¶ 1. Maintenance cycle of CFS PTFE tube

Under normal usage frequency, it is recommended to replace the PTFE tube every two months to ensure smooth filament feeding and retraction in various scenarios. For abrasive materials like fiber-reinforced filaments, it's advised to check monthly and replace promptly when obvious wear is observed.

¶ 2. Maintenance of PTFE tube

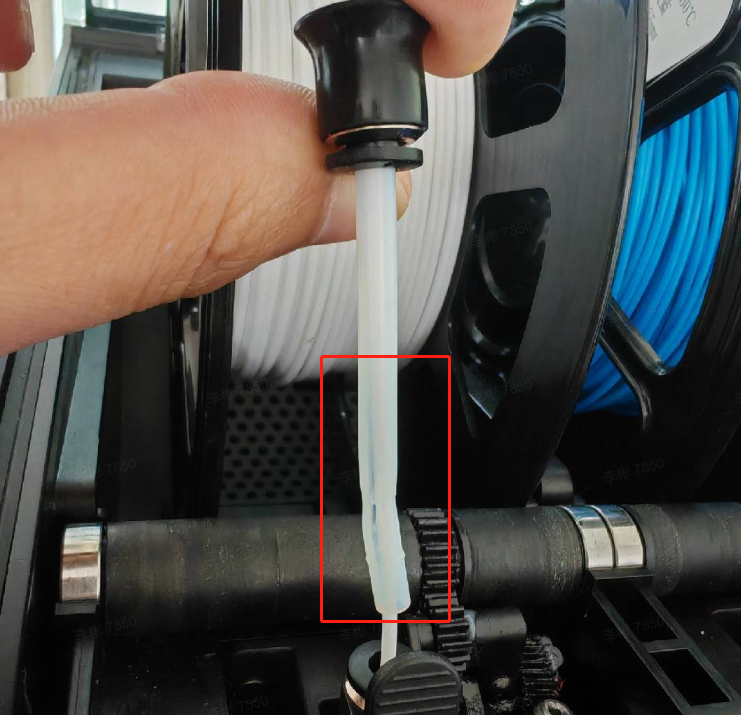

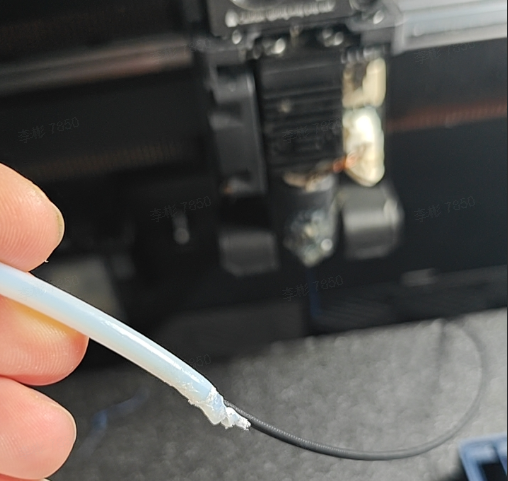

The PTFE tube is a consumable part that may wear out over time due to filament friction. It's recommended to regularly check the wear condition of the PTFE tube during routine maintenance. If a worn tube is not replaced timely, it may cause abnormal filament feeding and clogging in the CFS. The PTFE tube used in CFS has specifications of 4*2.5mm.

Below we will introduce the possible wear or damage locations of the PTFE tube used in CFS and the related maintenance and replacement procedures.

¶ 3. Replacement of PTFE tube

¶ 3.1 Required tools

The recommended PTFE tube has an inner diameter of 2.5 mm and an outer diameter of 4 mm. Other sizes of PTFE tubes may cause errors due to increased friction during filament feeding and retraction (for PTFE tubes with smaller inner diameters), so they are not recommended.

To replace the filament tube at the inlet, prepare 4 new 60mm PTFE tubes. SKU: 4004200027 (included).

To replace the tube between the inlet and the hub outlet, prepare 2 new 200mm (for middle 2/3 channels) and 2 new 230mm (for side 1/4 channels) PTFE tubes. SKU: 4004200027 (included).

