¶ 1. Phenomenon Description

¶ 1.1 Gear idling, no filament flowing from the nozzle.

¶ 1.2 Gears make a clanging noise while turning, and no filament flows from the nozzle.

¶ 2. Cause Analysis

¶ 2.1 Filament entanglement in the spool position.

¶ 2.2 Filament blockage at the front shell of the extruder kit.

¶ 2.3 Blocking at the Teflon tube of hotend.

¶ 2.4 The filament is clogged in the throat tube of hotend.

¶ 3.Troubleshooting and Solutions

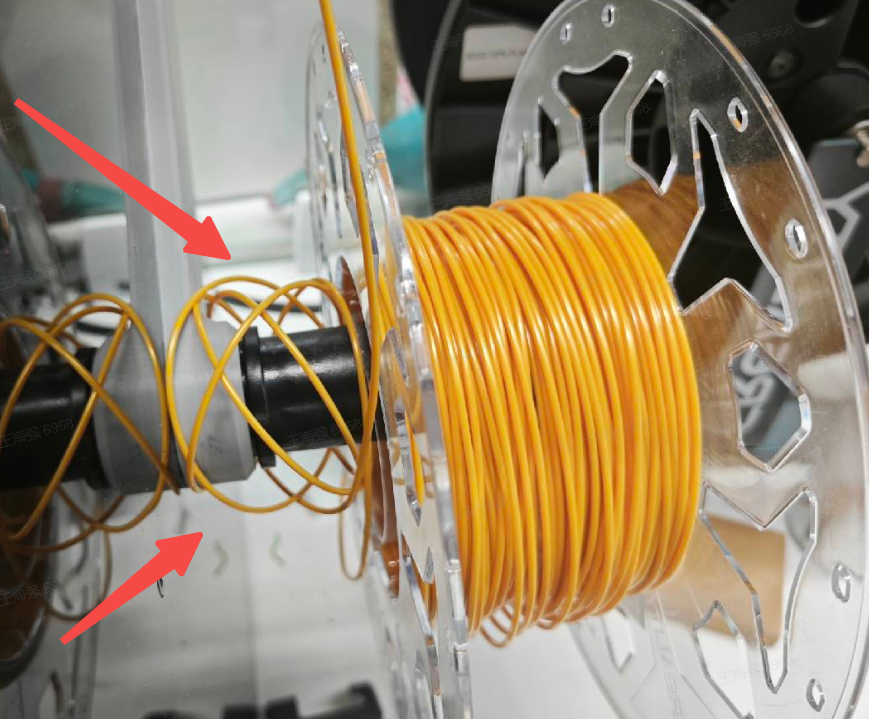

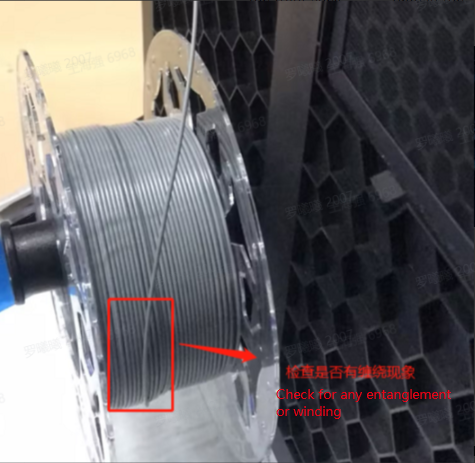

¶ 3.1 filament Entanglement Check and Handling

Check the backside of the machine for filament spool entanglement at the filament spool or PTFE tube inlet. If there's entanglement, carefully untangle the filament before attempting to print again.

If no filament entanglement is found, proceed to the next step.

¶ 3.2 Blockage/Tangling Troubleshooting

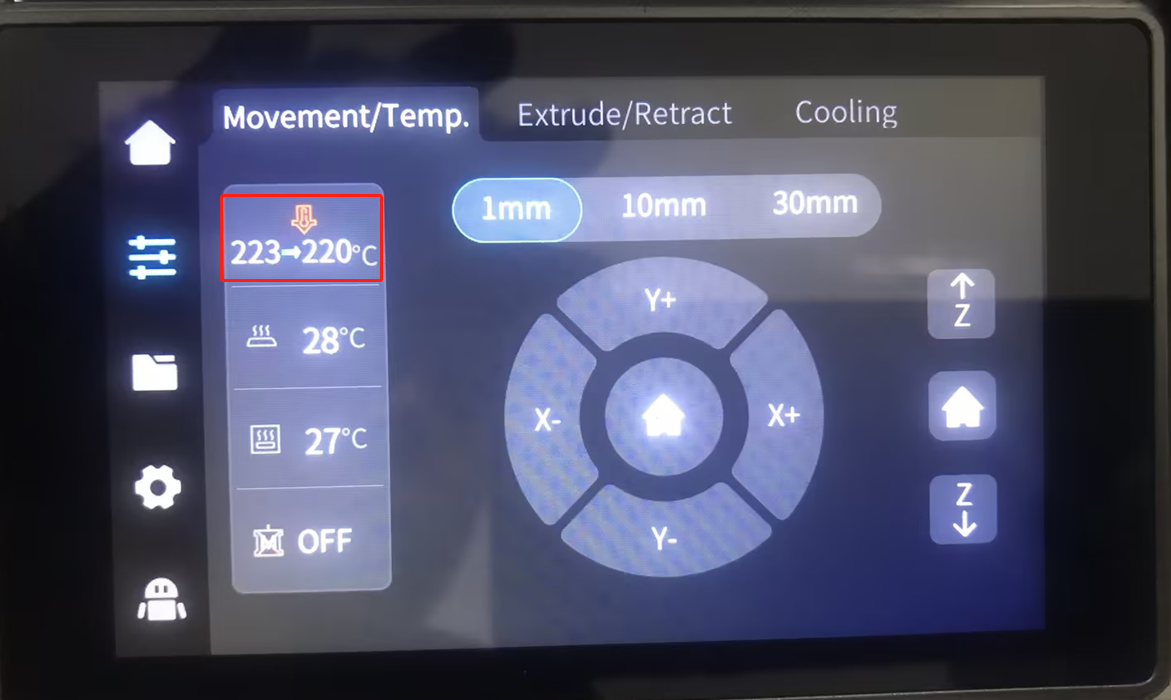

STEP 1: enter the control interface, click "OFF" to release the motor.

