¶ 1. Retract Filament

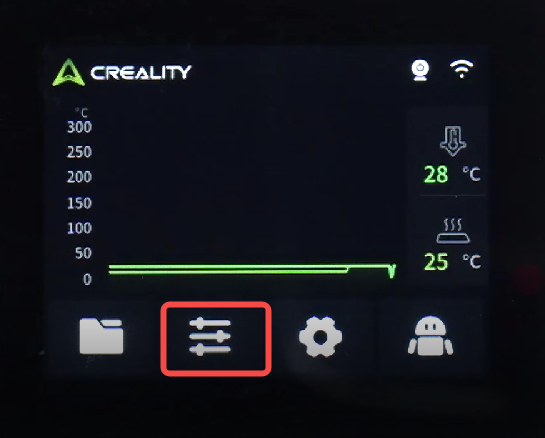

Click "Prepare" - "Filament" - "Retract", wait for the nozzle to heat, the machine will automatically unload filament.

Hold down the extruder and pull out the filament.

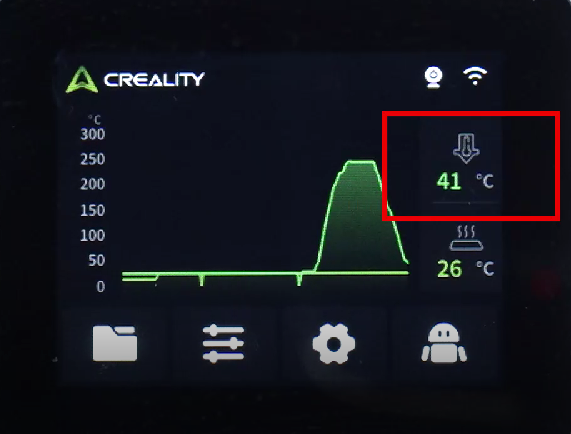

Click "Cooling" and wait until the temperature drops to normal temperature.

Turn it off.

