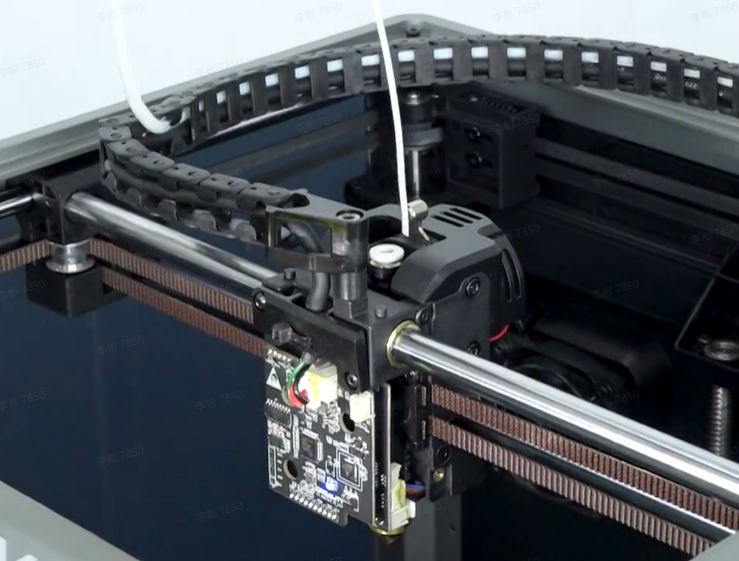

Prerequisite: K1 uses an integrated nozzle kit

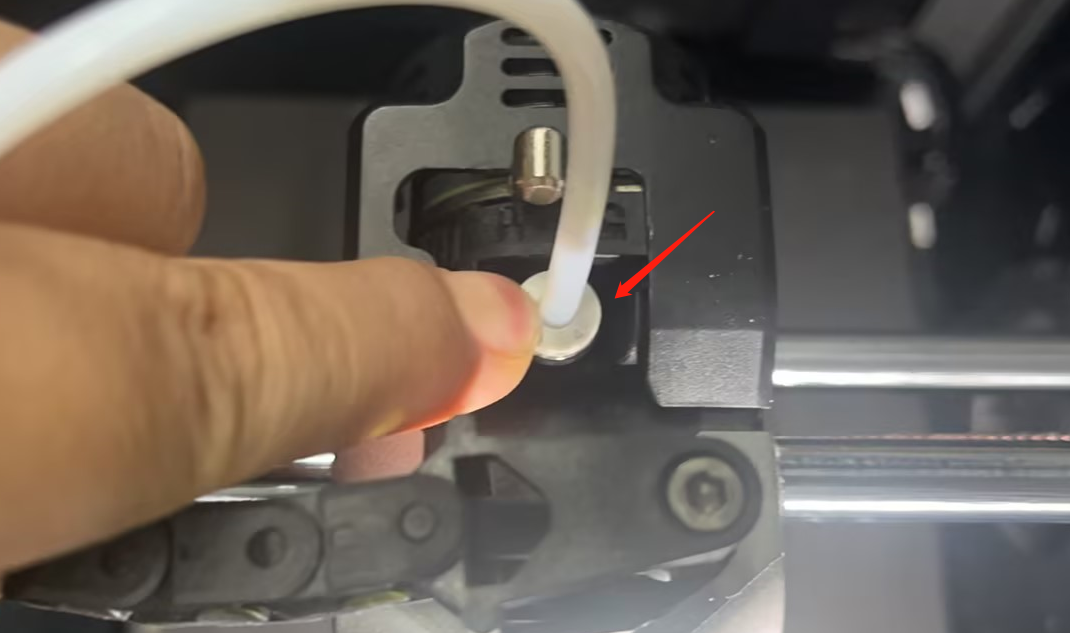

1、 Set the nozzle temperature to 220℃, press the pneumatic connector to remove the PTFE tube, shift the extruder to the unlocked position, and remove the filament.

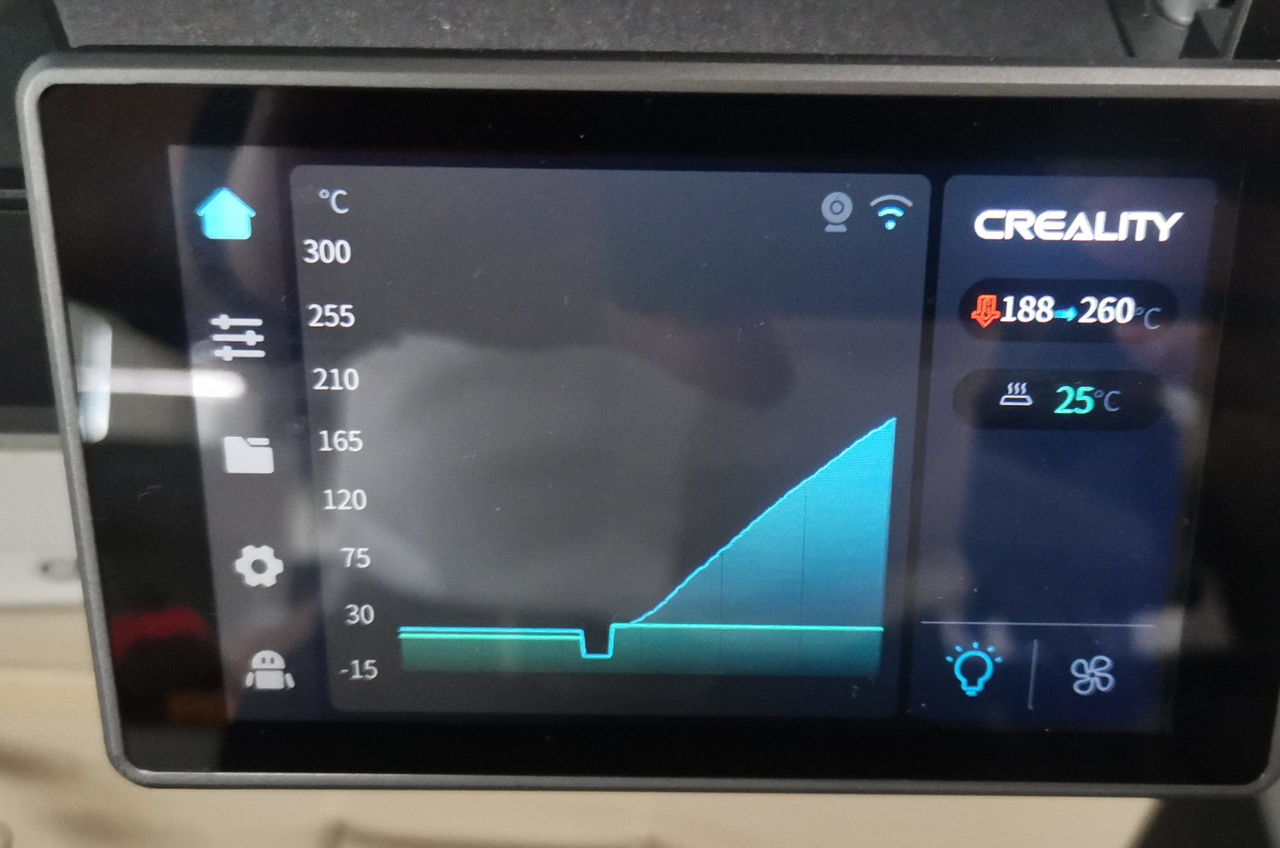

2、 Shutdown, waiting for the nozzle temperature to decrease.

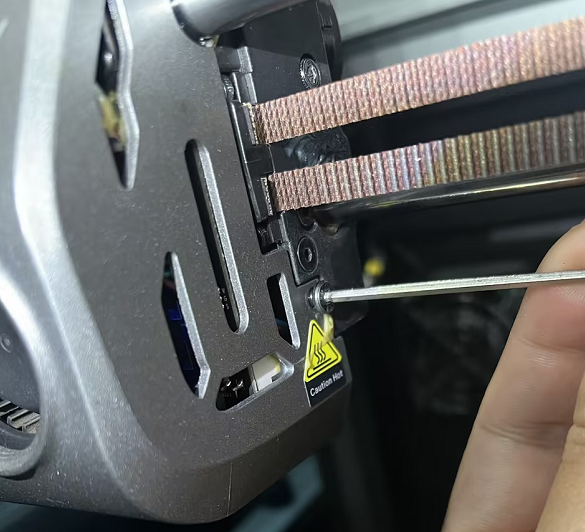

3、 Remove the fixing screws on both sides of the extruder cover.

