¶ TPU Filament Printing and Setup Steps

¶ Ensure NO high-temperature filament residue in the nozzle

Before printing TPU-type filaments, it is recommended to clean any residual high-temperature filaments (especially those with printing temperatures above 240°C) from the nozzle to further reduce the risk of nozzle clogging.

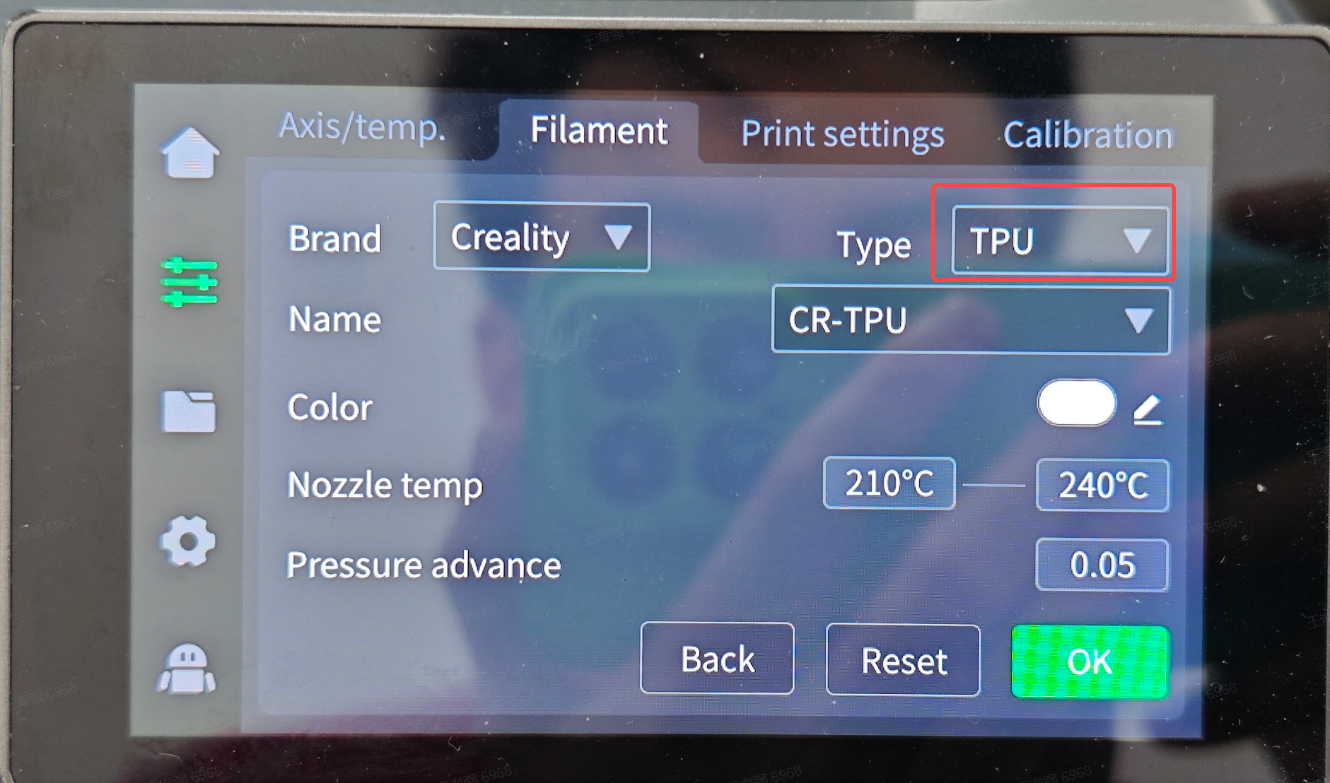