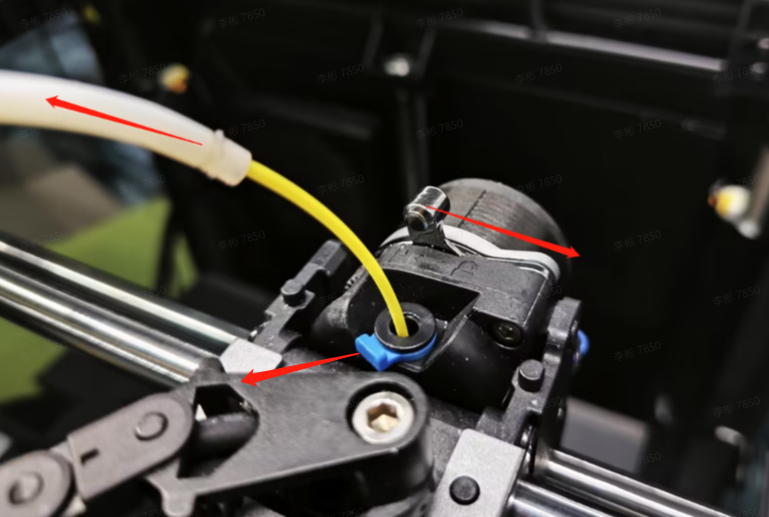

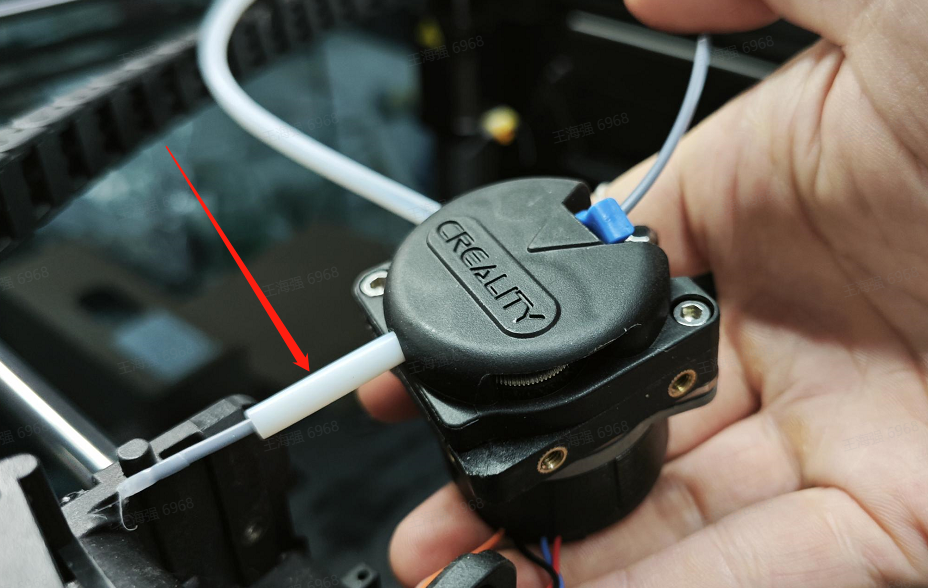

STEP 2: Remove the blue locking clip and gently pull out the PTFE tube from the top of the extruder, exposing the material. Set the nozzle temperature to the recommended printing temperature and wait for termperature to stabilize.

STEP 3:Set the nozzle temperature to the recommended printing temperature and wait for termpaerature to stabilize.

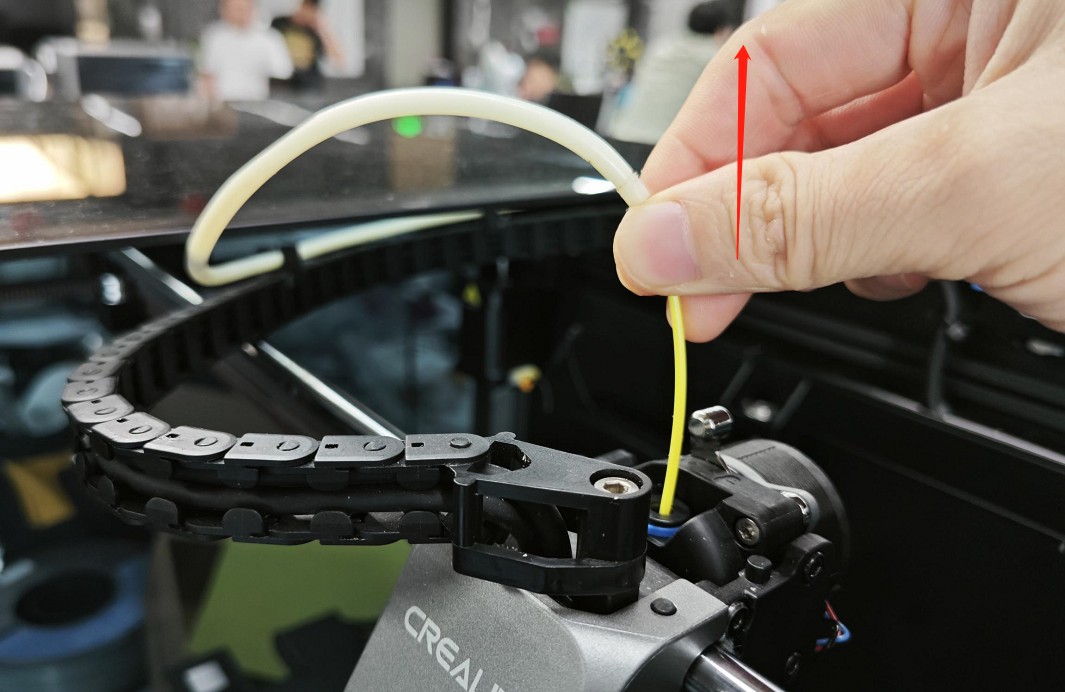

STEP 4:Use some force to quickly pull out the filament by hand.

¶ 3.2.1 If the filament Can Be Pulled Out

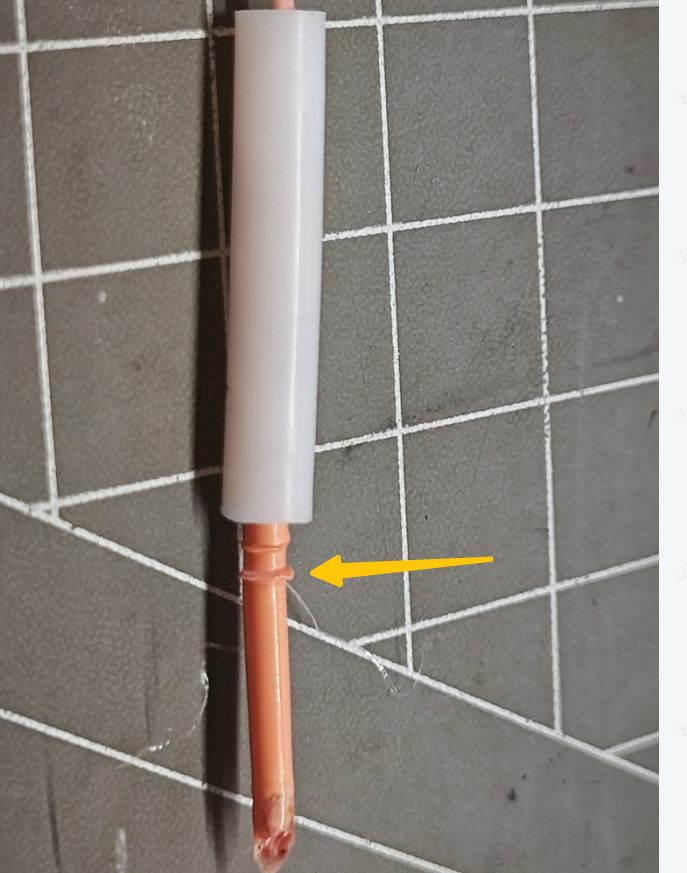

Check the end of the filaments for any umbrella-shaped protrusion. If there is a protrusion, replace the PTFE tube.

