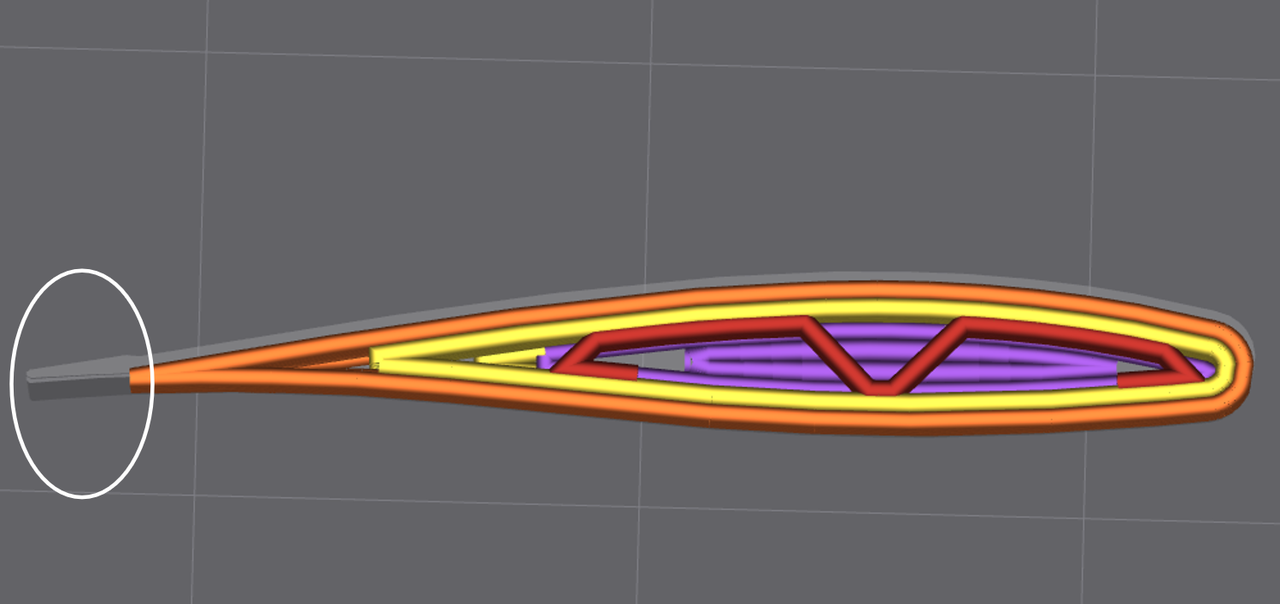

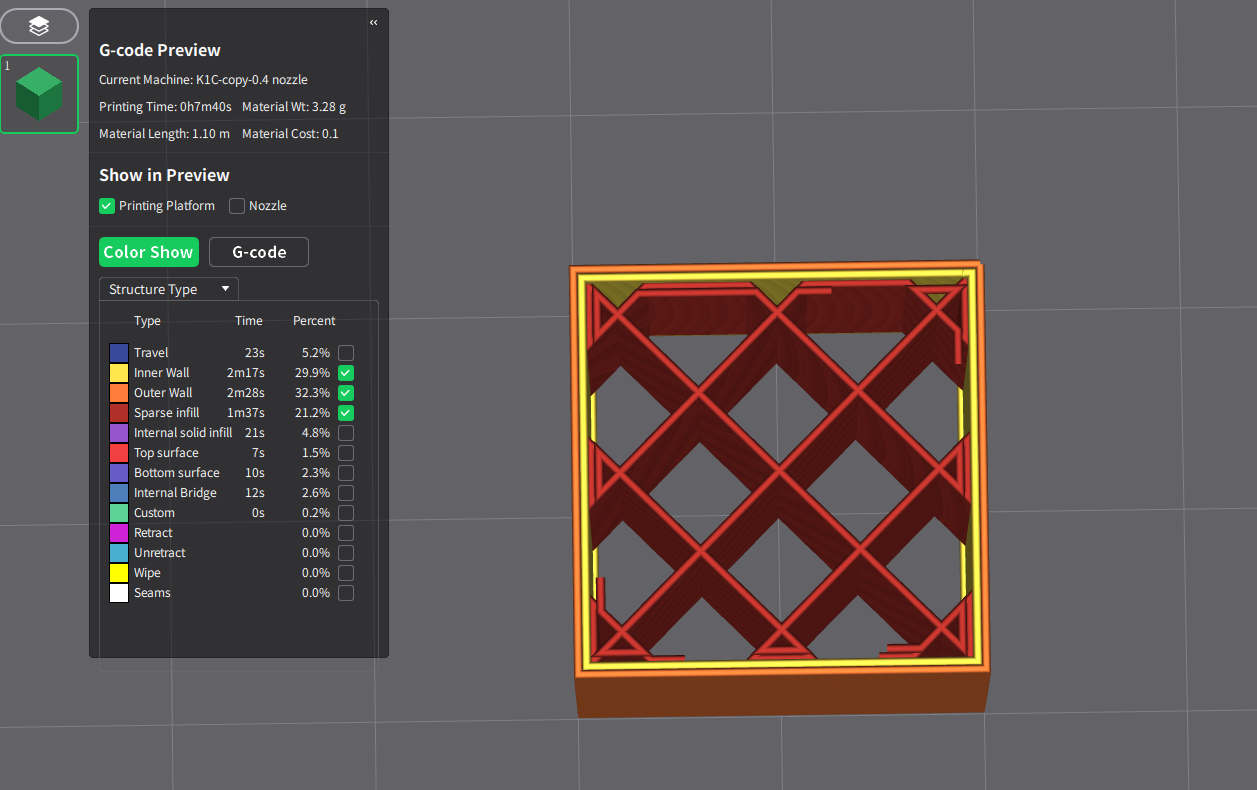

A wall consists of an inner wall and an outer wall, forming the boundary profile of a three-dimensional model section. It is mainly used to reproduce the surface details of the model and provide a certain degree of surface strength.

