¶ Tools

6mm Socket wrench

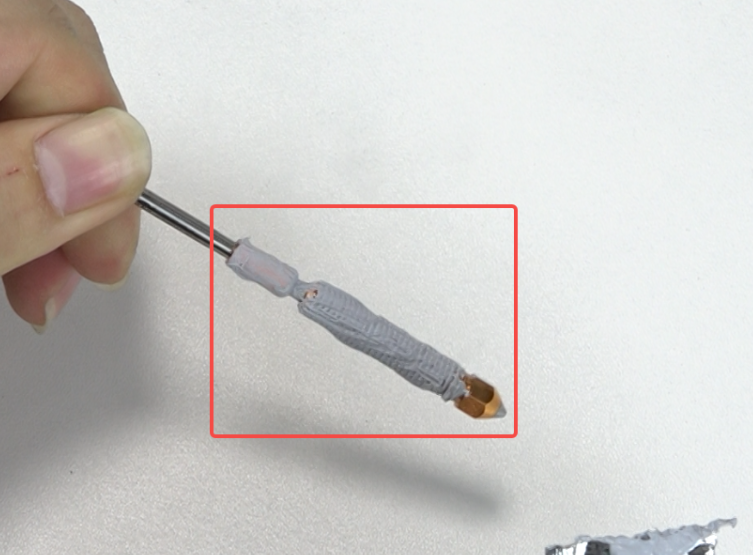

Thermal paste

New nozzle

¶ Replacement Steps

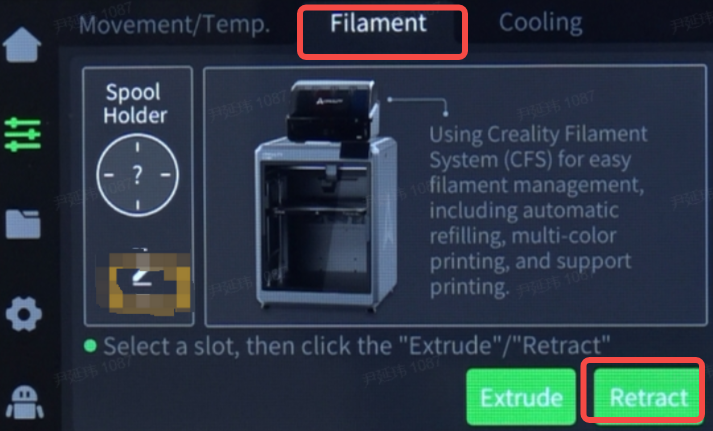

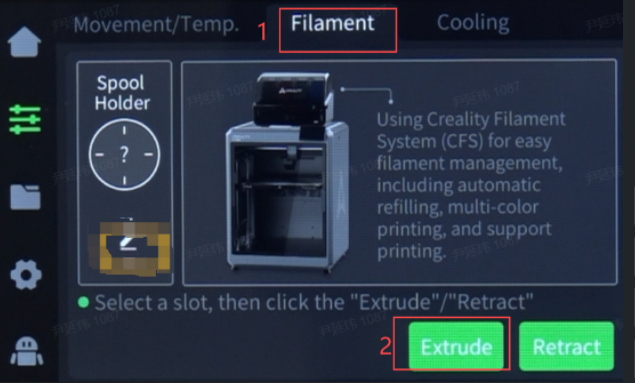

Click on "Filament" - "Retract", wait for the filament retraction to complete

Click "Axis/Temp" - "Z Home", wait for the machine to finish homing, then click "30mm" - "Z Down" to lower the platform to the middle or lower part of the machine to create operating space

Set the hotend temperature according to the filament being used, for example set to 220°C for PLA filament, 240°C for ABS filament.

