¶ New Features

¶ Added Scarf Joint Seam Feature

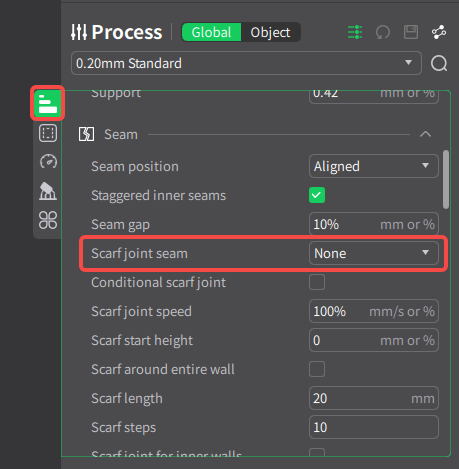

Scarf Joint Seam is used to conceal seams on models with fewer edges, making the seams less abrupt by turning them into short ramps, thereby improving print quality.

.png)

You can enable this setting under Quality - Seam - Scarf joint seam.

¶ Added Bridge Counterbore Holes Feature

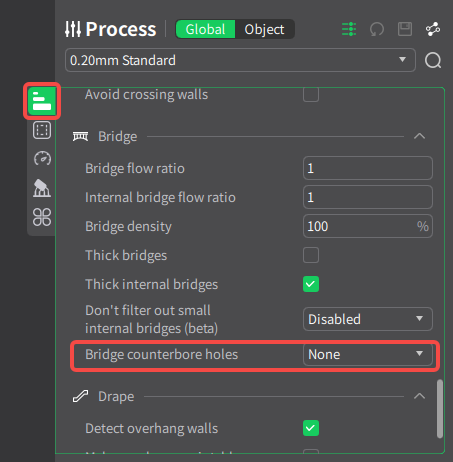

This feature allows bridging for sink holes, enabling printing without supports to enhance printing efficiency, save support material, and simplify post-processing steps.

You can enable this setting under Quality - Bridge - Bridge counterbore holes.

