¶ Overview

Q: Can regular filament print at high speed?

A:Yes, select the corresponding filament configuration in the slicer.

Q: What's the maximum print speed for my filament? Can it exceed 300 speed?

A:Need testing to determine

For filament loading steps, please refer to Wiki: K1C/K1C2025 Loading/Unloading/Changing Filament

¶ Slicer Settings

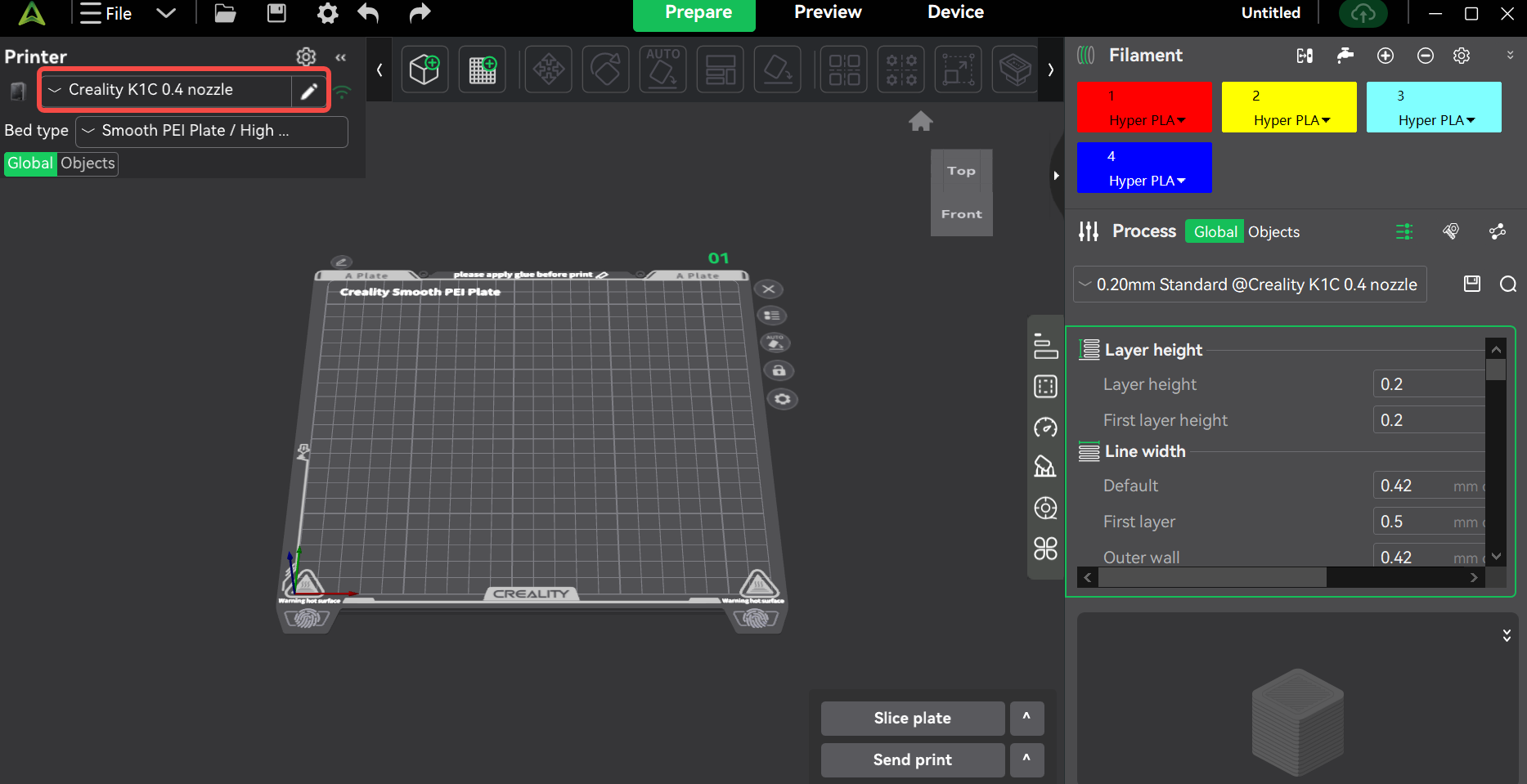

Open official slicer V6.1 or above

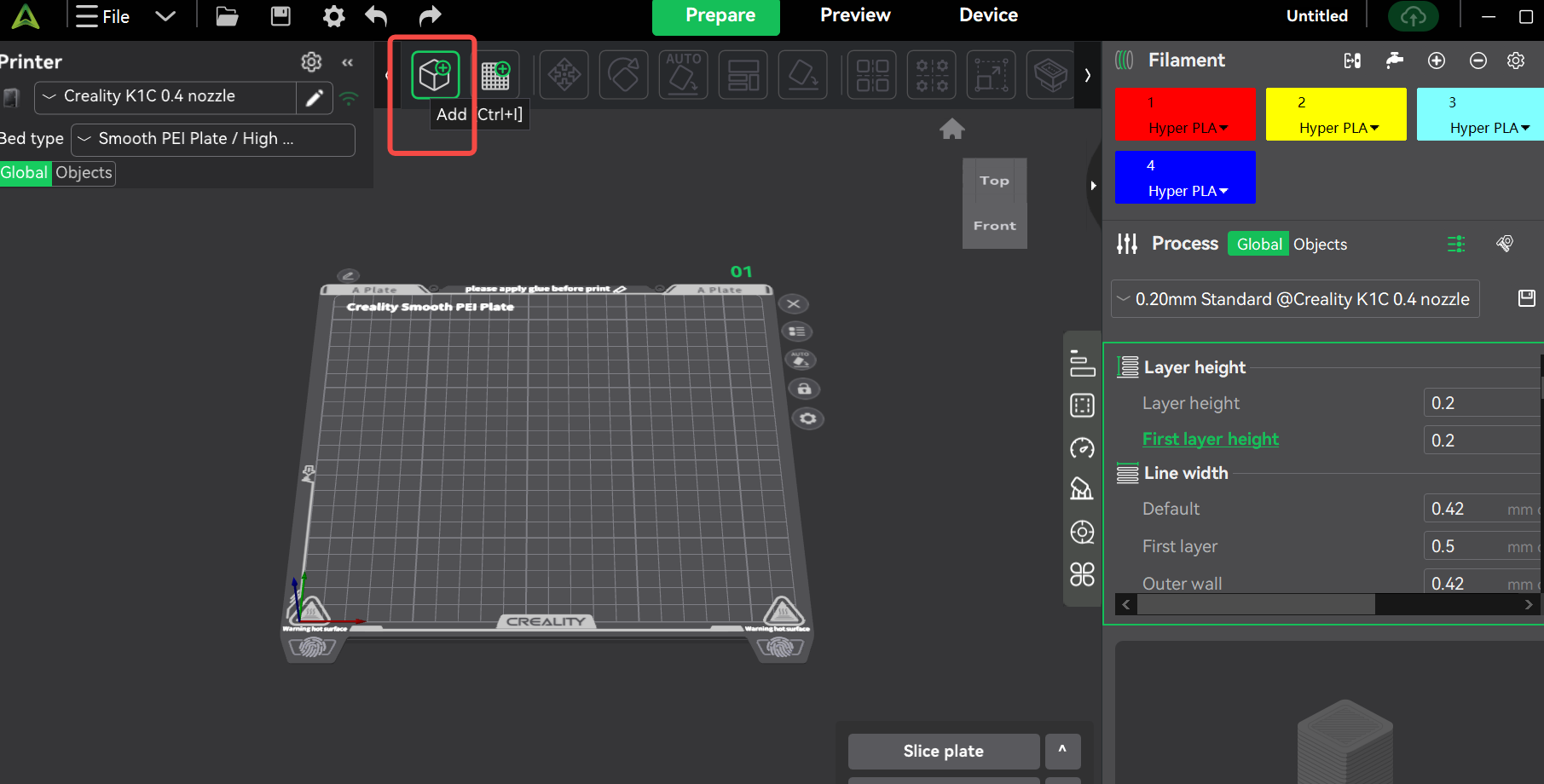

Select K1C printer and import model

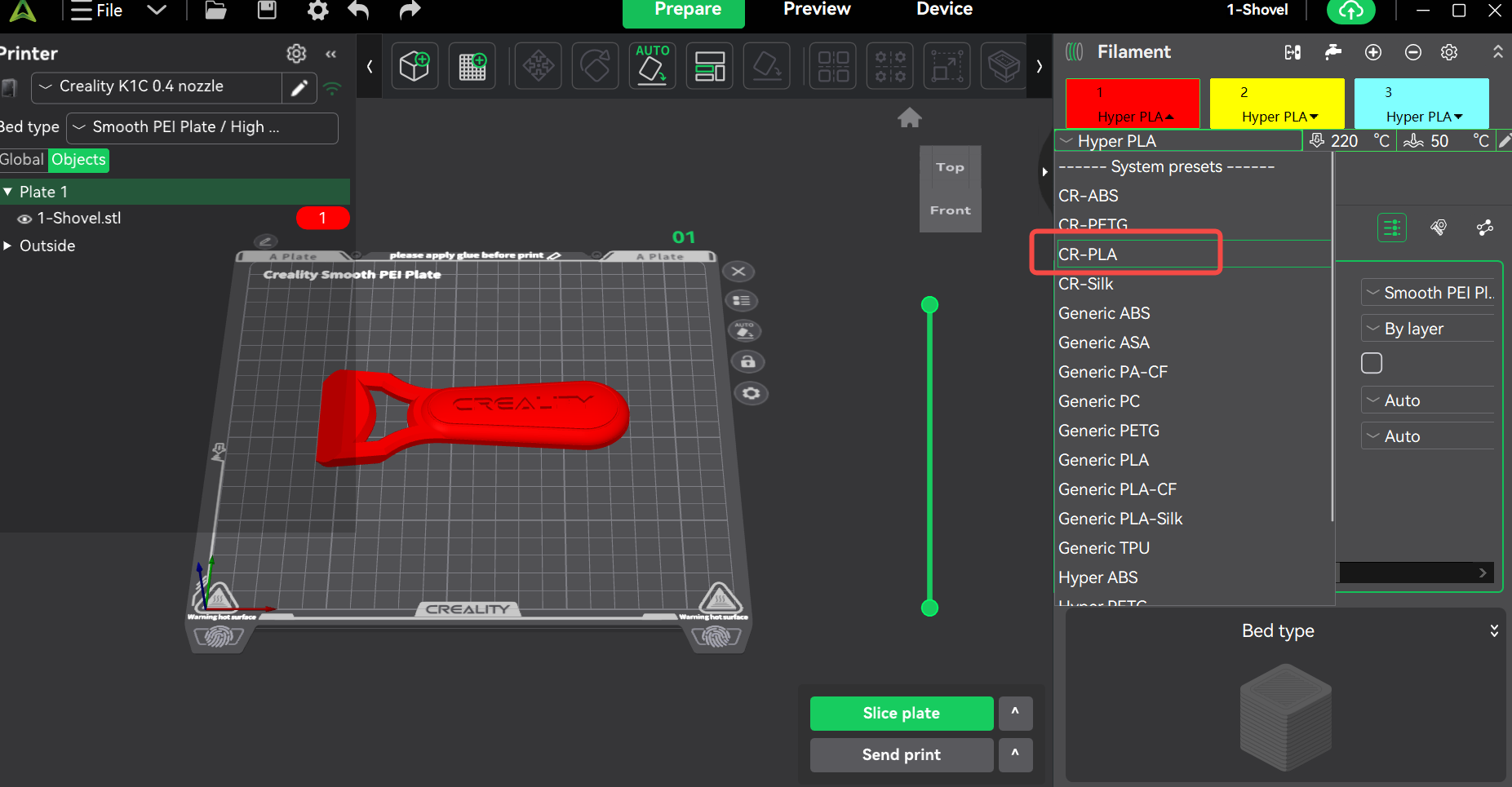

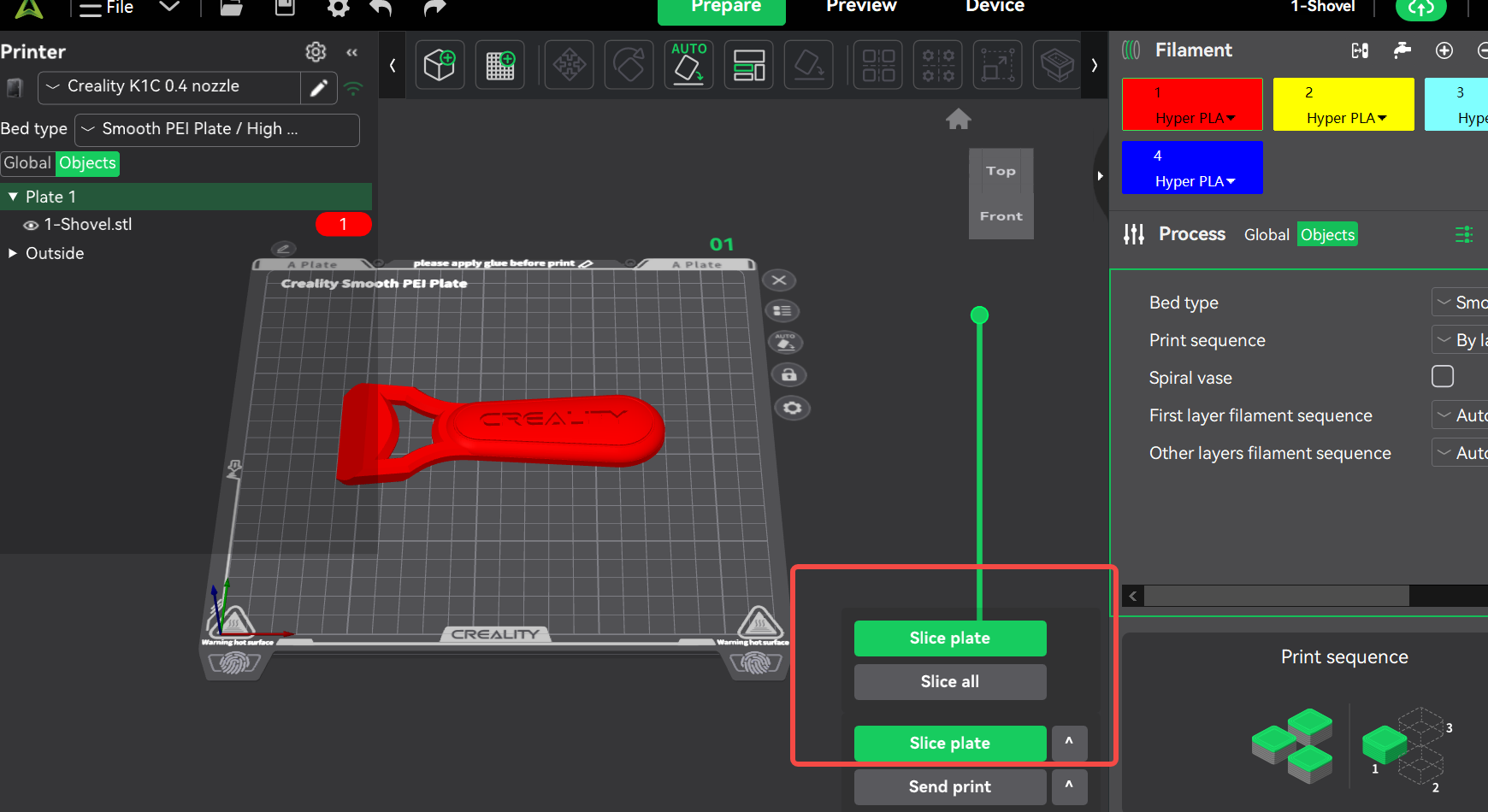

Select the filament you plan to use in the upper right corner, modify specific parameters as needed for the model. For simple regular models, you can click [Single Slice Plate] directly after selecting the filament

For example:

When using regular PLA, select Generic PLA on the right

When using official CR-PLA, select CR-PLA on the right

|

|

|

|

¶ Pre-printing Preparation

¶ Clean the platform plate

For dirty platform plate or hand sweat contamination; clean with detergent and water, or wipe with alcohol