To replace the tube from the hub outlet to the buffer, and from the buffer to K2 Plus inlet, prepare 1 new 400mm (500mm for first batch machines) and 1 new 300mm (400mm for first batch machines) PTFE tube. SKU: 4004200027 (included).

To replace the PTFE tube from K2 Plus inlet to the extruder, prepare 1 new 680mm PTFE tube. SKU: 4004200027 (included).

Note: Before performing any maintenance on the printer and CFS, please turn off the printer power and disconnect the power supply to avoid short circuits, which causes additional electronic equipment damage and personal safety hazards. Also, when maintaining or troubleshooting the printer, please first confirm the temperature of the hotend and hot bed to avoid operating at high temperatures. If operation at high temperatures is necessary, please wear heat-resistant gloves to ensure safe and effective maintenance work.

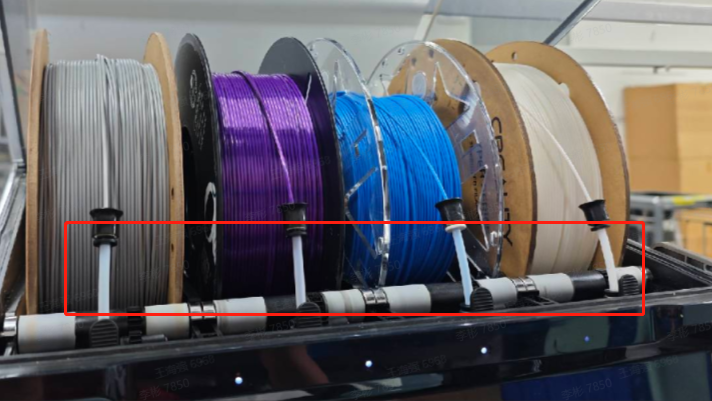

¶ 3.2 Damage to the inlet tube

¶ 3.2.1 Replacement steps

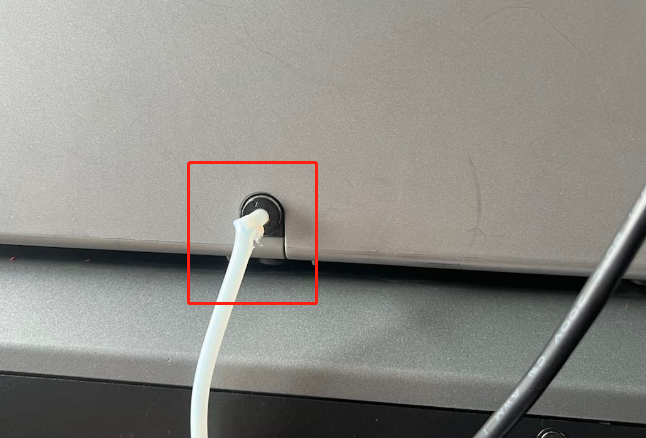

Press the pneumatic connector and pull out the PTFE tube.

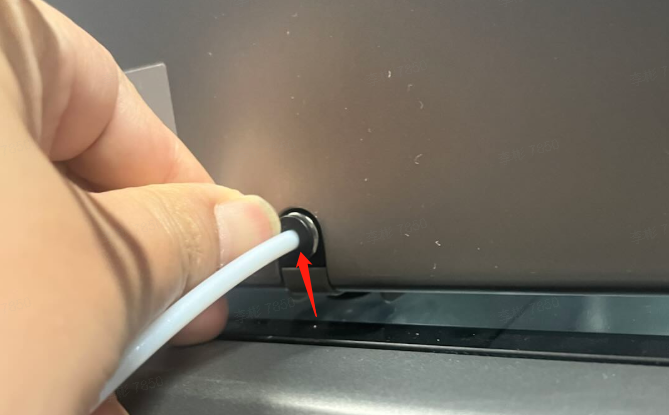

Press the pneumatic connector at the other end of the inlet and pull out the tube that needs to be replaced.

Replace with a new tube, install the pneumatic connector, and insert it into the feeding module to complete the replacement.

