¶ Tutorial Video

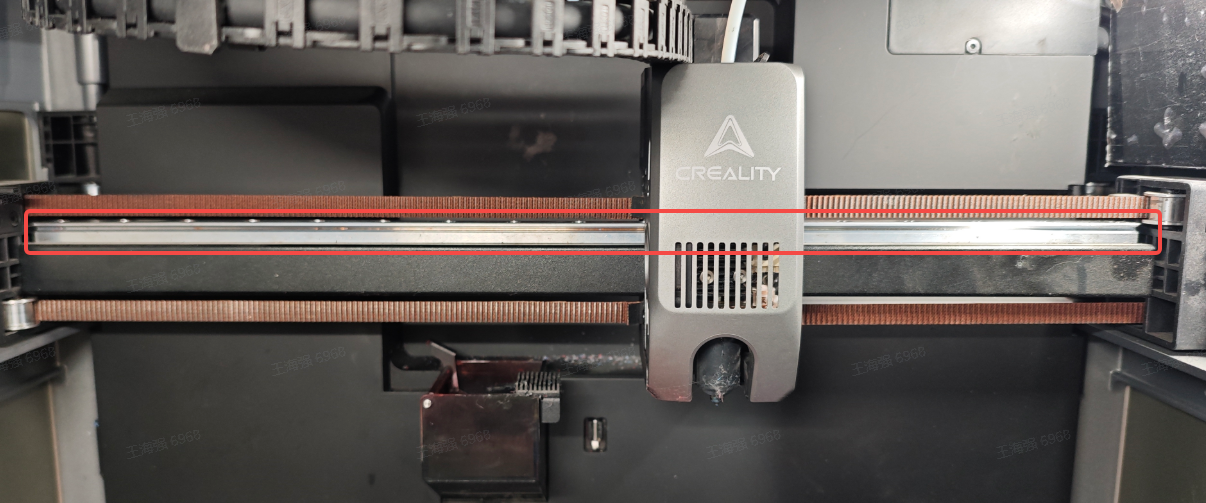

¶ 1. X-axis Guide Rails

The guide rails need to be checked regularly for depletion of lubricating oil, dust or filament debris accumulation, etc. Regular cleaning and lubrication is required.

¶ 1.1 When to Maintain

Check monthly for dust or debris accumulation.

¶ 1.2 How to Maintain

Use dirt-free cloth to clean the rails' surface and apply thinner coat of metal anti-rust oil.

