¶ Operation Video

¶ i7 Toolhead Filament Cutter

The filament cutter is installed on the left side of the Extrusion Assembly. When the Toolhead moves to the far left, the Cutter Arm is actuated by a lever mechanism, driving the internal cutter blade to cut the Filament. After cutting, the cutter automatically returns to its original position under the magnetic force of the built-in magnet.

This guide explains how to replace the i7 Series Toolhead Filament Cutter.

¶ When to Replace

The cutter is damaged or becomes dull;

Abnormal filament cutting occurs (it is recommended to run Cutter Detection first);

Replacement is recommended after more than six months of use.

¶ Required Tools

New i7 Toolhead Filament Cutter (purchase link);

Tweezers or any Hex Wrench.

¶ Safety Preparation

Power off the printer and unplug the Power Cable;

Before operation, make sure the Hotend and Heated Bed have cooled down to avoid accidental contact with hot components.

¶ Replacement Steps

¶ Remove the Old Cutter

Remove the Toolhead Front Cover to expose the Toolhead Assembly;

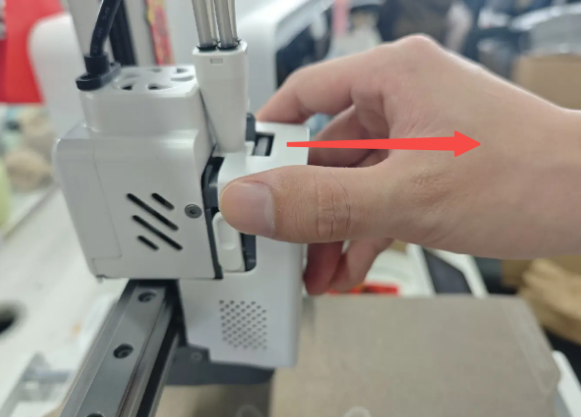

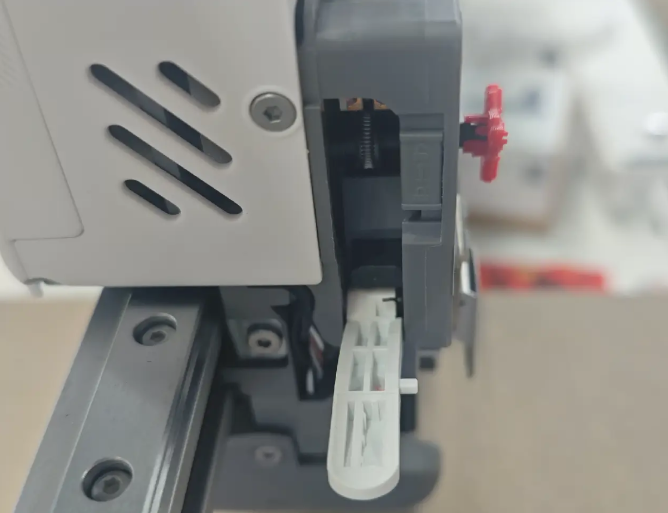

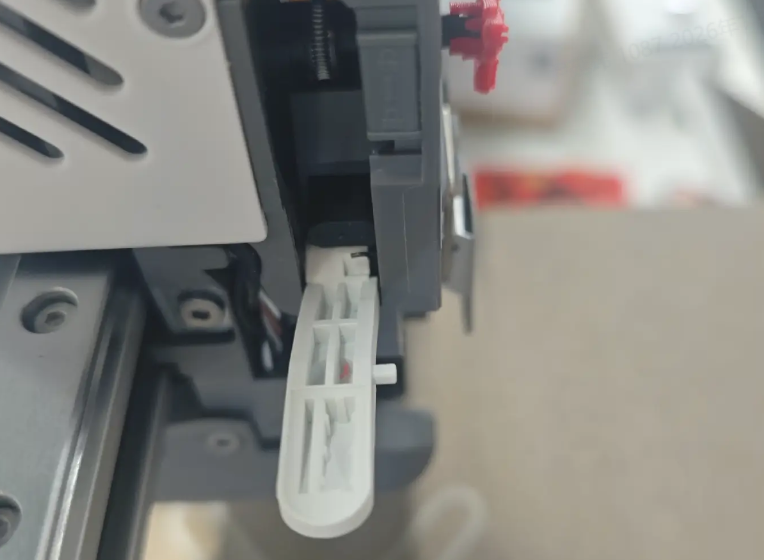

Locate the latch in front of the Cutter Arm on the left side. Push the latch upward; the cutter arm will automatically spring open;