For thick adhesive or multiple prints; clean the platform plate with water

¶ Ensure correct adhesive application

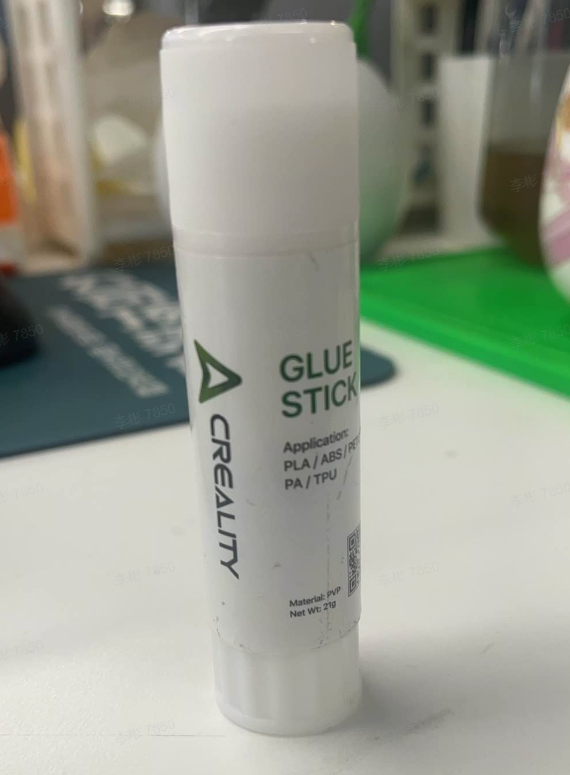

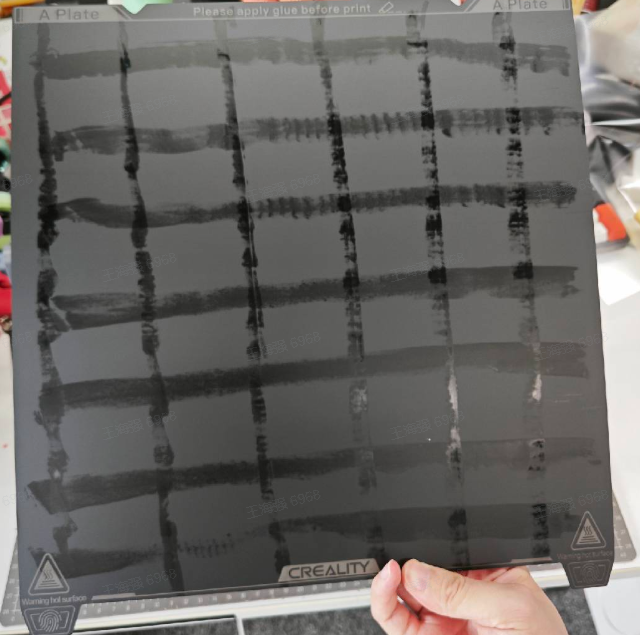

Use the correct glue, as shown below, Figure 1 shows the solid glue that comes with the machine

Apply a thin layer of solid glue on the plate (factory-supplied glue)

For example:

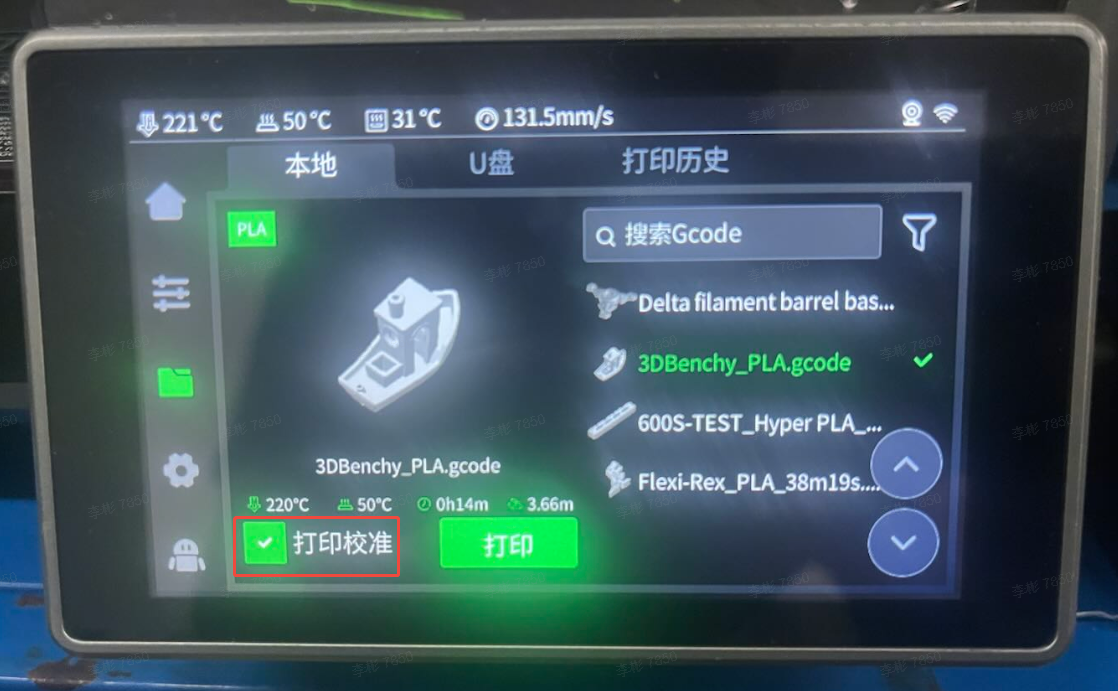

¶ Confirm whether to enable Print Calibration

Print calibration includes auto-leveling, flow calibration, and first layer detection (flow calibration/first layer detection disabled by default)

If unchecked, auto-leveling/flow calibration/first layer detection won't execute

When is Print Calibration necessary?

Print calibration must be checked in these situations:

- Different filament from last print, e.g., last print used PLA, this print uses ABS (different bed temperature, leveling data varies)

- Machine has been moved

- Just upgraded firmware

When is Print Calibration unnecessary?

- Repeat printing, last print was successful

- Small model printing in bed center

¶ During Printing

When printing ABS/ASA or engineering filaments, it's recommended to manually turn off the chamber fan.

¶ Official Recommended Filament Parameters

Use CrealityPrint Version 6.1 or above.

|

K1 Series Printer Filament General Parameter Table |

||||||

| Filament Name |

Nozzle Temp ℃ |

Hot Bed Temp ℃ |

Best Print Speed (0.2mm Layer Height) mm/s |

Maximum Volumetric Flow Rate mm³/s |

Model Fan | Side cooling Fan |

| Hyper PLA | 220 | 45 | 300 | 23 | 100% | 80% |

| CR-PLA | 230 | 45 | 150 | 20 | 100% | 80% |

| PLA-silk | 230 | 45 | 120 | 10 | 100% | 80% |

| Generic PLA | 230 | 45 | 200 | 18 | 100% | 80% |

| Generic PETG | 250 | 70 | 120 | 9 | 80% | 0% |

| Generic ABS | 260 | 100 | 250 | 20 | 70% | 0% |

| Generic TPU | 230 | 50 | 50 | 3.5 | 100% | 70% |

| CR-PLA Carbon | 220 | 45 | 150 | 11 | 100% | 0% |

| CR-PA Carbon | 250 | 100 | 120 | 10 | 80% | 0% |

| Generic ASA | 260 | 100 | 150 | 15 | 80% | 0% |

| Generic PC | 260 | 100 | 120 | 10 | 80% | 0% |

|

Note: 1. The maximum printing speed and temperature depend on filament properties. Please refer to the manufacturer's recommendations and official slicer software settings. 2. Before printing, it is recommended to evenly apply glue stick on the print platform to improve first layer adhesion. 3. Moisture-sensitive materials like PA/PA-CF/TPU should be dried before printing or kept dry during storage. 4. For non-official filaments, please select generic filament parameters in the slicer software. 5. It is recommended to use official high-speed filaments for better print quality. |

||||||

¶ Friendly reminder

If you still haven't resolved the issue after following the steps in this document, or if you encounter any difficulties during the process, you can click the right corner of the wiki page online support to contact our after-sales team for more help.