¶ FR2851:Retract issue, Filament Buffer failure.

¶ Applicable model: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear?

During the filament unloading process, the buffer failed to return to the empty position normally, causing an unloading exception. Possible reasons include:

Mechanical failure inside the buffer.

Poor connection or blockage between the buffer and other components.

¶ How to solve

Check buffer status: Ensure the buffer can move freely without being stuck or blocked.

Check connections: Confirm that the connection between the buffer and CFS is secure, ensuring there are no loose or detached parts.

Clear blockages: If foreign objects are obstructing buffer movement, disassemble and clean.

¶ General troubleshooting steps

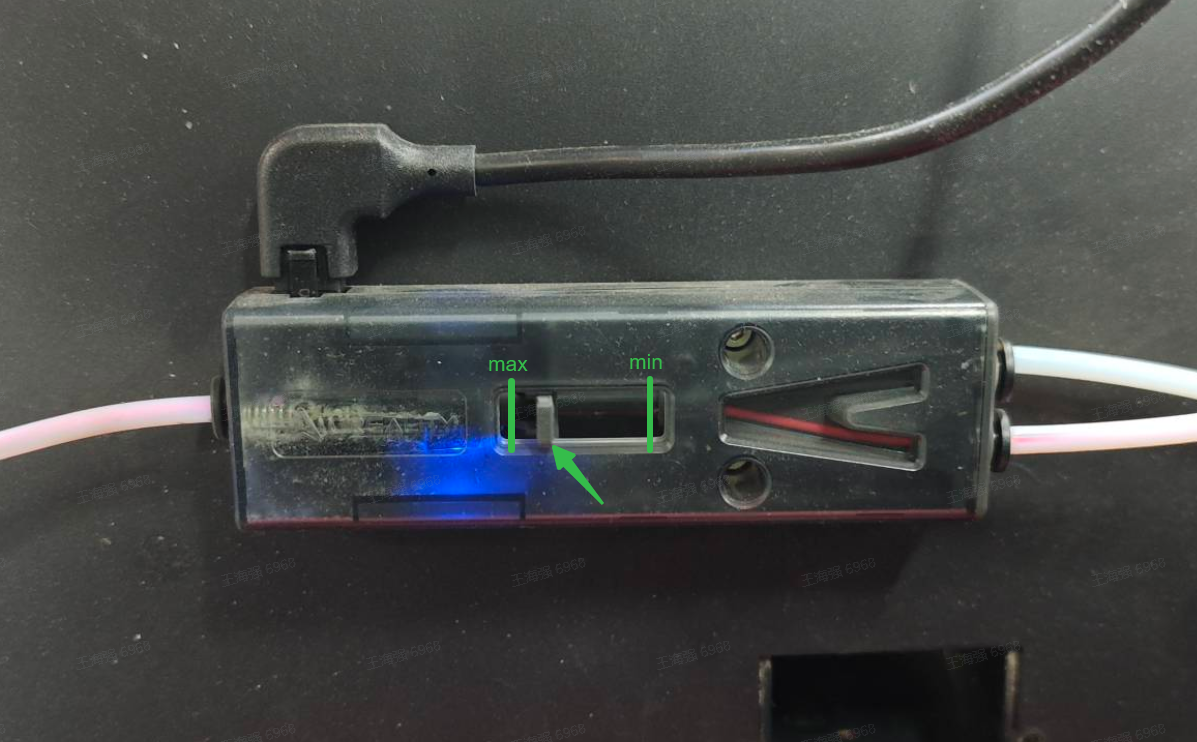

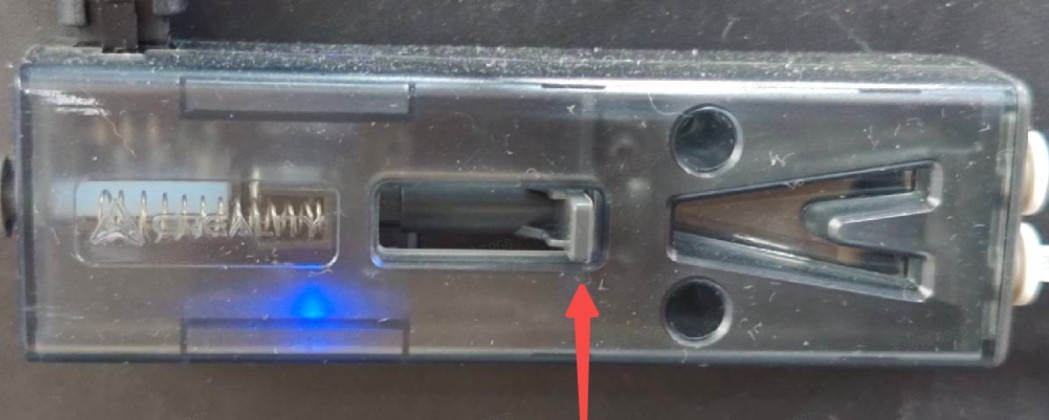

Check if the blue light on the buffer is on normally. If not, check the wiring.

Confirm if the buffer's movement is smooth. If there's any sticking, it needs to be addressed.

Try unloading the filament again and observe if normal operation can be restored.

The buffer's working principle: when the extruder consumes filament, the buffer moves to the min position. Upon receiving the buffer signal, the hub motor feeds filament to move the buffer to the max position. If the buffer is stuck on the left or right side and cannot move, causing a printer error, it may indicate a buffer malfunction that requires replacement.