¶ Creality Falcon2 Pro

¶ INSTRUCTIONS

¶ Thank You Notes

¶ 01 SECURITY STATEMENT

When a laser engraver engraves or cuts materials, it casts high-density laser beam that heats the surface to vaporize materials without burning them. But most materials are inherently flammable and can be ignited, which may burn the device and the surroundings.

Warning:

1. Do not place the device near flammable and explosive materials, volatile solvents or heat sources. Please place the device in a ventilated, cool and dust-free environment;

2. Please use the adapter and power cord provided with the device;

3. Regularly clean the body and laser module with an anti-static brush or a dry cloth when the device is powered off;

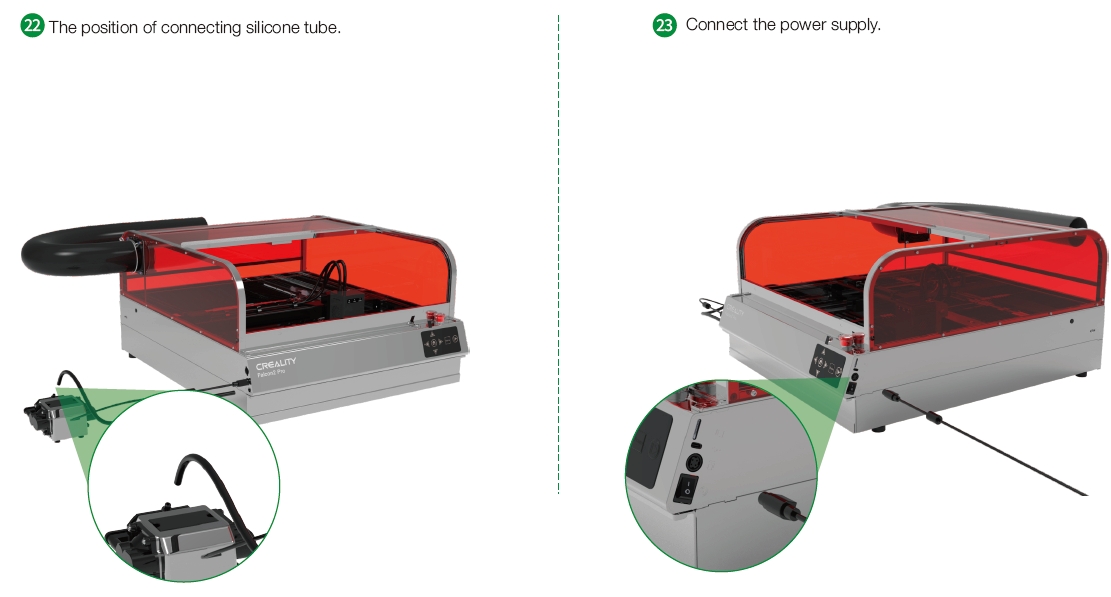

4. Please connect the silicone tube on the laser module no matter using an air assist or not. Otherwise, there will be a risk of lens contamination;

5. The working temperature of the power adapter is 5°C-35°C. Avoid using this product in a humid environment, and do not use it in thunderstorm weather;

6. If the device isn’t used for a long time, please turn off the device and disconnect the power cord;

7. When the device is connected to the power supply, please do not touch the electronic areas with your hands or other tools. It is forbidden to plug and unplug the laser module cable when the device is powered on;

8. When the device is running, please do not touch any part of the moving system and laser module;

9. When working, do not look directly at the laser and wear goggles to protect your eyes;

10. Smoke or smell may be produced during laser engraving and cutting. It is recommended to operate in a well-ventilated environment;

11. Children please operate under adult supervision;

12. Have a fire extinguisher ready just in case. Regularly maintain and inspect fire extinguishers;

13. It is forbidden to leave it unattended while the device is working;

14. Users should abide by the laws and regulations of the corresponding country and region where the equipment is located (where it is used), practice professional ethics and pay attention to safety obligations. It is strictly forbidden to use our products or equipment for any illegal purposes. If there is any violation, we will not be responsible for the relevant legal responsibilities;

15. Please clean the tray promptly and do not accumulate debris.

¶ Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. The laser safety classification of this product follows IEC 60825-1:2014. The laser safety level of laser radiation emitted through laser aperture exceeds level 1.

