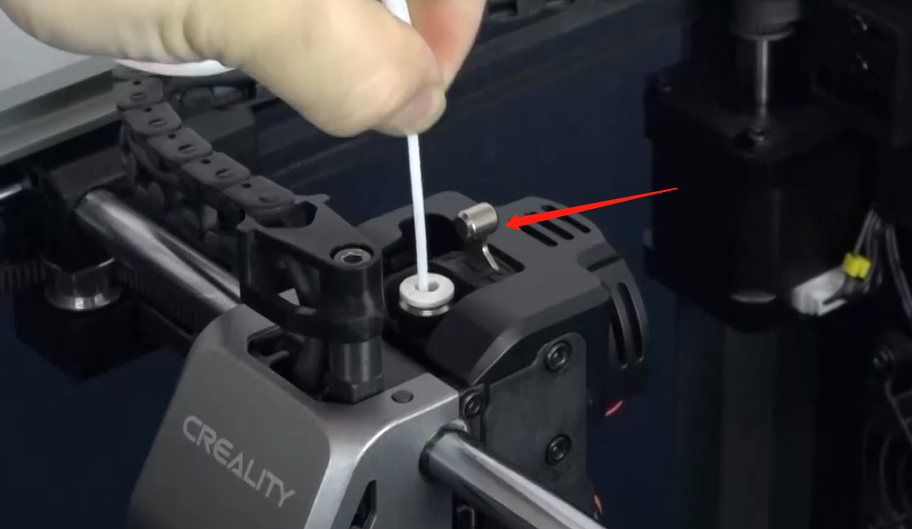

¶ Step 1

Set the nozzle temperature to 240°C to remove the filament, press the pneumatic joint to pull out the Teflon tube, and move the extruder to the unlocked state, but the filament cannot be pulled out;

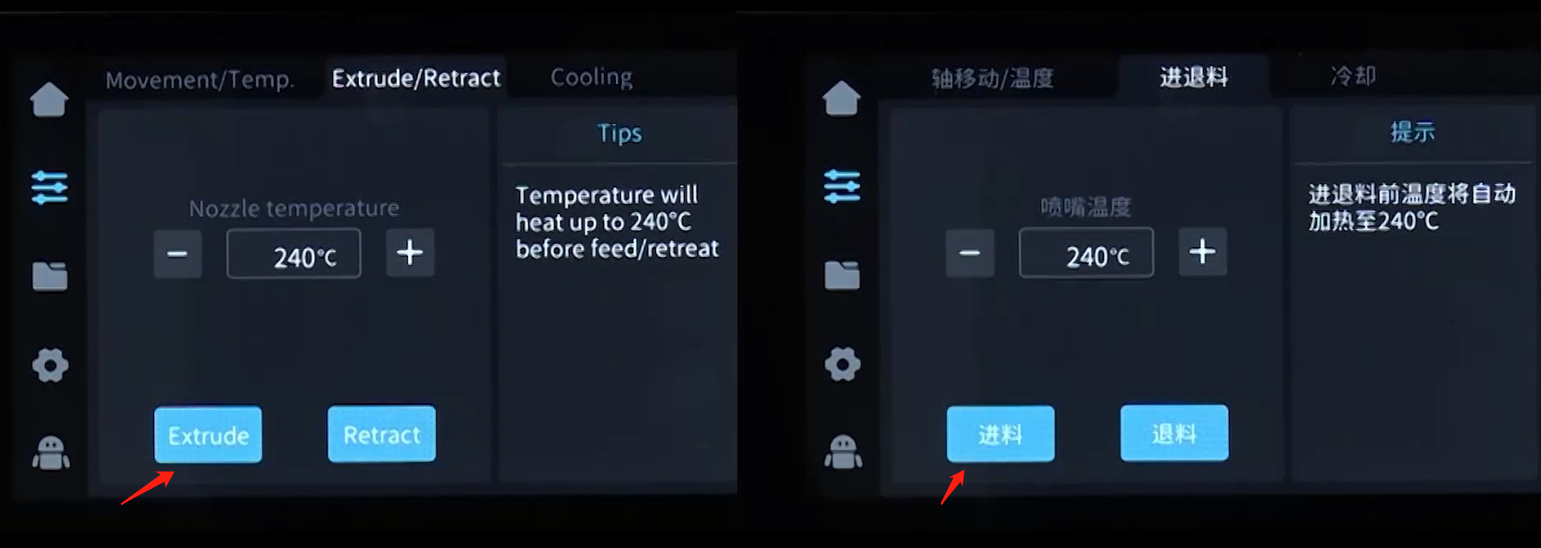

¶ Step 2

Manually set the nozzle temperature to 240 degrees. Then cut off the filament and remove the extrusion motor protective cover.