¶ 2. Remove

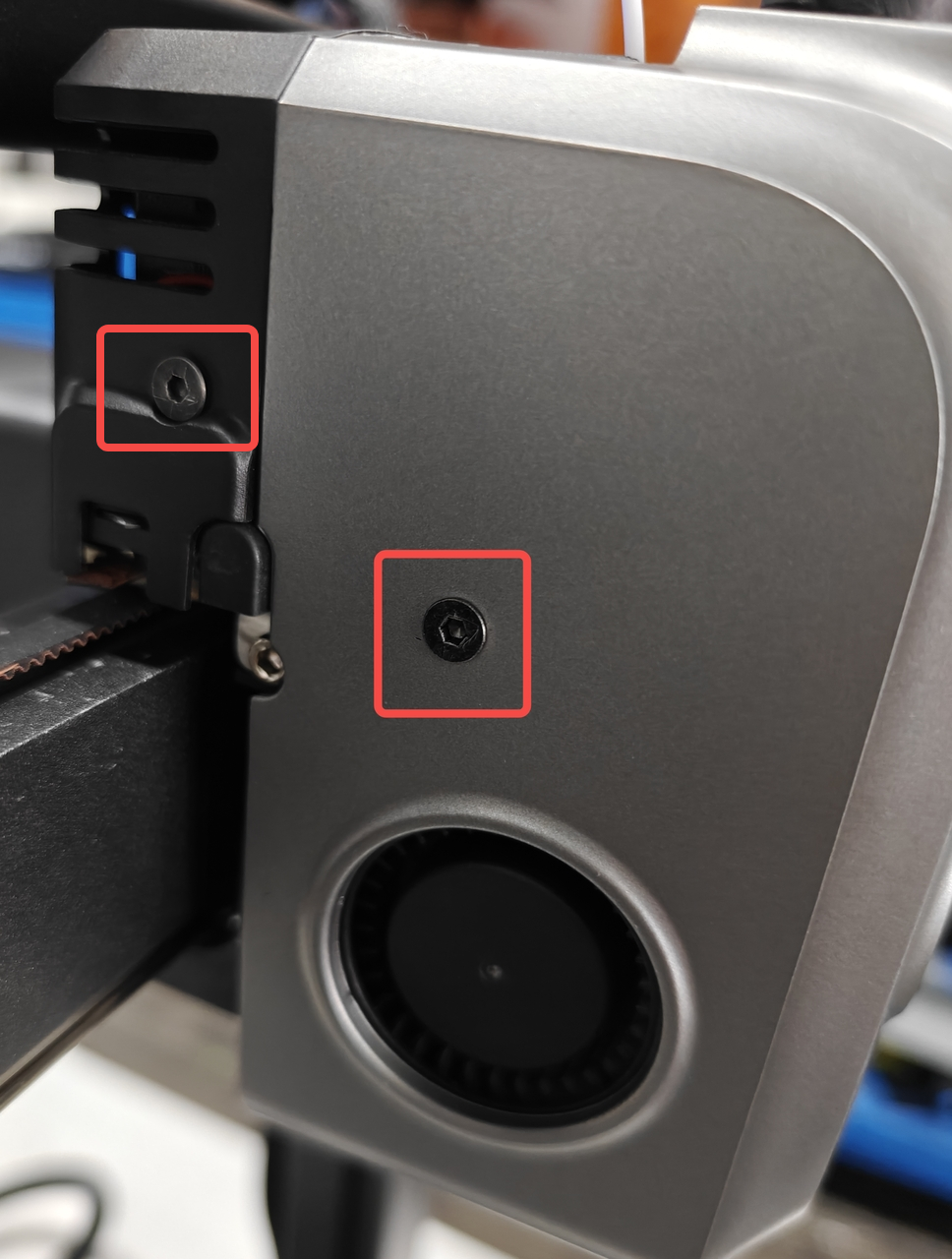

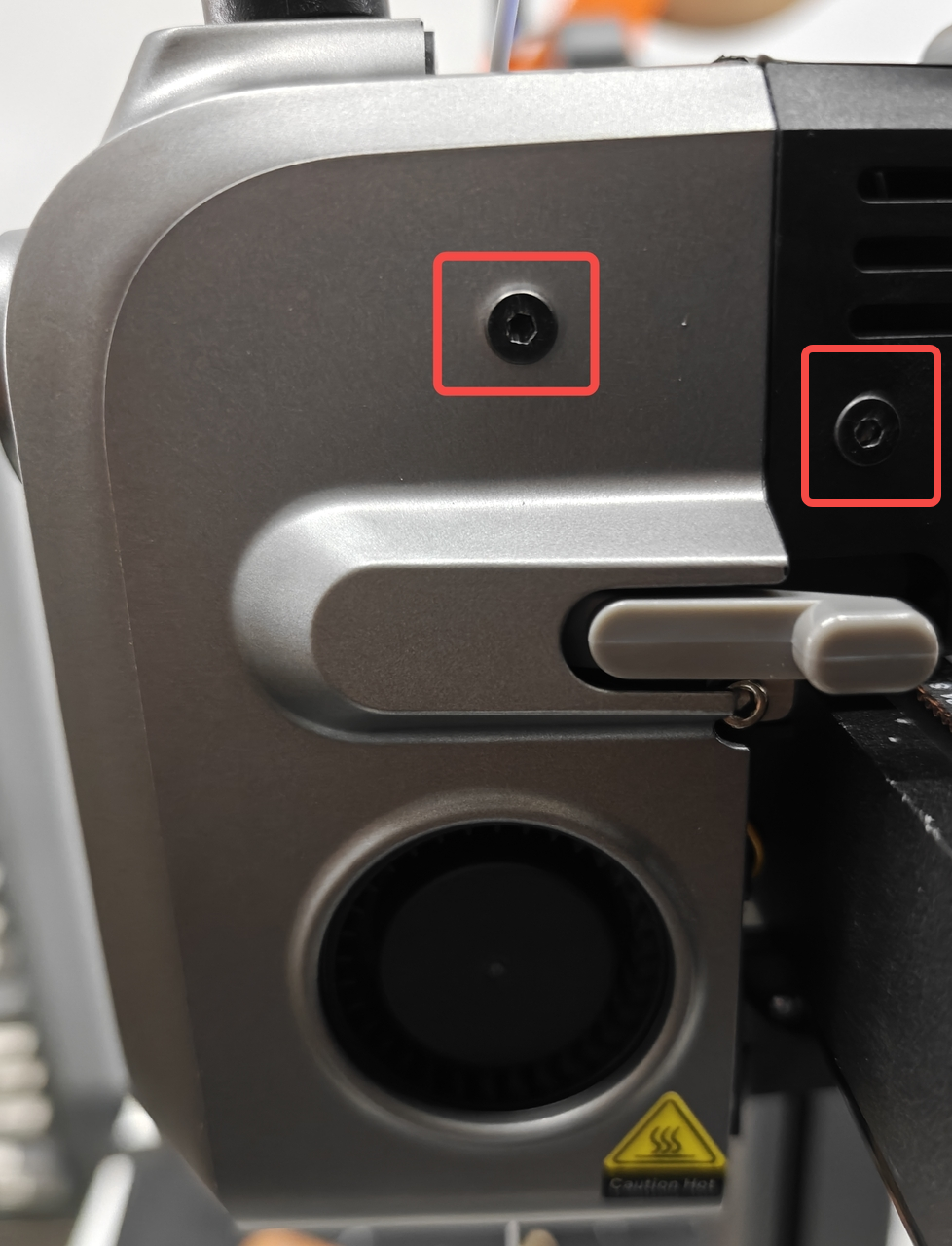

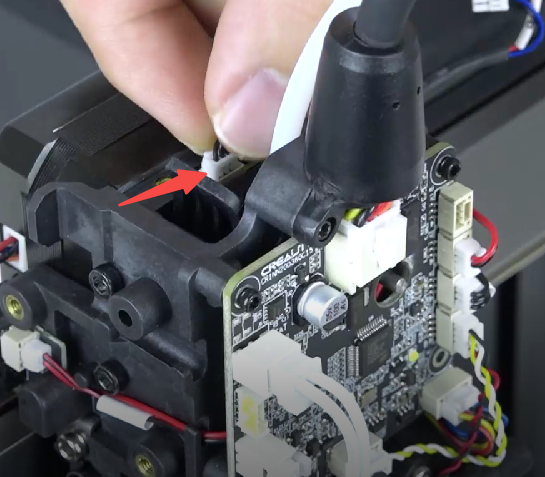

Use a hex key to remove the four screws on the hotend cover, and remove the hotend cover and motor protection cover.

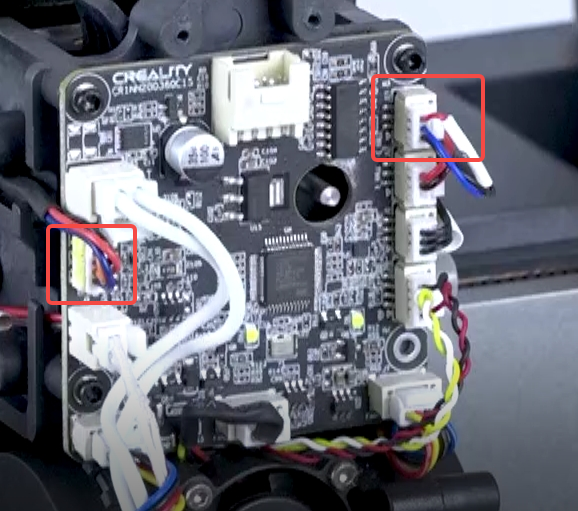

Remove the three cables.

