¶ Video Tutorial

Troubleshooting for K2 Clogged Hotend

¶ Tools

Allen wrench

Needle

Heating tool

Cutting pliers

¶ Phenomenon Description

Extruder abnormality: filament expands and bends inside the extruder or accumulates within the extruder. The main causes for filament accumulation in the extruder are excessively high extruder temperature or filament unable to enter the hotend.

|

|

|

¶ Cause Analysis

¶ Improper Chamber Temperature (Slicing filament settings inconsistent with actual filament)

For example: When printing with PLA filament, check if the printing chamber temperature is within 37°C (excessive chamber temperature will cause the filament to soften prematurely in the extruder).

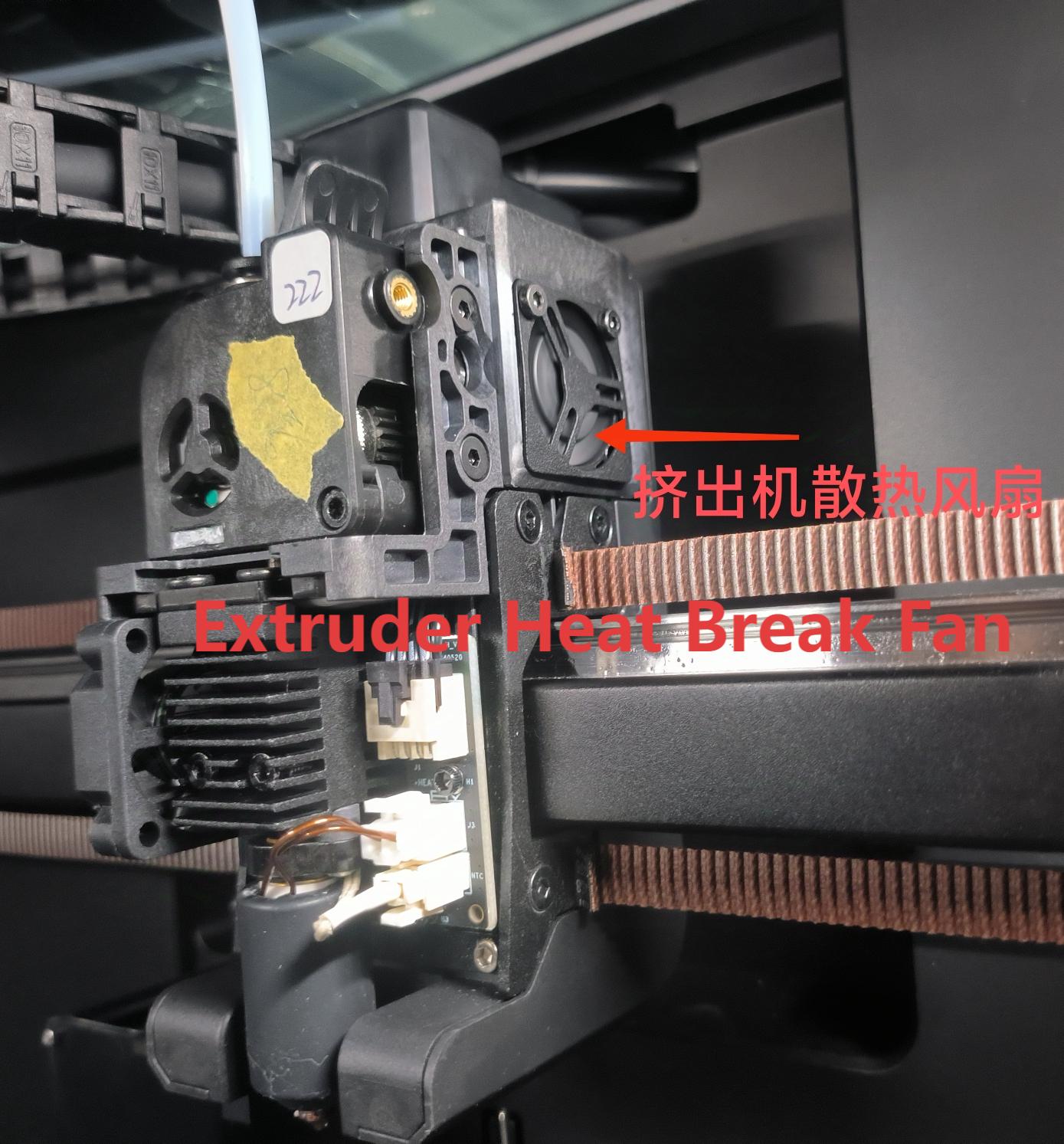

¶ Extruder Cooling Fan Abnormality

When the nozzle temperature rises to 100°C, check if the extruder cooling fan is spinning.