¶ Filament settings on the screen

Ensure that the selected filament type is TPU

|

|

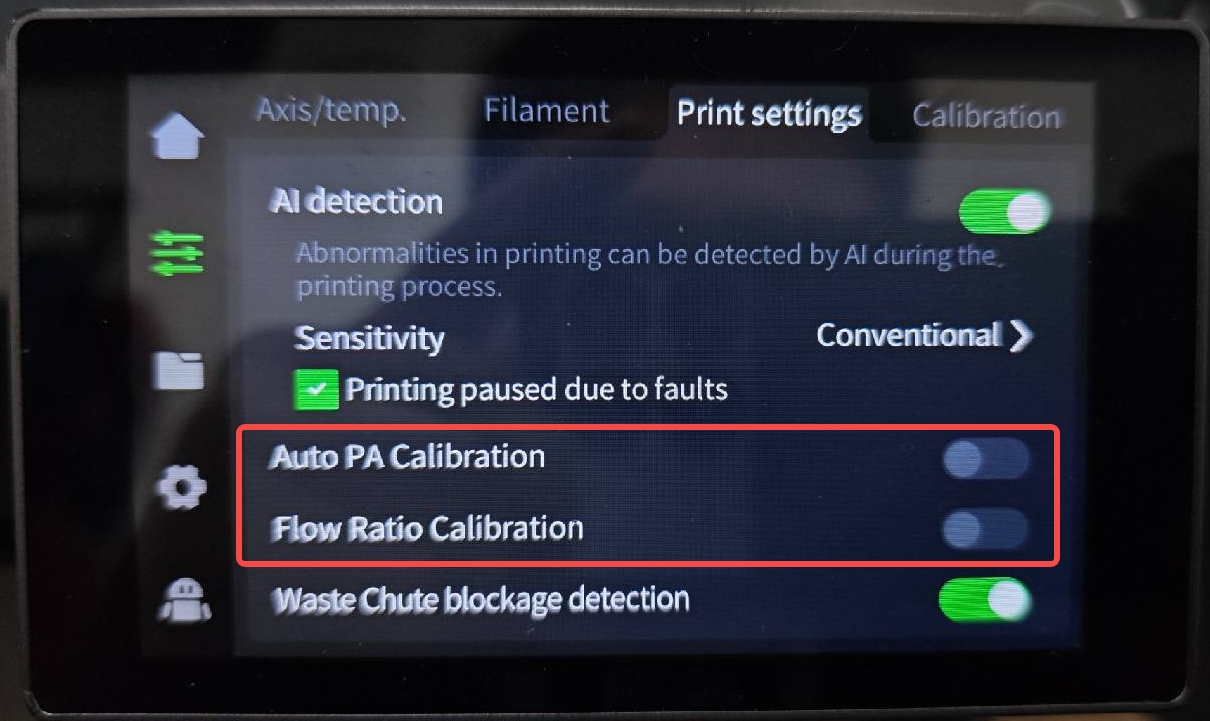

Due to the mismatch between the printing speed during flow calibration pattern and TPU printing, which can easily cause blockage, please disable "Auto PA Calibration" and "Flow Ratio Calibration" in "Print Settings" when printing TPU.

