¶ Maintenance Necessity

- Anti-rust and Noise Reduction: All-metal idler structure is susceptible to friction noise and rust. Regular lubrication can extend equipment life and ensure printing accuracy.

- Factory Pre-maintenance: All equipment undergo basic lubrication treatment before leaving the factory.

¶ Maintenance Cycle Recommendation

Frequent use: Once per week

Infrequent use: Once every two weeks

¶ Note

K2 Plus maintenance recommendation can be referenced in this Wiki Page: K2 Plus Periodic Maintenance Tips

Abnormal Response: If metal friction noise occurs during equipment operation, stop immediately for maintenance.

¶ Filament Specification

¶ Recommended Lubricant

WD-40 Specialist® Silicone(Must verify authentic anti-counterfeiting mark, suitable for belts without causing damage)

Prohibition Notice: Use of non-certified lubricants is strictly prohibited as they may cause bearing corrosion/steel shaft wear/seal aging and other failures

For more information about WD-40 Specialist® Silicone, please click here.

¶ Standardized Operating Procedure

¶ Required Tools

Lint-free cloth

WD-40 Specialist® Silicone

¶ Steps

Use a clean lint-free cloth to wipe dust and debris from the idler wheels on the left X-axis assembly (2102013343) and right X-axis assembly (2102013346). Do not use paper towels that may leave fibers