If the extruder cooling fan is not spinning, heat accumulation in the extruder motor will cause the filament to soften inside the extruder, resulting in a clog. Therefore, it's necessary to troubleshoot or replace the extruder cooling fan.

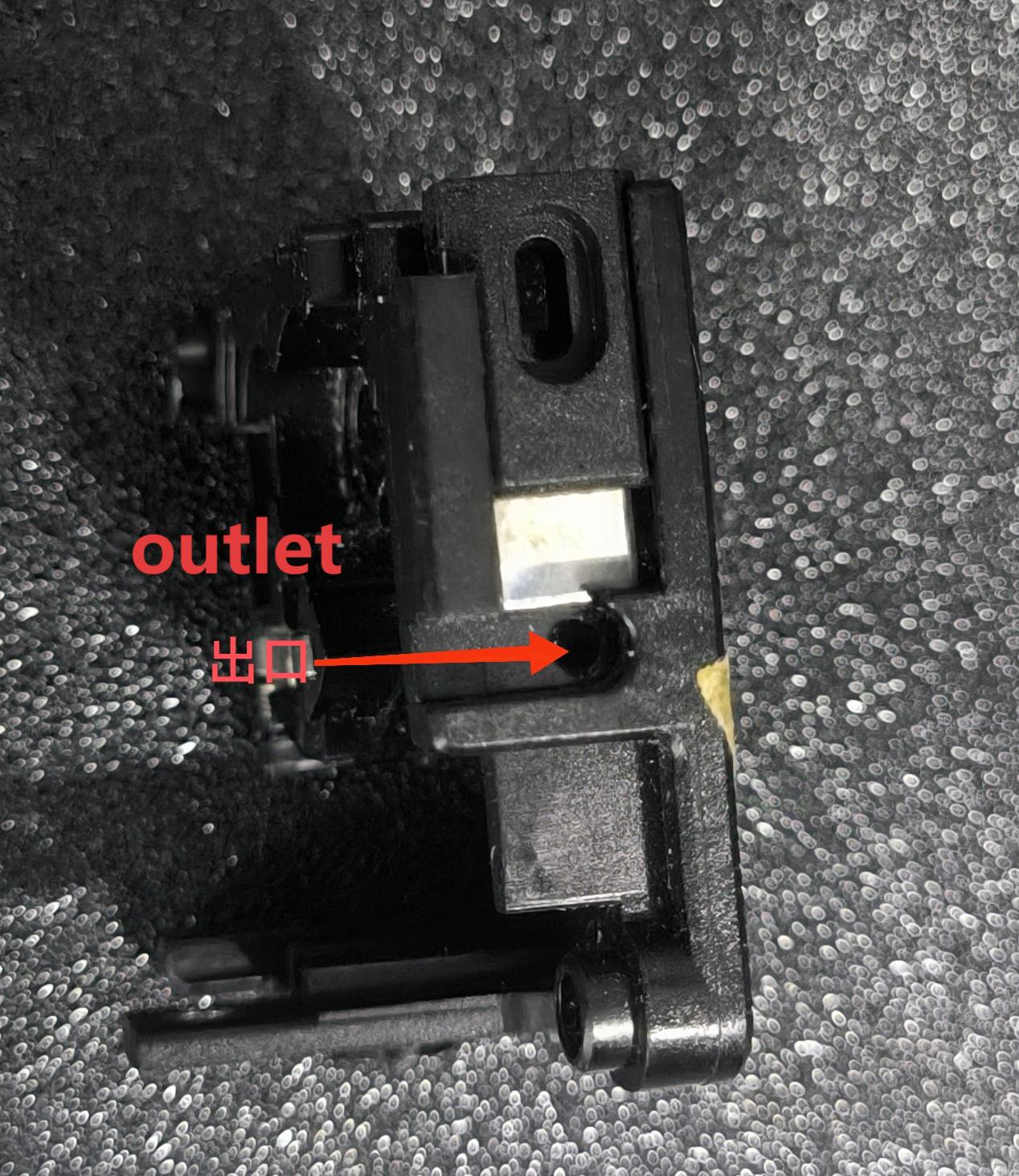

¶ Lower Outlet Blockage, Clogged Hotend

Check if the guide component is missing, if the cutter is blocking the outlet, or if there are foreign objects at the outlet.

