¶ 1. Phenomenon Description

First layer of the model appears compressed during printing

¶ 2. How to Solve

If it occurs during printing: Go to Setting - Expert Mode - Z_Offset - Adjust downwards by 0.05-0.1mm (positive value).

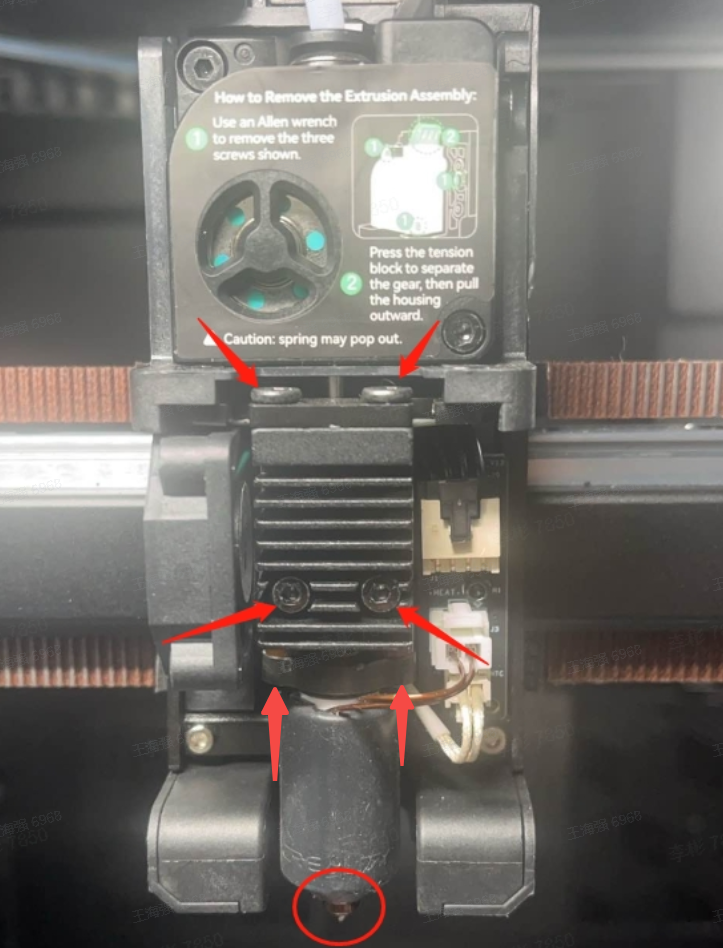

Loose hotend: Check the four screws affecting the leveling sensor.

Loose X-axis guide rail screws: Tighten the X-axis guide rail screws.

External interference during auto-leveling: Ensure the printer is placed in a vibration-free environment when starting to print.