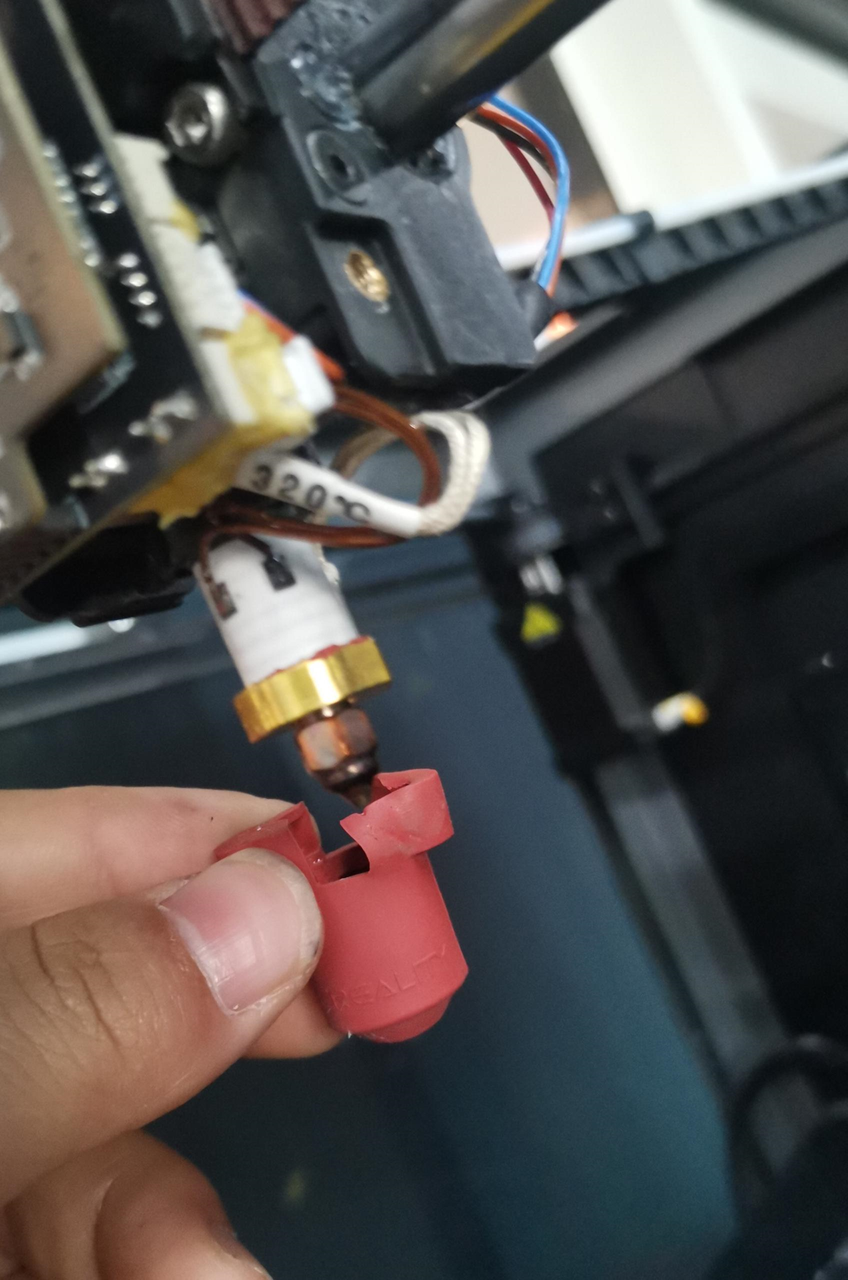

After removing the PTFE tube, it was found that the filament had a mushroom-shaped protrusion at the end

¶ 3.2.1.1 If the filament Can Be Inserted into the Hotend

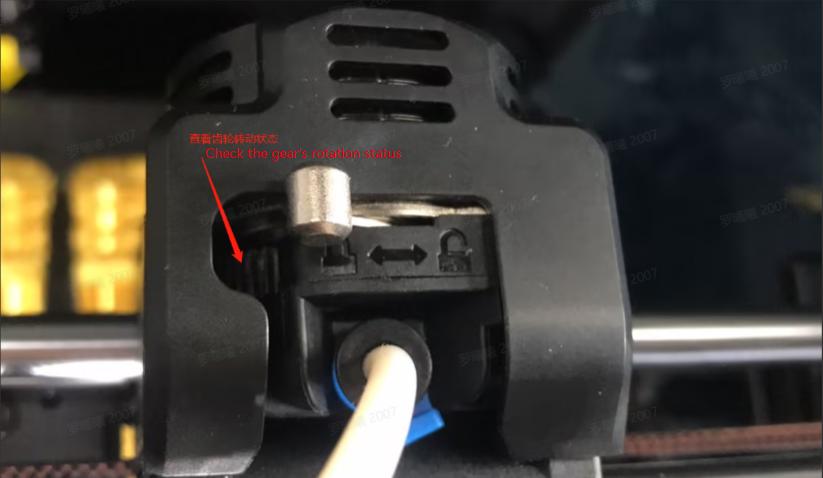

① If filament insertion is successful, and the extrusion is working properly, turn the extruder handle to the closed position and select "Auto Feed." Check the filament extrusion and monitor the rotation status of the extruder gears. If automatic extrusion works without issues, the problem is resolved.

② If the extruder gears do not rotate during automatic extrusion, the problem might be related to the extruder motor (or a connection board issue). Inspect the extruder motor's wire connections to ensure they are secure. If necessary, consider replacing the extruder motor to further troubleshoot the problem.

③ If the extruder gears are functioning correctly, but you notice a slight clicking sound in the gear area and uneven filament extrusion at the nozzle, you should analyze two potential sources of the issue:

a. If the extruder gears are operating normally without any unusual noises, but the nozzle still experiences uneven extrusion, replace a new one,proceed with Replace K1 Max Nozzle

b. If the extruder gears are not functioning properly, follow the troubleshooting steps for the extruder assembly to solve the issue.