If the cutter is blocking the outlet, a new cutter needs to be replaced.

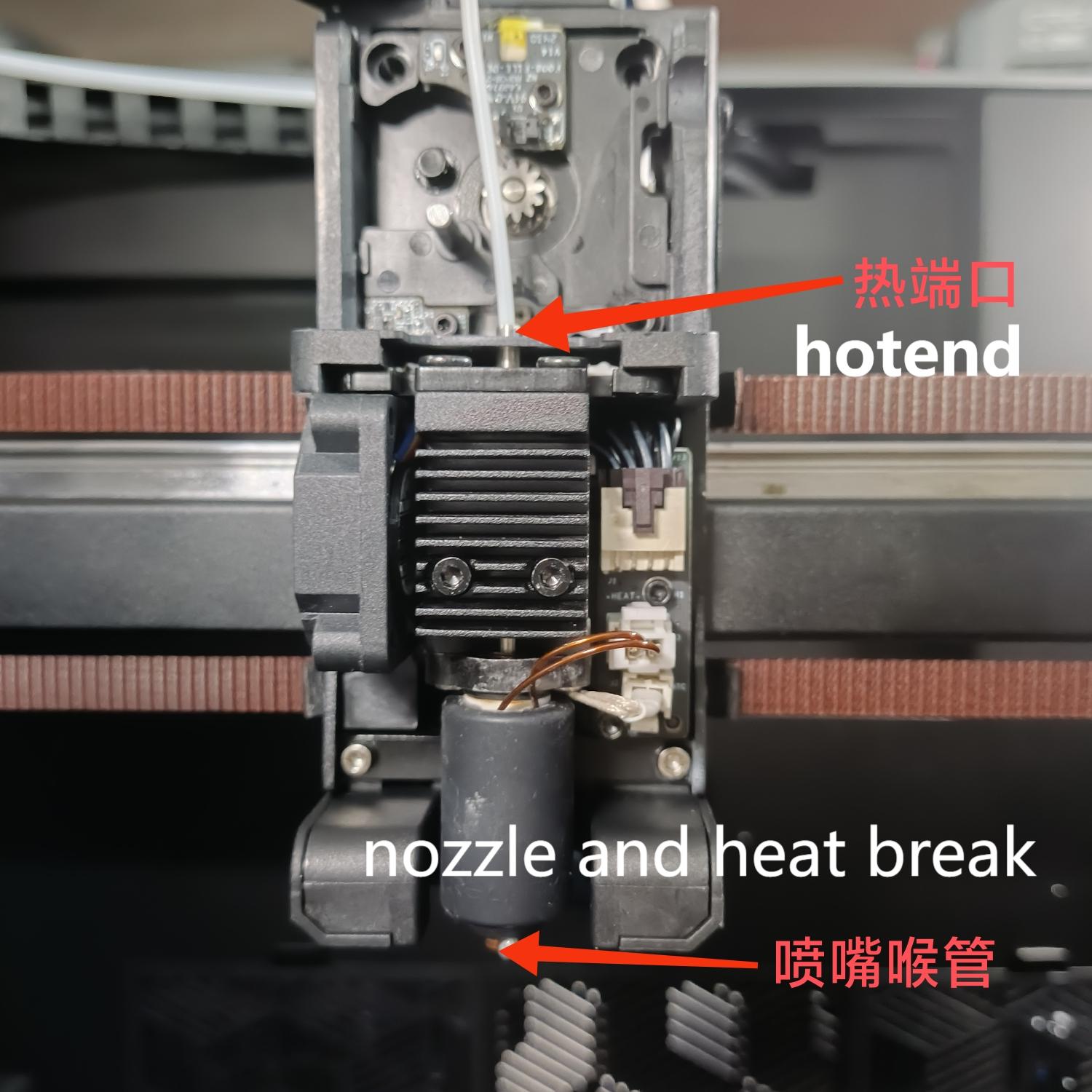

Heat the nozzle to 220°C and try inserting a piece of filament through the hotend port.

