Dear Users,

Thank you for choosing Creality. For your convenience, please read this quick guide carefully before use, and follow the instructions in the quick guide.

The Creality team is always here to provide you with quality service. If you encounter problems during use, please contact us via the phone number or email address provided at the end of the Quick Guide. In addition, video instructions are available on the TF card for your reference.

You can also visit Creality’s official website (www.cxsw3d.com) to learn more about software and hardware, contact information, operation, maintenance, etc.

¶ Firmware Upgrade

Download the latest firmware from https://www.crealitycloud.cn/en/software-firmware/other?type=16,back up and delete the files on the TF card, and save the bin file to the root directory of the TF card.

¶ Motherboard Firmware

When the machine is powered off, insert the TF card into the card slot, and it will automatically update the firmware when it is powered on. The buzzer will keep beeping during the update process, and the update will be completed when the beep ends (please keep the power on until completed).

¶ Laser Module Firmware

When the machine is powered off, insert the TF card into the card reader, then insert it into the USB-C port on the top of the laser module through the USB-A to USB-C adapter, and the firmware will automatically update when it is powered on. During the update process, the indicator of the laser module will turn orange with a marquee effect, and the update will be completed when it stops the marquee effect (please keep the power on until completed).

¶ Security Statement

When a laser engraver engraves or cuts materials, it casts a high-density laser beam that heats the surface to vaporize materials without burning them. But most materials are inherently flammable and can be ignited, which may burn the machine and the surroundings.

Caution - Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. The laser safety classification of this product is based on IEC 60825-1:2014. The laser safety level of laser radiation emitted through laser aperture exceeds Class 1.

Please use it as instructed below:

1. Do not place this product near flammable and explosive materials, volatile solvents or heat sources. Please place this product in a ventilated, cool and dust-free environment.

2. Do not use power cords other than the one provided in the package during the installation.

3. Regularly clean the body and laser module with an anti-static brush and a dry cloth when the machine is powered off.

4. Please connect the silicone tube on the laser module whether using an air assist or not. This will reduce the risk of lens contamination.

5. The working temperature of the laser module is 5°C-35°C. Avoid using this product in a humid environment, and do not use it during a thunderstorm.

6. If the product isn’t used for a long time, please turn off the product and disconnect the power cord.

7. When the product is connected to the power supply, please do not touch the electronic areas with your hands or other tools. DO NOT plug and unplug the laser module cable when the machine is powered on.

8. When the product is running, please do not touch any part of the moving system or laser module.

9. Please place a flat object that the laser cannot penetrate under the processed material, such as aluminum alloy.

10. During the laser engraving, please wear goggles to avoid vision damage caused by looking directly at the laser spot.

11. Smoke or smells may be produced during laser engraving and cutting. It is recommended to operate in a well-ventilated environment.

12. Children under the age of 10 are strictly prohibited from using this product without adult supervision to avoid injury.

13. Prepare fire extinguishers as a backup. Regularly maintain and inspect the fire extinguishers.

14. It is forbidden to leave it unattended while the machine is working.

15. Users should abide by the laws and regulations of the corresponding country and region where the equipment is located (where it is used), practice professional ethics, and pay attention to safety obligations. It is strictly forbidden to use our products or equipment for any illegal purposes. If there is any violation, we will not be responsible for the relevant legal responsibilities.

¶ Parameters

| Product Name | Creality Falcon Pro Laser Cutter and Engraver |

| Optical Power | 10W |

| Product Size | 568*638*198mm |

| Weight | 5.6kg |

| Input Voltage | 100-240V~50-60Hz |

| Output Voltage | DC 24.0V3.0A |

| Working Temperature | 5℃-35℃ |

| Safety Certifications | IEC60825、FDA、CE、ROHS、FCC、UKCA、UL Report、PSE |

| Engraving Area | 400mm*415mm |

| Laser Source | Diode Laser |

| Laser Wavelength | 455±5nm |

| Laser Class | Class IV (FDA) |

| Laser Engraving Software | LightBurn、LaserGRBL |

| Operating System | Windows/MacOS |

| Supported File Formats | Jpeg, jpg, png, bmp, svg, dxf, etc. |

| Supported Materials | Cardboard, wood, bamboo, rubber, leather, fabric, acrylic, plastic, etc. |

