¶ TC2855:Cutter calibration failed. Please try again after resolving it

¶ Applicable model: Creality Hi/K2 Plus/K2 Pro/K2

¶ Why does this prompt appear?

During the input shaping process, the cutter position calibration failed. This is usually due to the following reasons:

The cutter and cutter push rod are not correctly installed, or there are obstacles in the extruder's operating path.

The cutter position exceeds the range value set in the firmware, causing calibration failure.

¶ How to solve

Check if the cutter and cutter push rod are correctly installed, and ensure there are no obstacles interfering with the cutter's movement, then re-run Input Shaping.

¶ General troubleshooting steps

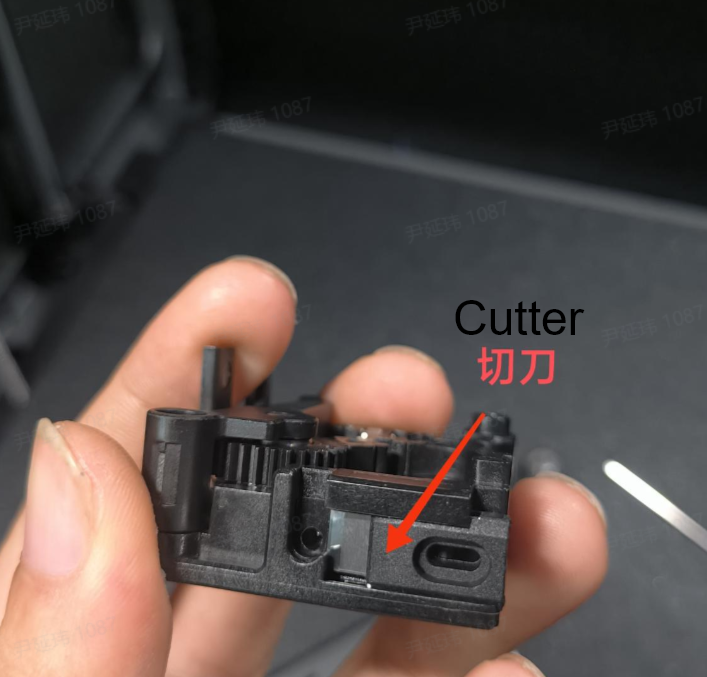

Confirm if the cutter is installed correctly and if the cutter push rod is installed properly.

Check if there are any physical obstacles in the extruder's X-axis movement.

Re-run the cutter calibration process and observe if it can be completed normally.