¶ Creality Hi CM2789:

¶ Troubleshooting for Creality Hi CM2789 Error Code

For Creality Hi CM2789 error code, please read this Wiki page :Troubleshooting for Creality Hi Error Code CM2789

¶ K2 Series CM2789:Abnormal resistance in the movement direction

¶ Troubleshooting for K2 Series CM2789 Error Code

For K2 Plus CM2789 error code, please read the following words:

¶ Why does K2 Series prompt appear?

The motor sensor detected abnormal resistance during motor operation, and the motor drive detected excessive position tracking error. To prevent further damage to other parts due to motor movement, the system triggered an emergency protection program and stopped running. When this error occurs, it is necessary to troubleshoot the fault and restart the machine to resume normal operation.

¶ How to solve it?

First, check the screen and view the pop-up content to see which axis is reporting an error:

¶ X-axis error: Abnormal resistance in the X-axis movement direction, motor released. Fix issue and restart.

Check if there are any obstructions in the movement path when the extruder moves in the corresponding axis direction.

Confirm if there is wear, abnormal tension, or other physical issues with the X-axis guide rail and belt.

¶ Y-axis error: Abnormal resistance in the Y-axis movement direction, motor released. Fix issue and restart.

Check if there are any obstructions in the movement path when the extruder moves in the Y-axis direction.

Check if the guide rail and Y-axis direction have excessive resistance. If so, first check if lubrication is insufficient and lubricate before further inspection.

Check if there is interference when the extruder moves across the full print area, and if the nozzle interferes with the nozzle wiper module during wiping.

Check if the hotend cover is properly secured. A loose nozzle cover can also cause Y-axis error. Please refer to the image below to ensure the hotend cover is installed correctly.

Check if the cutting module properly rebound and reset after collision. You can refer to the below picture that shows the arrow-indicated position of the cutting module.

¶ Z-axis error: Abnormal resistance in the Z-axis movement direction, motor released. Fix issue and restart.