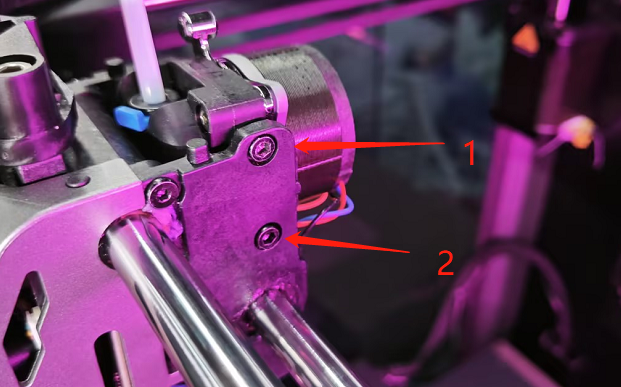

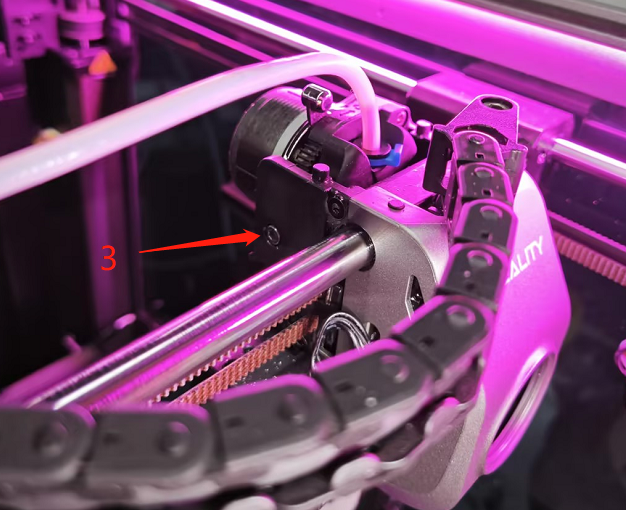

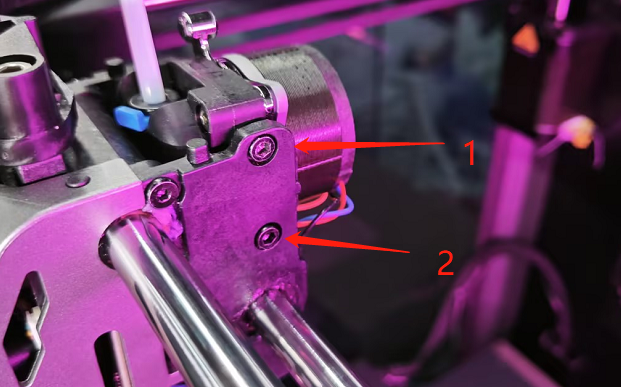

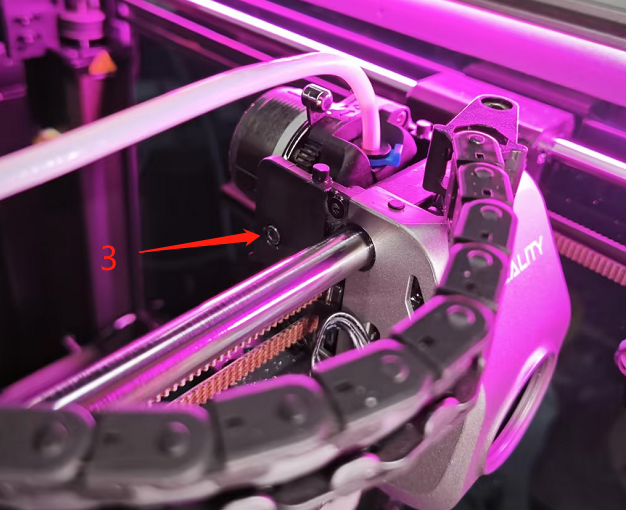

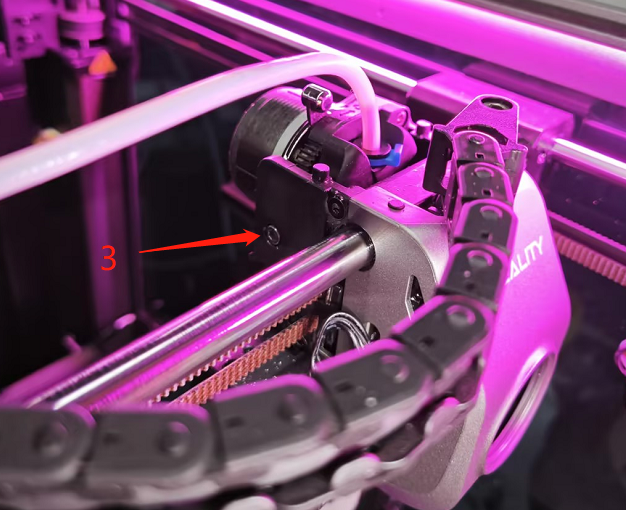

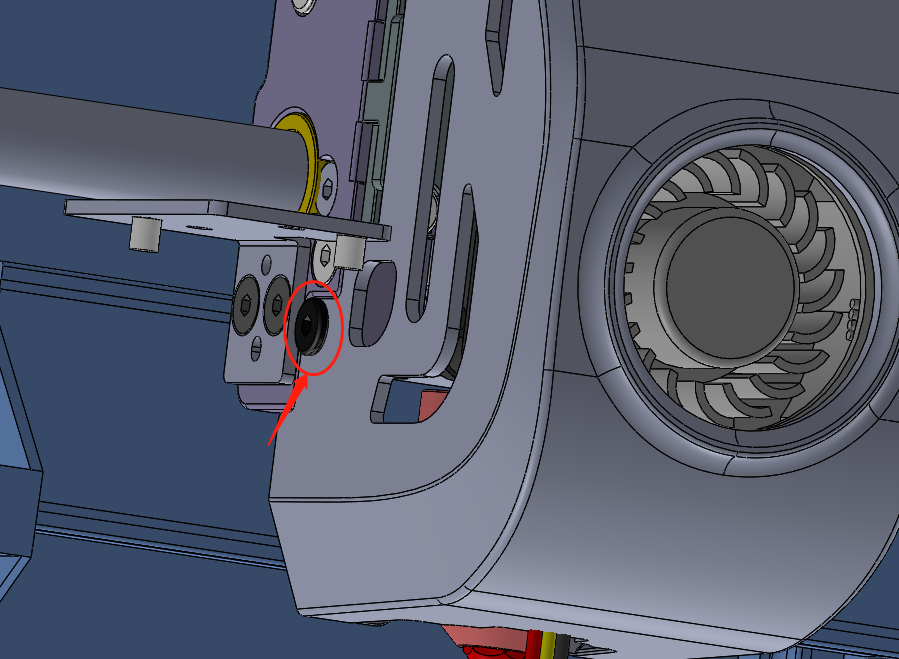

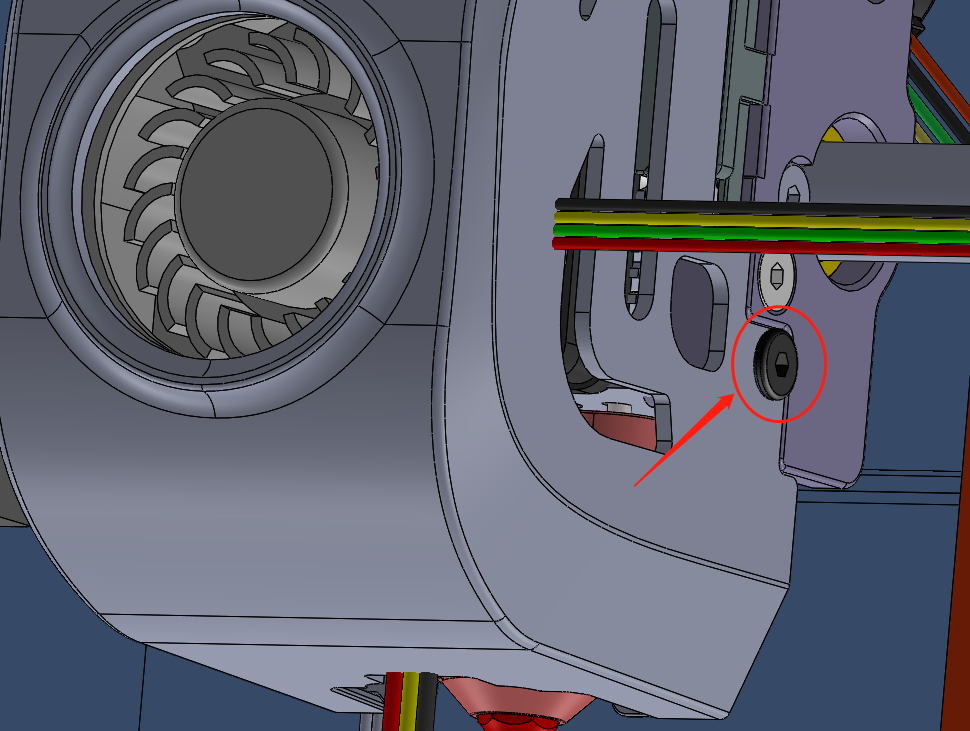

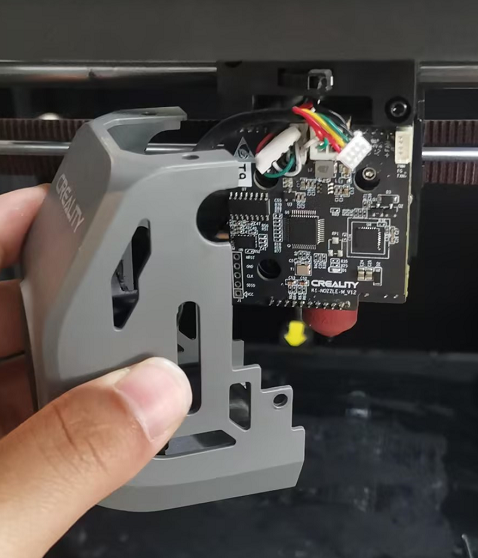

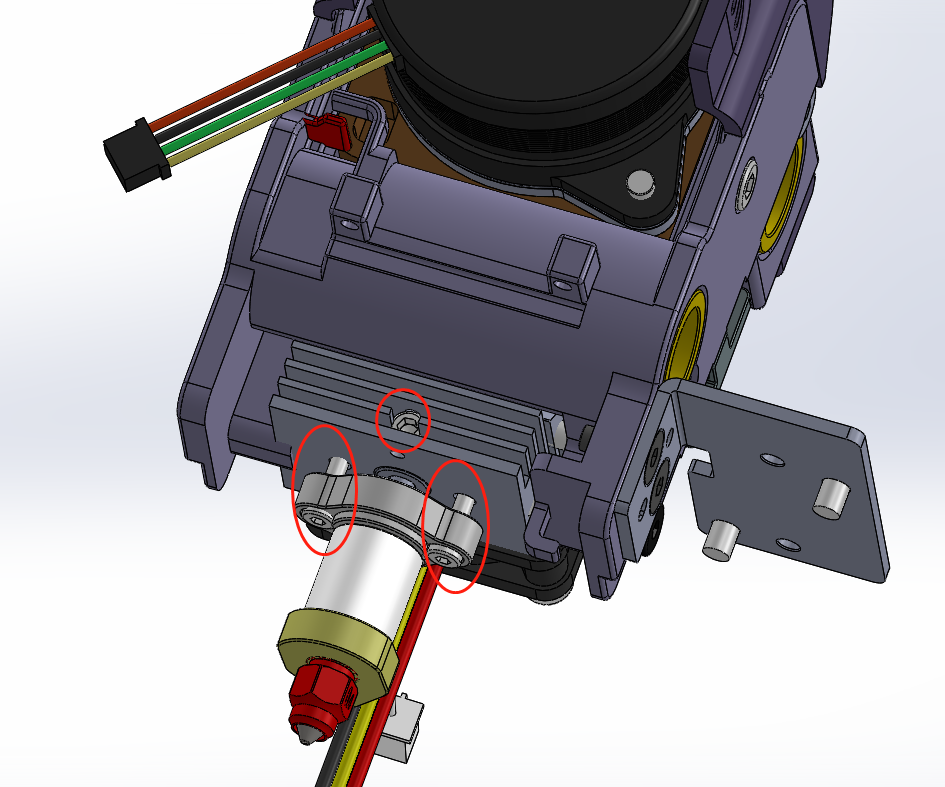

STEP1: Remove the extruder motor protective cover. Using the tools provided in the kit, carefully disassemble the 3 cylindrical head screws that secure the extruder assembly on both sides of the extrusion machine. Support the extrusion assembly from below and gently lift it upwards (be cautious not to lift it abruptly to avoid damaging the extrusion machine wiring).

