¶ FR2836:Feed issue, filament may be blocked between the CFS hub and extruder filament detector.

¶ Applicable Model: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear?

During the feeding process, the filament fails to reach the material break detector of the extruder after passing through the hub outlet. Common reasons include:

High resistance in the PTFE tube: The PTFE tube above the machine's drag chain or above the extruder's material break detector is bent or has increased friction, hindering filament movement.

High resistance in the pneumatic connector at the filament inlet on the machine's back panel: Filament Feeding issue causes clogged filament and unable to load.

Filament break detection not working properly: The extruder's material break detection module cannot be triggered.

Hub motor or other hardware failure: The hub outlet motor cannot operate normally or has mechanical issues, preventing the filament from advancing smoothly.

¶ How to solve?

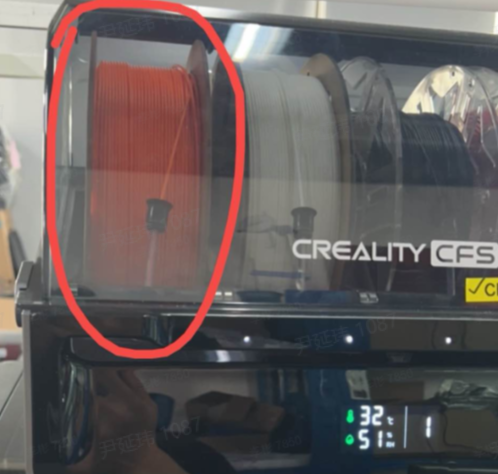

¶ Filament spool tangling

Check if the filament in the spool is knotted or tangled, and if the CFS shaft has too much rotational resistance, causing the filament to be immobile during feeding.

¶ Filament condition

Check if the filament in the spool is deformed. If using a cardboard spool, check if it's damaged or deformed, affecting normal filament delivery.

¶ PTFE tube condition from hub outlet to extruder material break detector

Check if the PTFE tube is bent, damaged, or has a reduced inner diameter (normal inner diameter should be 2.5mm) to rule out excessive resistance issues.

¶ Hub motor clogged with filament

Check if the filament has moisture absorption issues, is expired, or has uneven diameter, ensuring it doesn't break in front of the hub motor.

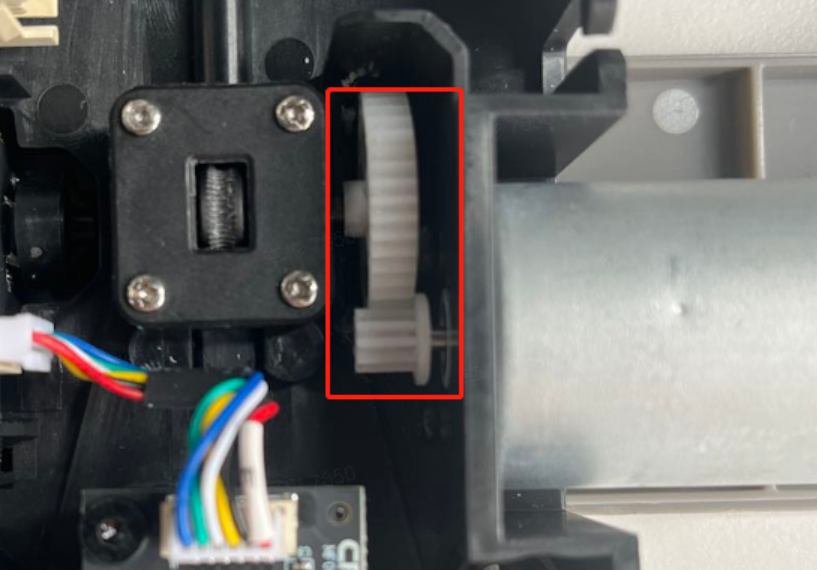

¶ Hub outlet motor operating status

Confirm if the hub outlet motor can work normally. If the motor gear slips or doesn't rotate, check the motor wiring and mainboard connection to rule out poor contact or unstable connection.