|

|

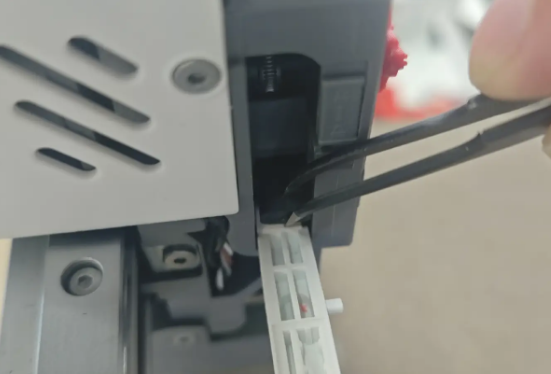

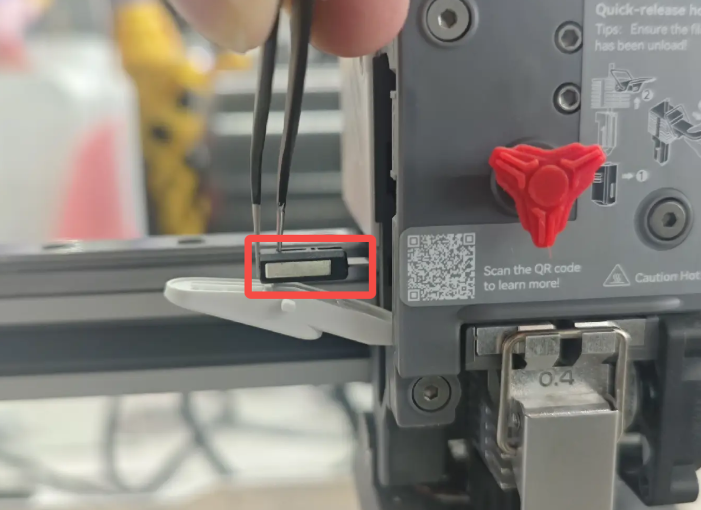

Using tweezers or a hex wrench, slide the cutter out from the rear toward the left side; Warning: The blade is sharp. Handle with care to avoid injury.

|

|

¶ Install the New Cutter

Prepare the new cutter and make sure the magnet side faces forward;

Insert the cutter into its original position. The cutter will be pulled into place by magnetic force;

Push the cutter arm latch upward, swing the Cutter Arm back into position, then release the latch to ensure it is securely locked;

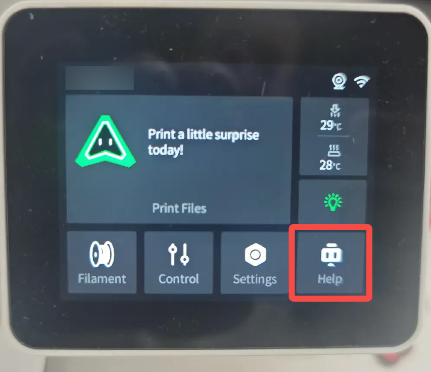

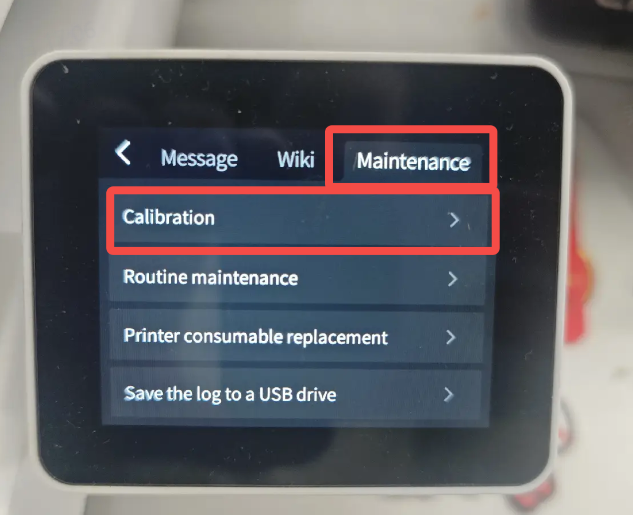

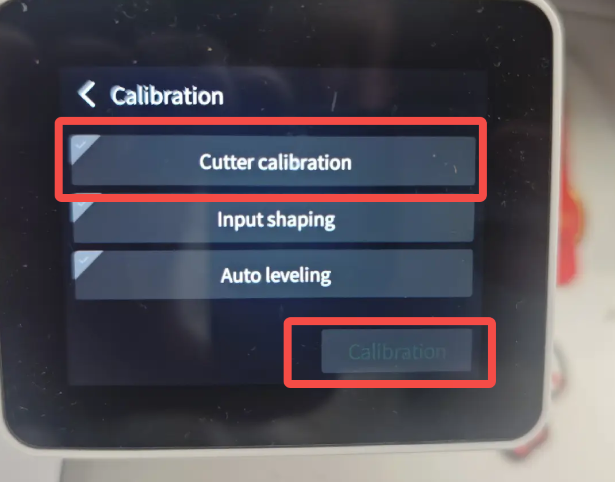

It is recommended to run Cutter Detection to ensure the cutter is in the optimal position.

|

|

|