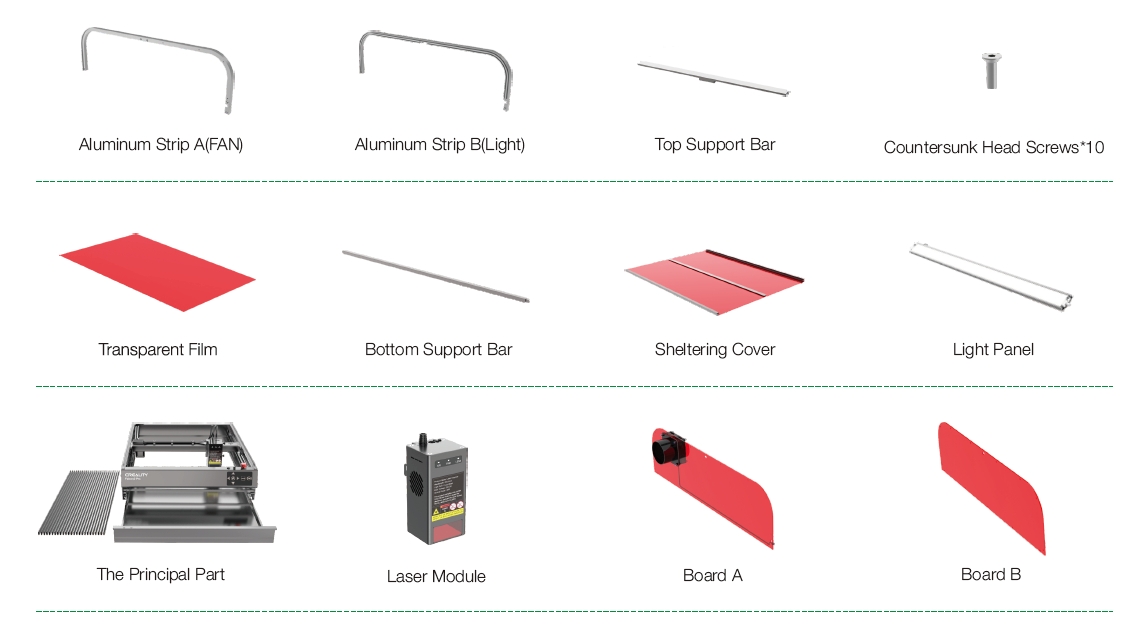

¶ 02 PACKING LIST

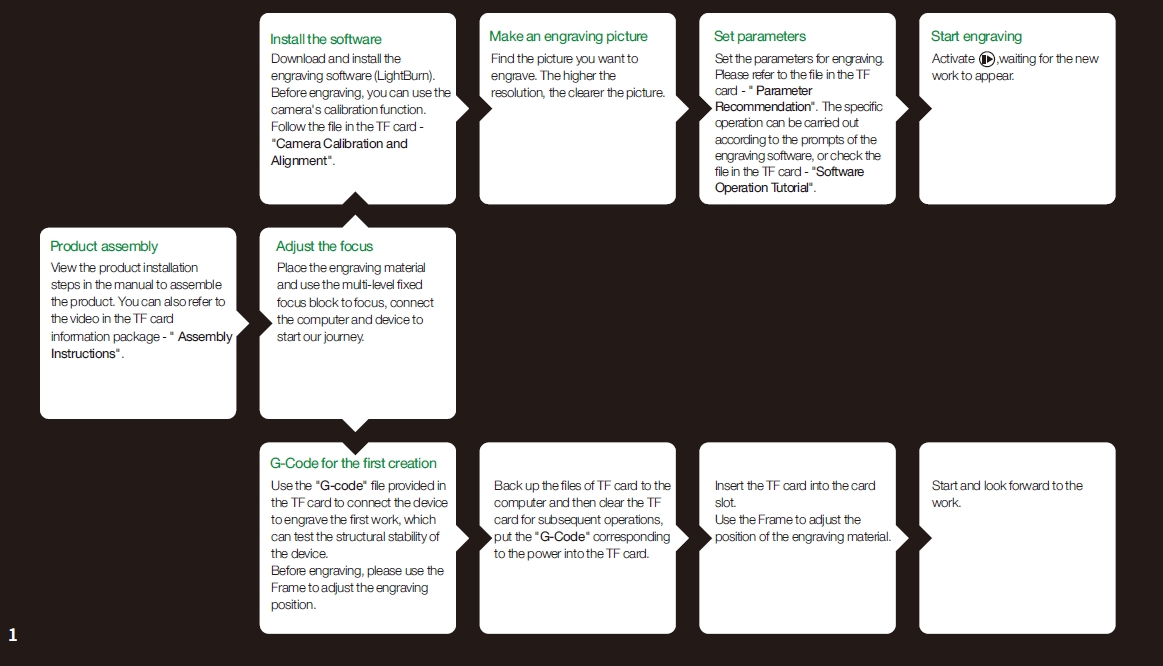