|

|

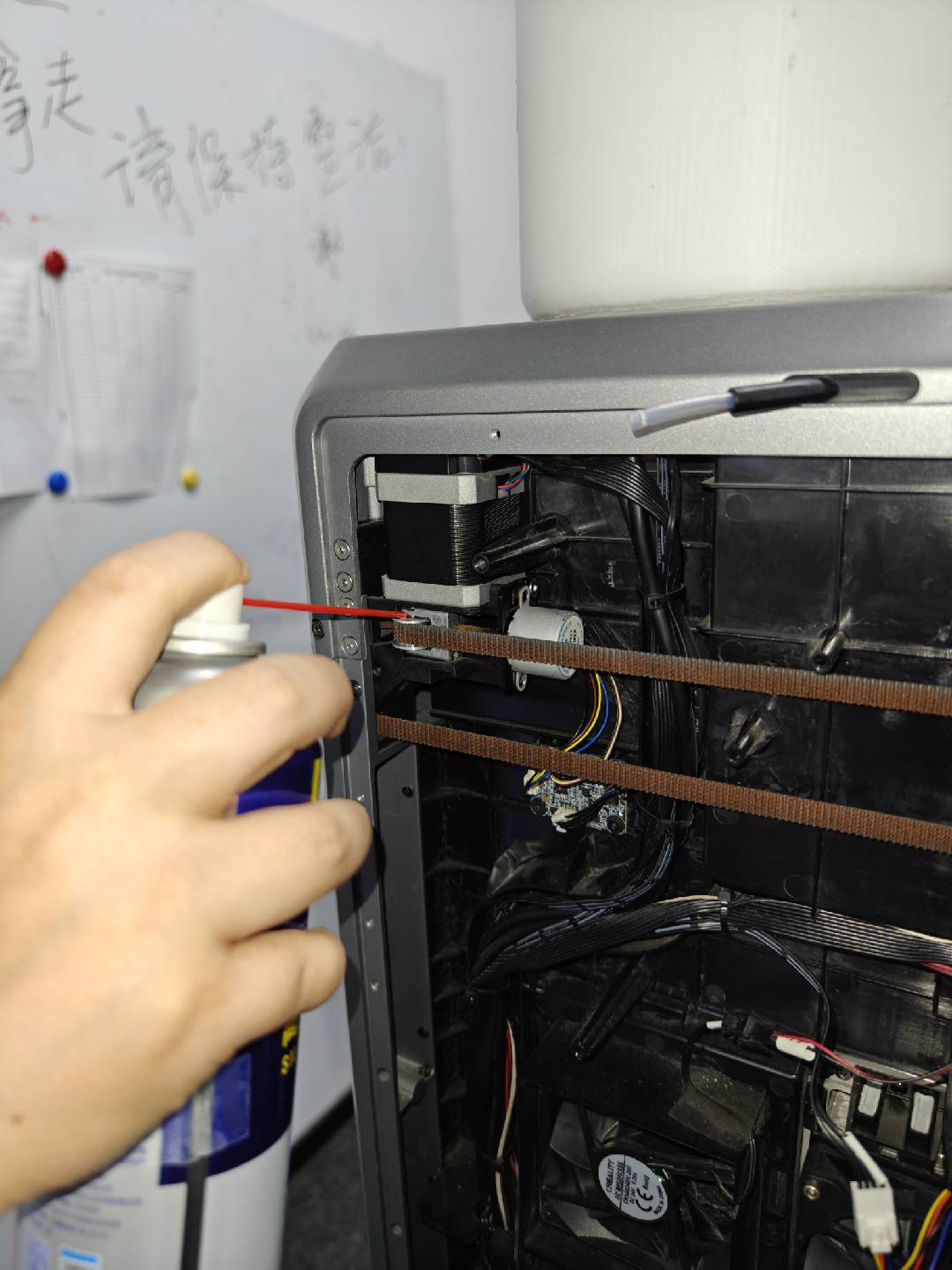

After shaking well, spray "WD-40 Specialist® Silicone" on this plastic assembly, wait about 5 seconds to allow the lubricant to penetrate the idler bearings, then manually move the hotend to ensure even lubrication of the idler wheels.

|

|

|

|

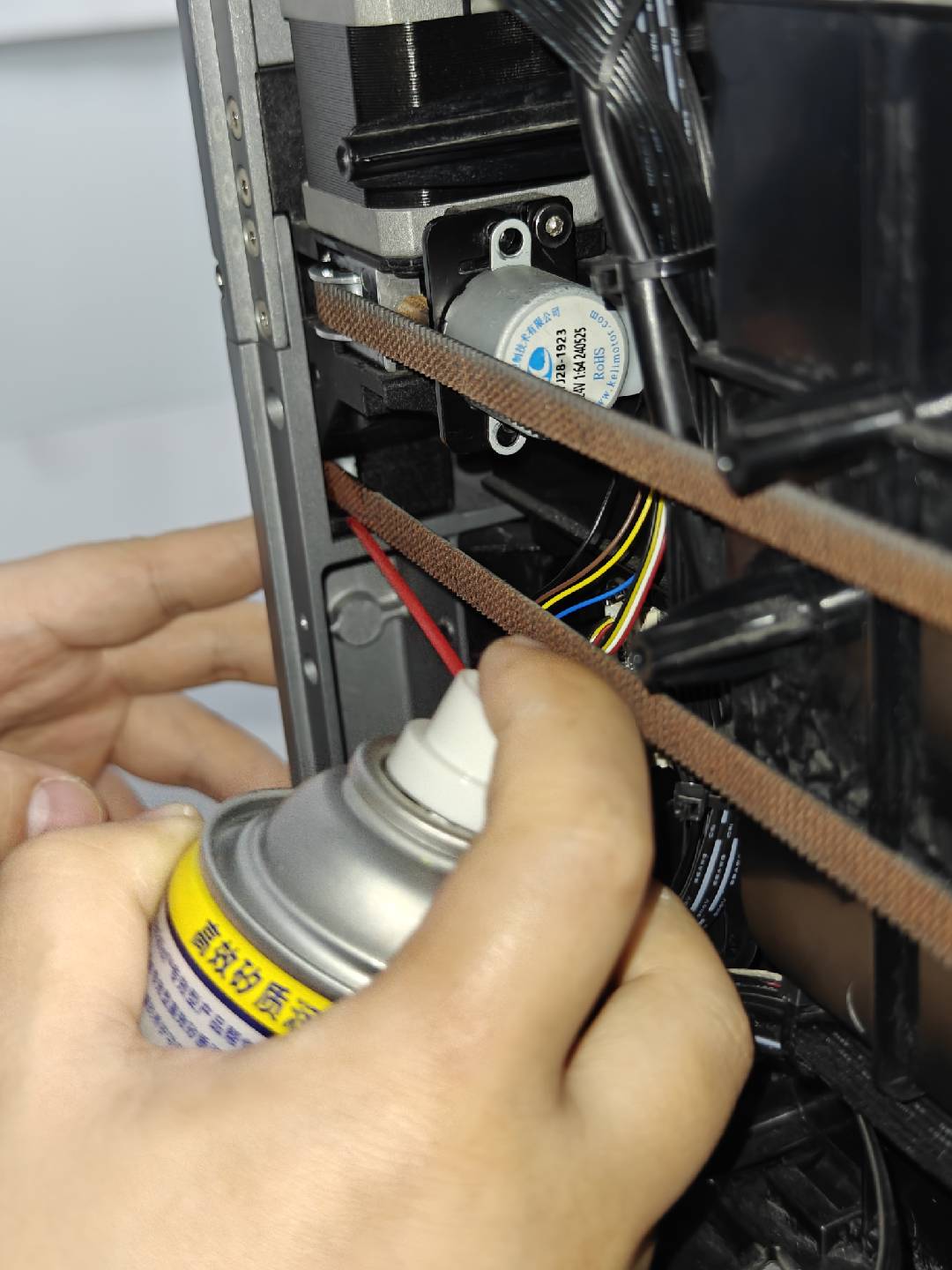

Similarly, apply "WD-40 Specialist® Silicone" to the idler wheels of the left front tension assembly (2102013345), right front tension assembly (2102013344), X-axis motor assembly (2102013352), and Y-axis motor assembly (2102013353).