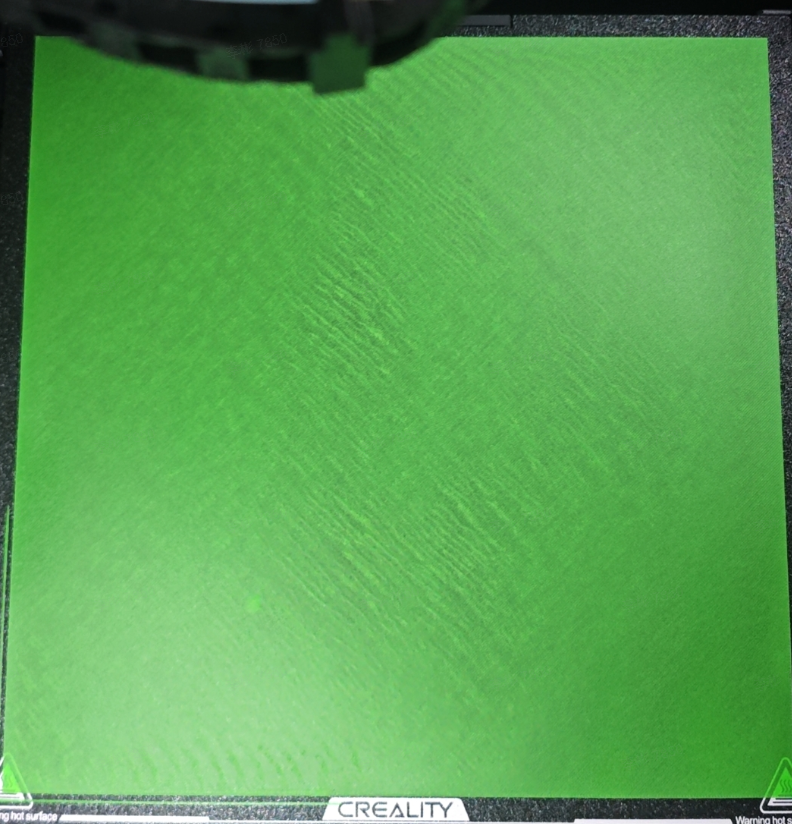

Platform plate issue: Clean residue from the platform plate.

¶ 3. Troubleshooting

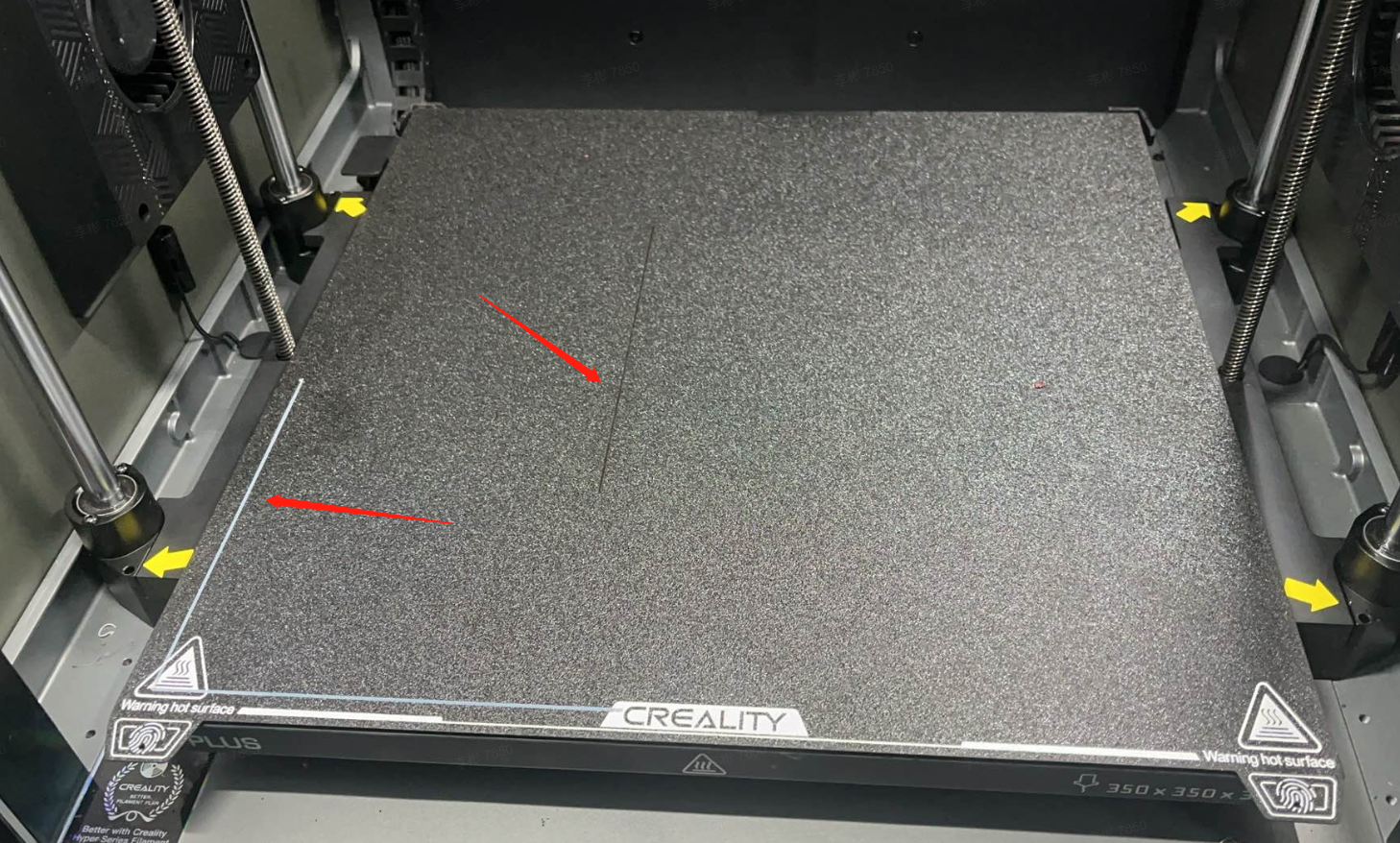

Check if the platform plate is damaged, bulging, or has uncleared filament residue.