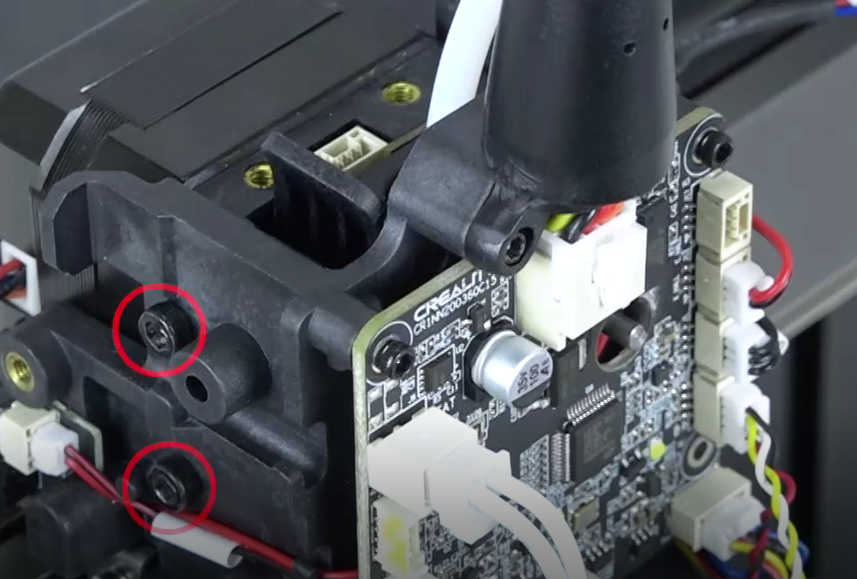

Unscrew the three screws fixing the extruder parts.

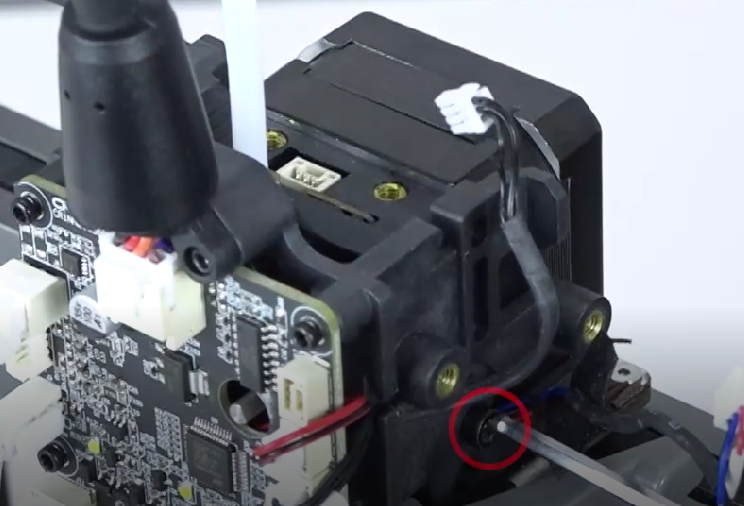

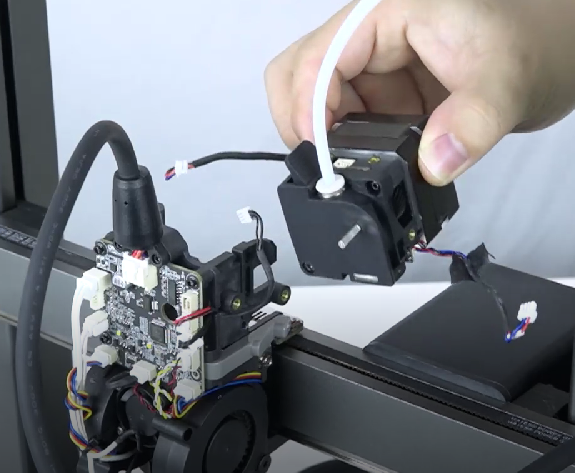

Take out the extruder and pull out the teflon tube.

¶ 3. Clean the heat break

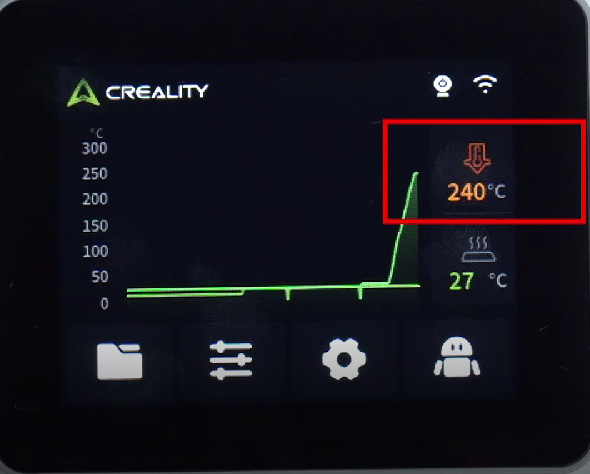

Startup the printer and set the nozzle temperature to 240°C.

