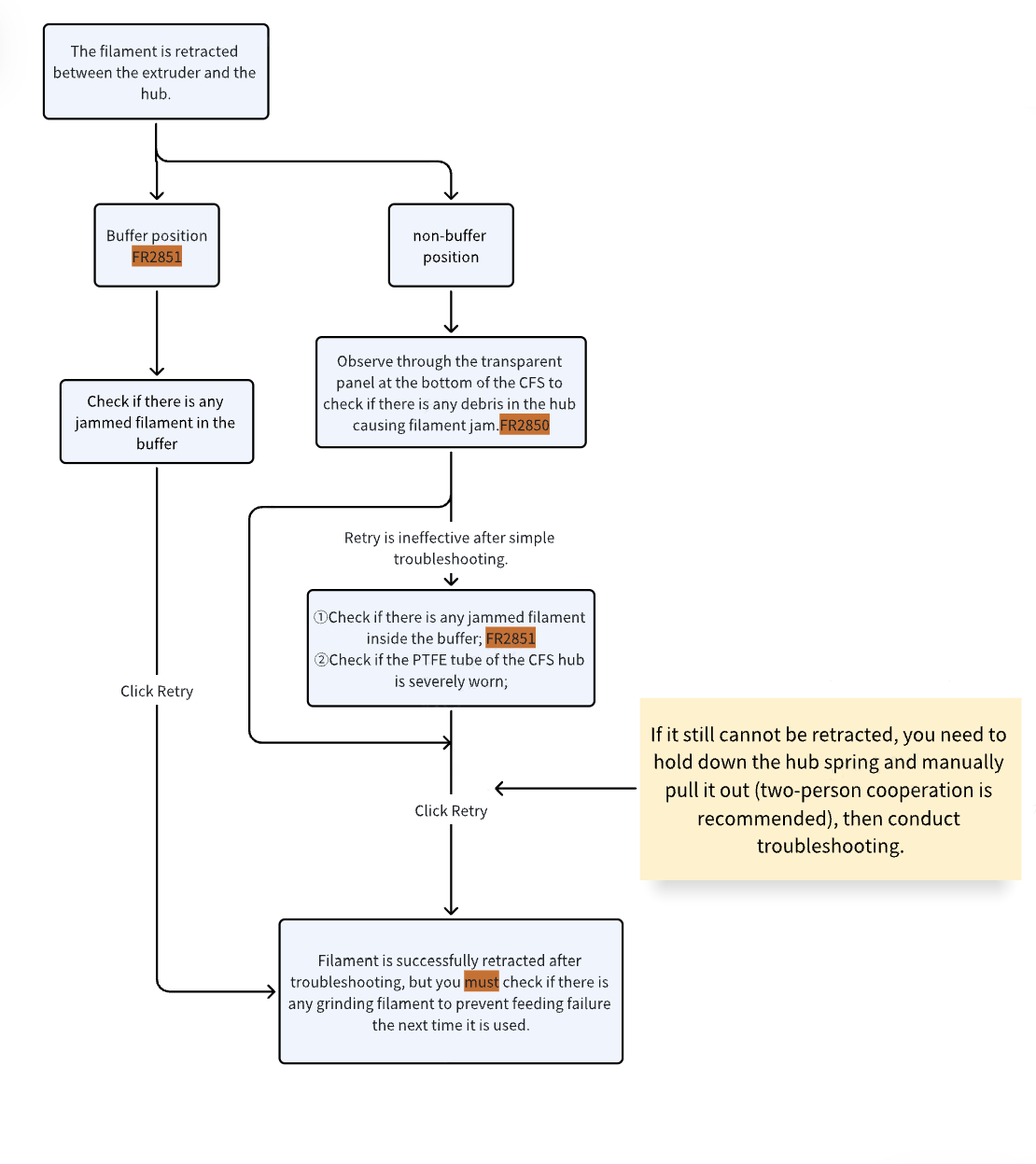

¶ Filament has retracted from extruder

If the filament has been retracted from the extruder, observe the position where it has retracted to for more precise problem-solving.