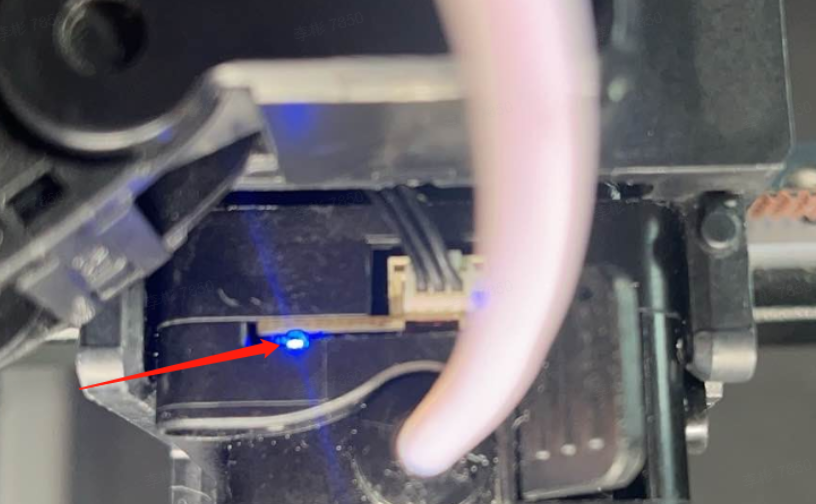

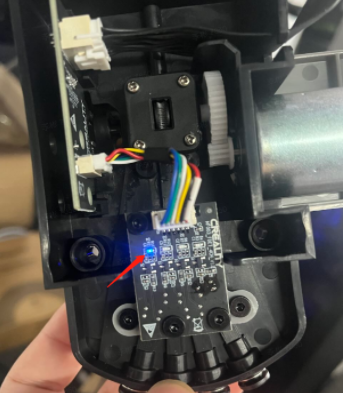

¶ Extruder filament break detection malfunction

Check if the extruder material break detection module is working properly, observe if it can trigger the LED light. If the detector cannot be triggered, check the connection of the material break detection cable and terminals. Please refer to Wiki Page: Troubleshooting for K2 Plus Filament Break Detector Board False Trigger

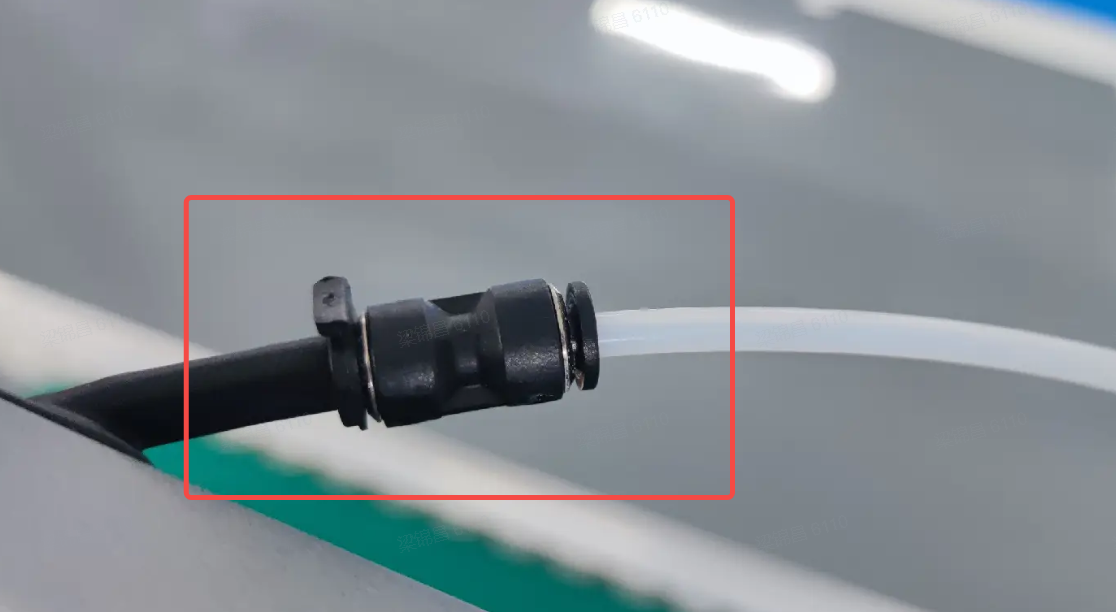

¶ High resistance at the pneumatic connector of the machine's back panel filament inlet

Check if the end of the filament is stuck at the pneumatic connector. If it is indeed stuck there, preventing the filament from feeding, you need to check the filament tube interior for any residual material or lack of chamfer that might be blocking the filament inlet.

|

|

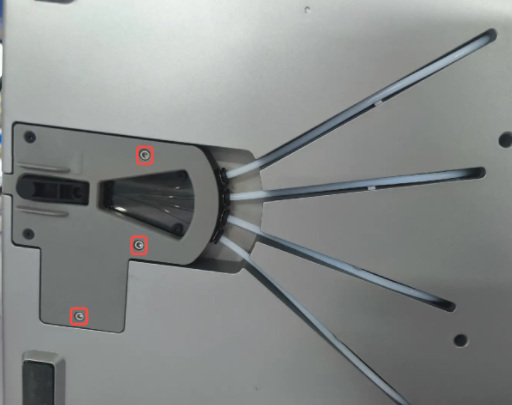

¶ Hub photoelectric board false trigger

There is no filament in the hub and the metal dome springs up normally. It's possible that the photoelectric board on the back of the hub is falsely triggering the blue light (normally, the blue light on the hub lights up when filament is detected, and doesn't light up when there's no filament). In this case, remove the 3 fixing screws of the hub to check the photoelectric board on the back. If it's confirmed to be a false trigger, please contact cs@creality.com to replace the hub photoelectric board.

|

|

¶ General troubleshooting steps

Check the filament path: Examine the entire path from the spool, PTFE tube to the hub outlet motor for any tangling, resistance, or filament damage issues.

Test hardware operation: Check if the hub outlet motor and extruder material break detection module are working normally. If faults are found, try to repair or replace.

Replace damaged filament: If the filament is too brittle or has uneven diameter, it's recommended to replace it with quality-assured filament to ensure smooth printing.