¶ Video Tutorial

Calibrate K2 Plus Extrusion Servo Motor

¶ When to calibrate

When the following print quality issues occur, it may be due to inaccurate calibration of the extruder servo motor:

Obvious regular diagonal patterns on the surface of parts, as shown in the image.

¶ Calibration tools

Extrusion Servo motor calibration is completed by sending fixed commands to the CrealityOS system, which automatically calibrates after executing the commands.

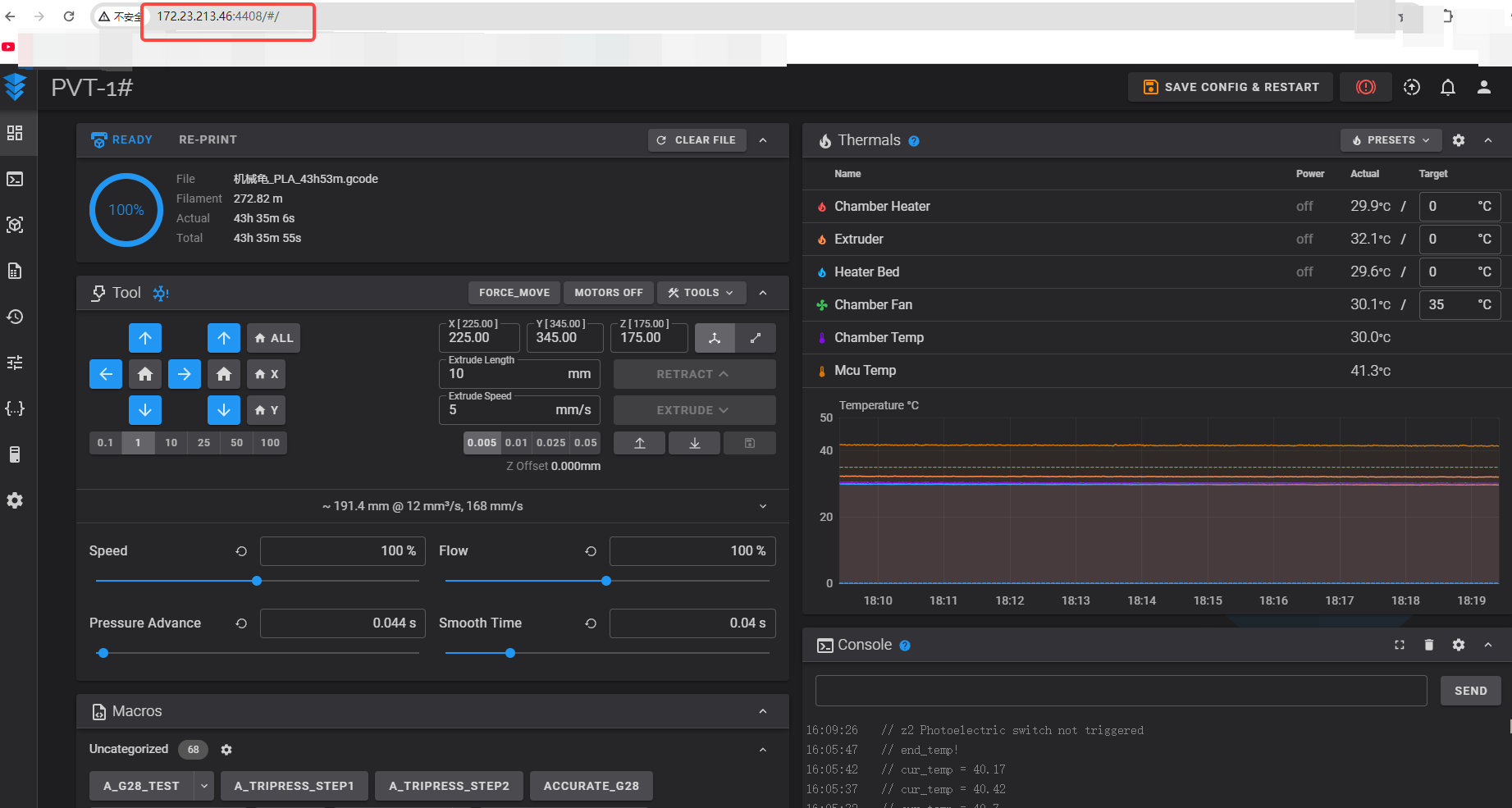

Therefore, the following steps require using the Fluidd interface:

Open a browser on your computer and obtain the printer's IP address from the machine's network interface

Enter the machine's IP address plus port number:4408in the browser (e.g. 192.168.1.1:4408) to access the Fluidd window.

¶ Calibration steps

1. Ensure there is no filament in the extruder

If there is filament in the extruder, click "Retract", wait for filament unloading to complete, and make sure there is no residual filament in the extruder, otherwise it will affect the calibration process.