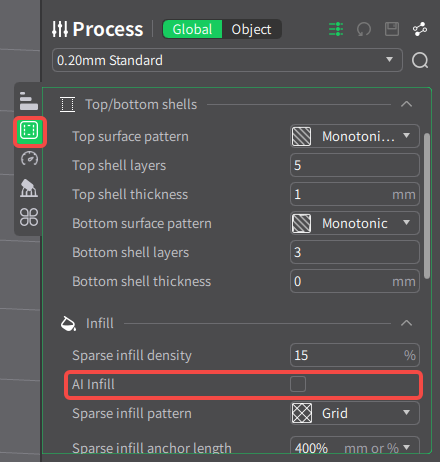

¶ Added AI Infill Feature

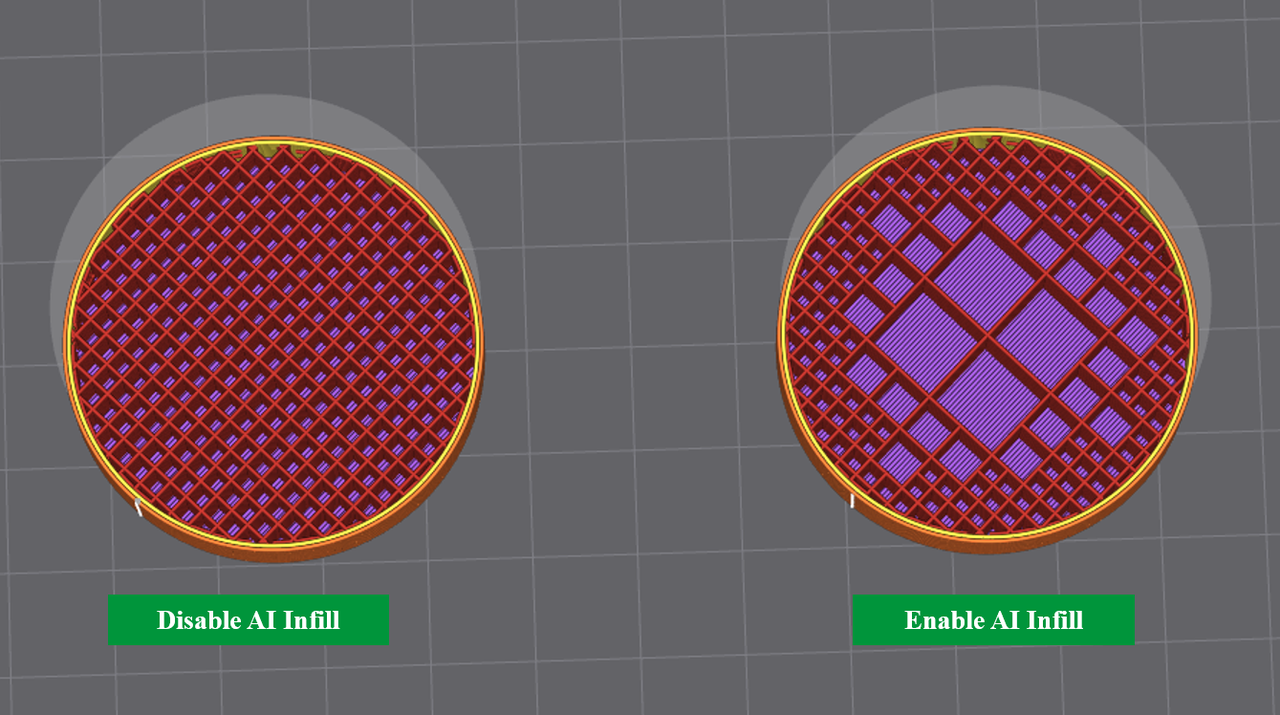

This feature densifies infill near walls while keeping infill sparse in the center of the model, reducing material usage and improving printing speed.

You can enable this setting under Strength - Infill - AI infill.