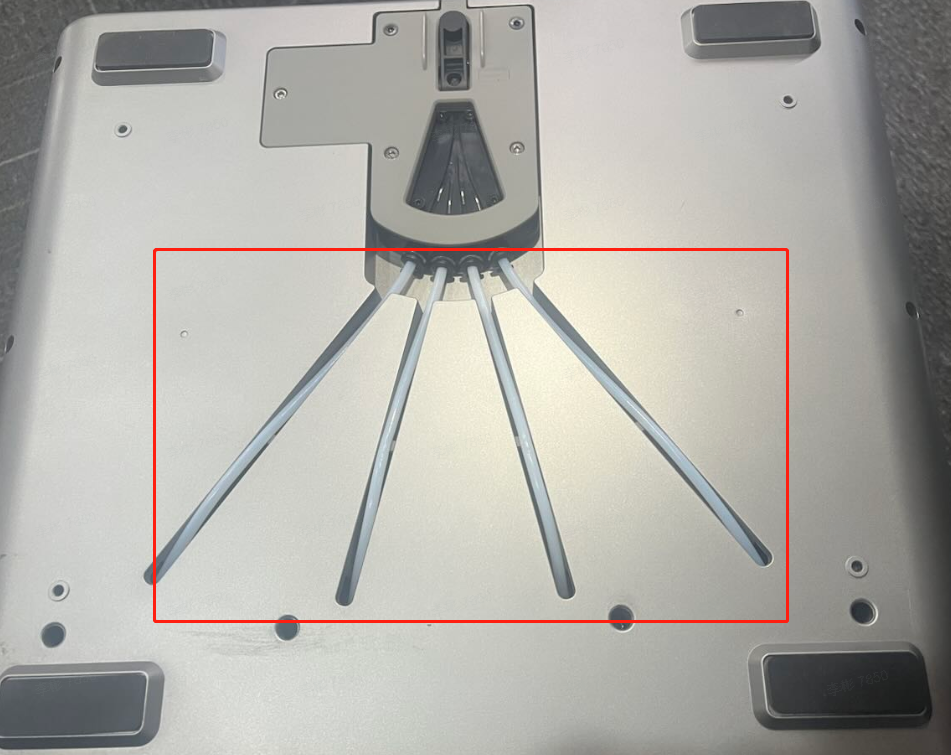

¶ 3.3 Damage to the tube between the inlet and the hub outlet

¶ 3.3.1 Replacement steps

Refer to Replace CFS Hub Teflon Tube

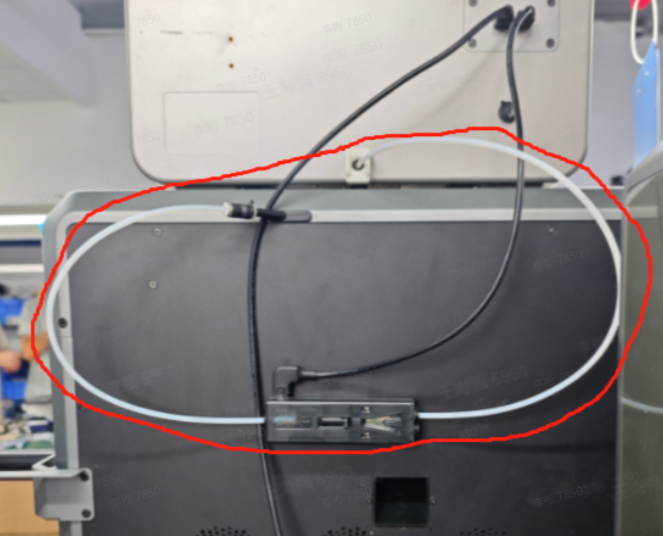

¶ 3.4 Damage to the tube from the hub outlet to the buffer, and from the buffer to the machine