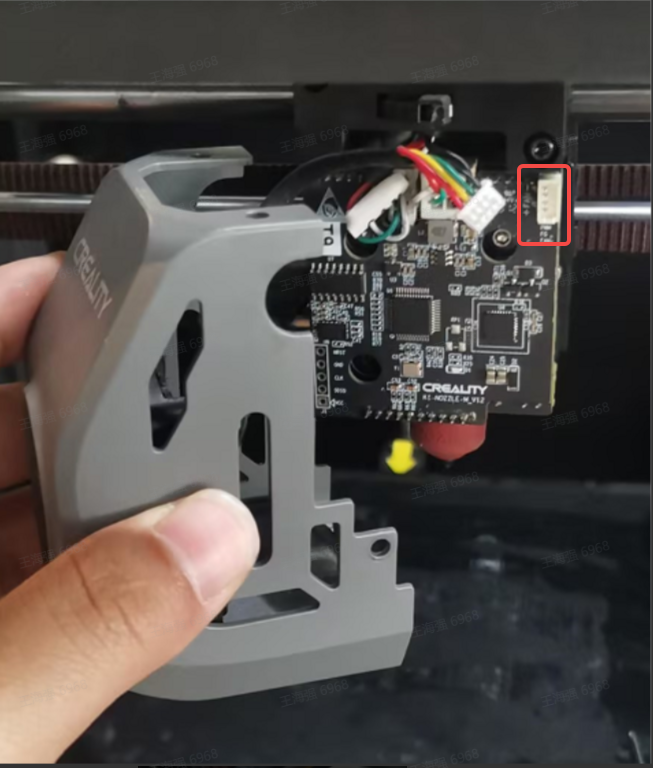

4、 Remove the nozzle cover and disconnect the model fan connector.

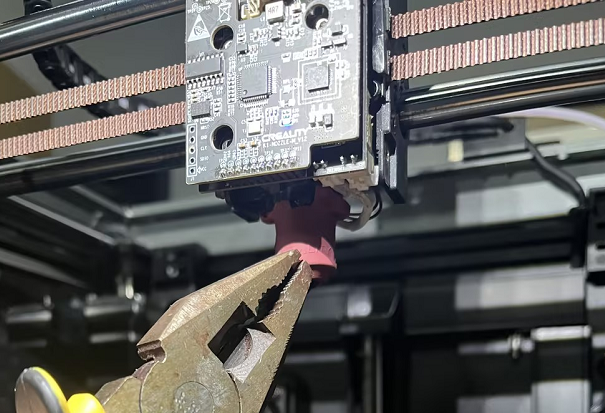

5、 Remove the silicone sleeve (if it is difficult to remove, the nozzle can be heated to 220 degrees, and needle-nose pliers or cutting pliers can be used to remove the silicone sleeve. Do not touch directly with your hands to avoid burns).