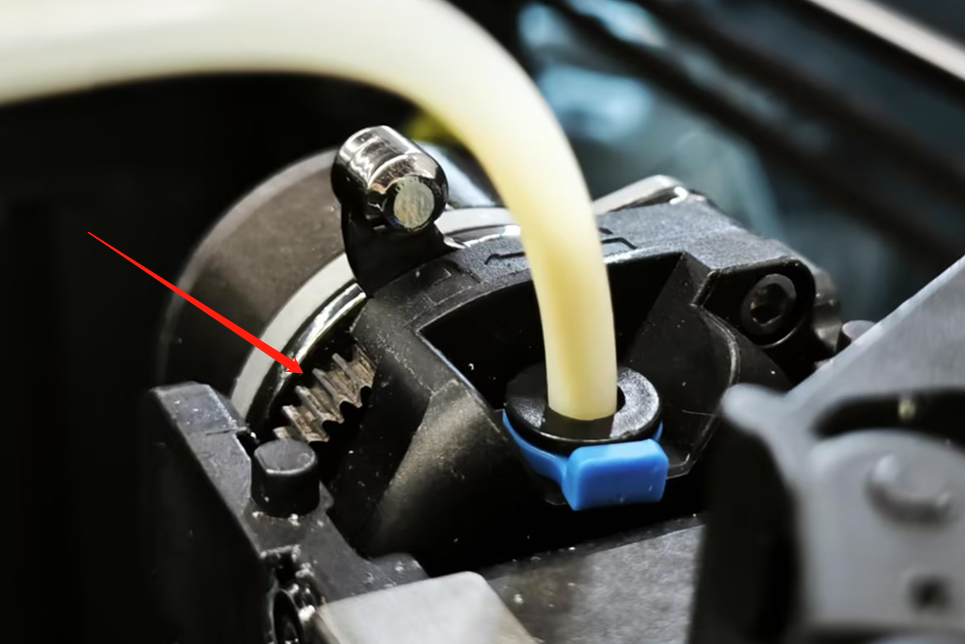

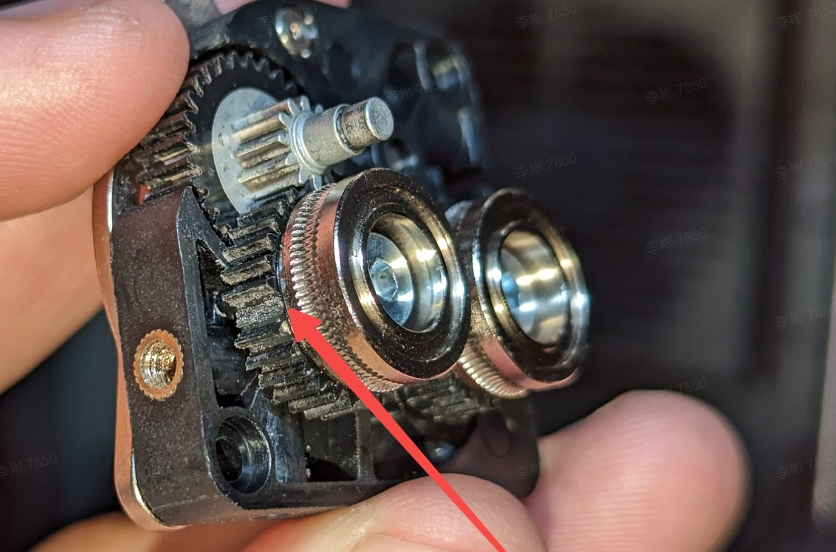

STEP2: Using the included float spanner from the tool kit, disassemble the two diagonal cylindrical head screws that secure the extrusion kit assembly's front cover. Open the extrusion kit front cover and inspect whether there are any residual filament debris on the extruder motor gear. Check if the gear is damaged or deformed. If it's damaged or deformed, proceed to replace the K1 Max extrusion kit assembly.

STEP3: If there is a substantial amount of filament debris on the extrusion gear, use a soft brush to clean the debris from the gear. After cleaning, replace the extrusion kit's front cover and reassemble the extrusion assembly screws on the X-axis slide block mounting position. Tighten the three fixing screws on both the left and right sides.

STEP4: Repeat the automatic feeding operation. Observe the extrusion of the filamentat the nozzle. If the extrusion is normal and the extrusion gear operates smoothly without any unusual noises, the no-filament issue has been resolved.