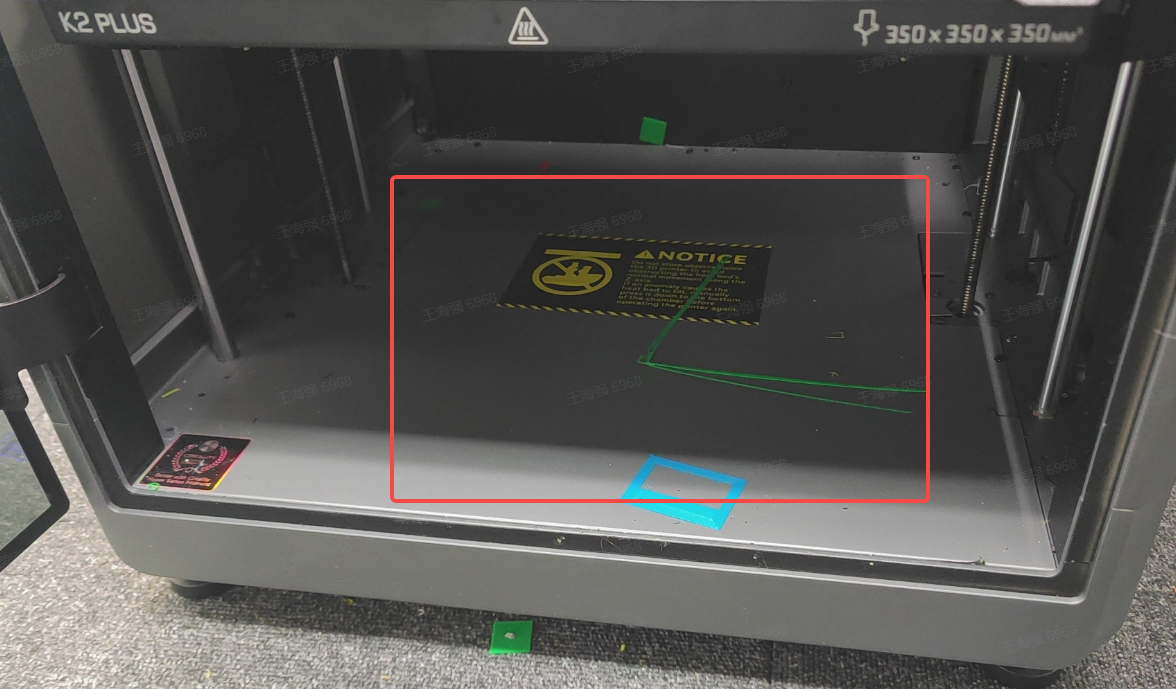

Check if there are any obstructions under the hot bed affecting its up and down movement. This is common when waste filament from flushing falls to the bottom of the hot bed, affecting downward homing.

¶ E-axis error: Extruder extrusion anomaly, possible clog or blockage. motor released.

If it occurs during printing or filament loading/retracting, the extruder will pause next to the waste chute. Follow the article Troubleshooting for K2 Plus Jammed Filament to handle the clog, then click continue printing to attempt recovery.

If it occurs during first layer printing, check if there is excessive layer compression causing extrusion difficulties. According to Troubleshooting for Layer Compression, then reprint and check the print calibration.

Frequent occurrences may be due to excessive nozzle resistance. Try replacing with a new nozzle to see if it resolves the issue.

¶ Common troubleshooting steps for K2 Series Extruder Motor:

¶ Applicable for CM2784/CM2788/CM2786/CM2789

Pause printing, deal with jammed filament refer to Troubleshooting for K2 Plus Jammed; after troubleshooting, heat the nozzle and directly load filament into the nozzle to check if the clog is resolved;

Follow steps to switch to external spool holder filment loading, refer to Filament Switches from CFS loading to Spool Holder loading to check if error still occurs.

If external spool holder filament feeding reports error, handle clogged nozzle/jammed filament Troubleshooting for K2 Plus Jammed Filament. Check if nozzle itself is clogged. If clogged, replace the nozzle directly. K2 Plus package includes a spare nozzle, you can replace a new nozzle based on the Wiki Page ( Replace K2 Plus Nozzle). If nozzle is not clogged, check if filament settings on screen match, e.g. PLA on screen corresponds to PLA filament used.

If external spool holder feeding has no error but printing reports error, check if caused by first layer compression. Refer to Troubleshooting for Layer Compression.

For materials like ABS requiring high hot bed temperature, try preheating the bed before starting print, select print calibration.

If external spool holder feeding has no error, switch to CFS filament feeding. Click any slot to feed, observe if filament buffer and hub motor can move normally.

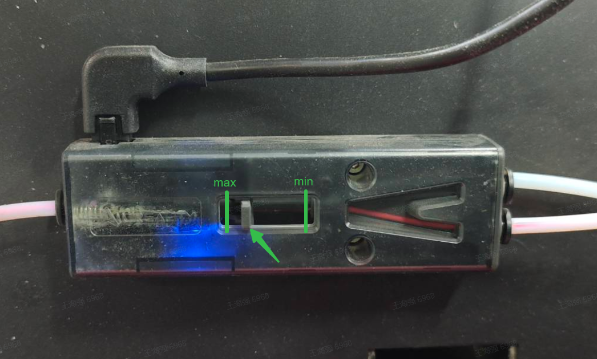

Buffer working principle: extruder consumes filament causing buffer to move to min position (as shown), hub motor receives buffer signal to feed filament causing buffer to move to max position (as shown). If buffer is stuck on left or right side unable to move, printer reports error, possibly buffer failure, needs replacement.

¶ General troubleshooting Steps

Pause machine. It is recommended to turn off the power before troubleshooting.

Print model interference: If the interference is caused by a failed print model, it is recommended to recheck the model slicing parameters and start a new print.

Check the corresponding axis movement parts: Check if the guide rail and X-axis direction have excessive resistance. If so, first check if lubrication is insufficient and lubricate before further inspection.

Check for interference with other parts: Check if there is interference when the extruder moves across the full print area, especially the cutter rod interfering with filament cutting, and if the nozzle interferes with the nozzle wiper module during wiping.

Restart the device: After resolving the issue, restart the machine and click "homing" to confirm if the fault has been eliminated.