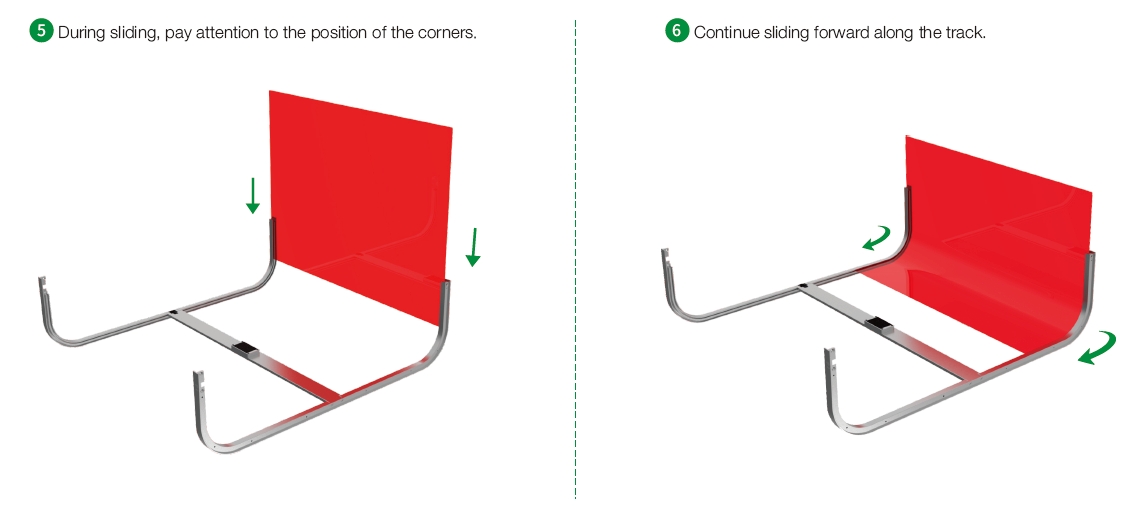

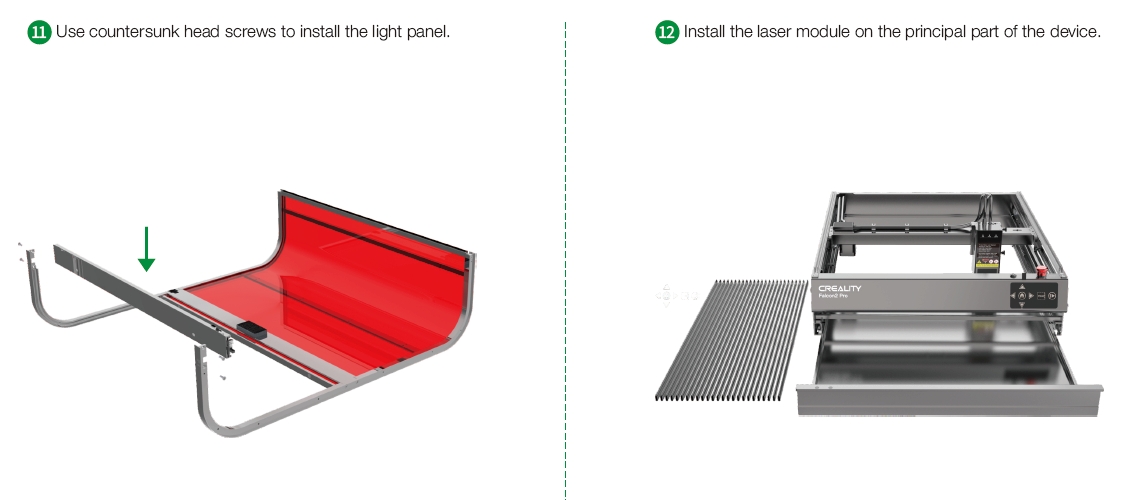

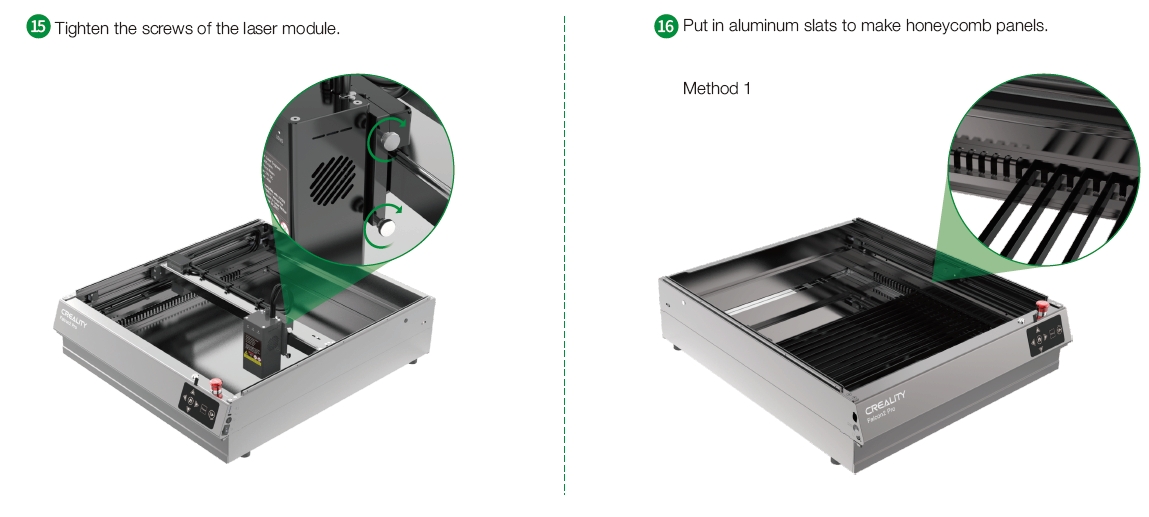