¶ 3.2.1.2 If the filament cannot be inserted into the hot end

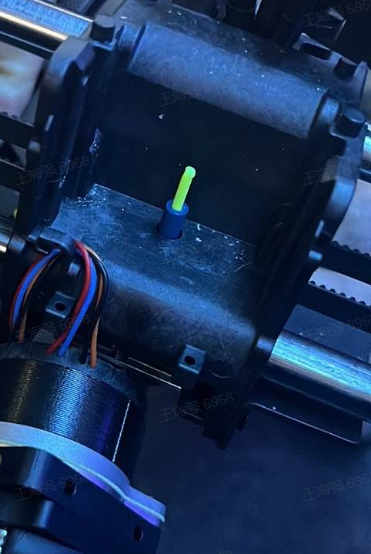

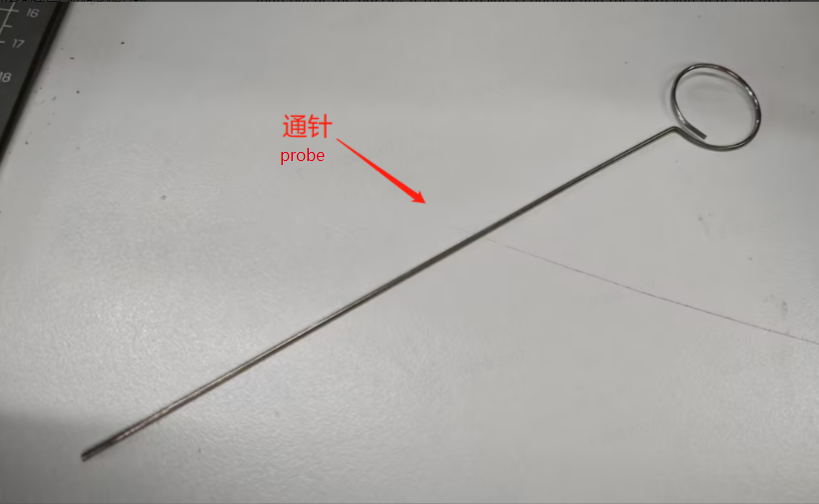

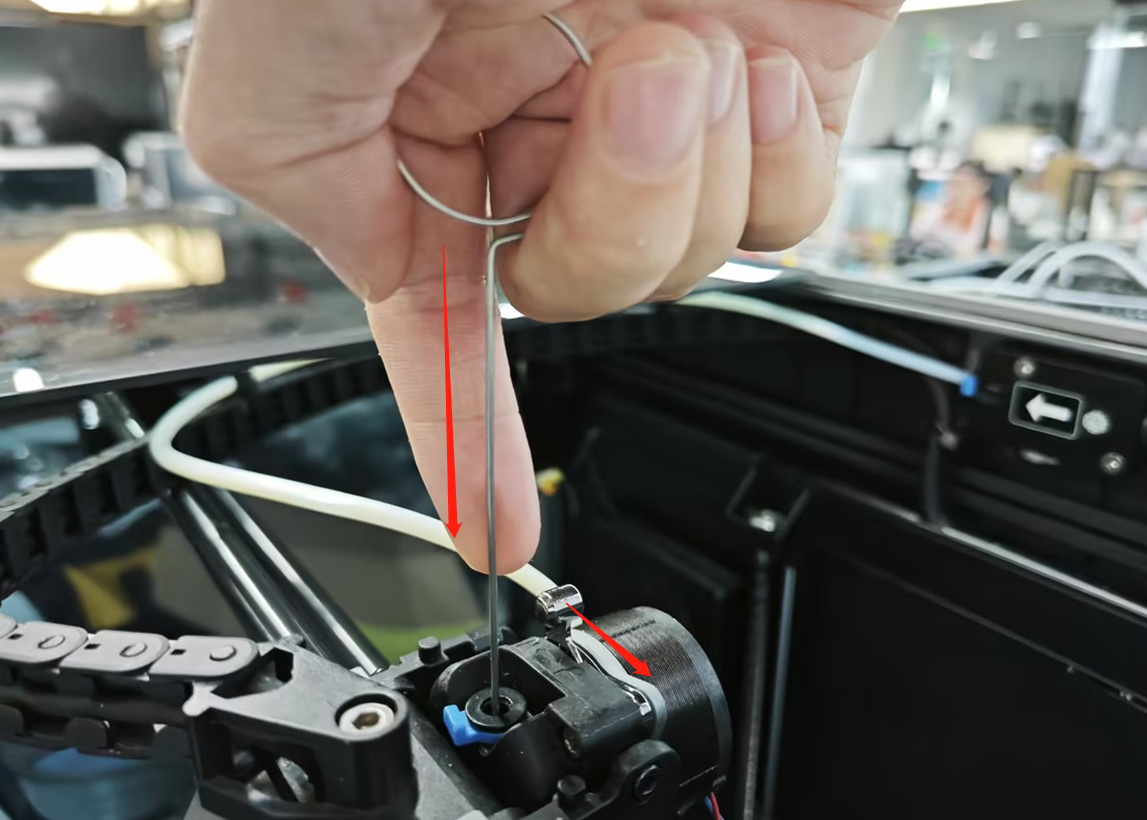

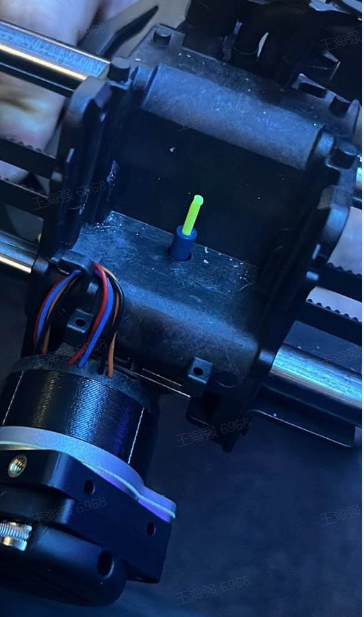

Quickly remove the filament, and use the included probe from the tool kit to push any remaining filament debris in the extrusion channel towards the hotend:

Open the extrusion switch and insert from top to bottom

a. If the remaining filament debris in the extrusion channel is pushed completely out through the nozzle and out of the extruder, retract the probe quickly. This prevents the molten filament adhering to the inner wall of the throat tube and extrusion gear. Repeat this process to resolve the no-filament issue.

b. If the remaining filament debris in the extrusion channel can not be pushed through with the probe, the issue may be a hotend clog. Proceed with the clog resolution process.

c. If you cannot retract the filament, it might be a front cover clog. Refer to the front cover clog/filament jam process.

¶ 3.3 Front cover Clog/Filament Jam Resolution Process (Revised based on existing tutorials)

¶ 3.3.1 How to determine if it's a filament jam:

Heat the nozzle to the extrusion temperature. Unlock the extrusion kit. Try to manually retract the filament by hand or pull it out from the extrusion gear area (pull it from the nearest extrusion end).

¶ 3.3.2 How to prevent filament jams:

① Re-level the build platform.

② Do not turn off the enclosure fan.

③ Use official slicer settings, avoid setting the bed temperature too high (do not exceed 50°C for PLA, 70°C for PETG), and ensure the nozzle temperature is not too low.