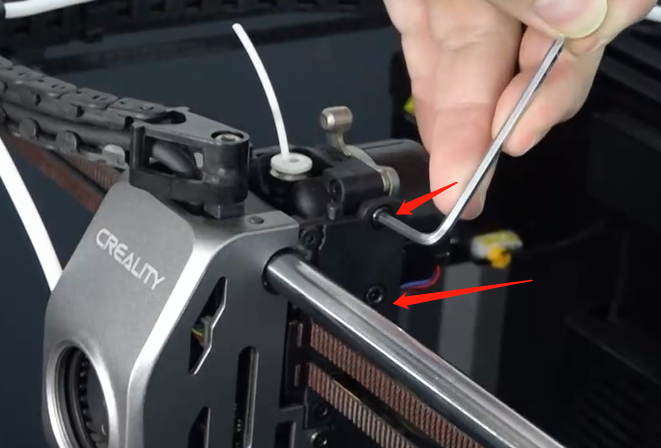

¶ Step 3

Use the hexagon socket to remove the 3 fixing screws on the left and right sides of the extrusion motor.

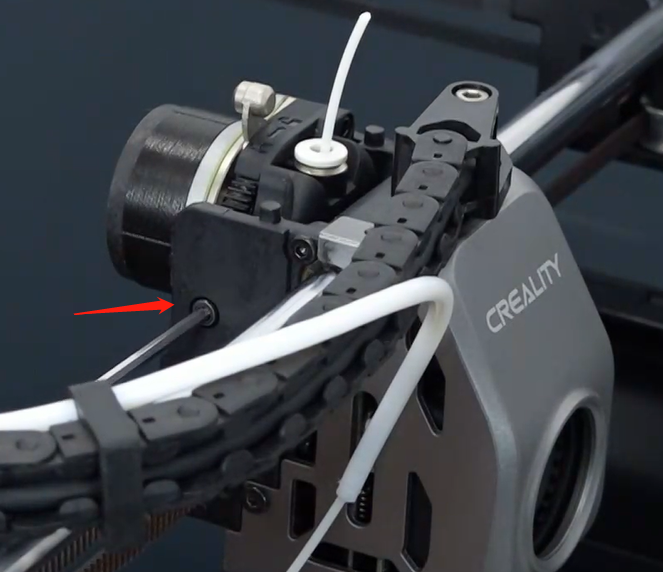

¶ Step 4

Take out the extrusion motor. Remove the two fixing screws of the extrusion clamp (be careful not to break the extrusion motor cable), and then disassemble the extrusion clamp to check the internal clogged situation.

