¶ Introduction

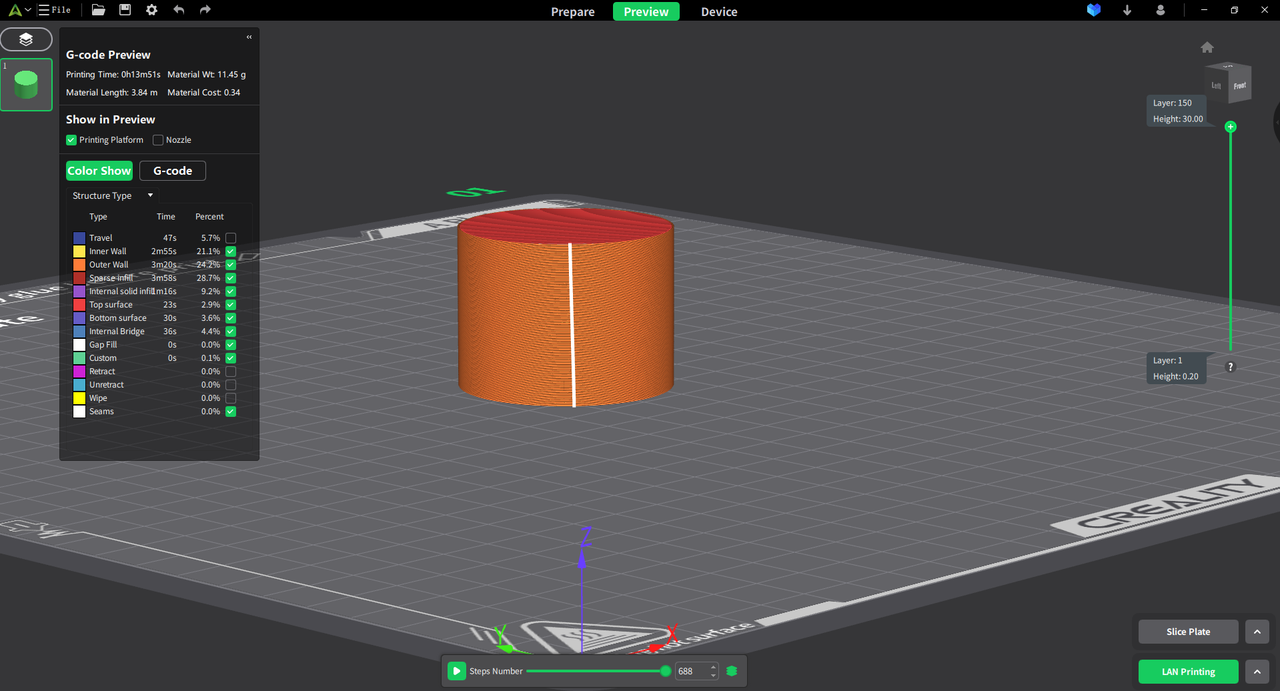

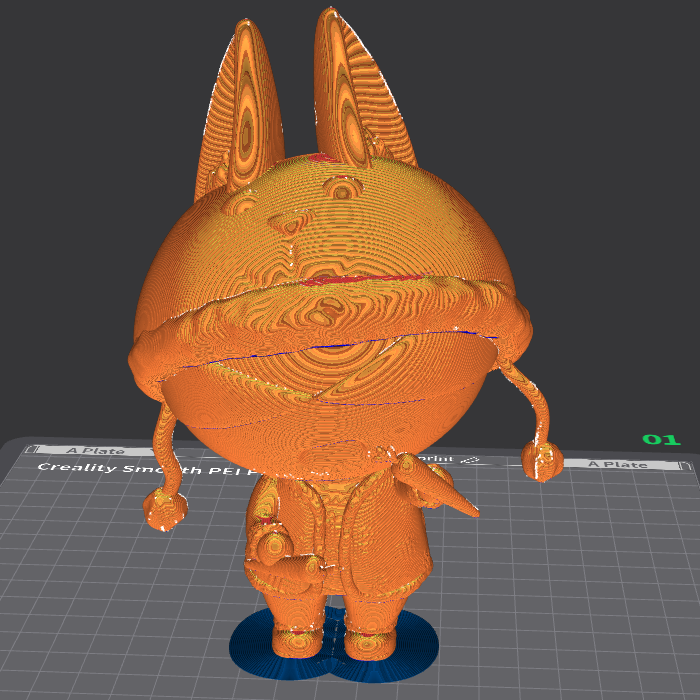

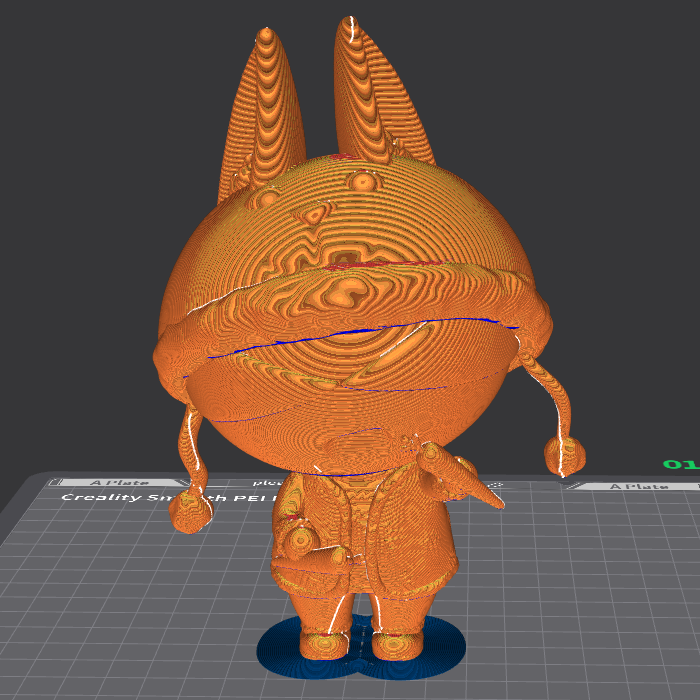

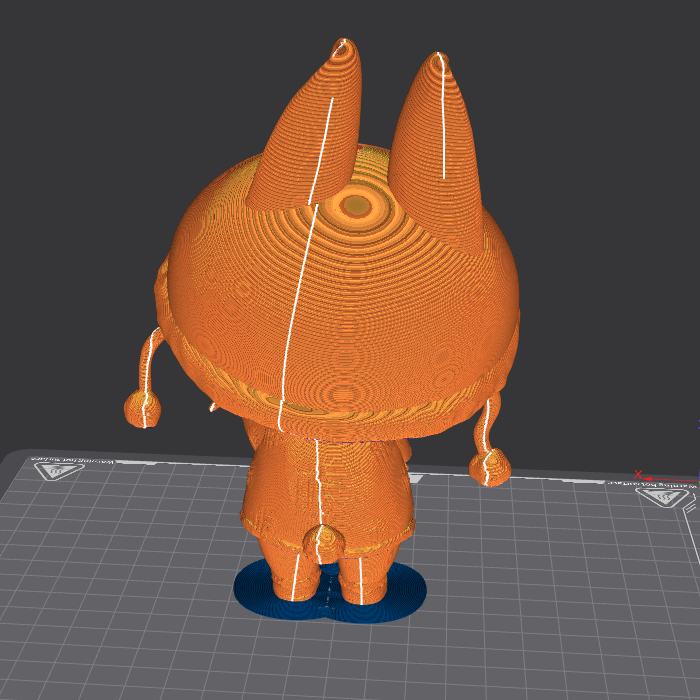

The seam is a kind of gap between the start point and the end point of each perimeter of the layer. It typically appears as a vertical line on the side of printed objects and directly affects the surface quality and appearance of the model.While seams can be relatively well hidden on irregular surfaces with concave and convex vertices, they are challenging to completely avoid on curved models such as cylinders. Therefore, handling and optimizing seams are crucial in FDM printing.

¶ Seam position

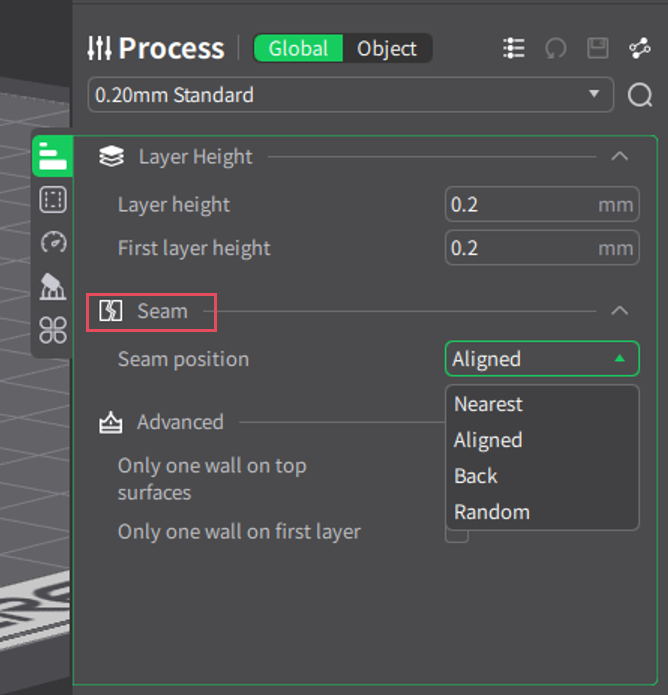

To minimize seam visibility, you can choose from several different seam placement options in the process parameters - quality - seam position. There are four types of seam positions to choose from: Nearest, Aligned, Back, and Random.

¶ Nearest

This option will attempt to place the seam at the nearest edge of the current layer. If your model has sharp corners, this will make the seam almost invisible. The priority is as follows: concave non-overhang vertex > convex non-overhang vertex > non-overhang vertex > overhang vertex.

¶ Aligned

This option will select the position closest to the start point of the previous layer to ensure alignment of the seam throughout the entire model.

¶ Back

This option will place the seam on the back of the model to achieve a smooth surface on the front.

¶ Random

This option will select a different point for each layer to make the seam less noticeable, but the surface may not be as smooth.

¶ Seam painting

Sometimes the auto seam position may be not ideal,You can customize the seam position by manually painting the method.Its main functions are as follows:

- Enforce seam: Use the left mouse button to draw, generating the seam position according to the drawn area.

- Block seam: Use the right mouse button to draw, masking the seam position within the drawn area.

- Erase: Hold down the shift key + left mouse button to modify the enforced or blocked area's seam position.

The operation methods are as follows: