¶ 1. When to calibrate hot bed

1. The hot bed is uneven or tilted.

2. Printing in mid-air or scraping the platform occurs during printing.

3. Non-stick platform or layer compression issues appear.

4. After replacing the hot bed assembly or leveling plate or strain gauge.

5. After replacing Z-axis motor/belt/lead screw/optical shaft.

¶ 2. How to calibrate hot bed

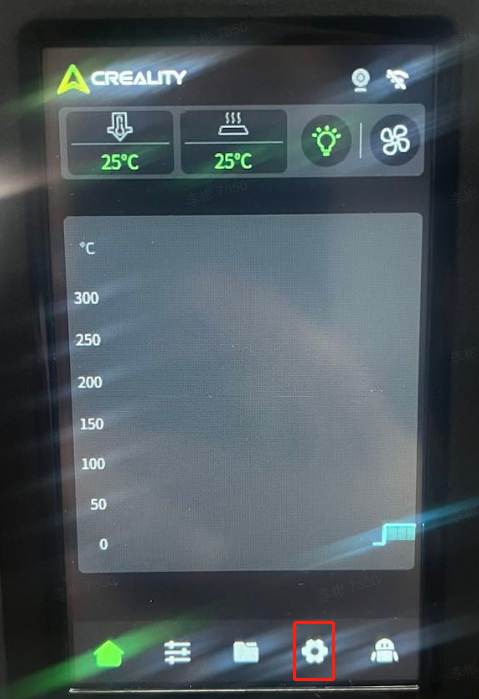

1. On the main interface, enter “Settings”.

2. Select and enter “Expert Mode”.

3. Click “Hot Bed Tilt Calibration”.

4. Click “Start”.

5. Wait for about 5 minutes. During calibration, when the hot bed lowers to the lowest point, there will be a clicking sound from the motor, which is normal for forced hot bed leveling operation.

6. After calibration is complete, it will prompt for automatic leveling operation. Click “OK”.

7. The machine will automatically enter printer self-check. Not all self-test operations will be performed here. The system will automatically select"Hot Bed Heating"+ "Auto Leveling" for self-check, which takes about 10 minutes.

After the self-check is complete, click “OK” to finish the entire hot bed calibration process.