¶ The filament is retracted between the extruder and the hub

Wiki Pages:

Troubleshooting for Grinding Filament

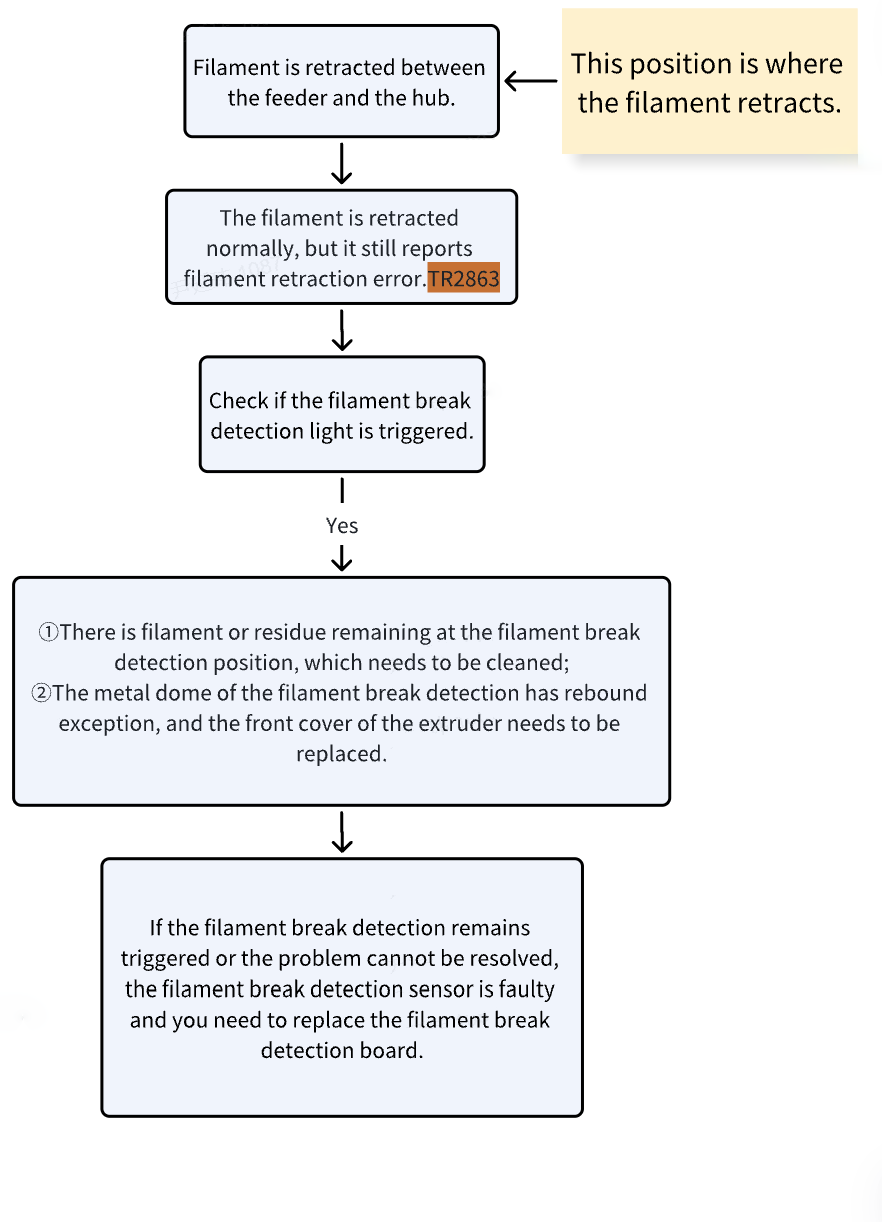

¶ The filament is retracted between the feeder and the hub (Normal Location)

Wiki Pages:

