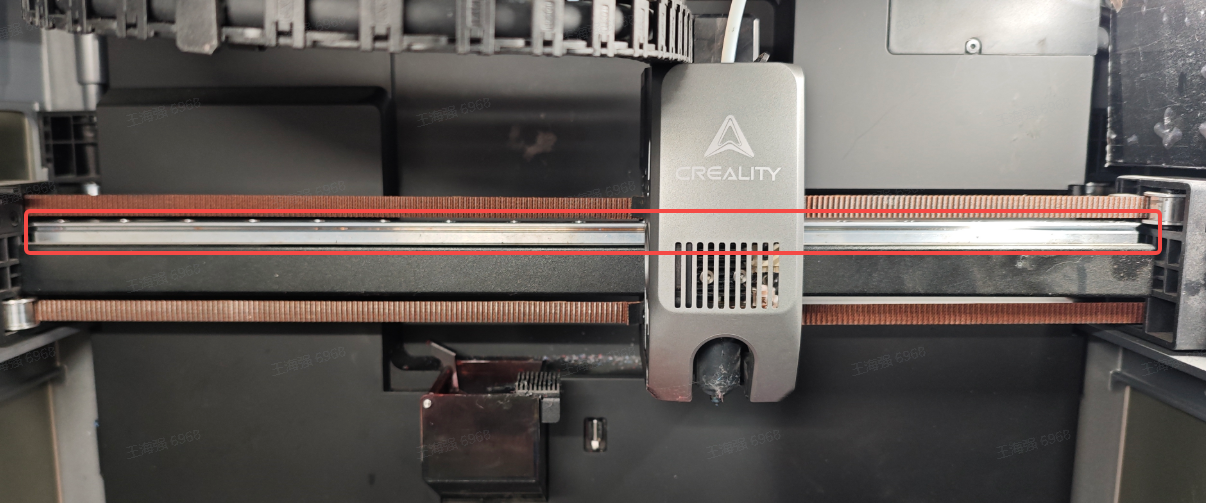

¶ X-axis Guide Rails

The guide rails need to be checked regularly for depletion of lubricating oil, dust or filament debris accumulation, etc. Regular cleaning and lubrication is required.

¶ When to Maintain?

Check monthly for dust or debris accumulation.

¶ How to Maintain?

Use dirt-free cloth to clean the rails' surface and apply thinner coat of metal anti-rust oil.

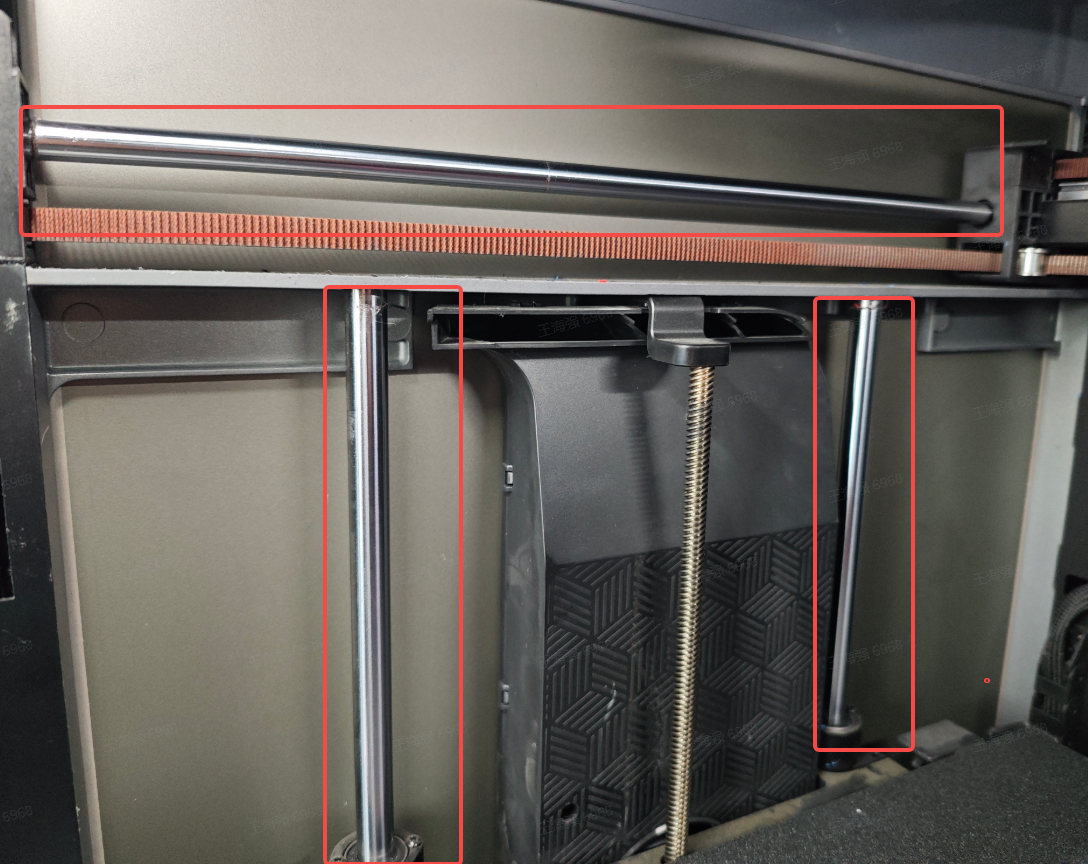

¶ Y-axis and Z-axis Optical Shafts

The Y-axis optical shafts and Z-axis optical shafts are pre-greased before leaving the factory. To prevent corrosion and to extend its service life, we suggested periodic maintenance.

¶ When to Maintain?

Check and maintain them every 3 months. If frequently printing volatile materials like ABS or ASA, maintain them every 5 days.

¶ How to Maintain?

Use a dirt-free cloth to clean the optical shafts' surface and apply grease.

¶ Z-axis Lead Screws

K2 Pro has two lead screws on the left and right side responsible for the up/down motion of the hot bed. Regular cleaning and lubrication is needed to ensure service life.

¶ When to Maintain?

Check and maintain every 3 months. If frequently printing volatile materials like ABS or ASA, maintain it every 5 days.

¶ How to Maintain?

Use a dirt-free cloth to clean the lead screw surfaces and apply grease.

¶ Friendly Reminder

If you still haven't resolved the issue after following the steps in this document, or if you encounter any difficulties during the process, you can click the right corner of the wiki page online support to contact our after-sales team for more help.