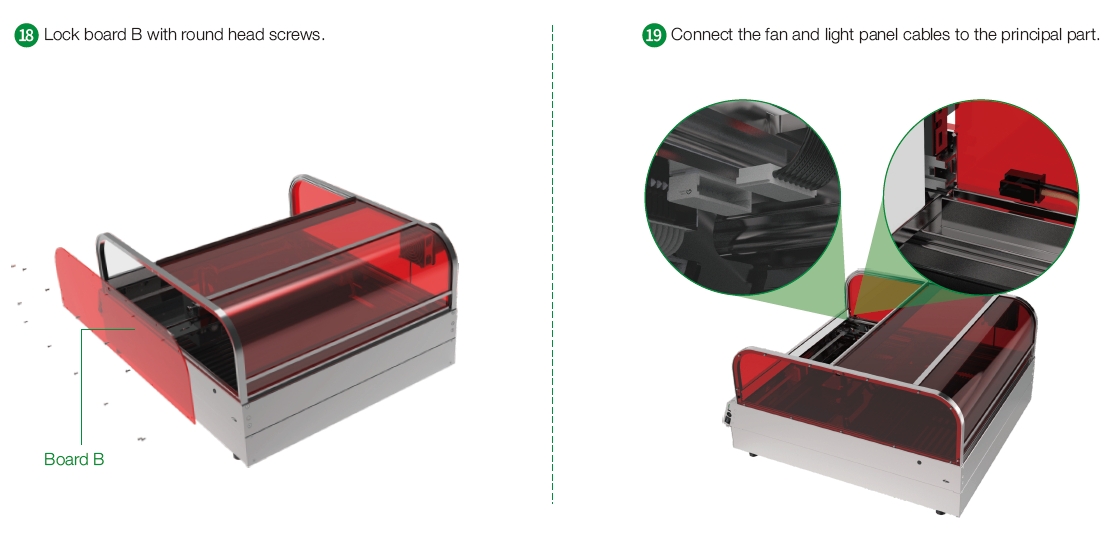

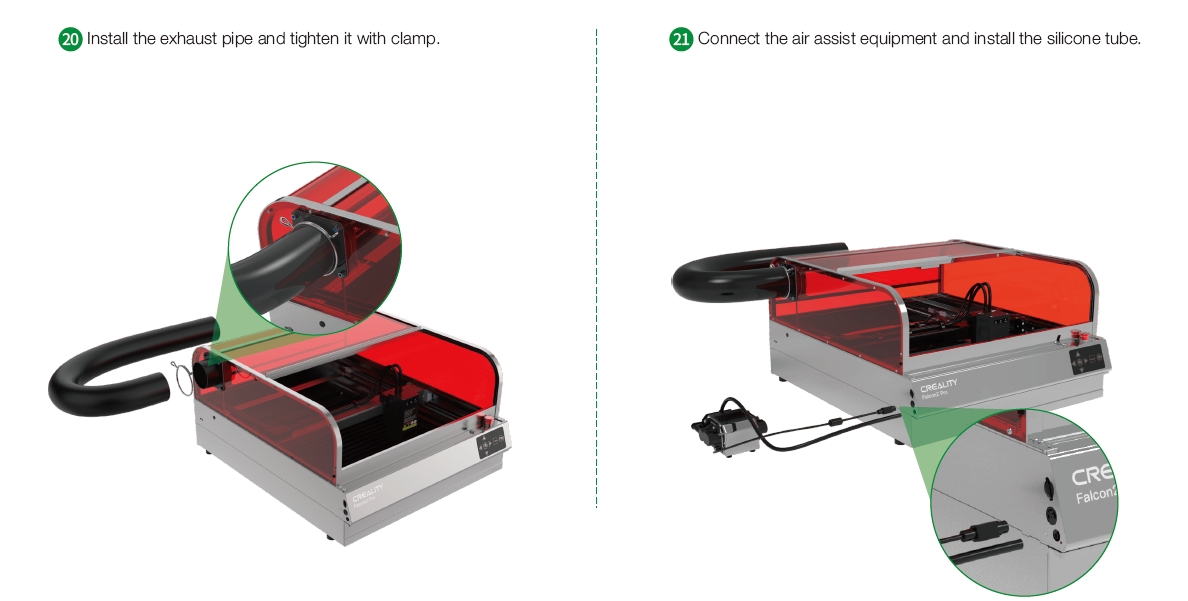