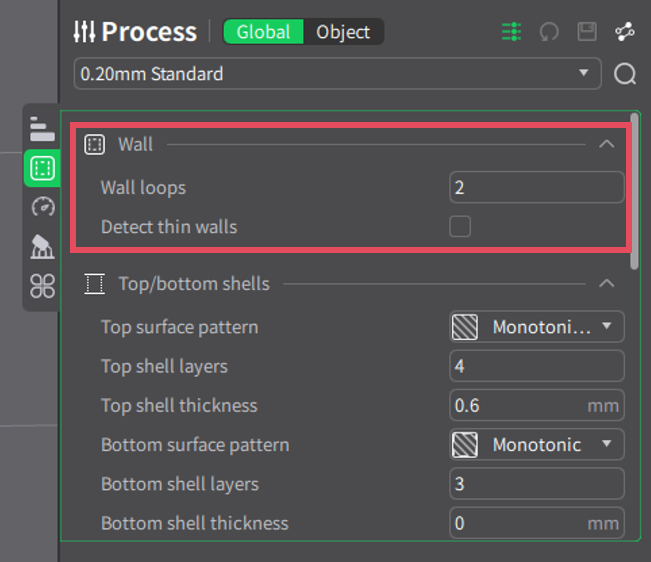

¶ Wall loops

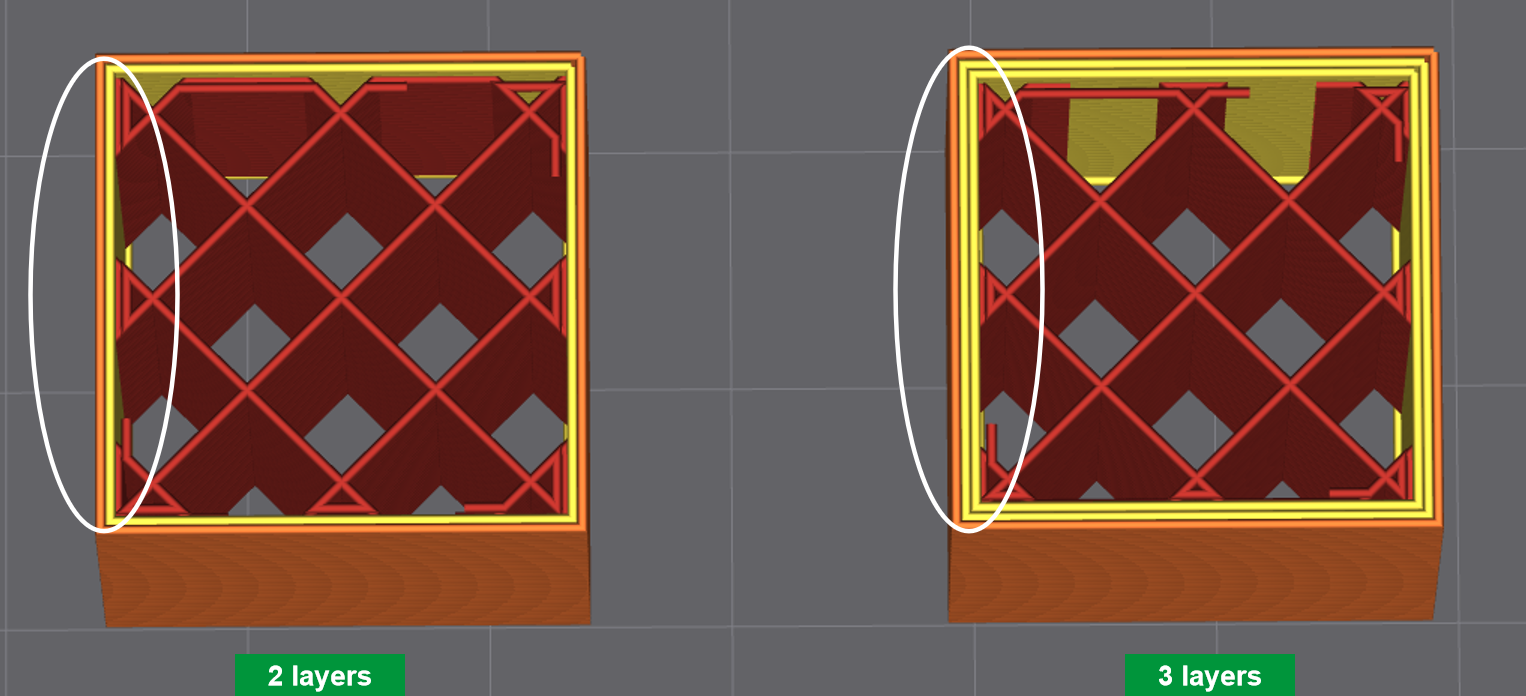

This refers to the total number of layers of the inner and outer walls combined. The wall encloses a filling part with lower density and strength, which occupies a large portion of the entire three-dimensional model's volume. Therefore, the more wall layers there are, the thicker the wall, the higher the surface strength, and the smaller the proportion of the filling pattern. This results in a higher overall structural strength of the model. However, having too many wall layers is not always better, as it can cause the printed model to become more solid, thereby increasing the printing time. Typically, setting the number of layers to 2-3 is sufficient.

¶ Detect Thin Walls

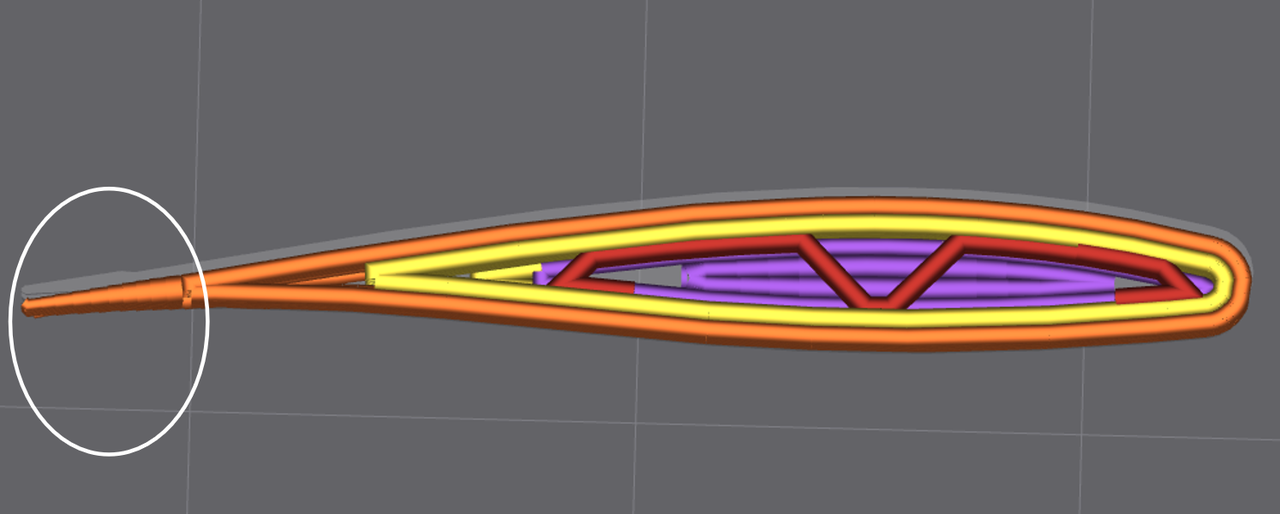

The generated wall paths are usually closed. When printing certain smaller features of a model, the width of the wall paths may prevent the creation of continuous and closed wall paths. This is mainly because the center distance of the wall paths generated in these smaller feature areas is too small to accommodate the full line width.

If the wall generator is set to classic mode, this can result in gaps where wall paths cannot be generated, leading to missing details. When the center distance of the wall is less than the line width, it can cause wall overlap, which may lead to excess filament sticking to the nozzle and adhering to other parts during printing, thereby degrading the surface quality. To avoid this issue, wall paths cannot be generated in classic mode under these conditions.