Check if the X-axis guide rail screws are loose, tighten them if necessary.

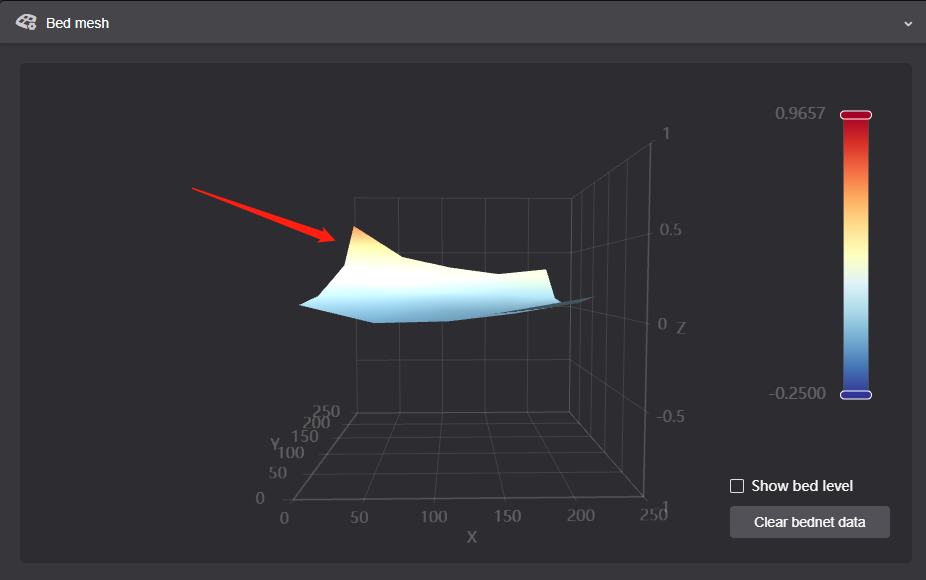

Check if the hot bed is deformed, uneven, if the soft magnet is bulging, or if there are impurities between the soft magnet and platform plate. You can view the hot bed deformation map to locate issues (Connect the device to WiFi, enter the device IP:4408 address in a computer browser, for example192.168.1.1:4408, and press keyboard Enter to view).

Check the 4 fixing screws of the hotend and the integrated nozzle for any looseness, re-secure if necessary

If the nozzle is found to be loose, first heat it to the filament printing temperature, ≥200°C, then use a socket wrench to tighten the nozzle.

Re-run auto-leveling

Please place the machine in a stable, vibration-free environment during auto-leveling