Replace K2 Plus Filament Break Detection

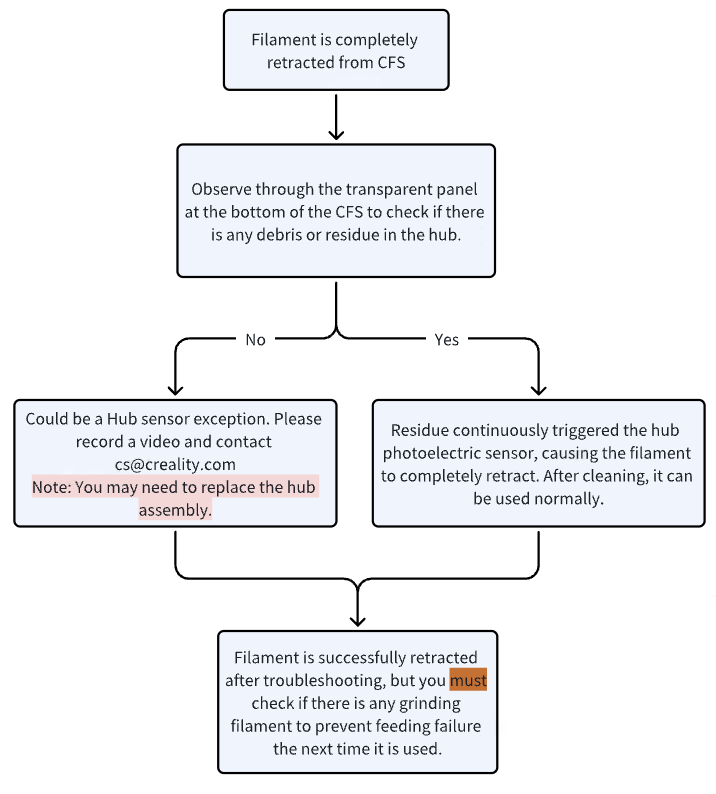

¶ The filament is completely retracted from CFS

Wiki Pages:

Troubleshooting for CFS hub filament clogged

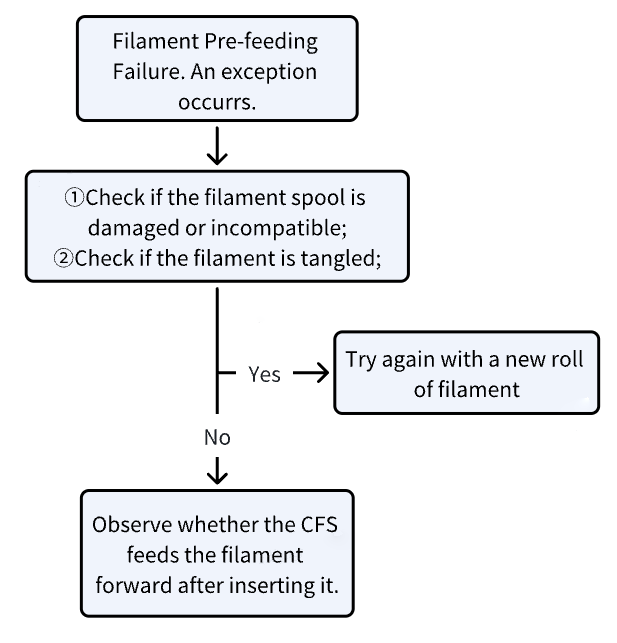

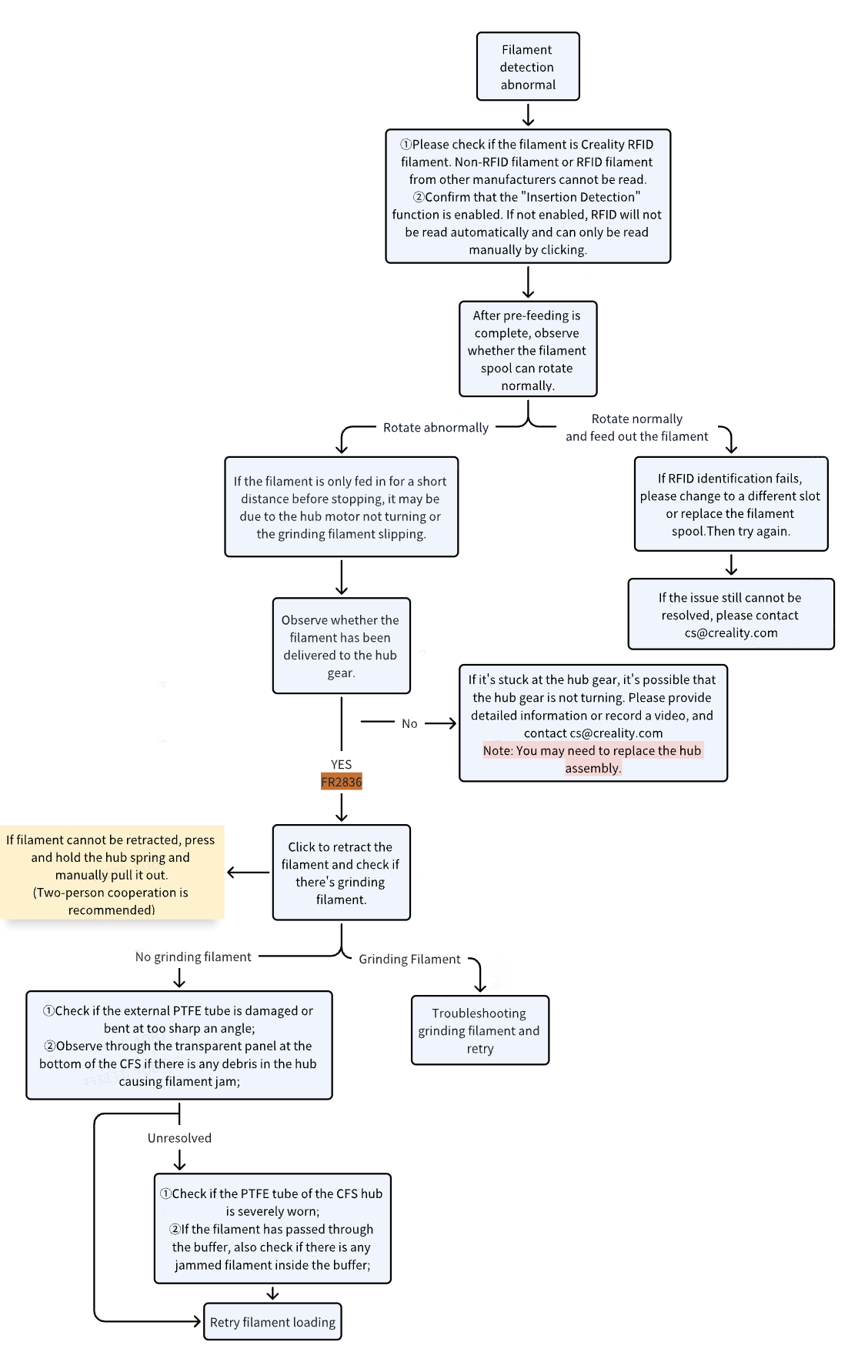

¶ 2.3 Filament Pre-feeding Failure

When CFS is idle, inserting filament into the feeder will cause it to load the filament into the hub until detected by the sensor, then retract it. This entire process is Filament Pre-feeding. If you experience loading issues or other exception when loading filament before printing, follow these troubleshooting steps:

Wiki Pages:

CFS Filament Compatibility Description

Filament entangling Solution:FB2847

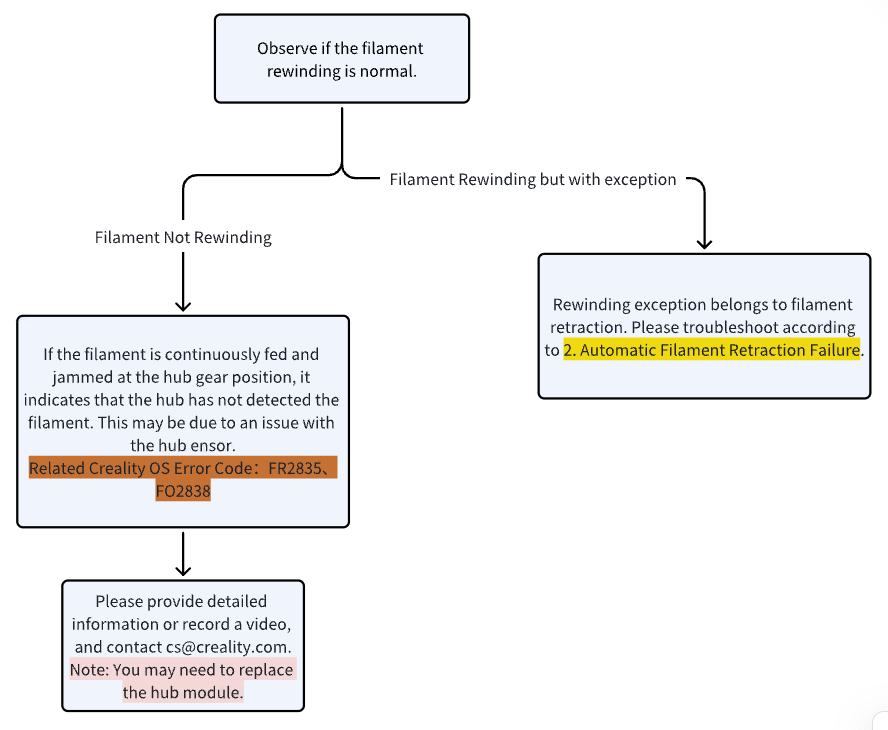

¶ Observe if the filament rewinding is normal

Wiki Pages:

