¶ 1. Phenomenon Description

The first layer of the model doesn't adhere to the platform, or the nozzle scrapes the platform, causing layer compression.

¶ 2. Cause Analysis

If there's a minor adhesion issue, it may be due to filament residue on the nozzle/platform before leveling, leading to inaccurate leveling.

Abnormal leveling plate/strain gauge causing inaccurate leveling data, resulting in layer compression or nozzle scraping the platform.

Tilted hot bed or bubbling of soft magnetic sticker.

¶ 3. Troubleshooting

1. Clean the hotend thoroughly, wash the platform with water, and re-level with self-test to confirm if the leveling data is normal.

2. Check if the hotend and hot bed are loose, tighten if they are.

3. It's recommended to use the official slicing software and select the default parameters for the corresponding filament when slicing.

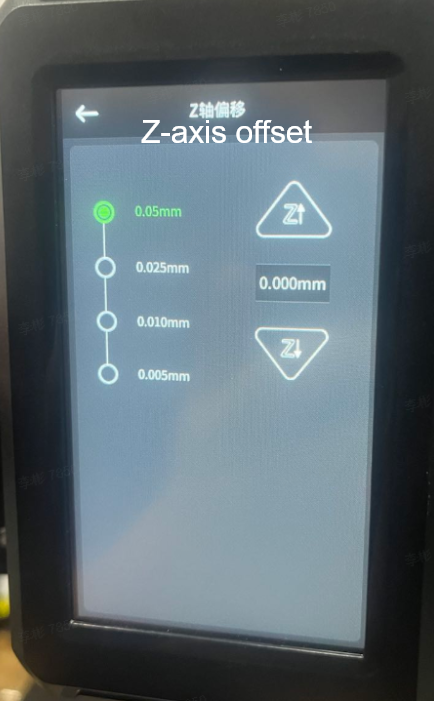

4. During the first layer printing, slightly adjust the Z-axis compensation based on the printing effect. (Printing model interface/Settings/Expert mode/Z-axis offset)

|

|

5. Check if the platform plate or soft magnetic sticker is damaged or bulging.

6. Recalibrate the hot bed tilt refer to the article Ender-5 Max Hot Bed Calibration Guide

If the problem persists after following these steps, please contact cs@creality.com