¶ 3.4.1 Replacement steps

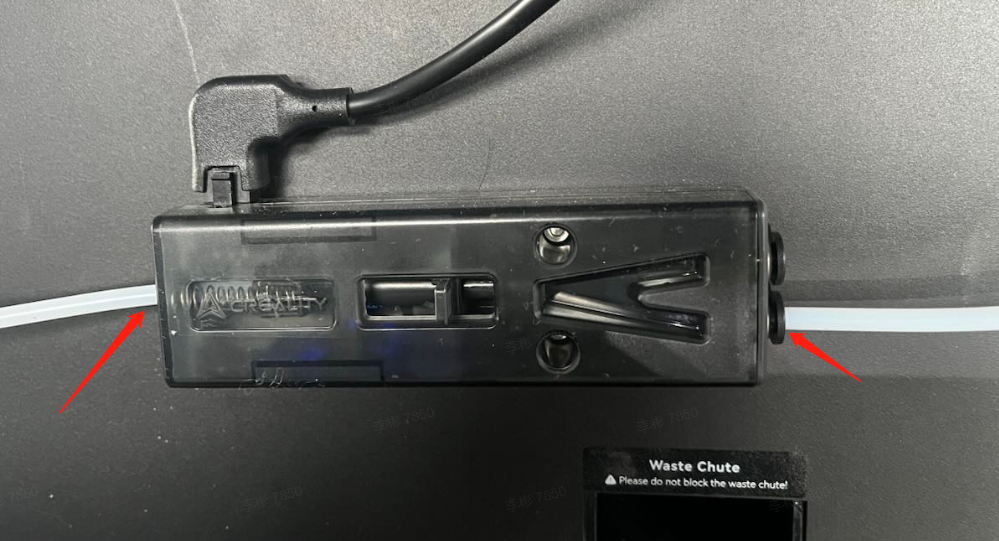

Press the button on the hub outlet's tube connector and remove the tube.

Then press the pneumatic connector on the machine side and pull out the tube.

Press the pneumatic connector on the right side of the buffer and pull out the tube.

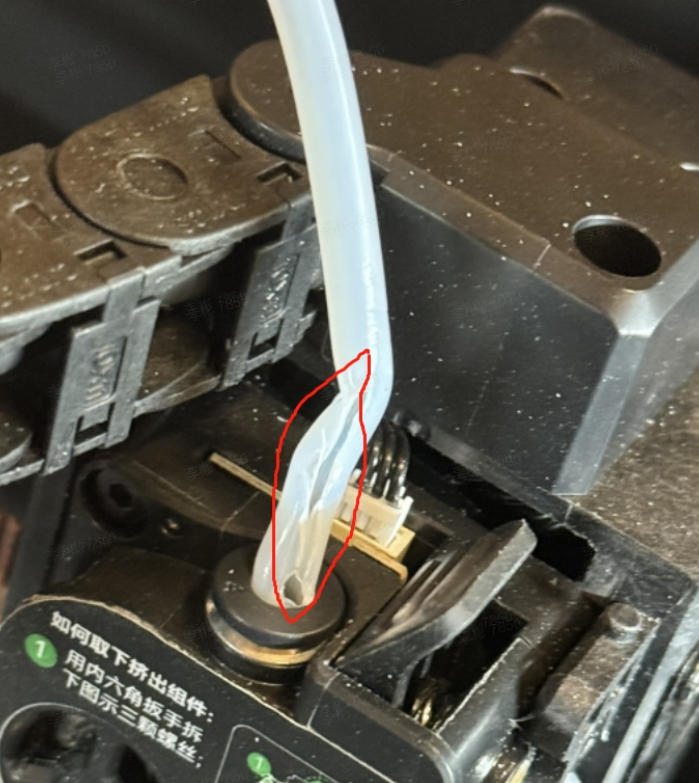

To remove the tube from the left side of the buffer, use two fingers: one to press the outer casing, and another to gently squeeze the buffer's lever to the left. Use the other hand to pull out the tube.

Connect the new 300mm and 400mm PTFE tubes to both ends of the buffer respectively (the shorter one connects to the buffer and K2 Plus inlet pneumatic connector, the longer one connects to the buffer and hub outlet).

Connect the other end of the new tubes to the K2 Plus inlet connector and hub outlet tube connector.

¶ 3.5 Damage to the PTFE tube of K2 Plus machine inlet

¶ 3.5.1 Replacement steps

Refer to Replace K2 Plus PTFE tube