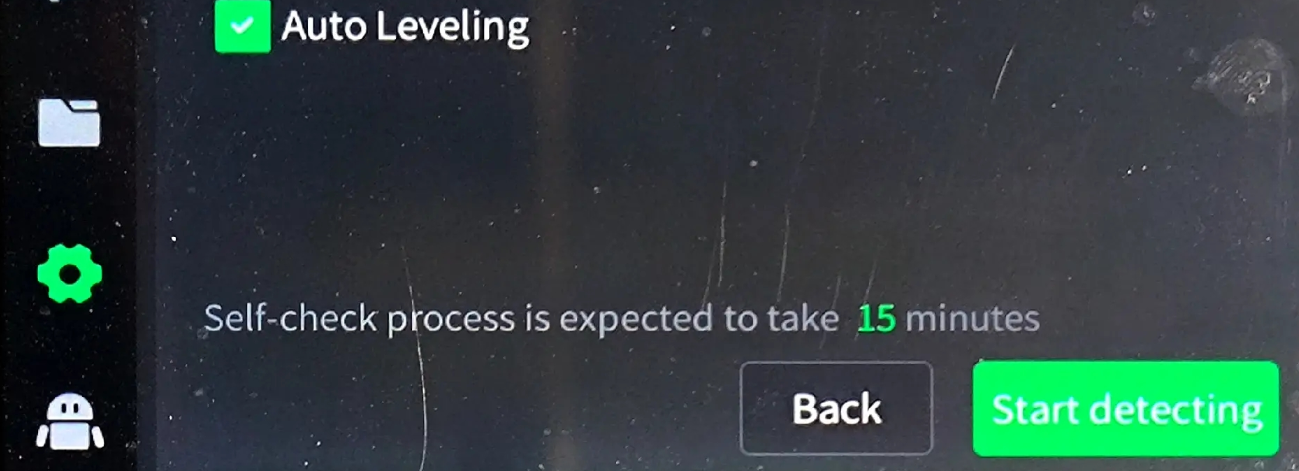

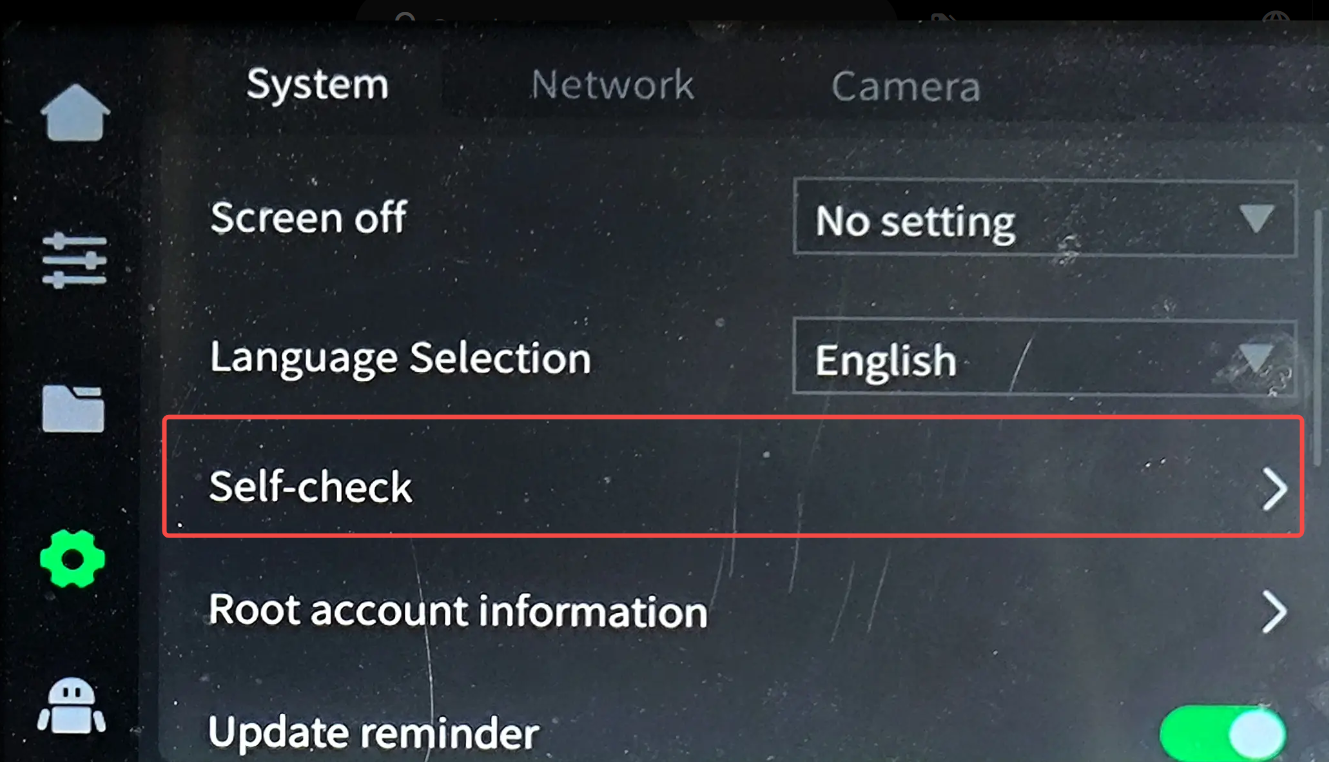

STEP 1: Click Settings - Device Self-Check

STEP2:Check Auto leveling, click Start detecting (It will take about 15 minutes, please wait for completion)