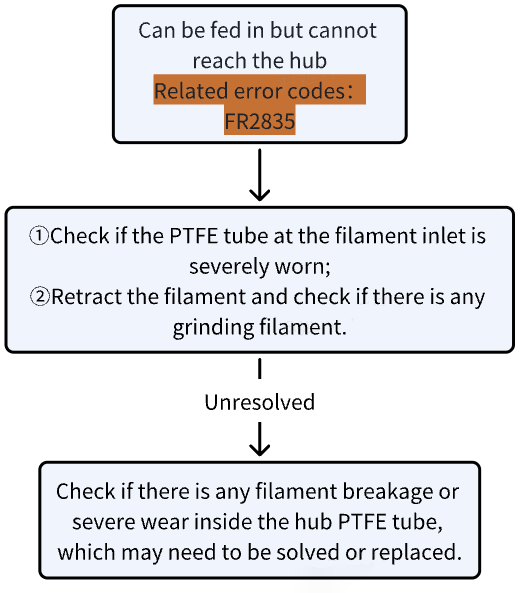

¶ Filament can be fed in but cannot reach the hub

Wiki Pages:

Replace worn CFS PTFE tube and Maintenance

Troubleshooting for Grinding Filament

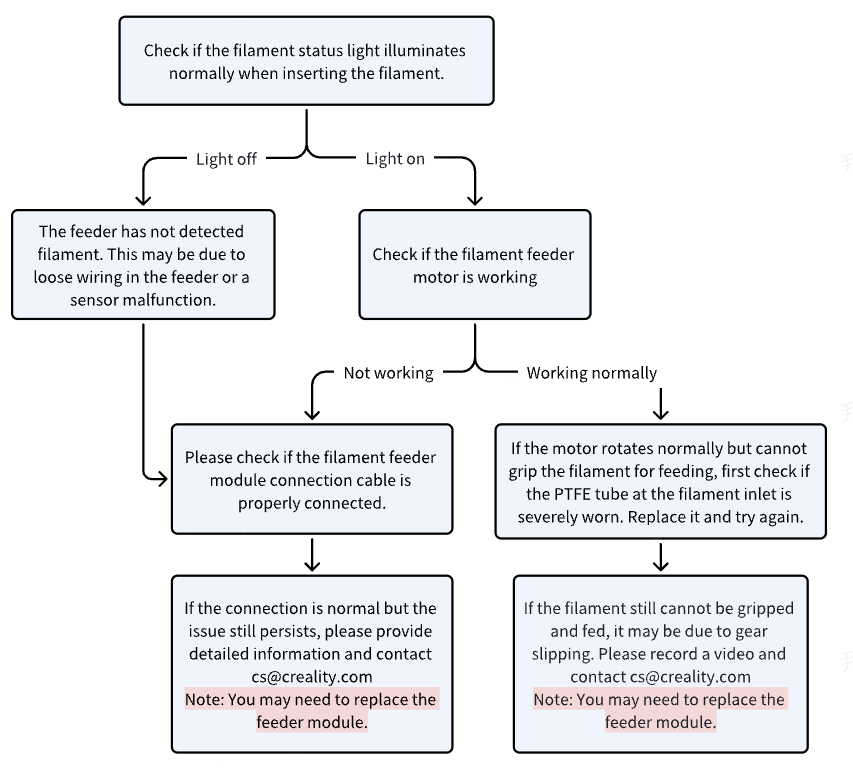

¶ No filament feeding

Wiki Pages:

Replace Filament Feeder of CFS

¶ 2.4 Filament detection Failure

Filament detection is the RFID reading process. When enabled, it occurs after power-on/filament pre-feeding. The feeder will feed a section of filament to ensure sufficient spool rotation for RFID chip reading. The filament is typically fed to the PTFE tube between the buffer and the machine's rear pneumatic connector.

For RFID filament information reading failure or the filament unable to be fed during reading, follow these troubleshooting steps:

Wiki Pages:

Intro of CFS Main Function and Worklfow

Troubleshooting for Grinding Filament

Troubleshooting for CFS hub filament clogged

¶ 3. Faulty Feedback

If you encounter difficulties during troubleshooting, please prepare your issue information according to this Wiki: Feedback Guidance on Device Faulty and provide it to our after-sales team (cs@creality.com). We will address your concerns as soon as possible.