¶ FB2847:Filament may tangled, please try again after resolving.

¶ Applicable models: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear?

This usually indicates that during printing, the extruder is unable to smoothly pull the filament due to excessive external resistance, leading to poor extrusion. Common causes may include:

Filament spool tangled or knotted, preventing smooth feeding.

Spool deformed or not meeting CFS requirements, with thickness or diameter too large, preventing normal rotation.

Filament tubes are too long or severely bent, increasing feeding resistance.

Uneven filament diameter, causing jams in the feeding path.

¶ How to solve:

Check spool winding: Examine if the filament in the spool is knotted or tangled, preventing smooth pulling during feeding.

Check the spool:Verify if the spool rotates smoothly, and if it's too small or too large. CFS requires spool outer diameter to be between 197-202mm.

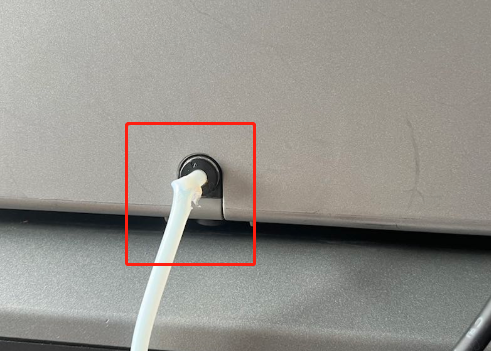

Check PTFE tube: Inspect the PTFE tube between the hub outlet and extruder, ensure no bends, damage, or reduced inner diameter (standard inner diameter is 2.5mm) to avoid excessive feeding resistance.

Uneven filament diameter: Check if the filament has uneven diameter issues, ensure the filament diameter is within 1.75mm±0.5mm to avoid jams in the feeding path.

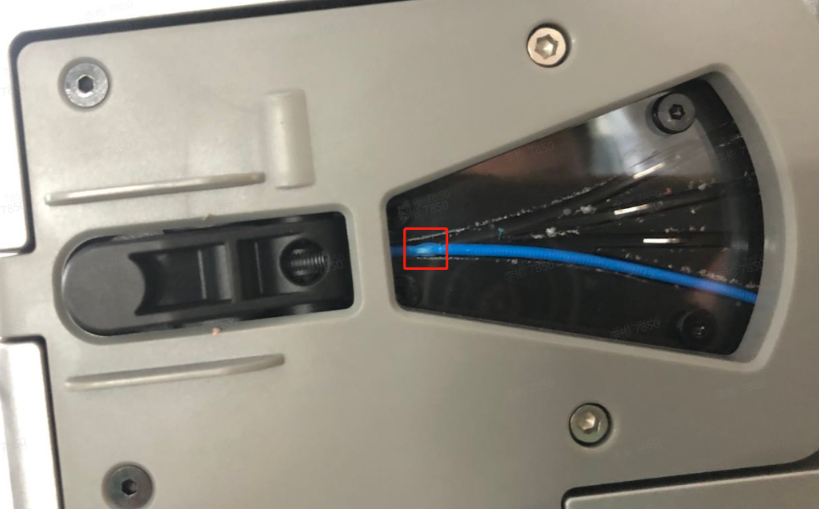

Check motor gears: Inspect the feeding motor, hub outlet motor, and extruder motor gears for broken teeth or slipping, ensure motors are working normally without increased resistance.

¶ General troubleshooting steps:

Check if the filament spool in the corresponding CFS is tangled or jammed and address it. The faulty slot will flash a red light.

Check if the spool can rotate smoothly in the CFS. If not, check if the spool's outer diameter meets the requirement of 197-202mm.

Check for any abnormal resistance in the feeding path, such as PTFE tube issues, and address them.

Check if the filament has quality issues like oversized or undersized diameter preventing normal gripping by the hub outlet and extruder. Normal filament diameter should be within 1.75mm±0.5.

Check the status of the hub outlet and printer's extrusion module, confirm that gears are not damaged or slipping, and motors are operating normally. If problems exist, replace motors or gears promptly.

Check if the filament has been worn by the hub outlet extrusion gear. If so, cut off the damaged part and re-feed.