¶ FR2835:Feed issue , filament may be stuck from loader to CFS hub.

¶ Applicable Model: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear?

During the feeding process, the filament fails to trigger the filament detector at the hub outlet. Possible reasons include:

The feeder is not working properly

The filament cannot be pulled due to excessive resistance

The filament break detector at the hub outlet is damaged

¶ How to solve:

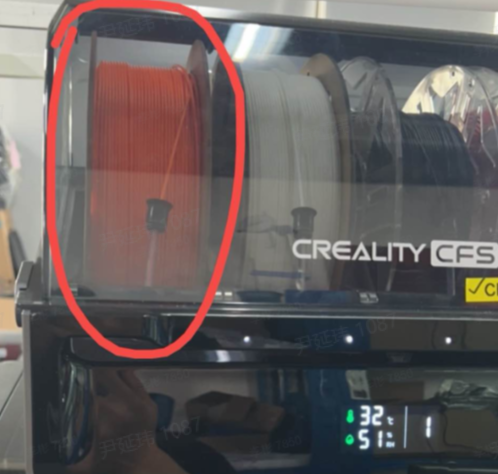

Check filament spool entanglement: Check if the filament in the spool is tangled, making it difficult to feed.

Check if the spool shaft rotates normally: Confirm if the feeding motor is working properly, if the shaft rotates smoothly, and check if the motor gear has broken teeth or slippage.

Check if the spool filament is deformed: It is recommended to use plastic spools. If using paper spools, check for deformation or damage that prevents normal rotation.

Check if there are abnormalities in the feeding tube from the hub outlet to the inlet: Check if the feeding tube is bent, damaged, or has an inner diameter that is too small (normal inner diameter is 2.5mm). These issues can increase feeding resistance.

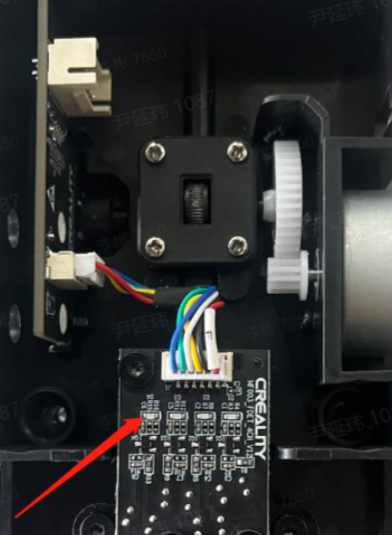

Check if the filament break detector at the hub outlet is damaged: Check if the metal dome of the filament break detector triggers normally. Under normal circumstances, the LED light behind it should light up. If it doesn't light up, the filament break detector may be damaged.

¶ General troubleshooting steps:

Confirm if the filament in the spool is tangled or knotted, straighten it and ensure smooth feeding.

Replace or repair deformed paper spools to ensure they can rotate normally and supply filament.

Check the feeding tube, ensure there are no bends or damage, replace if necessary.

Test the functionality of the filament break detector at the hub outlet to ensure it works properly. If detection fails, the component needs to be replaced.

If the problem persists, check the feeder's working status to ensure it's operating normally. Check the feeding motor's operation status, confirm if the shaft can rotate smoothly, the motor is working normally, and ensure the motor gear is intact.