|

|

|

|

|

|

|

|

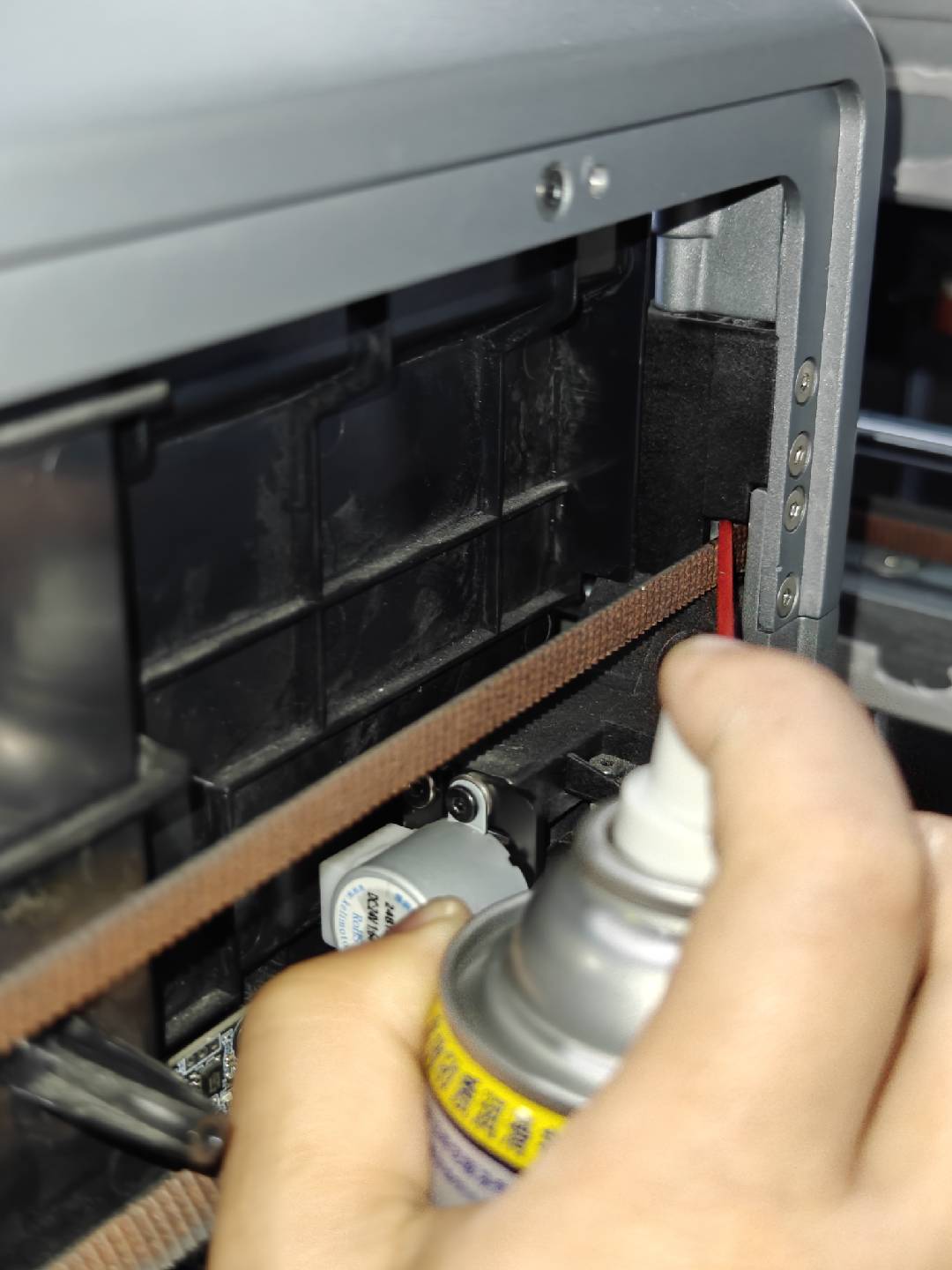

First clean the X-axis guide rail with a lint-free cloth, then spray "WD-40 Specialist® Silicone" along the entire guide rail. Follow the steps in the Wiki article: K2 Plus X-axis Guide Rail Cleaning Guide

After long-term use, Y-axis lead screws may accumulate black, thread-like sticky substances. Use a lead screw cleaning tool (recommended to print with PETG filament) to clamp both sides of the lead screw and perform a homing operation to clean it. Follow the steps in the Wiki article: K2 Plus Z-axis Lead Screw Cleaning Guide