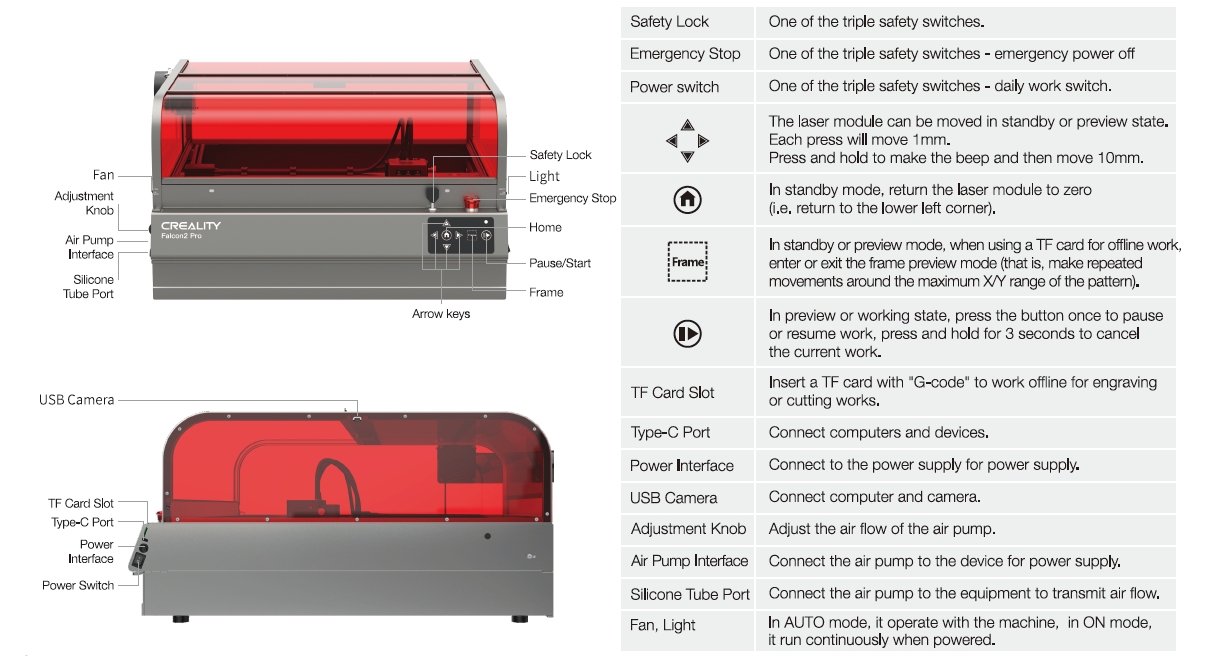

¶ 03 ASSEMBLE

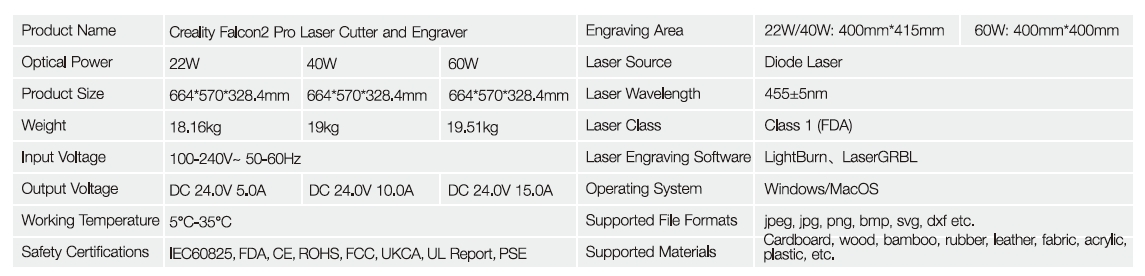

¶ 04 PRODUCT STRUCTURE

¶ Warning Light

1.Didn’t Light Up: The device is in a power-off state, or some abnormality occurs.