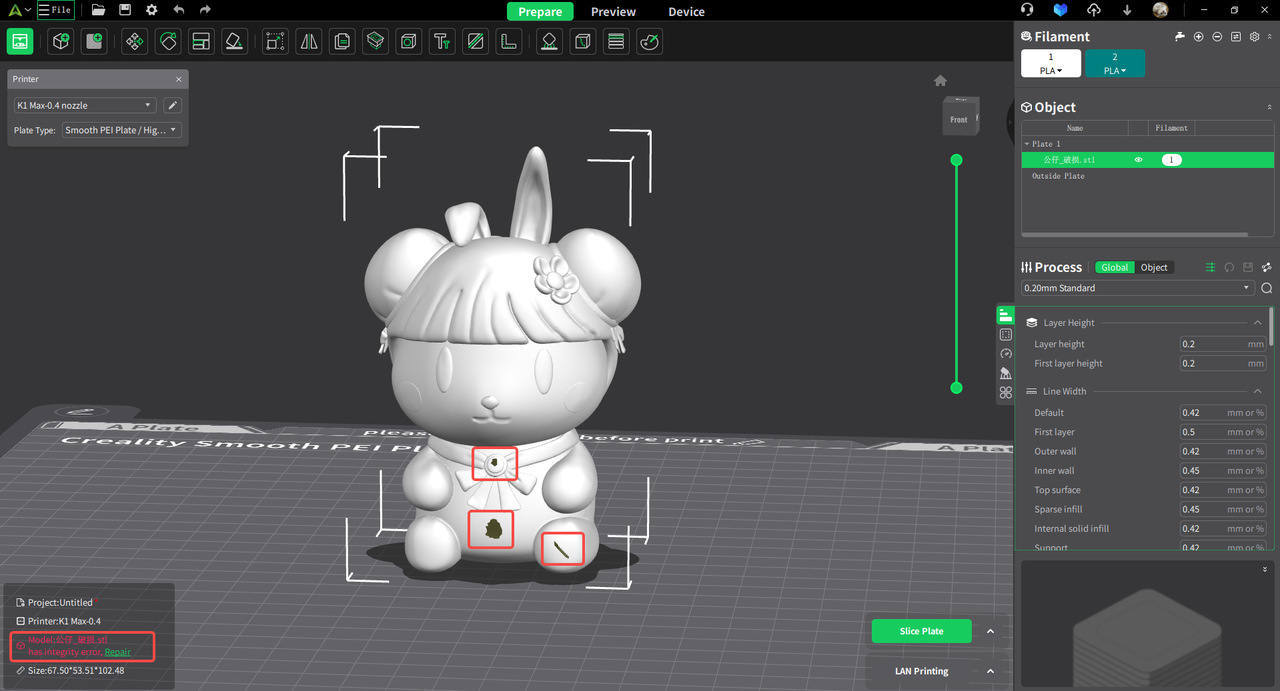

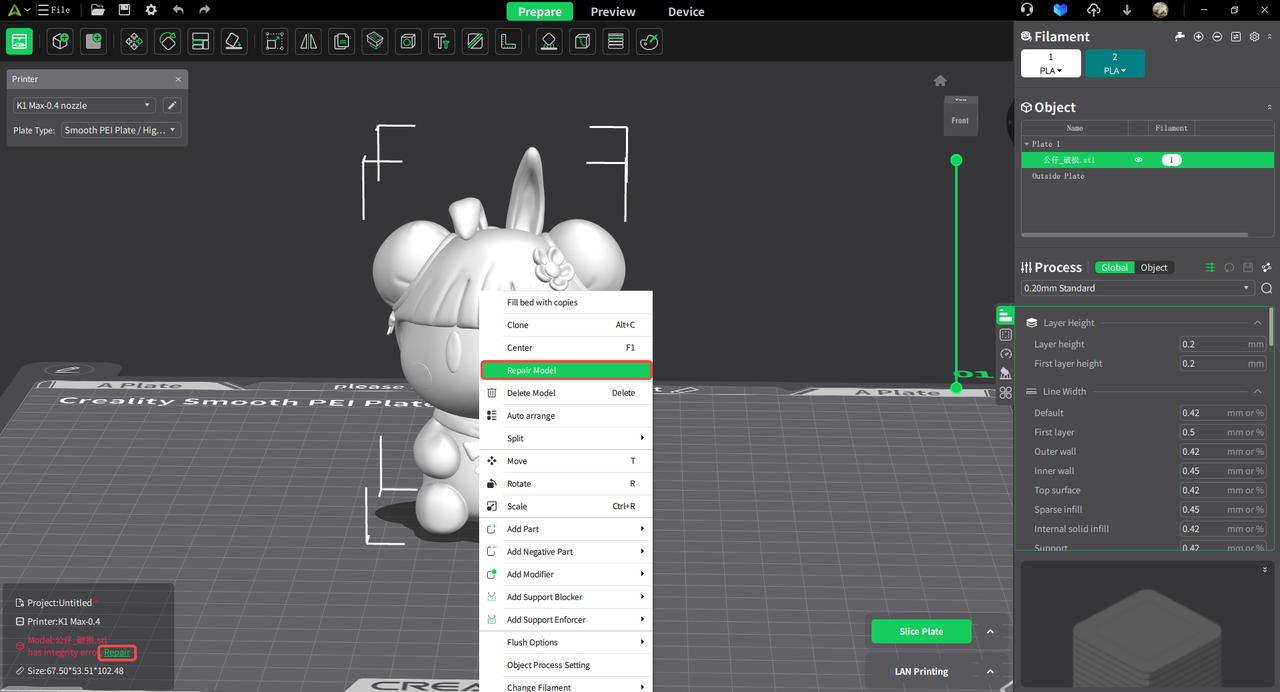

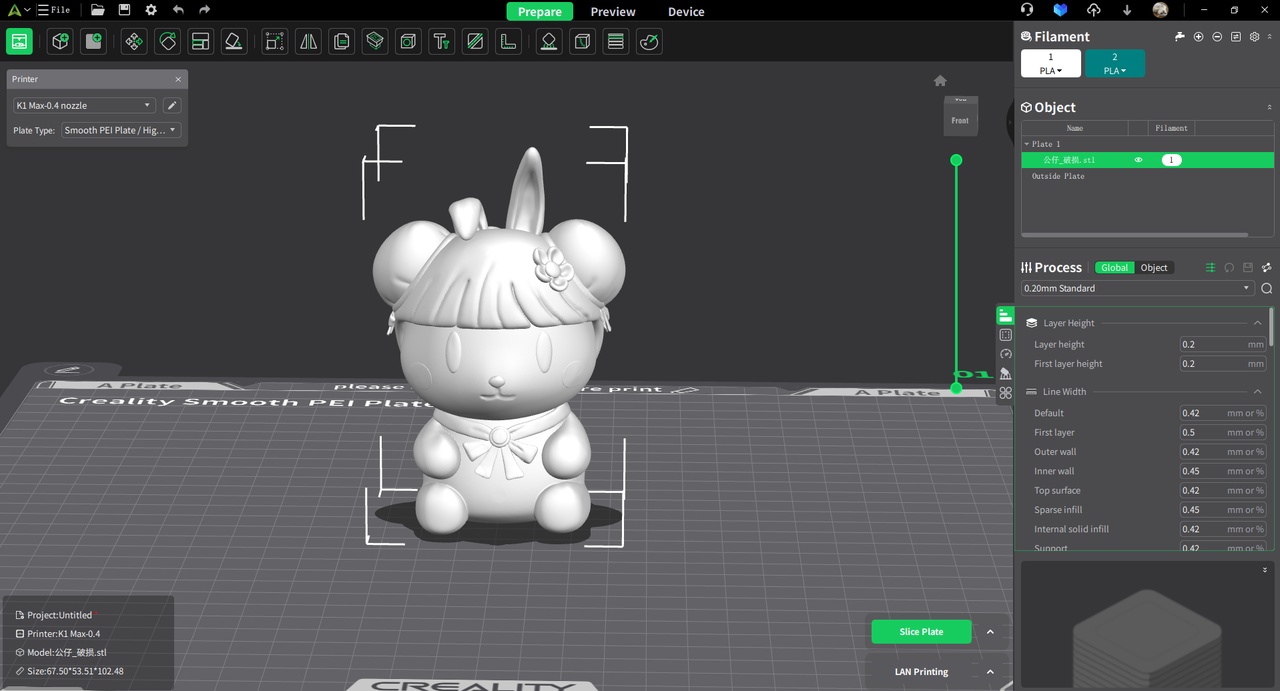

¶ Added Model Integrity Check and Repair Feature (Windows)

To prevent printing failures caused by damaged models, we have added a model integrity check and repair feature (repair function supported only on the Windows version).

- When you pick a damaged model, a prompt will appear in the bottom-left corner.

- You can click the "Repair Model" button to fix the model instantly, or right-click and select "Repair Model."

- Repair completed.

¶ Added Assemble Feature

The assemble feature allows you to group model objects, making it easier to batch adjust filament usage and process parameters within the group.

For example, you can modify filament usage for objects within the group in bulk.

¶ Added Part Feature

Parts are subsets of objects, and final slicing generates path data only for these parts. Other types of parts (such as negative part, modifier, etc.) are used solely for modifying these parts and do not generate path data.

¶ Added Negative Part Feature

When you need to create a recessed effect, where one shape subtracts from another shape within a model, you can achieve this with the negative part feature. Negative part subtraction occurs only during slicing and does not alter the geometry of the objects, thus it cannot export STL files containing subtraction results.

¶ Added Modifier Feature

The modifier feature allows for localized adjustments of part characteristics when different process parameters or filament settings need to be applied to specific areas of solid parts.

For example, setting a sparse infill density of 50% in areas where modified objects overlap with the modifier.

¶ Added Support Enforcer and Blocker Features

You can easily select parts where supports need to be added and parts where supports should be blocked using this method.

- Support Enforcer

- Support Blocker

¶ Added 3MF Project File Upload to Creality Cloud Feature

Upload 3MF project files to Creality Cloud for convenient sharing and storing of your work.