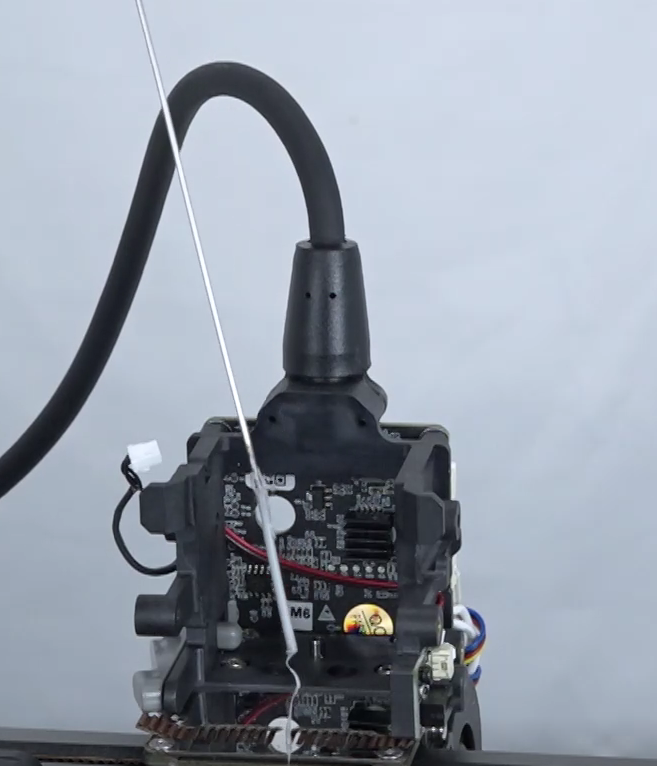

Use the needle to clean the blocked filament in the nozzle.

If the needle does not go through directly, perform the following operations:

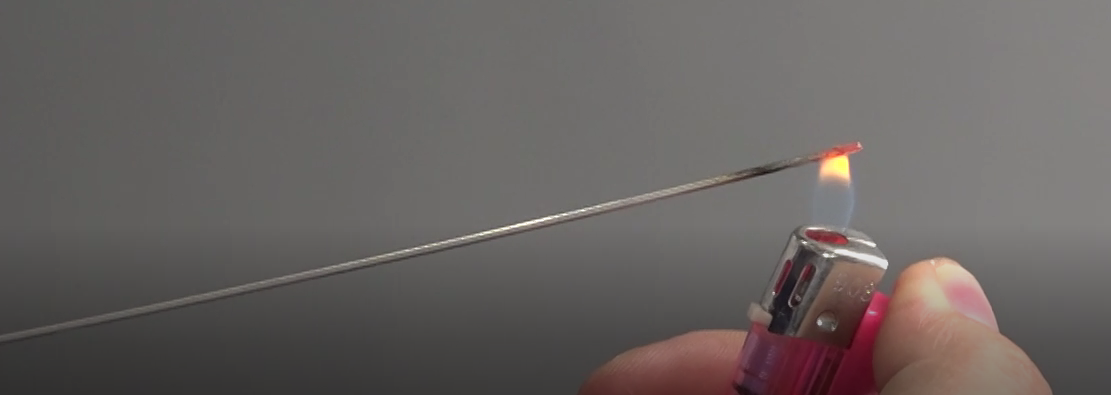

Heat the tip of the needle by using a heating tool.

Insert the hot needle into the nozzle, wait for 30 seconds, and wait for the needle to be cooling.

Slowly pull out the needle after cooling to take out the clogged filament in the heat break.

Cool, wait until the nozzle temperature drops to normal temperature.

¶ 4. Restore the extruder

Shut down the printer and restore the extruder.