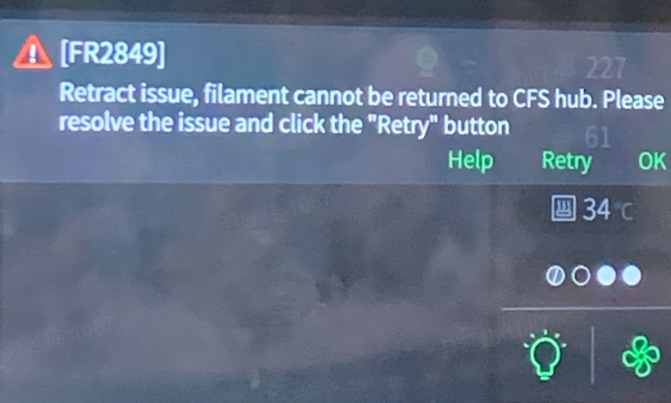

¶ FR2849:Retract issue, filament cannot be returned to CFS hub.

¶ Applicable models: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear

When the printer performs filament unloading, the filament has been pulled out of the extruder, and the filament detector of the extruder has been released, but the filament detection at the hub outlet position of the CFS is still in a triggered state. Possible reasons include:

The filament spool did not rotate correctly during unloading, causing the filament to fail to retract into the CFS.

Excessive resistance or filament jam somewhere in the PTFE tube, affecting filament retraction.

Abnormal triggering of the filament detector corresponding to the hub outlet slot or malfunction of the hub outlet.

¶ How to solve

¶ Spool problem

Check if the spool diameter is too small or deformed, causing the CFS drive wheel to fail to rotate the spool smoothly, or check if the spool is jammed.

¶ Buffer jammed filament

Troubleshooting for CFS Buffer jammed filament (Refer to the wiki page for buffer jammed troubleshooting)

¶ Check hub outlet extrusion status

Check if there is a jam at the hub outlet. If jammed, follow the CFS hub outlet jam handling procedure Troubleshooting for CFS hub filament clogged.

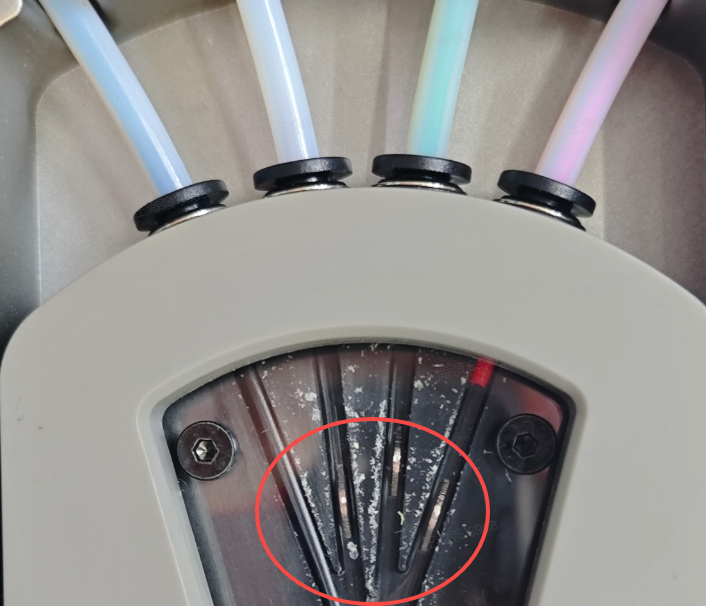

¶ Filament break detection abnormality at hub outlet

If the filament break detection metal dome at the hub outlet has not sprung up, it may be jammed by filament debris. In this case, disassemble the hub outlet and clean the debris.

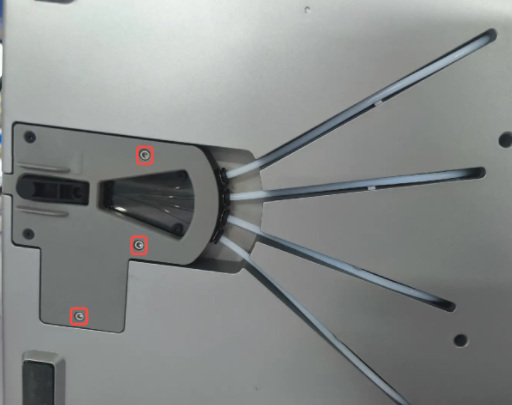

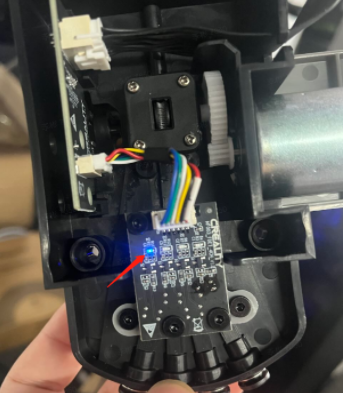

¶ Hub photoelectric board false trigger

After checking that there is no filament in the hub and the metal dome springs up normally, it's possible that the photoelectric board on the back of the hub is falsely triggering the blue light (normally, the blue light on the hub lights up when filament is detected, and doesn't light up when there's no filament). In this case, remove the 3 fixing screws of the hub to check the photoelectric board on the back. If it's confirmed to be a false trigger, please contact cs@creality.com to replace the hub photoelectric board.

|

|

¶ General troubleshooting steps

Check the spool: Ensure the spool is working normally, not jammed or deformed.

Check the buffer: Confirm if there are any faults or jams in the buffer.

Check hub outlet status: Ensure the hub outlet extrusion is working normally without blockage.

Check filament break detection: Confirm if the filament break detector at the hub outlet is working properly.