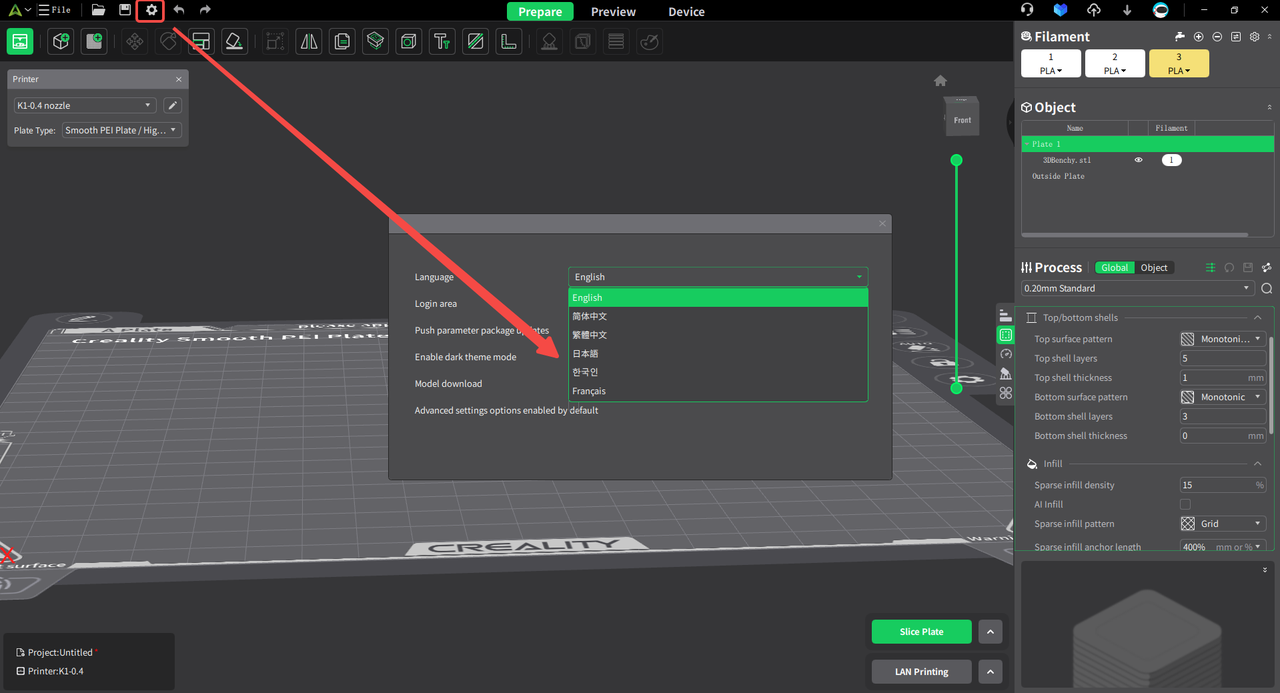

¶ Added Language Support (Japanese, Korean, French)

You can select additional languages in the preferences settings.

¶ Added Enhanced Error Message Prompts

Improved pre-print checks to identify anomalies and enhance print success rate:

- Model collision detection

- Model overhang detection

- G-code path conflict detection

- G-code exceeding heated bed boundary detection

- Model empty layer detection

¶ Improved Performance

¶ Added speed improvement after modifying parameters and re-slicing

After slicing the model in version 5.1, if you modify the relevant parameters and slice again, the speed improves compared to previous versions. For example, if you move the model and slice again, the speed increases by approximately 33% compared to the previous version.

¶ Others

- Added sphere tool (Seam Painting, Color, Support Painting)

- Upgraded user feedback system

- Expanded sliding hot zone range for 2D cross-section progress bars

- Added "Hot Plate Temperature" field to various calibration parameter pop-ups

- Arrow keys can now control layer and step movements on the preview page

- Changed nozzle style on preview interface

- Automatically selects nozzle when dragging step bar on preview page

- Added coordinate axis and speed to step bar on preview page

- UI optimization for engraving window

- Added "Advanced settings options enabled by default" checkbox for printer, filament, and process parameter.

- Added one-click select feature on filament page

- Optimized other interactive operations

¶ Bug fix

- Fixed issue of supports penetrating through models.

- Fixed issues where bridging slicers did not generate bridges

- Fixed issues where user configurations turned into system configurations and couldn't be deleted

- Fixed issue of partial data loss in temporary files.

- Fixed overlapping model issues in auto-layout

- Fixed the issue of skipping the prompt for pass1 results when adjusting pass2 flow settings directly.

- Fixed issue where air filtration was ineffective.

- Fixed problem where installation agreement was blank.

- Fixed issue where modifying printer configurations twice under the same name scenario resulted in loss of all filament.

- Fixed problem where rendering caused damage to the bottom of some models.

- Fixed issue where parameter modifications in special scenarios did not trigger re-slicing.

- Fixed issue where software only displayed the exceeding model when multiple models were loaded simultaneously and exceeded the printer platform size.

- Fixed problem where some printer models did not display LED switch and side fan.

- Fixed issue where print preview images were not displayed.

- Fixed the issue where printer parameters had a high travel distance threshold, causing nozzle collisions when the printer crossed small gaps in models.

- Fixed issue where engraving could only be done on some part of the surface when the model was not a single entity.

- Fixed problem where saving after changing process parameters caused all line width parameters to disappear.

- Addressed some translation issues.

- Fixed some UI compatibility issues.

- Fixed some software crash issues.

- Fixed issues where renaming machines in LAN search couldn't be saved.

- Fixed issues with quick search commands not working in search box.

- Fixed other known issues.