¶ FO2845:Extruder may be clogged. Click "Retry" after resolving

¶ Applicable Model: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear?

This prompt usually occurs due to a clogged nozzle, preventing normal filament extrusion, especially during the flush stage of CFS filament switching. Reasons for clogging may include:

Filament issues: Such as uneven filament diameter, moisture absorption, or deformation.

Spool problems: Spool getting stuck or CFS shaft not running smoothly.

Slicing parameter issues: Mismatch between filament and slicing parameters, causing abnormal extrusion.

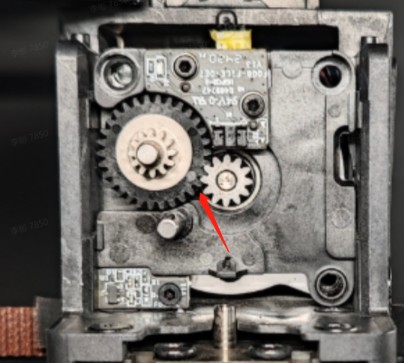

Damaged extruder gear: The extruder gear may have broken teeth or be worn out.

Filament stuck in the hot end: Blockage in the hot end can also trigger this prompt.

CFS buffer malfunction: Abnormal or failed detection function of the CFS buffer, leading to false detection, showing the prompt when there's actually no clog.

¶ How to solve it

Dealing with nozzle clogging: Refer to the corresponding model's handling solution (Wiki Page), disassemble the extrusion module and address the clog.

Troubleshooting for K2 Plus Jammed Filament

Troubleshooting for Creality Hi Clogged Nozzle

¶ Investigate the cause of clogging:

Check filament issues: Confirm consistent filament diameter, check for moisture absorption or deformation.

Check spool issues: Inspect spool movement and CFS shaft operation for normality.

Check slicing parameters: Ensure slicing parameters match the filament used, avoid extrusion settings that are too high or too low causing clogs.

Check extruder gear and structure: Confirm if the extruder gear has broken teeth causing filament slippage; if intact, check if the extruder motor is working normally.

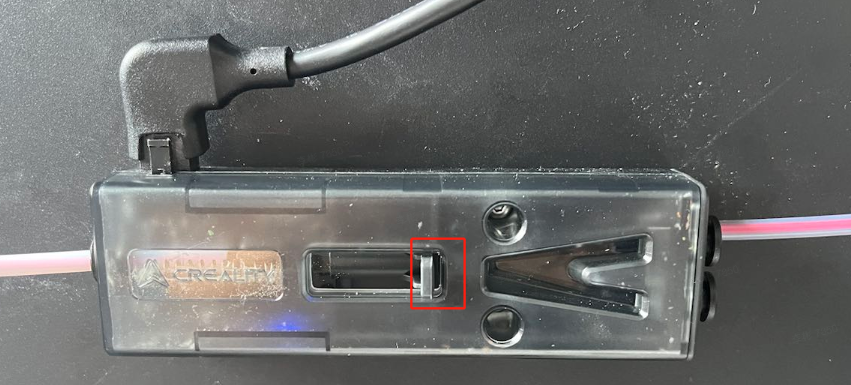

Check if the CFS buffer connection is normal: Verify if the buffer's power supply and communication are normal, check if the blue light on the buffer is on.

Check if the CFS buffer and detection function are normal: Observe if the buffer's power supply and communication are normal, check for false detection, confirm if the blue indicator light is on.

¶ General troubleshooting steps:

- Address the nozzle clog.

- Check slicing-related clog causes, such as filament diameter, slicing parameter settings, etc.

- Investigate extrusion-related component issues, such as whether the extruder gear and extruder motor are working normally.

- Check clog detection elements, such as whether the CFS buffer is working normally, and if there are false detections.

- Perform a feeding operation to see if the clog is resolved.

¶ K2 Plus Troubleshooting steps:

Disassemble the extruder to address nozzle clogging: Troubleshooting for K2 Plus Jammed Filament

Check if the extruder gear and motor are working normally.

Check if the CFS buffer is normal: Verify if the CFS buffer connection is normal: Observe if the buffer's power supply and communication are normal, check the buffer's 485 communication cable. First measure if there's 24V voltage on the ribbon cable, then test the cable's continuity.

Analyze based on buffer limit switch status:

Middle limit: Extruder failure or nozzle clog preventing filament from being pulled.

Right full limit: Filament can be pushed partially, but the extruder can't pull subsequent filament. Possible causes include abnormal buffer board, unable to trigger the hub motor to rotate towards the extruder for feeding, or the PTFE tube is bent or has a small inner diameter, causing high resistance.

Observe if the clog is resolved during feeding.