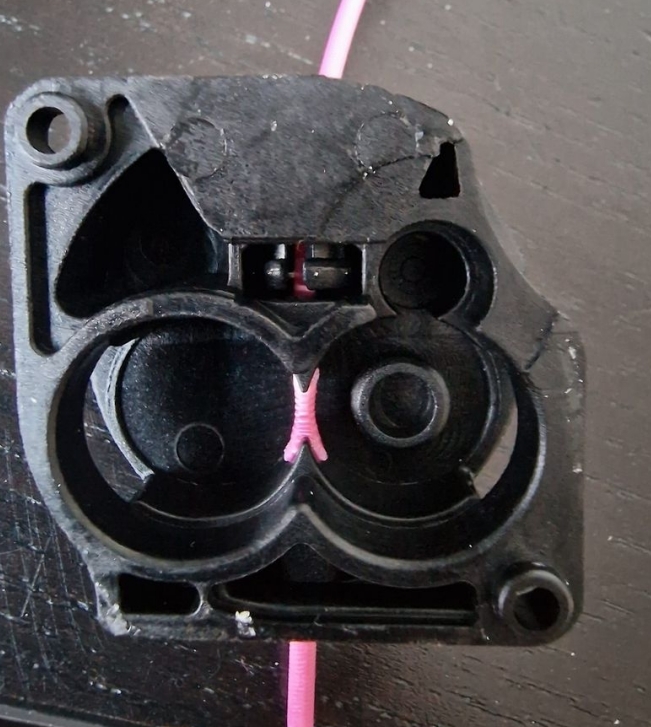

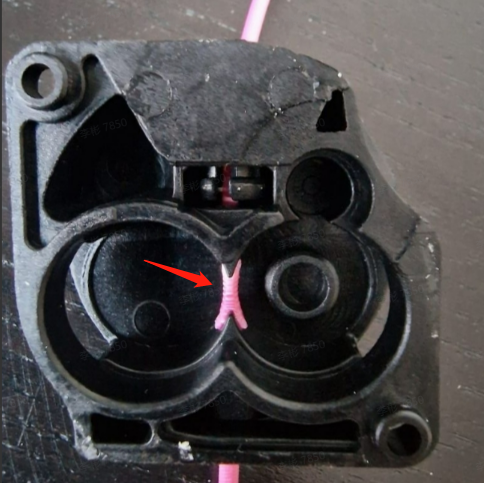

¶ Step 5

Carry out targeted cleaning operations according to different stuck materials situations

- The filament in the middle of the extrusion clamp shell expands (just cut the expansion filament in the middle, and then pull out the participating filaments)

- Residual filament in the middle of the gear causes blockage (unlock the extrusion dial, turn the gear, and clean the remaining filament)

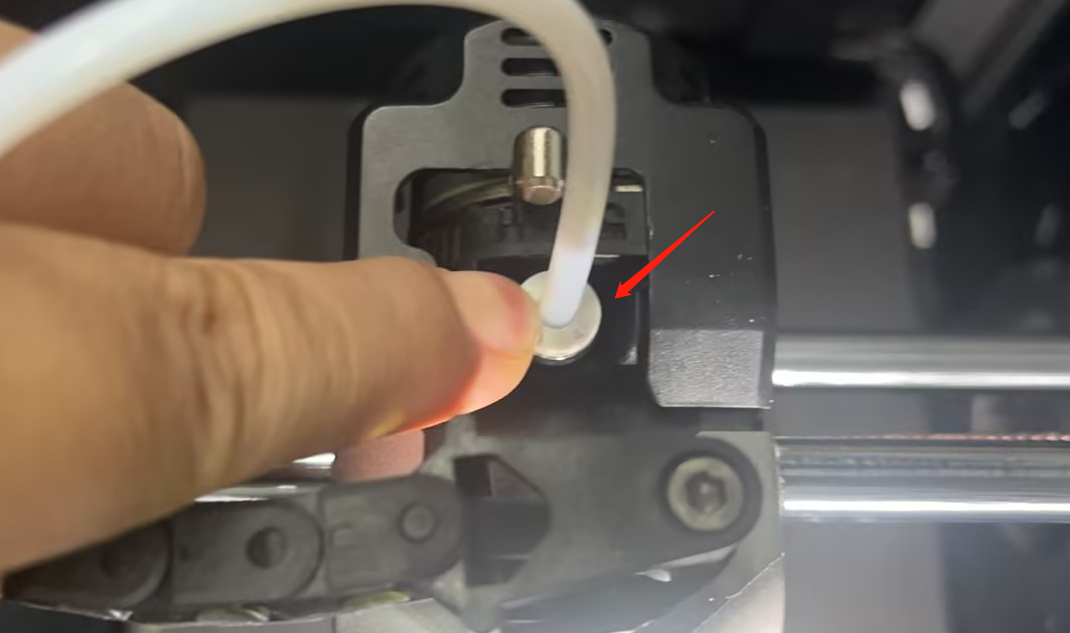

¶ Step 6

After cleaning up the clogged consumables, install the extruder (pay attention to the small movable bearings and do not miss them), and lock the motor screws.

¶ Step 7

After installing the filament, lock the dial. Carry out feeding operation on the machine to verify whether the feeding is normal.