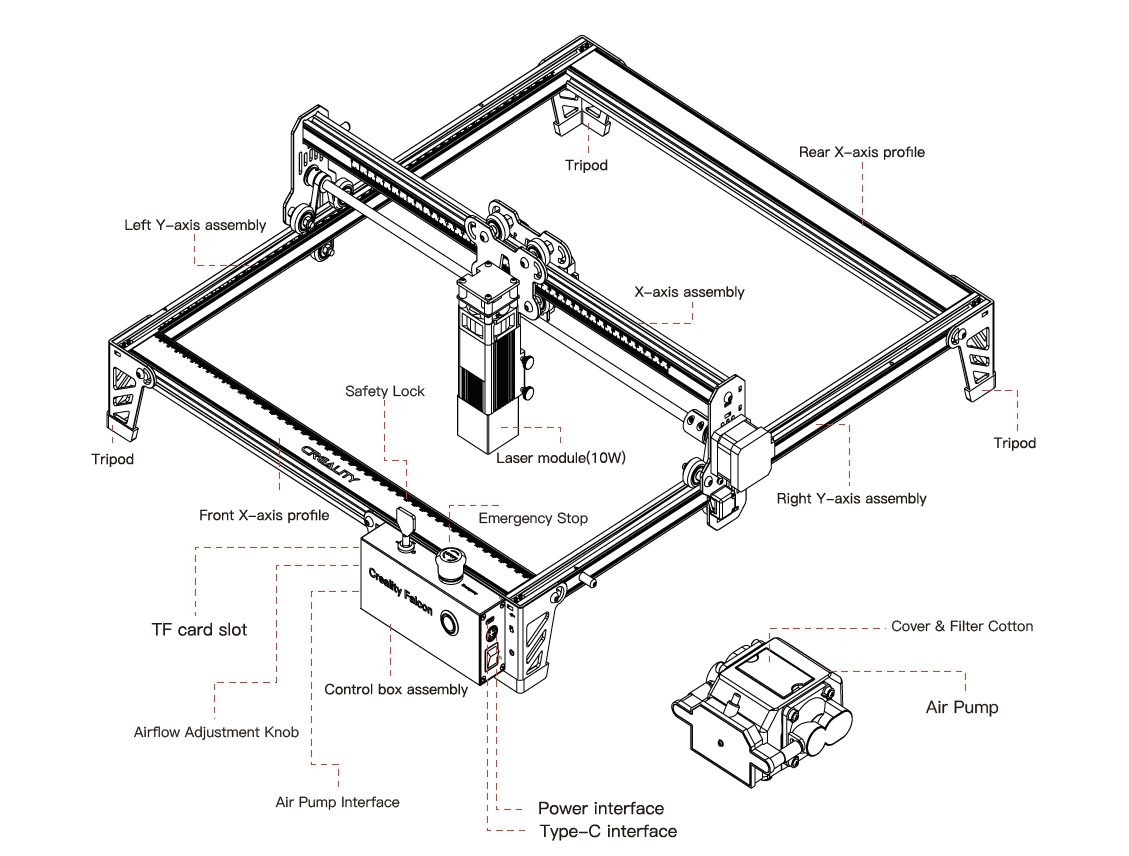

¶ Product Overview

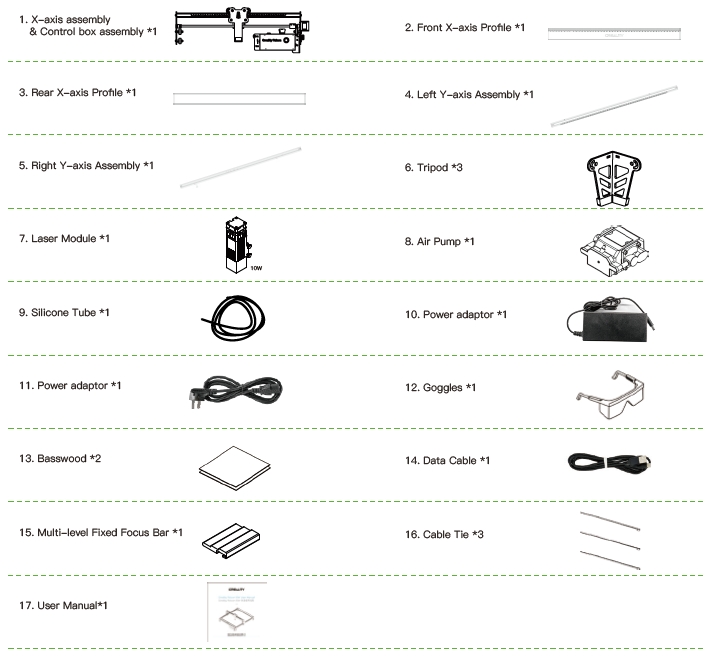

¶ Parts List

¶ Assembly directions

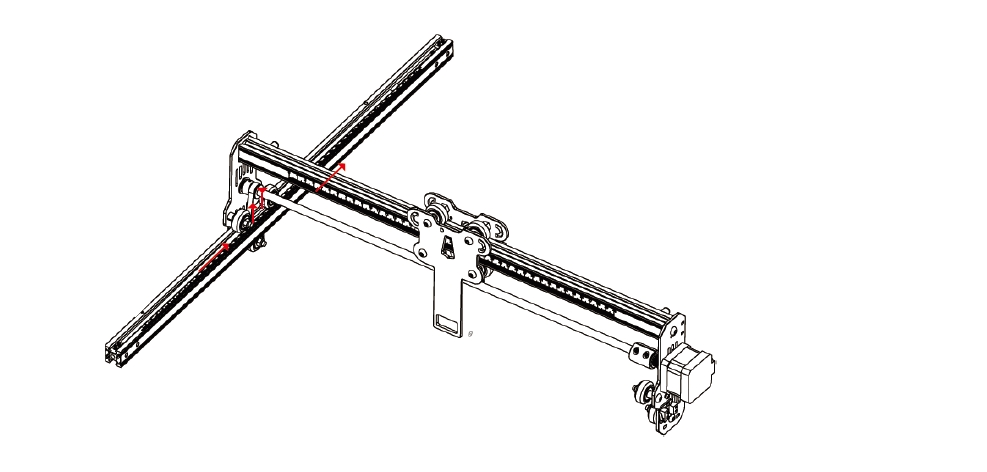

1. Assemble the left Y-axis assembly:Pass the left Y-axis assembly (with the belt up) through the X-axis assembly and put on the belt in the direction shown in the figure:

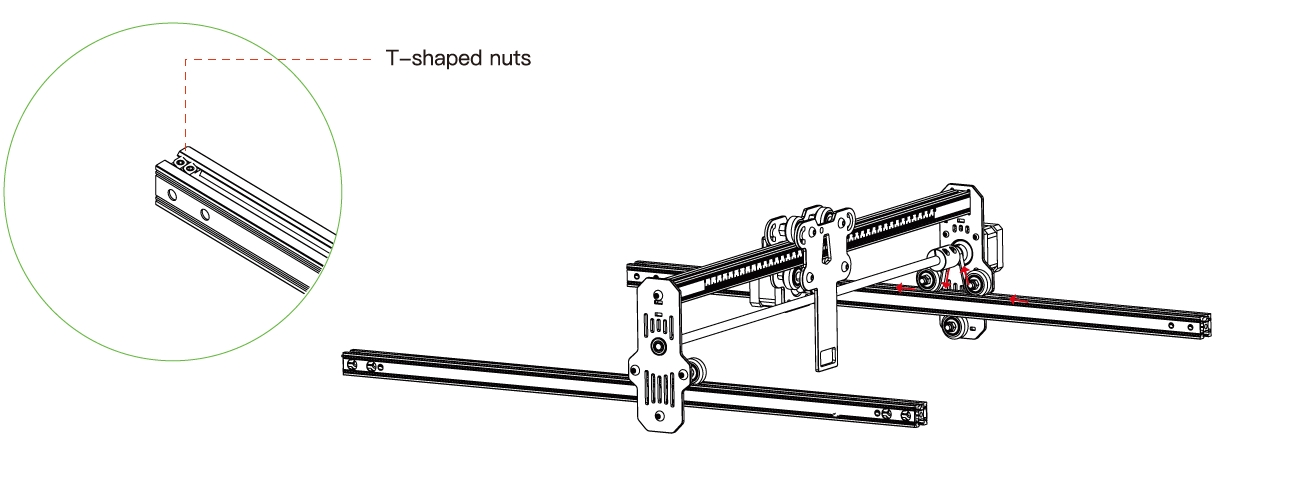

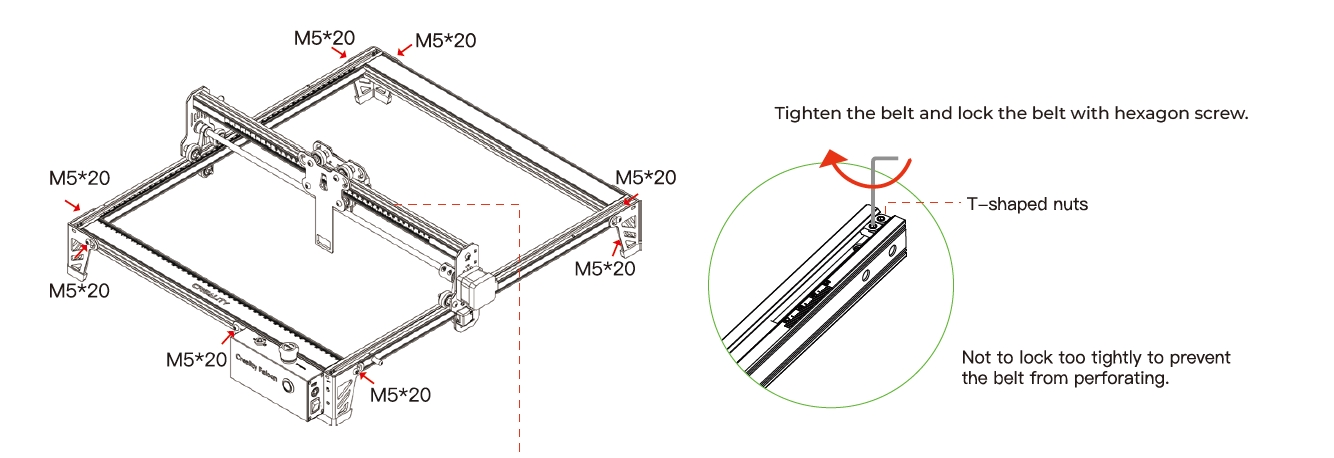

2. Assembl the right Y-axis assembly and it is the same as above.lnsert two T-shaped nuts into the left and right y-axis assembly.

3. Assemble rear X-axis profile and front X-axis profile: Lock with eight M5*20 screws.

4.Assemble three tripods and control box assembly: Lock with eight screws.

Assemble 10W laser module: lease place the multi-level fixed focus bar between the laser module and the processed material.Follow the tips and make the bottom of the laser module contact with the corresponding surface of the multi-level fixed focus bar.Finally lock it with two hand screws on the right.For example, if you engrave or cut a 2mm basswood or other material:

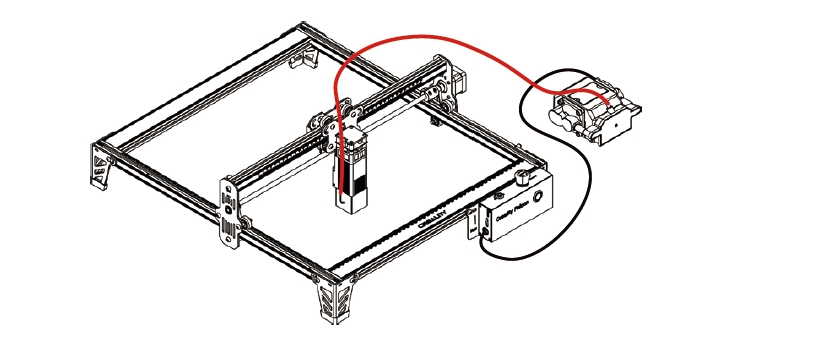

Connect the air pump and the control box. Use the silicone tube to connect the air pump and the laser module.

Finally use the cable straps to fix them.

For better engraving effect, try to elevate the laser module as far away from the workbench as posible on the premise that the focal lenath is corect.

The laser module must be installed and remaved only when the power is off.

¶ Software Installation & Use

The machine can be controlled with LaserGRBL or LightBurn after being connected to a PC via a USB-C cable, and can also work by reading codes (exported from Lightburn) on a TF card. For software tutorials, please refer to the information provided on the TF card.

¶ Control from PC

Connect the machine to a PC via a USB-C cable. If your computer does not have a USB-A port, please use the included adapter to convert it. While controlling from PC, you can also control it through the Start/Pause button on the control panel of the machine.

