¶ FB2844:PTFE Tube may have detached from the pneumatic fitting, please try again after resolving.

¶ Applicable printer: K2 Plus/Creality Hi/K2 Pro/K2

¶ Why does this prompt appear?

This usually occurs when a PTFE tube pneumatic connector somewhere in the printer becomes loose, causing the filament to continuously feed (the hub outlet can detect the filament, but the extruder's material break detection cannot detect the filament).

After this message appears, first click "Retract" on the screen to unload the filament. If one time retraction is not enough, you can click "Retract" again. After retraction is complete, reattach the pneumatic connector and continue using.

¶ How to solve

PTFE tube detached from pneumatic connector or pneumatic detached: Check if there is any detachment or damage to the PTFE tube interface at the hub outlet, buffer PTFE tube interface, PTFE pneumatic connector at the back of the printer, or PTFE tube or pneumatic connector at the extruder.

PTFE tube detached from Extruder: If only the PTFE tube has come off, first click to retract the filament back into the CFS. Then cut off a small section from the front end of the PTFE tube and reinstall it to resume printing. If the pneumatic connector at the extruder has come off, you need to replace the front cover of the extruder to resolve the issue. Please refer to this article: Replace K2 Plus Extruder Front Cover

¶ General Troubleshooting Steps:

Click "Retract" to retract the filament.

Check the connection status of the pneumatic connectors and PTFE tubes. If a PTFE tube is detached, reconnect it; if a pneumatic connector is detached, replace the corresponding part.

Confirm that the filament spool and feeding motor are working normally.

Check if the hub outlet motor is operating normally.

¶ K2 Plus troubleshooting steps:

Click "Retract" to unload the filament.

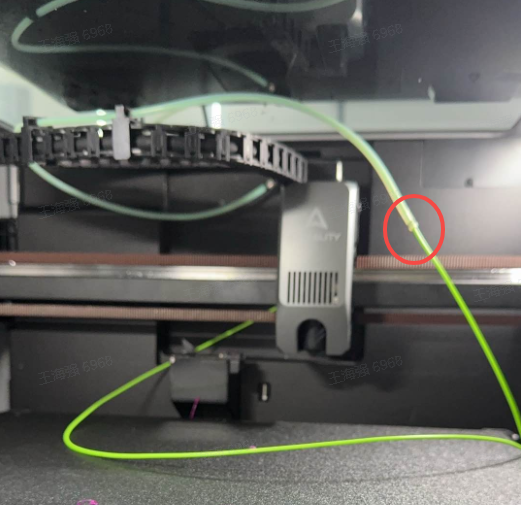

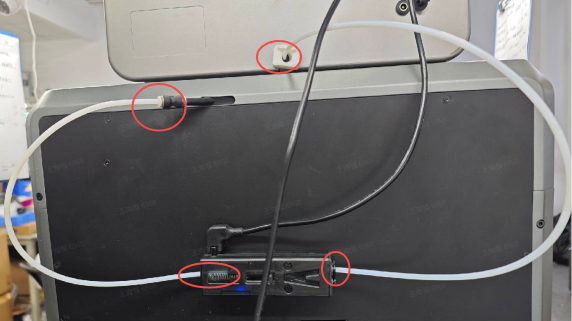

Check the connection status of the pneumatic connectors and PTFE tubes at the locations shown in the pics. If a PTFE tube is detached, reconnect it; if a pneumatic connector is detached, replace the corresponding part.

Confirm that the filament spool and feeding motor are working normally.

Check if the hub outlet motor is operating normally.