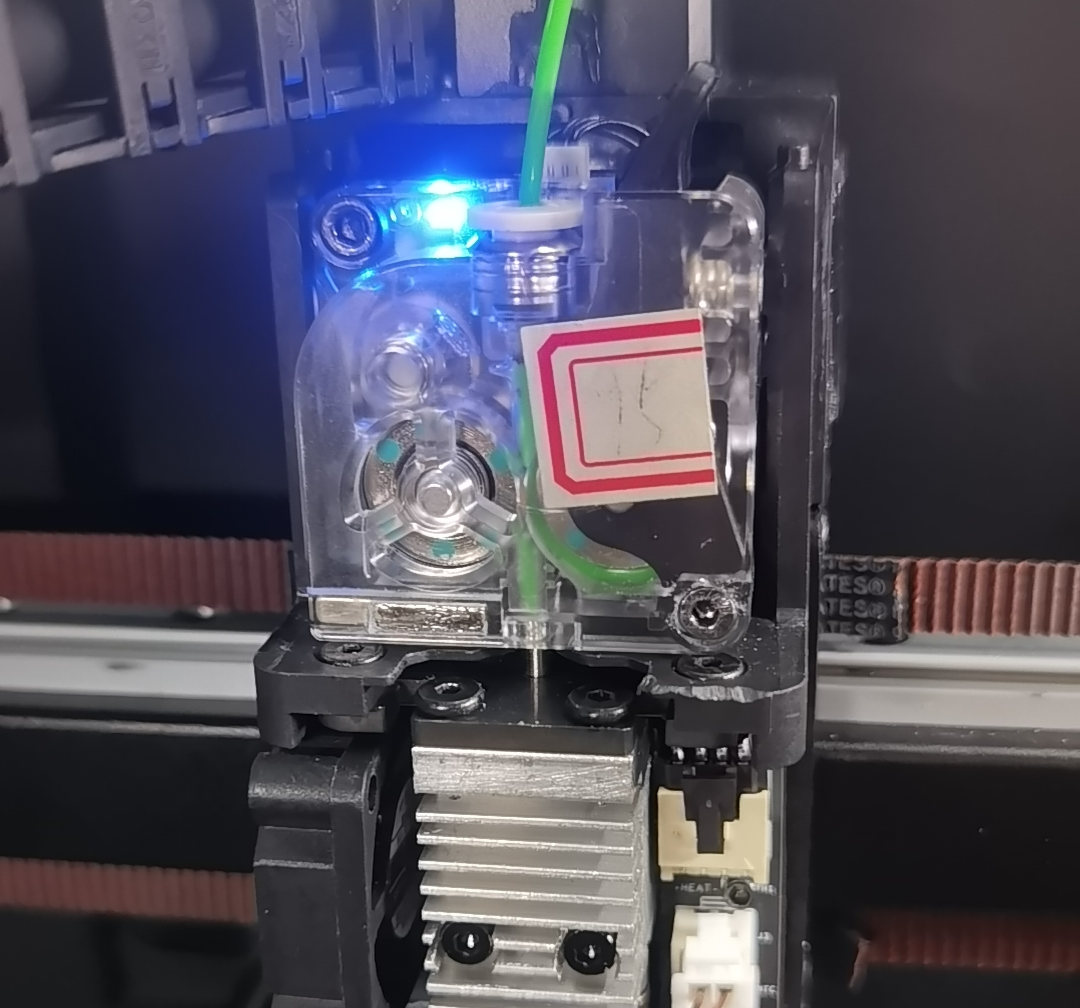

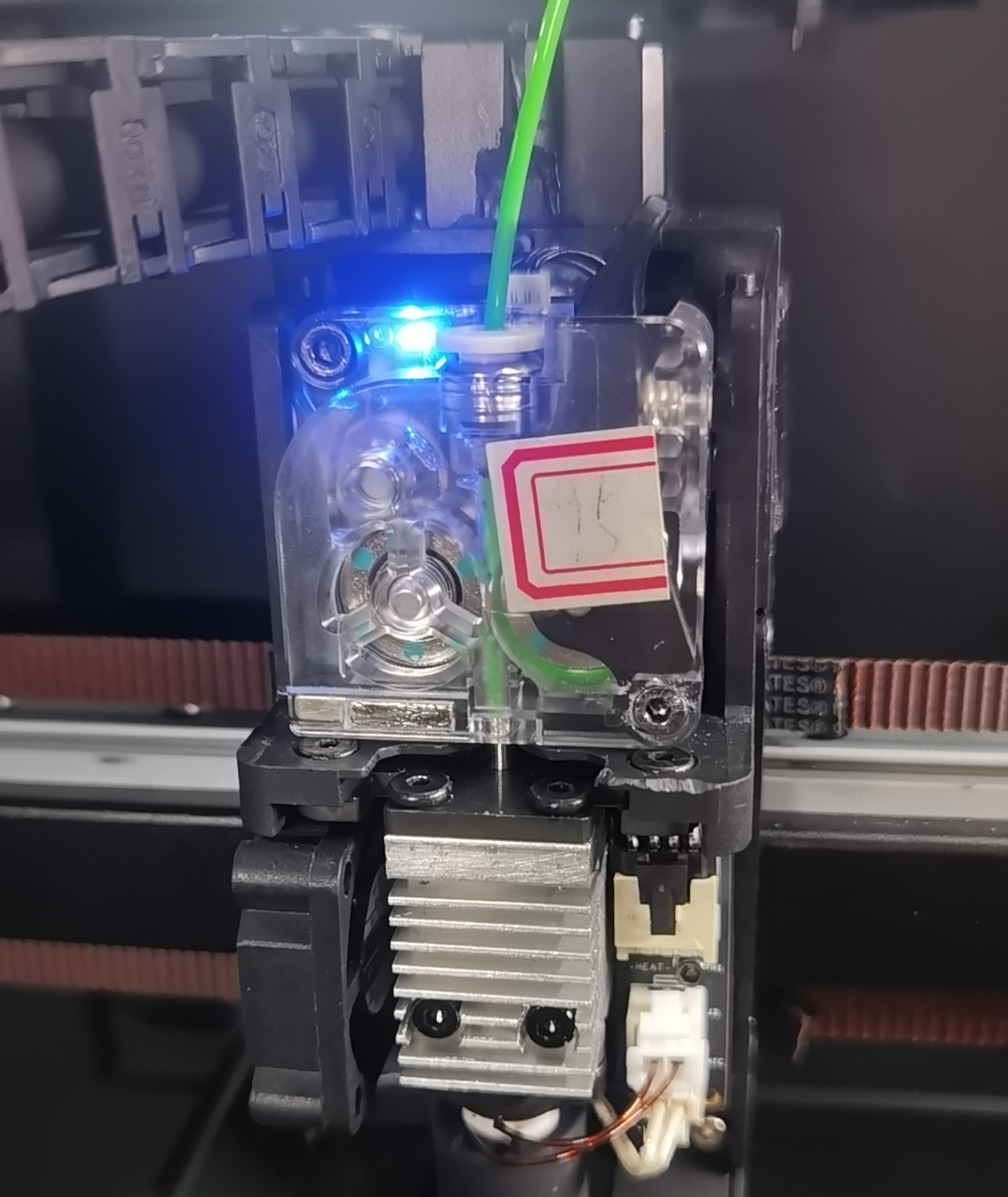

¶ Filament placement

To ensure better printing results and stability, it is recommended not to print TPU-type filaments directly through the PTFE tube. This is because: TPU filaments passing through the PTFE tube further increases resistance, affecting the final printing result.

|

|

Click on the screen to load the filament.

¶ Precautions

TPU filament is not allowed to use CFS printing, as it is prone to bending in the CFS filament tube, easily causing feeding and unloading failures;

TPU with hardness of 90A, 80A, 75A, 70A (or lower) cannot be printed with the Creality K2 Plus printer, as the TPU material is too soft and can be flattened by extruder gear, leading to nozzle clogging;

¶ How to improve TPU filament printing results?

¶ Dry Filament

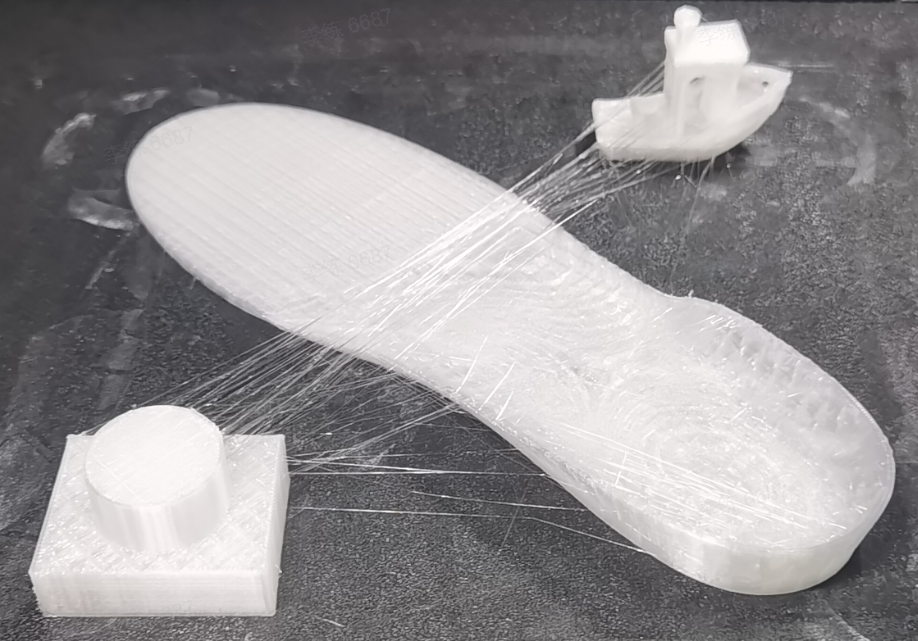

TPU flexible filaments have strong water absorption properties. When the filament absorbs moisture, it can easily cause stringing, oozing, and nozzle clogging. Drying the filament before printing can effectively solve some of these issues. The following images show a comparison of printing results for HP-TPU filament before and after drying in a 70°C forced-air drying box for 8 hours.

|

|

¶ Filament parameters

There are three types of TPU available in CrealityPrint6.0, namely CR-TPU, HP-TPU, and Generic TPU; please select the corresponding filament for slicing.

If you are using non-Creality filament to slice, we recommend:

Maximum volumetric speed: For CR-TPU/Generic TPU, the maximum volumetric speed should not exceed 2mm³/s; for HP-TPU, the maximum volumetric speed should not exceed 3mm³/s

Nozzle temperature: Recommend 220°C

Hot bed temperature: For smooth PEI plate bed, the temperature should not be lower than 40°C