If it cannot be inserted or there is excessive resistance, it can be confirmed that the hotend is clogged.

If the filament can be inserted into the hotend, other issues may be causing the jam.

Click "Extrude" on the screen:

- Check if the nozzle temperature is normal

- Check if the extruder motor is rotating normally

- Check if there is filament breakage or foreign object in the extruder

If the nozzle temperature is abnormal, the extruder motor cannot rotate, or there is filament breakage or foreign object in the extruder, please contact cs@creality.com.

¶ Troubleshooting

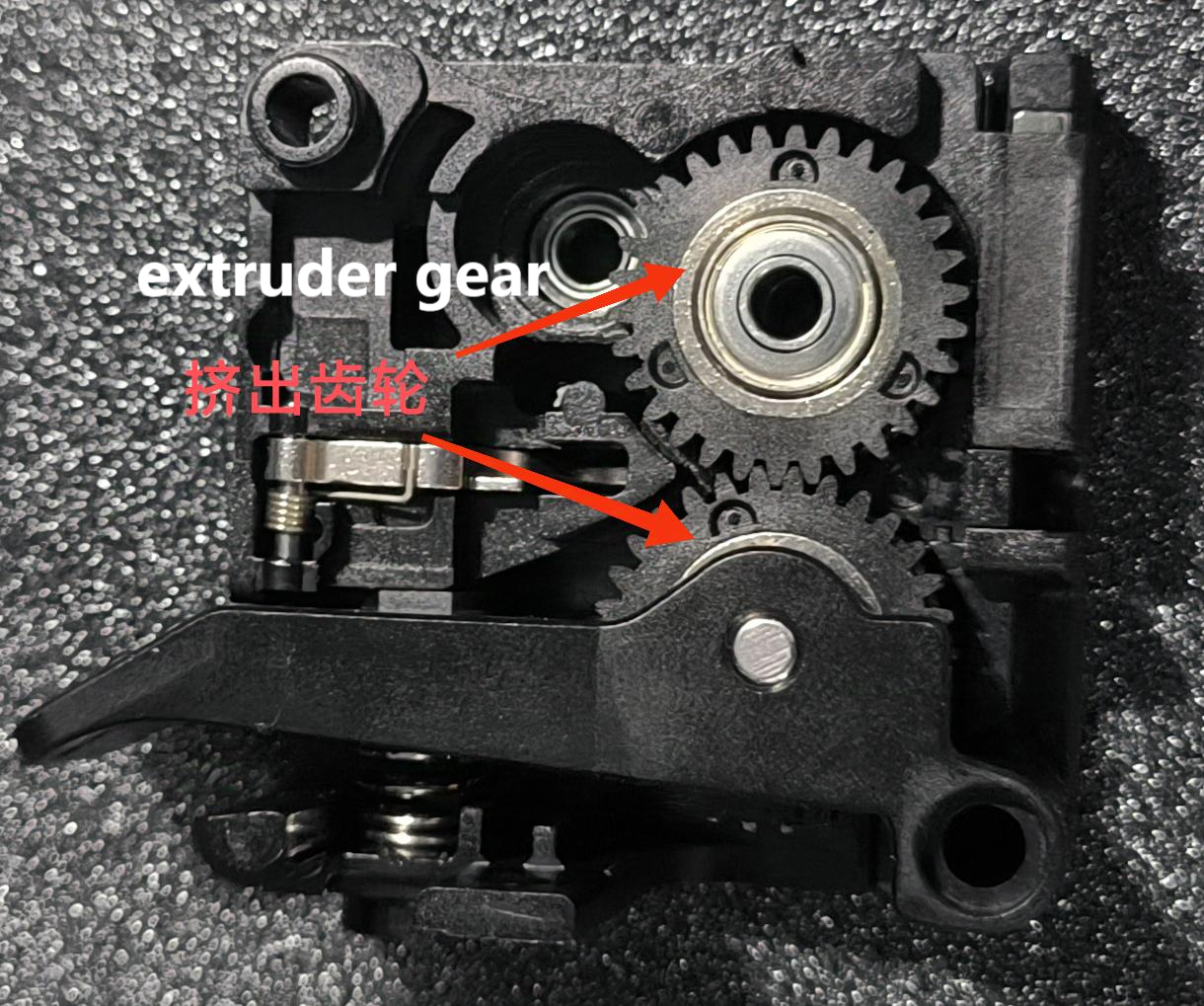