2.Solid white: The device is in the initialization mode, and it will automatically enter the standby mode after the initialization is completed.

3.Flashing Red Light: The red light flashes twice, indicating that the sealing state is broken and the preview mode fails to be entered; When the red light keeps flashing, the device is in abnormal mode and the buzzer makes a rapid sound. It will automatically enter standby mode after the abnormality is cleared. For example, in the working state, the equipment rolls over, the confined space is destroyed, the laser module is abnormal, etc.

4.Green Gradient Light: The device is in standby mode, and you can press Frame button to enter preview mode.

5.Solid blue: The device is in preview mode or engraving mode, and the laser module is emitting a beam. Special attention should be paid to safety.

6.Flashing Yellow light: Couldn’t read G-Code file in the TF card, and the buzzer will sound twice.

7.Flashing Purple Light: The device is in the firmware upgrade mode, and the buzzer makes a rapid sound at the same time. It will automatically enter the standby mode after the upgrade is completed.

¶ 05 SPECIFICATIONS

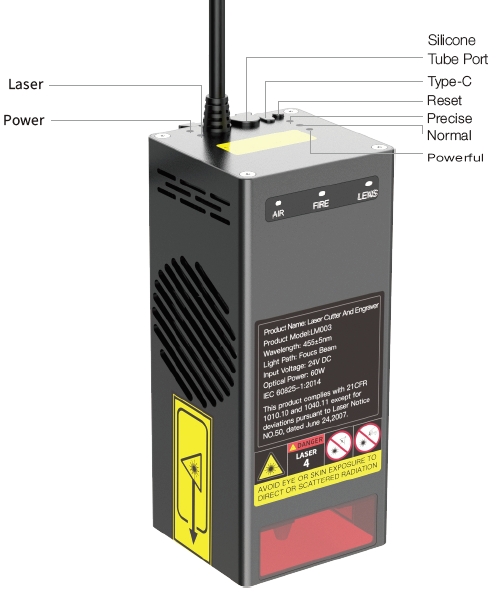

¶ 06 LASER MODULE

Power: Indicates powered on.

Laser: Shows that the laser emits a normal beam.

Silicone Tube Port: Connect air pump to pass air flow.

Type-C: Connect TF card to upgrade firmware, equipped with TF card reader and A to C adapter.

Reset: Use it to clear the alarm information after alarming; another situation is for the 60W or 40W power laser module, doing a long press to switch three modes - 60W,40W,22W.

Precise: If only this light is on, it means that the current mode is precise, the maximum light power is 22W, the engraving effect is more delicate, and the cutting gap is smaller.

Normal: The two lights are on, which means it is in Normal. The maximum optical power is 40W, which can cut thicker materials and the cutting speed is faster.

Powerful: Three lights are on, which means it is in Powerful. The maximum optical power is 60W, which means it can cut thicker materials and the cutting speed is faster.

¶ Notes:

1. The alarm function of the laser module is turned on by default and can be turned off manually. When the alarm function is turned off, the indicator light will still indicate the current situation normally. Please refer to the "Laser Module Alarm Functions" in the TF card.

2. When alarming, press Reset on the laser module to stop the alarm, but you need to pay attention to the current working status of the laser module. For more information about this function, please refer to the "GRBL Configuration Parameters" in the TF card.

¶ 07 OPERATION

¶ 08 FAQ

1. Why does the carved work fail to achieve the expected effect compared with the original image? (Like the engraving effect is relatively light and the lines are crooked)

A. There are recommended parameters for engraving and cutting on the official website or TF card.

B. At the same time, please check whether the device screws are tightened and whether the belt is appropriately tight to eliminate hardware problems.

Note:

1) When the laser module is under the action of gravity, it can slide slowly on the X-axis profile perpendicular to the desktop;

2) When there is no idle slip on any pulley in the laser head assembly;

3) The belt tightness is appropriate. Otherwise, please adjust the belt tightness manually.