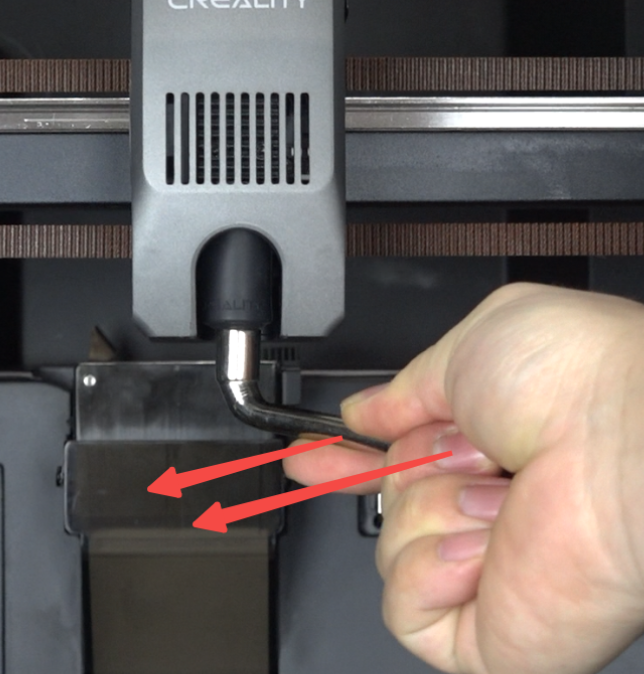

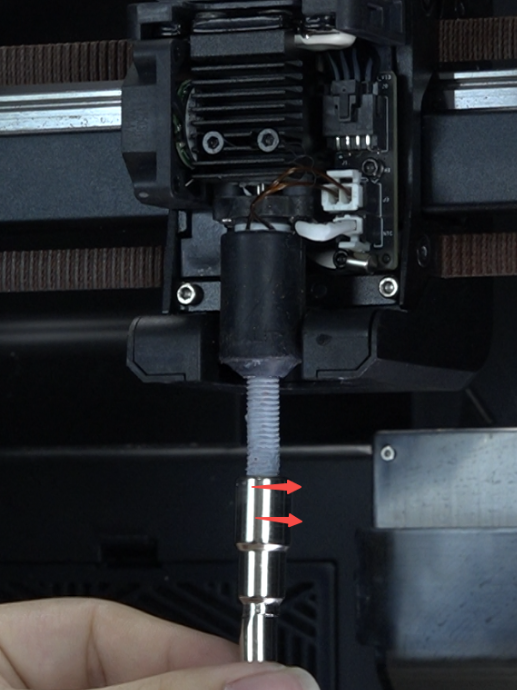

Use the socket wrench to rotate the old nozzle counterclockwise to remove it. Be careful of the high temperature of the nozzle to avoid burns.

|

|

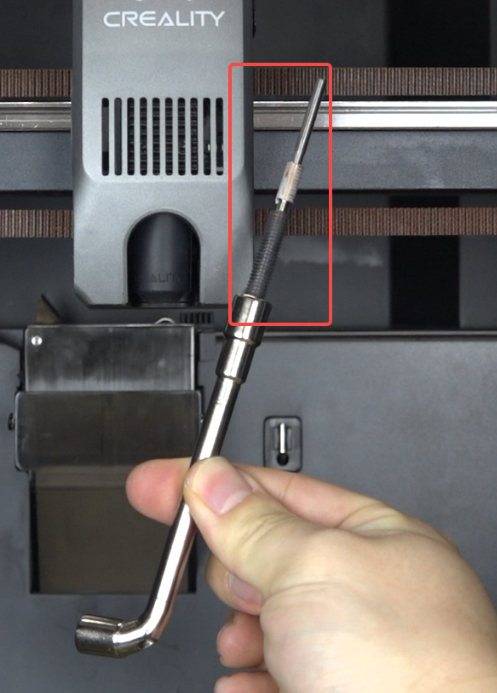

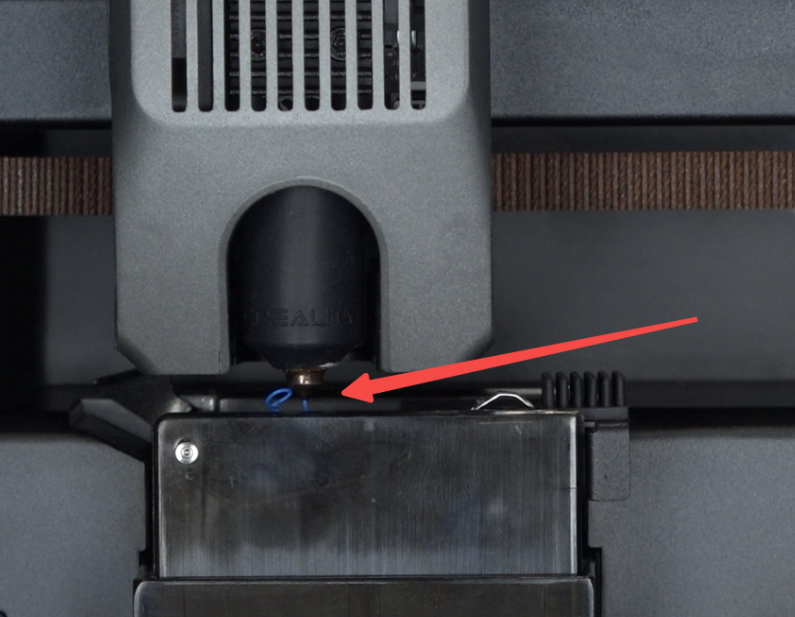

Apply thermal paste evenly on both the heat break and threads of the new nozzle.

