¶ Phenomenon description

The nozzle does not discharge filament when printing starts.

¶ Cause analysis

-

Filaments are wrapped around the material rack

-

Filament are not assembled in place

-

There are residual filament in the nozzle and throat

-

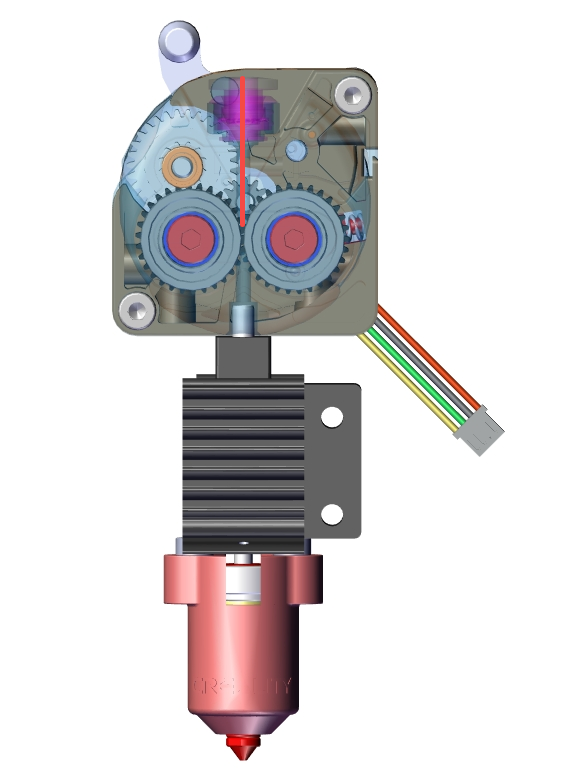

Extruder jams

¶ Troubleshooting and solution

- Check whether the material rack is tangled and whether the anti-tangle material rack is correctly assembled.

- Use scissors to cut the filament at 45° and straighten it, unlock the gear extruder and insert it into the feed port.

- If you feel that there is resistance and cannot continue to push down (the filament is loaded about 22mm), lock the gear extruder and perform the automatic feeding function.

- Heat the nozzle to 240 degrees, straighten the filament, open the gear extruder, and feed the material manually.

- It is recommended to use option 2 for loading filament, automatic feeding; please note that whether it is automatic feeding or manual feeding, the filament must be straightened.

-

The above methods cannot feed the filament. Please refer to the after-sales video - cleaning the nozzle through the needle to clean the nozzle.

https://youtu.be/IjCItbow7I8 -

Extruder jamming solution: Extruder Abnormality / Extruder Jam / Extruder Abnormal Noise