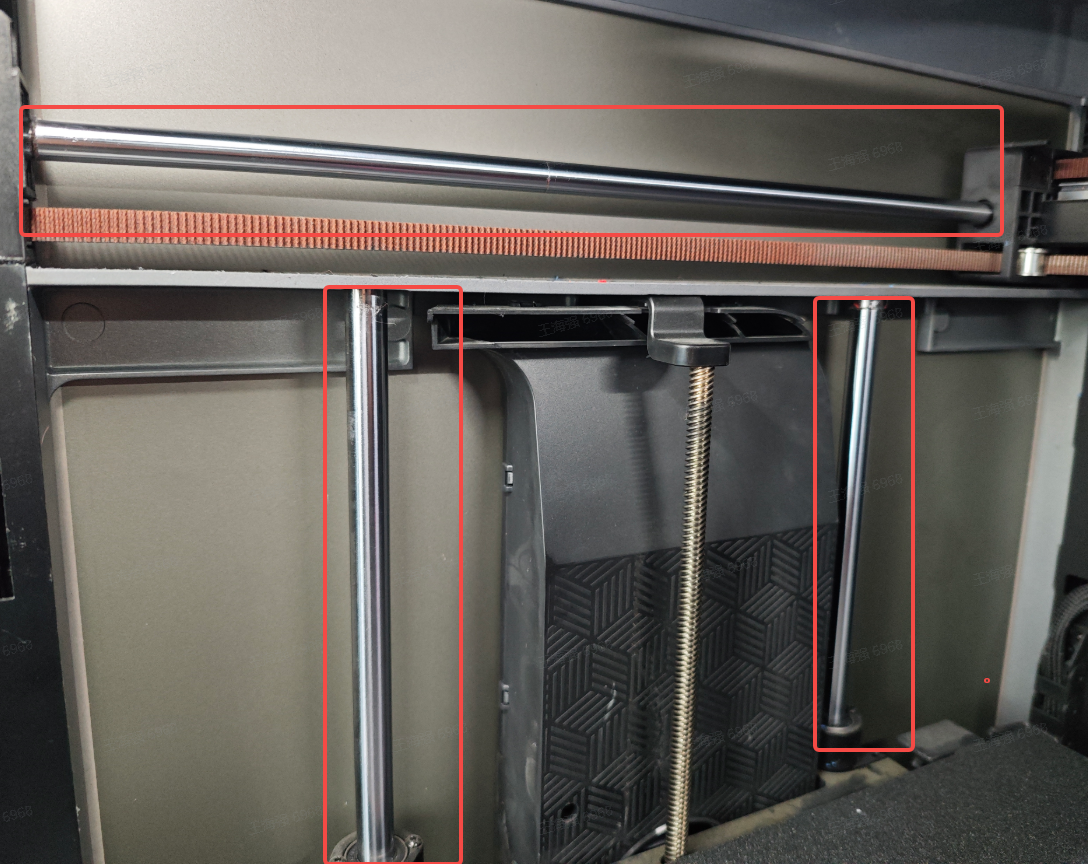

¶ 2. Y-axis and Z-axis Optical Shafts

The Y-axis optical shafts and Z-axis optical shafts are pre-greased before leaving the factory. To prevent corrosion and to extend its service life, we suggested periodic maintenance.

¶ 2.1 When to Maintain

Check and maintain them every 3 months. If frequently printing volatile materials like ABS or ASA, maintain them every 5 days.

¶ 2.2 How to Maintain

Use a dirt-free cloth to clean the optical shafts' surface and apply grease.

¶ 3. Z-axis Lead Screws

K2 Plus has two lead screws on the left and right side responsible for the up/down motion of the hot bed. Regular cleaning and lubrication is needed to ensure service life.

¶ 3.1 When to Maintain

Check and maintain every 3 months. If frequently printing volatile materials like ABS or ASA, maintain it every 5 days.

¶ 3.2 How to Maintain

Use a dirt-free cloth to clean the lead screw surfaces and apply grease.