¶ Work with TF Card

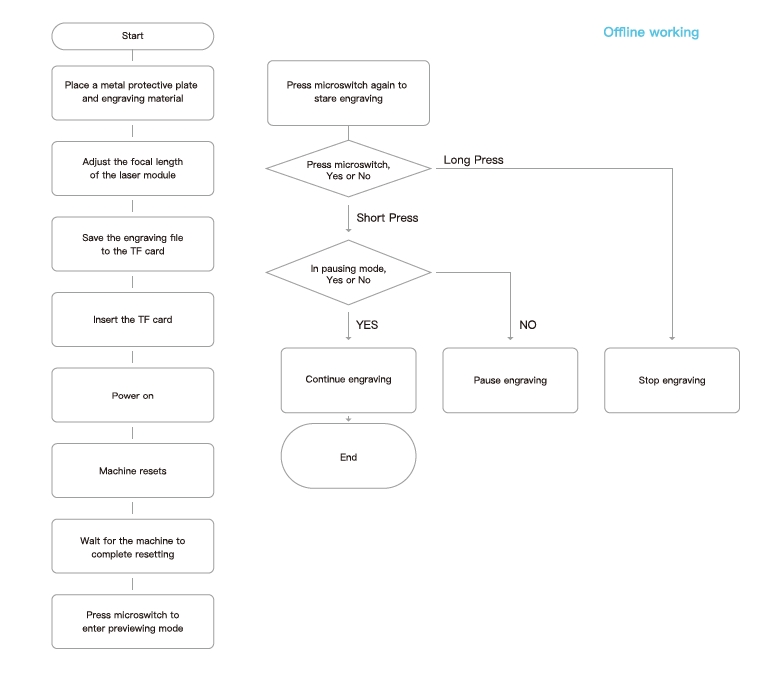

1. Generate the engraving file (gcode) through the LightBurn software, and save the file to the root directory of the TF card (the machine will access the file with the latest data in the root directory of the TF card by default, so it is advised to delete other irrelevant files in the first directory). Insert the TF card into the machine before powering it on, plug in the power adapter and power cord, and turn on the power button.

After the machine is powered on, it will sound two beeps and enter standby mode. The indicator light will pulse green slowly.

2. Press the Frame button, and the machine will exit the standby mode and enter the preview mode. The laser module will emit a weak beam and move along the X/Y axis to frame the target working area. The indicator will be in solid blue. You can adjust the material to a suitable position, or make fine adjustments through the arrow buttons on the control panel.

3. In the preview mode, press the Start/Pause button to enter the engraving mode, the laser module will emit a strong beam, and the machine will start engraving. The indicator will be in solid blue. If you need to pause the engraving, please press the Start/Pause button, and the indicator light will pulse green slowly. Press the Start/Pause button again to continue engraving.

If you need to cancel the engraving, please press and hold the Start/Pause button for 3 seconds, the machine will sound a beep, and the machine will reset. After the reset is completed, the machine will sound two beeps and enter the standby mode. The indicator will pulse green slowly.

4. After the engraving is completed, the machine will sound three beeps and then reset. After the reset is completed, the machine will sound a beep and enter the standby mode, and the indicator will pulse green slowly.

¶ Indicator Atatus

1.Light off: The machine is in a power-off state, or the power is abnormal.

2.Breathing light: The machine is in standby mode, you can press the microswitch to enter preview mode or engraving mode. (Present a light effect with a gradual change of light and shade.)

3.Light flashes: the machine is in upgrade mode or abnormal mode, and the buzzer beeps rapidly, and it will automatically enter standby mode after the upgrade is completed or the abnormality is cleared.

4,Licht always on: the machine is in preview mode or engraving mode. The laser head is working, please pay attention to safety.

¶ Exception Handling

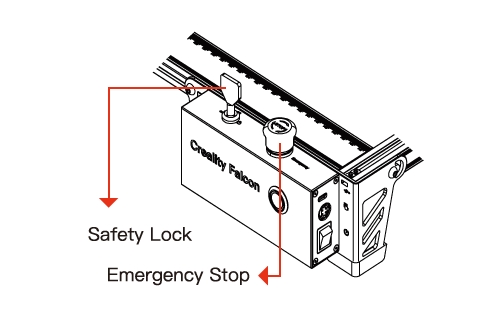

1. The machine cannot be turned on normally.

Solution: Please check the emergency stop and the safety lock.

2. lf the machine overturns or moves suddenly during working, it wil turn off the laser, Motor stops moving indicator light flashing, and buzzer emits alarm.

Solution: Please move the machine to its original position and press microswitch on the machine control box to continue previewing or engraving after clearing abnormality/The microswitch only works during offline working)

3. The machine cannot enter frame-previewing mode: ln standby mode, after pressing the button, the buzzer beeps twice, and the white indicator light flashes twice.

Solution: Check whether the TF card is inserted, and whether there is a gcode file in the root directory of the TF card.

※ Users should abide by the laws and regulations of the country and region where the equipment is located (place of use), abide by professional ethics, and pay attention to safety obligations. It is strictly forbidden to use our products or equipment for any illegal purpose.Our company is not responsible for the relevant legal responsibilities that the violator should bear.

※ Since each model is different, the actual product may be different from the picture. Please refer to the actual product. The final interpretation right belongs to Shenzhen Chuangxiang 3D Technology Co., Ltd.