2. Is it possible to engrave on reflective/transparent materials such as ceramics/glass?

Yes, but before engraving, you need to apply anti-reflective material on the surface of the material to ensure the engraving effect and prevent reflected light from damaging the laser module.

3. What should I do if the software does not respond or cannot connect when engraving online?

A. Make sure the data cable has communication function and the end of the data cable connected to the computer is a USB-A interface. If the computer does not have a USB-A interface, there is an A to C adapter to convert it, or use a hub with a USB-A port.

B. Make sure you have successfully imported the Creality Falcon2.lbdev file according to the LightBurn software tutorial in the TF card.

C. Make sure that the COM port corresponding to the engraving device is not occupied.

D. If it still can't be connect, please record a short video of the connection operation, and feed back the relevant system information and software version number to the after-sales team to troubleshoot the problem more quickly.

¶ 09 TROUBLESHOOTING

¶ ERROR:01

The angle data is abnormal and it has stopped working.

Please check whether the workbench is shaking, the screws are locked tightly and the frame of the machine is firm.

¶ ERROR:02

There is no G-Code file in the root directory of the TF card.

Please check whether the suffix of the file in the TF card is ".gcode/.gc/.nc ", and ensure the file is saved in the root directory.

¶ ERROR:04

No airflow is detected and the machine has stopped working.

Please check whether the air pump is connected to the machine, check whether the knob switch on the left side of the machine is adjusted to the maximum, and check whether the silicone air tube above the laser module is inserted and there is no kinks in the tube.

In the Falcon Machine Settings you can change: $153 to 0 to cancel the alarm function (it is recommended to set it according to the actual situation).

¶ ERROR:05

A flame has been detected and the machine has stopped working.

Please press the Reset button if the material is not burning, and the FIRE light will turn orange, indicating that there is a risk of fire. You can press the start button to continue working and after restarting the machine, the FIRE light will be green. Refer to “Laser Module Alarm Functions.pdf” for more information.

In the Falcon Machine Settings you can change: $154 to 0 to cancel the alarm function (it is recommended to set it according to the actual situation).

¶ ERROR:06

Lens contamination is detected and the machine has stopped working.

Please press the Reset button and the LENS light will turn orange. You can press the start button to continue working and the lens needs to be cleaned when powered off. The LENS will still keep red light flashing when power on. You need to press the reset button again to confirm that the lens is clean and the LENS light will be green. Refer to “Laser Module Alarm Functions.pdf” for more information.

In the Falcon Machine Settings you can change: $155 to 0 to cancel the alarm function (it is recommended to set it according to the actual situation).

¶ ERROR:07

The temperature of the laser module is high and it has stopped working.

You can press the Reset button and then press the Start button to continue the current work.

It is recommended to clean the laser module when powered off and wait for the laser module to cool down to a suitable temperature before working.

In the Falcon Machine Settings you can change: $158 to 0 to cancel the alarm function (it is recommended to enable the alarm function).

¶ ERROR:08

The air pressure sensor of the laser module is not performing correctly.

It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support.

¶ ERROR:09

The flame sensor of the laser module is not performing correctly.

It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support.

¶ ERROR:10

The lens sensor of the laser module is not performing correctly.

It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support.

¶ ERROR:11

The laser module does not have an LD temperature sensor.

It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support.

¶ ERROR:12

Laser module LD sensor short circuit.

It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support.

¶ ERROR:13

The CPU temperature of the laser module is too high.

It is recommended to clean the laser module after power off and wait for the laser module to cool to the appropriate temperature before working.

¶ ERROR:14

The temperature of host CPU is too high.

Please check whether the ambient temperature is too high. It is recommended to wait for the host to cool down to a suitable temperature before working.

¶ ERROR:24

The machine is in an unsealed state.

Please close the protective cover and drawer, and then press the start button of the device to continue working.

¶ ERROR:25

The air pump is not performing normally.

Please contact the after-sales service for relevant technical support.