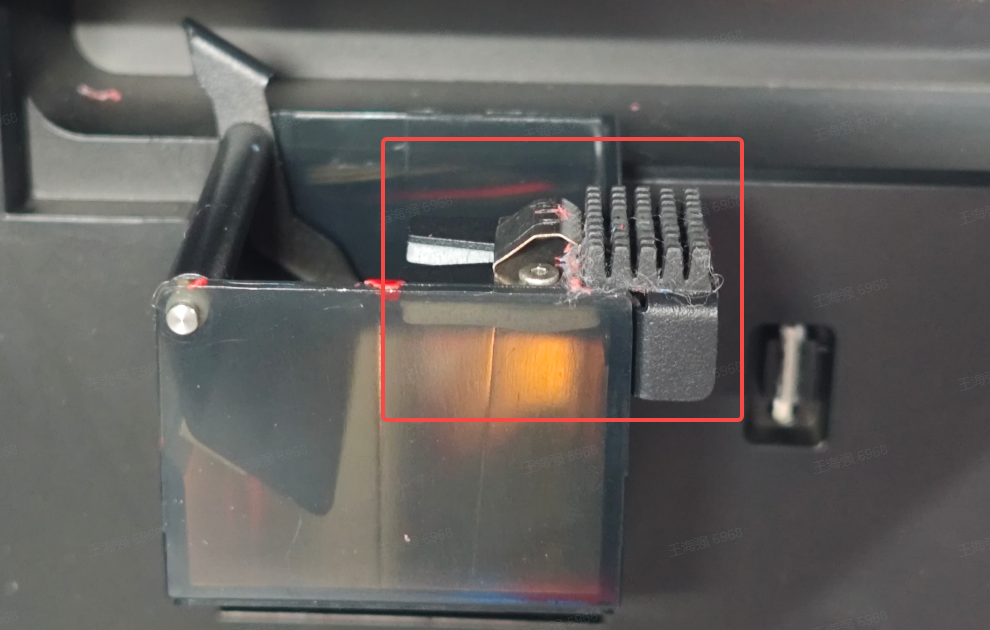

¶ 4. Cutter

To cut the filament during replacing. After frequent cutting, the cutter's blade may become dull, eventually failing to cut the filament properly. Regular check and replacement is needed.

¶ 4.1 When to Maintain

For PLA/ABS/PETG/PC filaments, inspect after printing 5 rolls of filament.

For fiber-reinforced filaments, inspect immediately after printing 1 roll if frequent cutting occurs.

¶ 4.2 How to Maintain

Follow the cutter replacement procedure, remove the cutter. Replace it if the cutter worn.