¶ Filament Expansion/Bending or Accumulation in Extruder

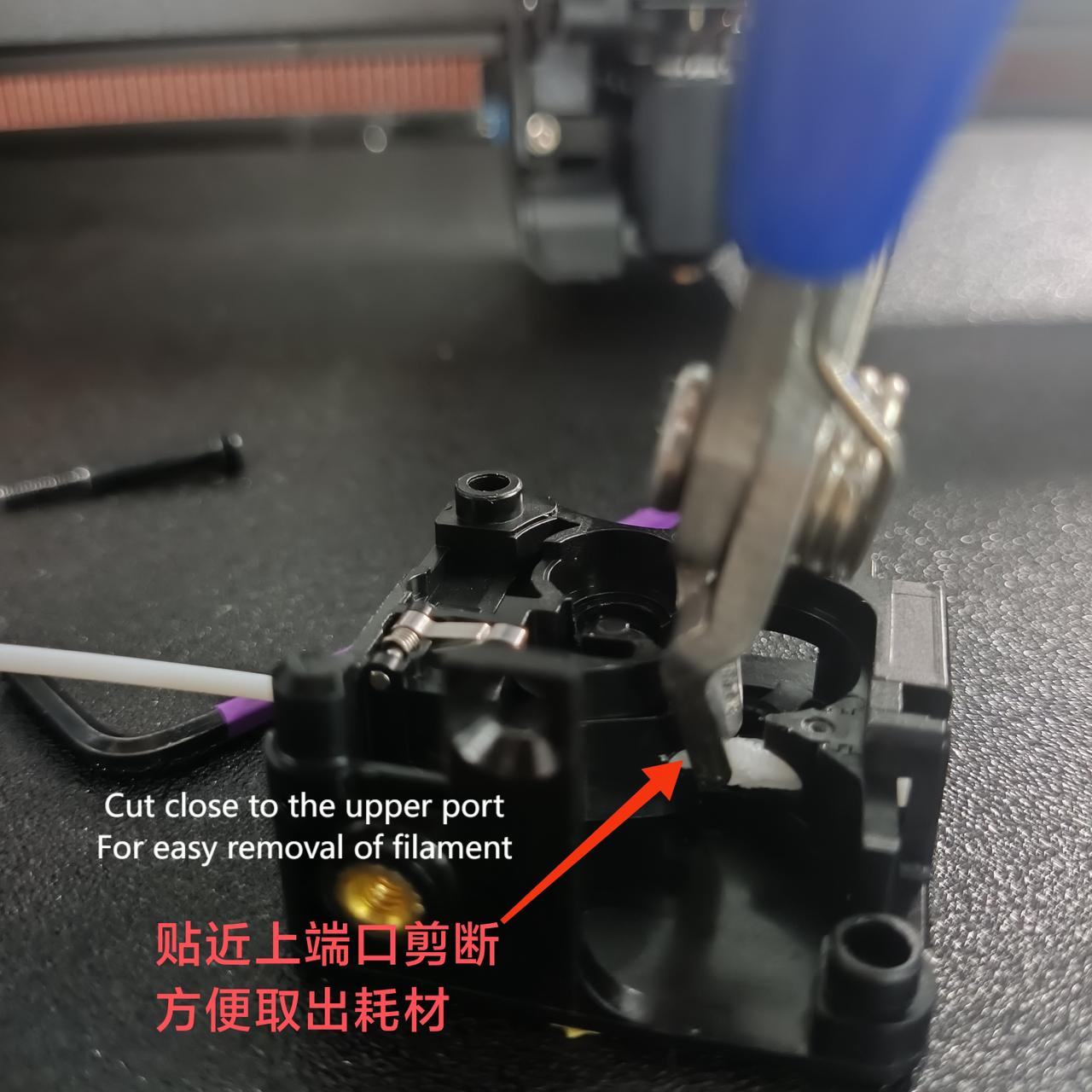

Remove the extruder gear, use cutting pliers to diagonally cut the filament, and pull out the filament.

|

|

Check if the three gears are damaged. If damaged, please contact customer service (cs@creality.com) to replace the extruder front housing kit, SKU: 4001020081.

After cleaning the filament inside the extruder, if the gears are intact, reassemble them.

¶ Clogged Hotend

On the screen, click on the nozzle temperature and heat the nozzle to the filament extrusion temperature.