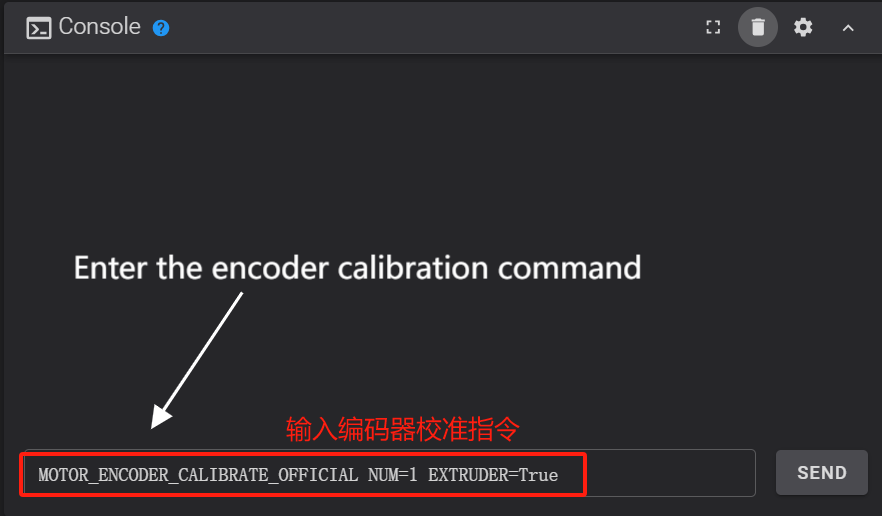

2. Enter the command for encoder calibration

Enter the encoder calibration command in the Console command line terminal to calibrate the extruder encoder.

Encoder calibration command:

MOTOR_ENCODER_CALIBRATE_OFFICIAL NUM=1 EXTRUDER=True

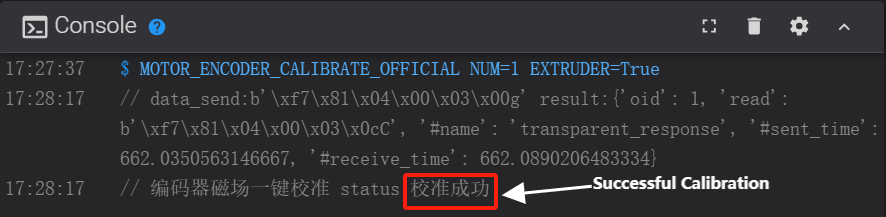

Wait about 50 seconds for the motor calibration to finish, and the calibration result will be returned in the Console

3. Restart the printer

Turn off the printer power switch, then turn it on again and wait for it to restart

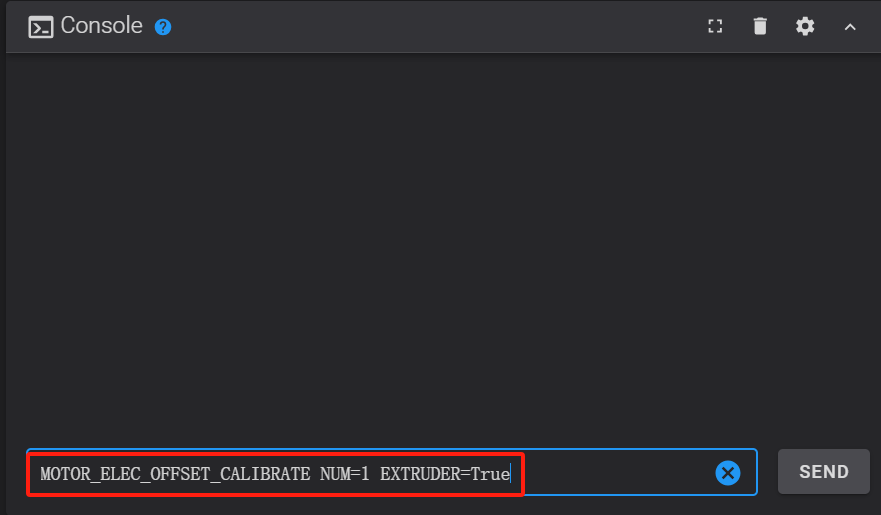

4. Enter the command for electrical zero position calibration

After restarting, enter the electrical zero position calibration command in the Console command line.

MOTOR_ELEC_OFFSET_CALIBRATE NUM=1 EXTRUDER=True

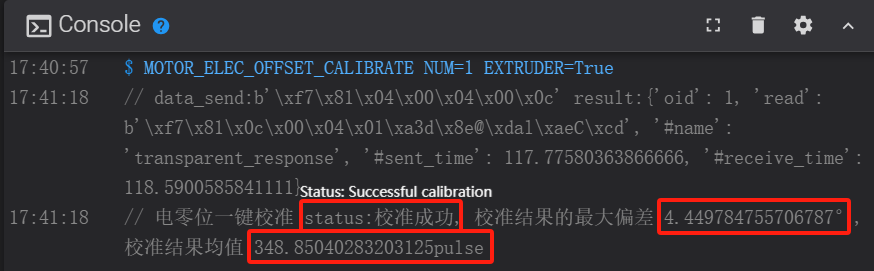

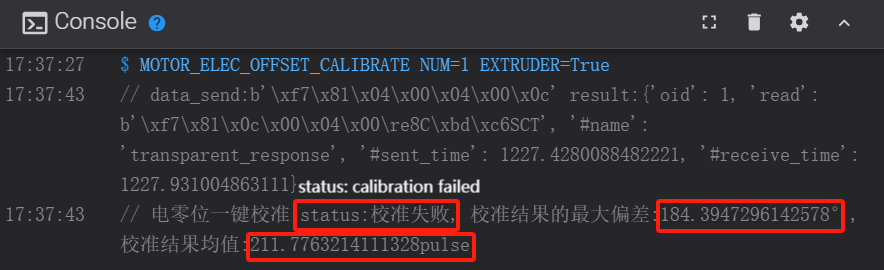

5. Confirm calibration results

After about 15 seconds, the calibration result will pop up in the Console.

Successful calibration example: Maximum calibration deviation is less than 15°

Failed calibration example: Maximum calibration deviation is greater than 15°

Please ensure to test print quality after completing all steps. If problems persist, repeat the above steps