¶ Phenomenon Description

All waste material is blocked in the waste chute and cannot be discharged.

¶ Cause Analysis

Filament tray deformation

Nozzle wiper deformation/damage

Rough interior wall of waste chute

Improper waste chute assembly

Insufficient cooling

¶ Troubleshooting

¶ Filament tray deformation

When the tray is deformed, waste material won't tip over after extrusion, causing accumulation. Solution: Straighten the deformed tray to ensure normal movement. If the issue still can't be solved, please contact customer service(cs@creality.com)

¶ X/Y motor step loss

Check previous error logs, usually Error 2789, refer to CM2789

¶ Nozzle wiper deformation/damage

Deformed or damaged nozzle wiper results in incomplete nozzle cleaning, and residual material won't drop. Please follow the wiki page: Replace K2 Plus Nozzle Wiper

¶ Rough interior wall of waste chute

High friction due to rough surface prevents material from falling. Refer to tutorial video: Replace K2 Plus waste chute.

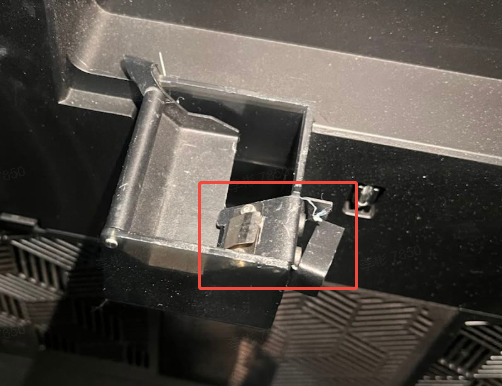

¶ Improper waste chute installation

Normally, the nozzle should have some contact with the wiper strip during cleaning. Improper assembly may leave a gap between nozzle and strip, resulting in ineffective cleaning. Solution: Reassemble following the tutoroal video: Replace K2 Plus waste chute.

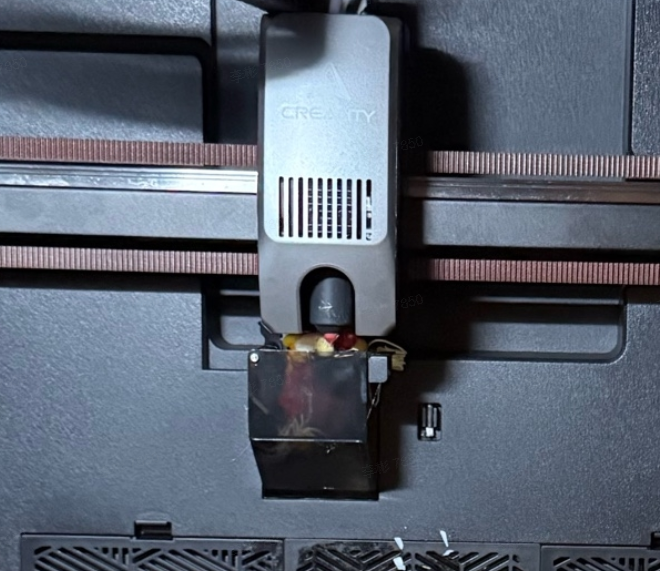

¶ Insufficient cooling

Normally, the nozzle fan helps quickly solidify extruded waste material to prevent sticking to the tray. When the fan isn't working, material remains sticky, increasing friction and hindering discharge. Solution: Refer to video tutorial: Replace Model Fan Assembly

¶ Enable AI waste chute detection

AI waste chute detection will automatically pause printing if blockage occurs.