Replace Cutter

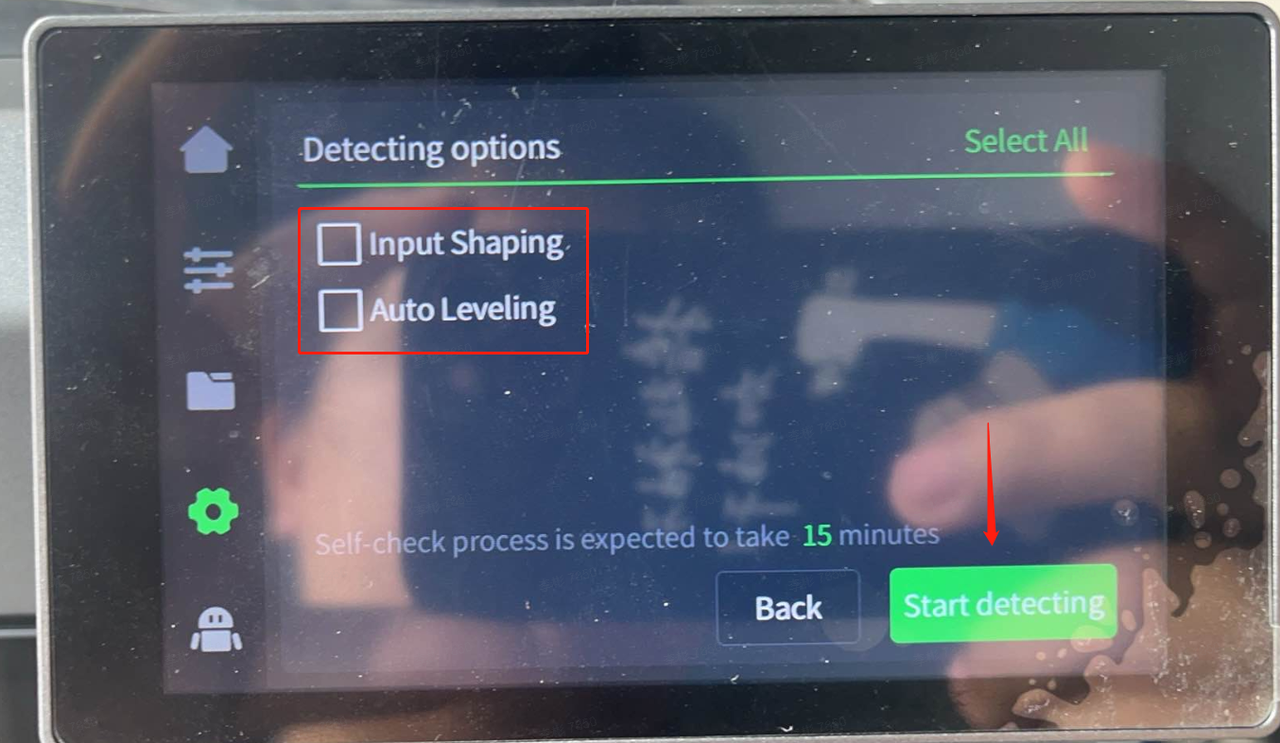

¶ 5. Input Shaping

K2 Plus Input Shaping includes active belt tensioning, filament cutter position calibration, and compensation. After extended use, the belts may loosen, affecting print quality and the cutter position. Regular input shaping is needed.

¶ 5.1 When to Maintain

Operate it once per month.

¶ 5.2 How to Maintain

Ensure NO FILAMENT is loaded, as it may affect cutter position calibration.

Go to Settings - Detecting options - Tick "Input Shaping" then click "Start detecting"

¶ 6. Nozzle Wiper

Keep the nozzle clean after filament flushing to keep it clear.

¶ 6.1 When to Maintain

Check the wiper‘s metal dome per day to ensure it moves freely.

Inspect the silicone adhesive tape weekly.

¶ 6.2 How to Maintain

If the metal dome is severely deformed, replace the entire nozzle wiper. Replace Nozzle Wiper

Clean debris off the silicone adhesive tape. If heavily worn, replace it.