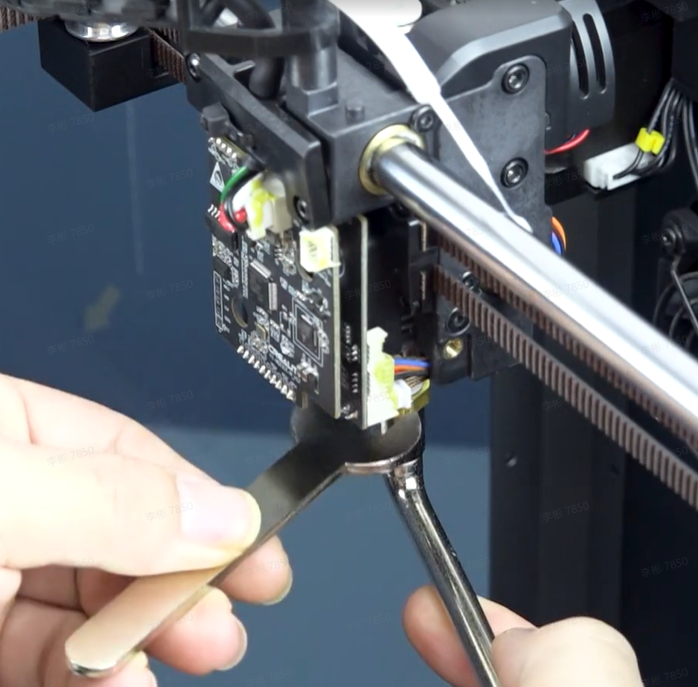

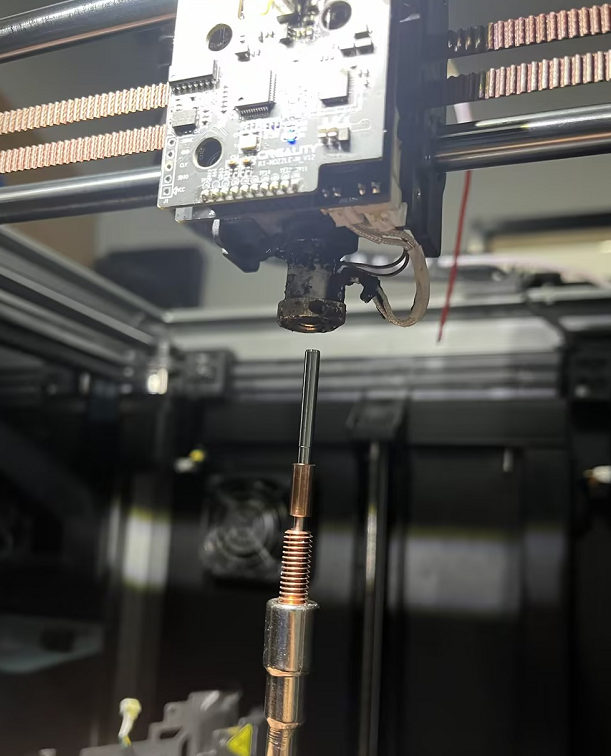

6、 Maintain the nozzle temperature at 220 degrees. Use the wrench provided in the toolkit to secure the nozzle, while using a socket with the other hand to loosen the integrated nozzle. (Note: Do not touch the nozzle with your hands to avoid burns.)

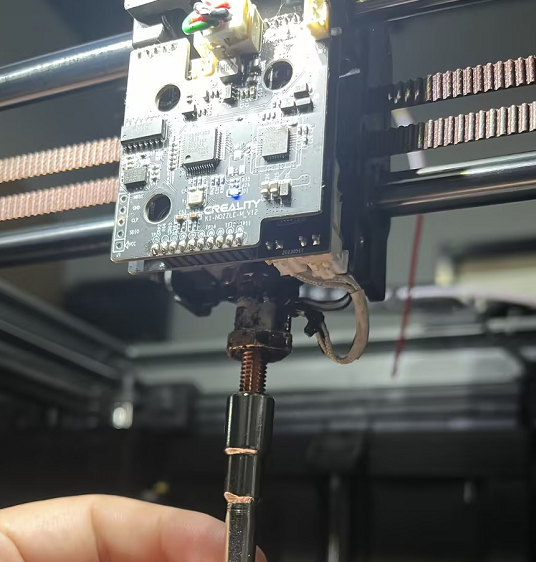

7、 After removing the nozzle, replace it with a new one. Screw it in with a socket, and do not attempt to twist it by hand to avoid burns.

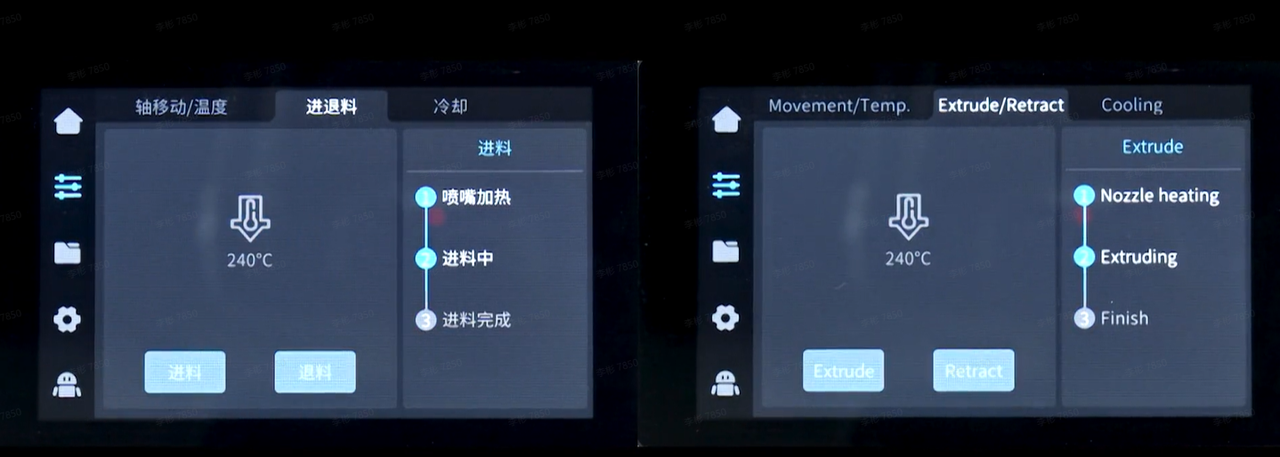

8、 Tighten. Load the filament and lock the extruder clamp. Operate the feeder to check if the filament extrusion is normal.

9、 After the material ejection is normal. Power off the machine, wait for the nozzle temperature to decrease, and install the silicone cover. Install the printhead fan connector and screws on both the left and right sides accordingly.