Use a heating tool to heat the needle tip.

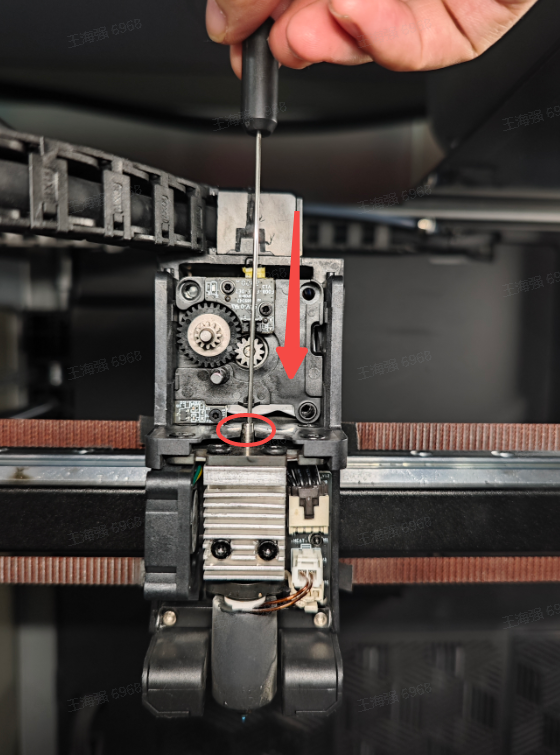

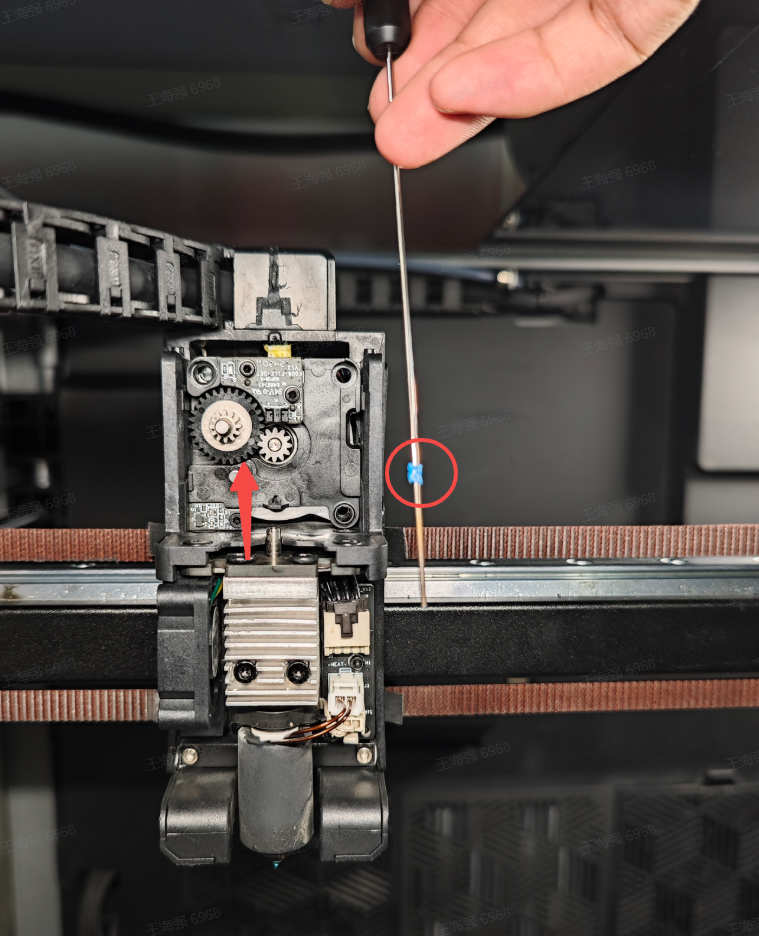

Insert the cleaning needle into the heat break, wait 30 seconds until the cleaning needle cools down.

After the cleaning needle has cooled, slowly pull out the residual filament.

If the jammed filament cannot be cleared after attempting this method, contact customer service (cs@creality.com) to replace the new integrated nozzle.

¶ Friendly reminder

If you still haven't resolved the issue after following the steps in this document, or if you encounter any difficulties during the process, you can click the right corner of the wiki page online support to contact our after-sales team for more help.