¶ 6.2.1 How to Replace Wiper Adhesive Tape

¶ 1. Tool

New wiper adhesive tape

¶ 2. Operation Steps

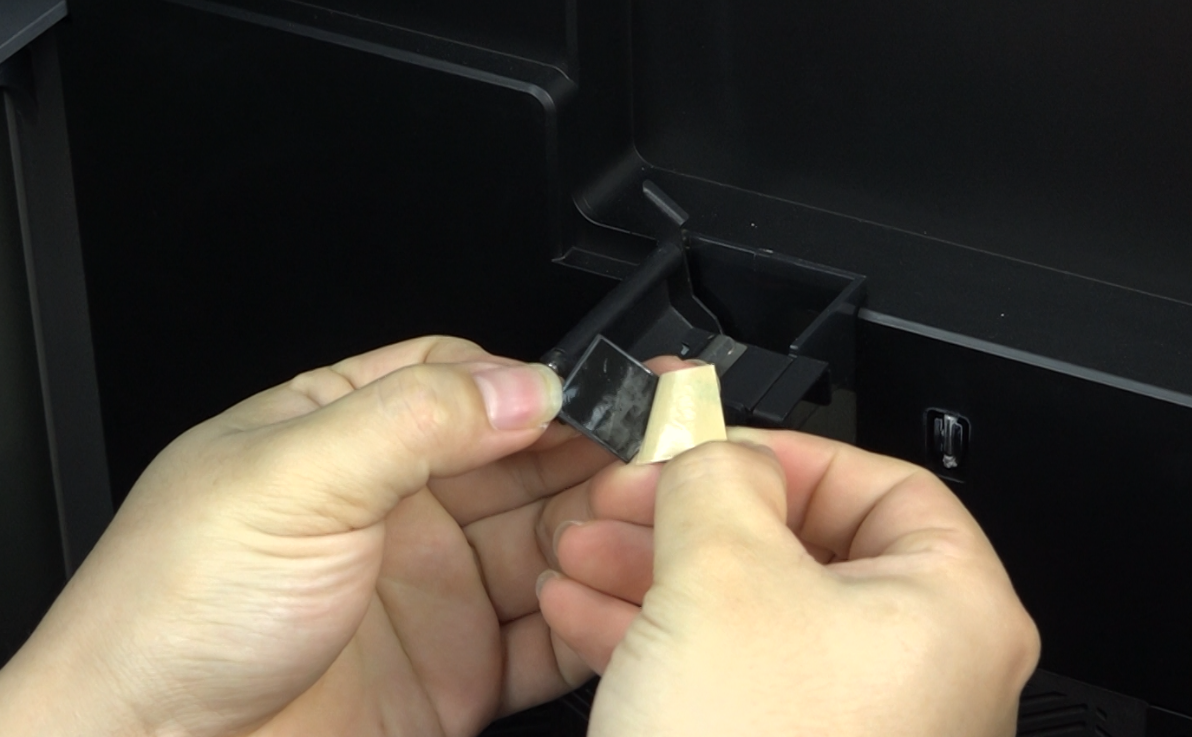

Remove

Peel off the old damaged adhesive tape from the nozzle wiper.

¶ 3. Installation Steps

Remove the protective backing.

Attach the new adhesive tape onto the nozzle wiper base.

¶ 7. Nozzle & Chamber Cameras

Tip:

K2 Plus has two cameras - one on the right side for monitoring/AI detection, and anpther is close to nozzle for flow/PA calibration. Both need regular cleaning to maintain clear visibility.

Nozzle Camera

Chamber Camera

¶ 7.1 When to Maintain

Clean camera lenses when video is blurry or visibly dirty. For ABS printing, clean them every week.

¶ 7.2 How to Maintain

Use a dirty-free cloth and alcohol to gently wipe the camera surfaces.

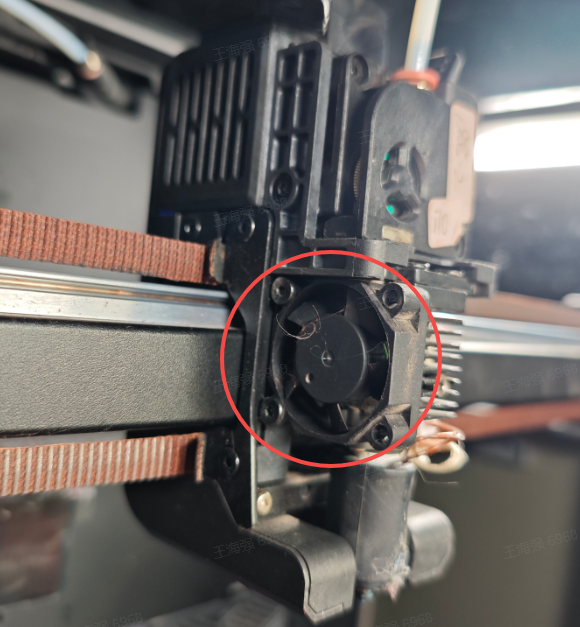

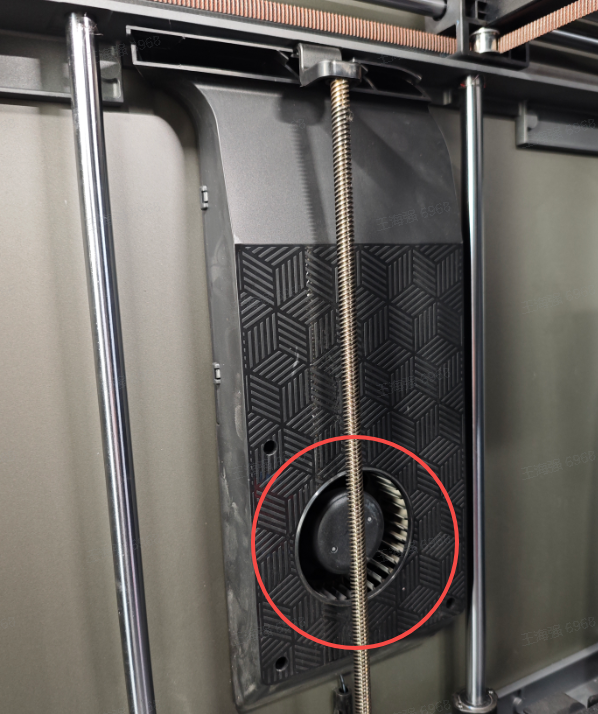

¶ 8. Fans

Regularly check the extruder motor cooling fan, model fan, heat break fan, and auxiliary fans for dust/debris accumulation. Clean promptly to ensure proper operation.