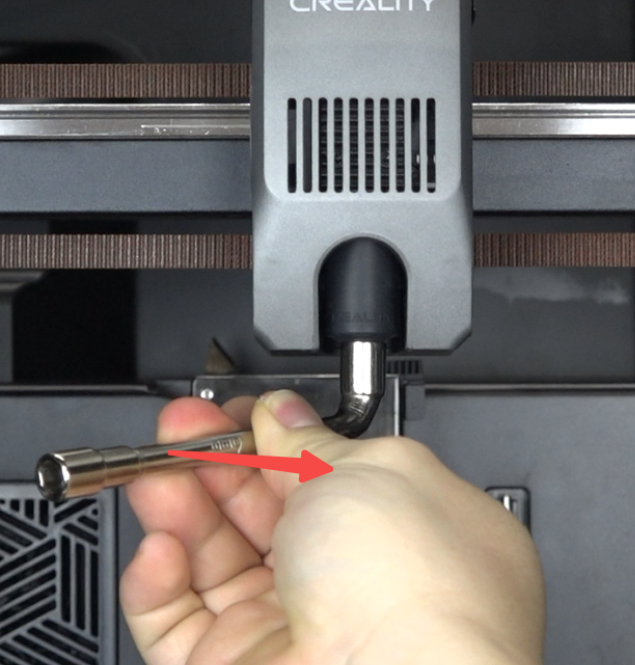

Use the socket wrench to rotate the new nozzle clockwise to install it. Be careful of the high temperature of the nozzle to avoid burns.

|

|

Click "Filament" - "Extrude" and observe if the filament extrudes smoothly from the nozzle.

¶ Device Self-Check

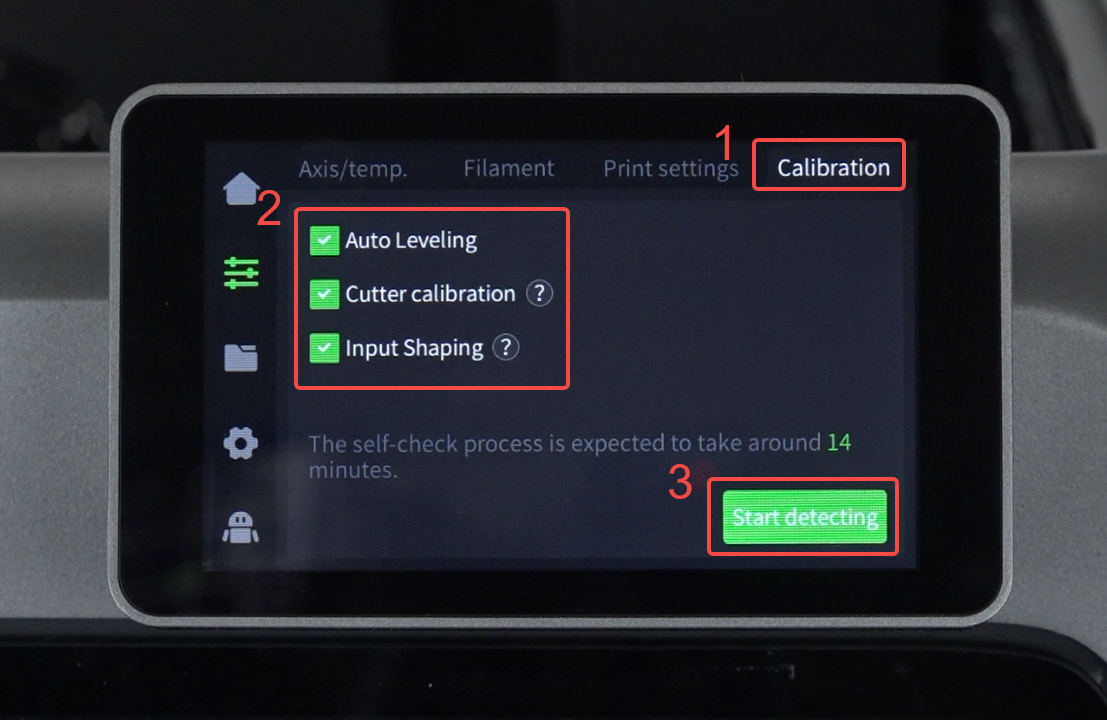

Click "Calibration" - check "Input Shaping" and "Auto Leveling" - "Start Detecting", wait for the detection to complete