Extruder Motor Cooling Fan

Model Fan (the back of the extruder)

Heat Break Fan (the left side of the extruder, inside the front cover)

Auxiliary Fans (the both sides of the chamber)

¶ 8.1 When to Maintain

Check weekly for dust and debris.

¶ 8.2 How to Maintain

With the printer powered off, use tools to clear dust/debris from the fans.

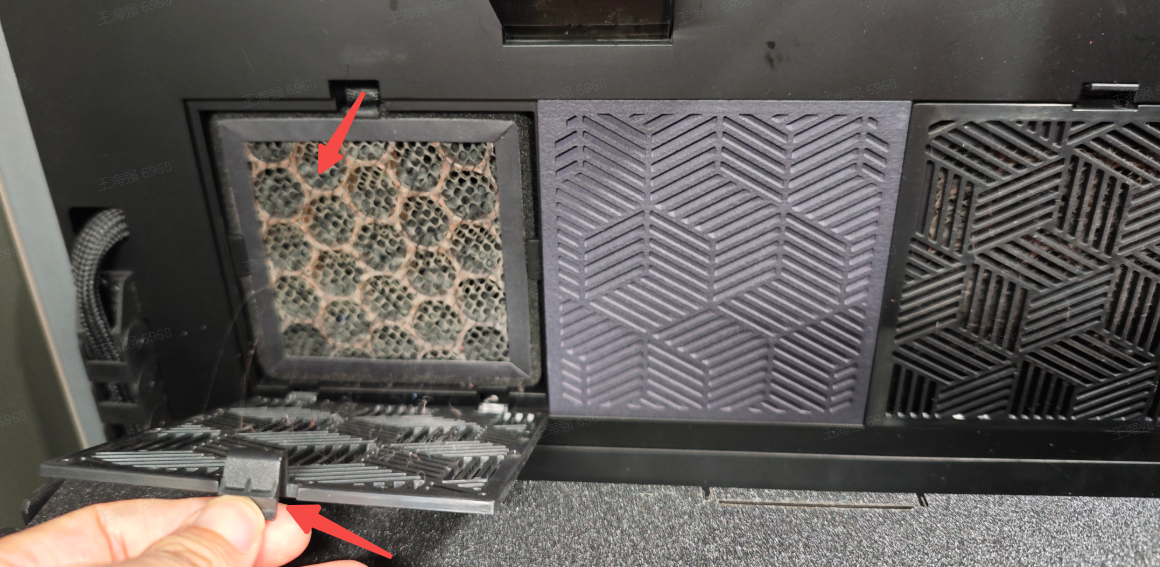

¶ 9. Air Filter Cartridge

The activated carbon air filter cartridge filters particles generated during printing and should be replaced periodically.

¶ 9.1 When to Maintain

If printing 8 hours per day, replace it every 3 months.

If printing frequently, replace it every month.

¶ 9.2 How to Maintain

Open both sides of the air filter cover plate, take out and replace.

Open the side air filter covers and remove/replace the cartridge.

¶ 10. Other Parts that require maintenance

Parts that may need replacement during printer use.

- Nozzle: Replace K2 Plus Nozzle

- Hotend: Replace K2 Plus Hotend

- Extruder front cover: Replace K2 Plus Extruder Front Cover

- Extruder filament cutter: Replace K2 Plus Cutter

- Nozzle wiper assembly: Replace K2 Plus nozzle wiper

- K2 Plus PTFE tube: Replace K2 Plus PTFE tube

- CFS PTFE tube: Replace CFS Hub PTFE tube