¶ 3.3.3 filament Jam Resolution

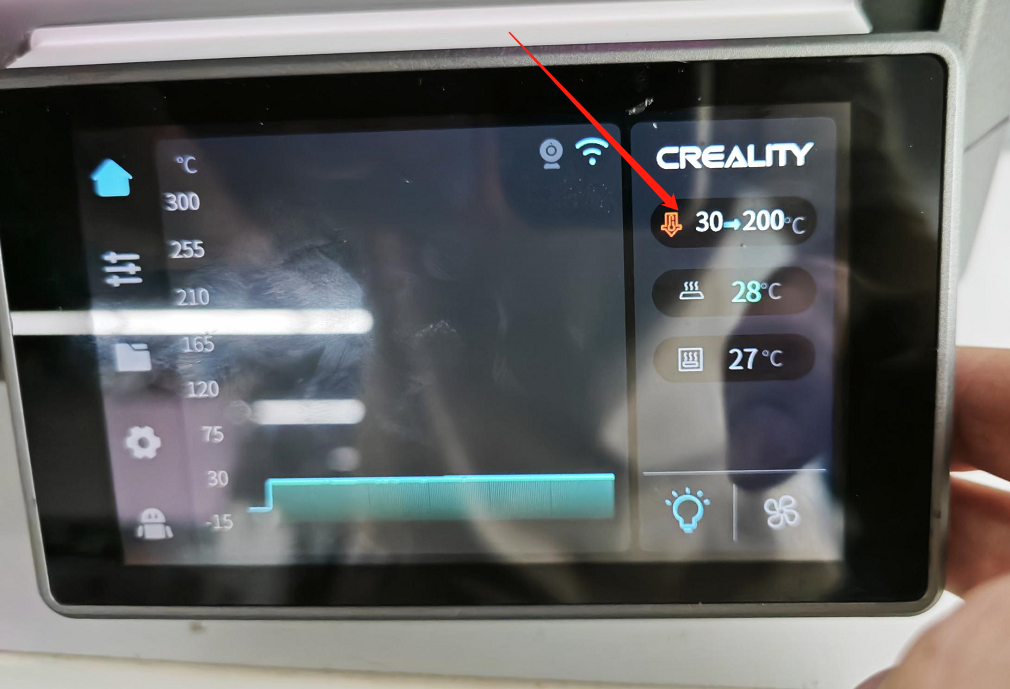

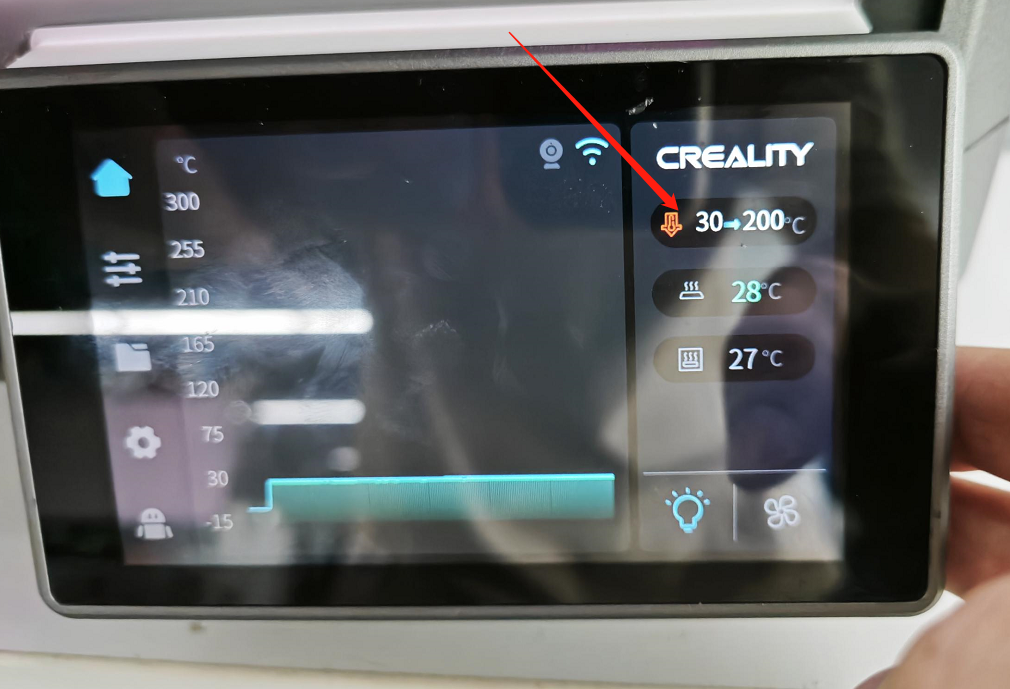

STEP1: Heat up the nozzle to the filament extrusion temperature,PLA 200 ℃,ABS 240℃.

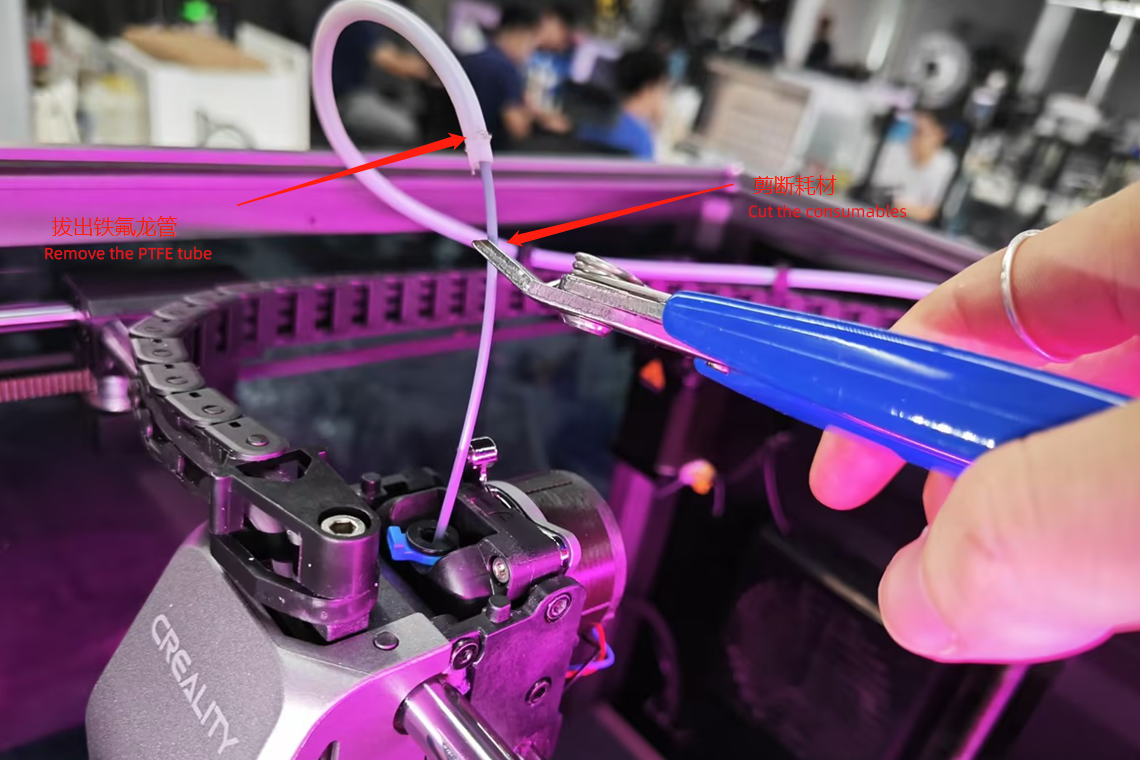

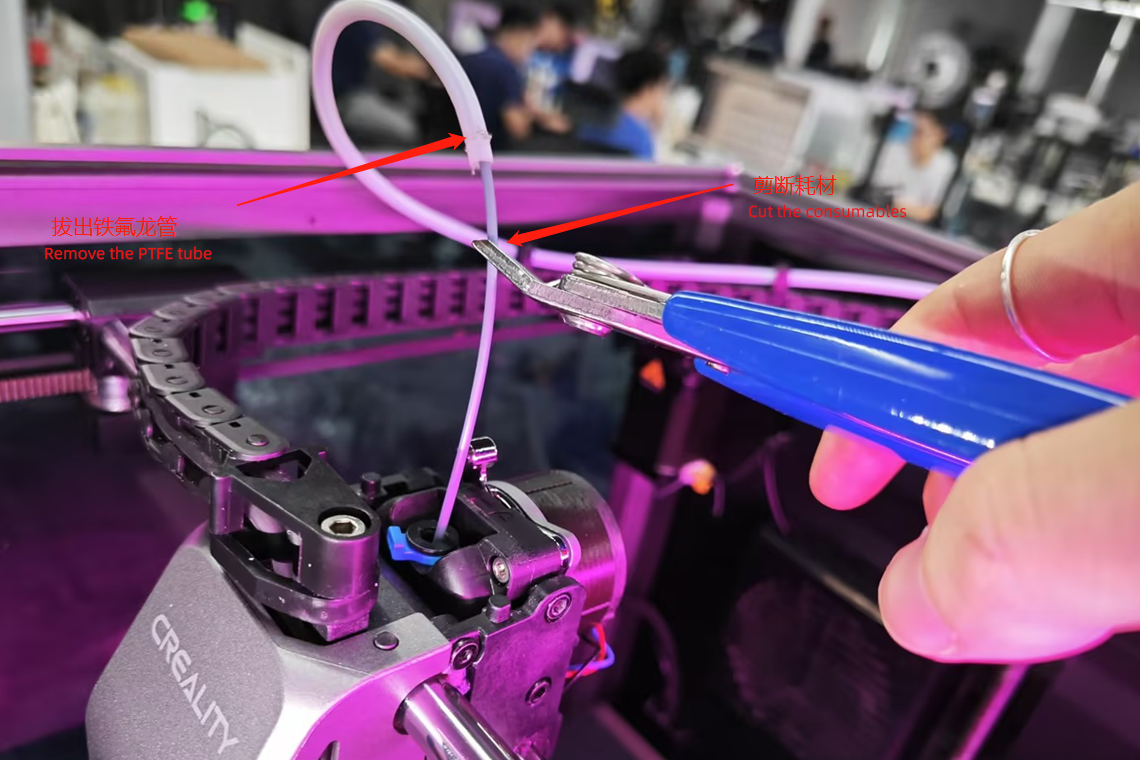

STEP2: Unlock the extruder kit, remove the PTFE tube, and cut the filament.

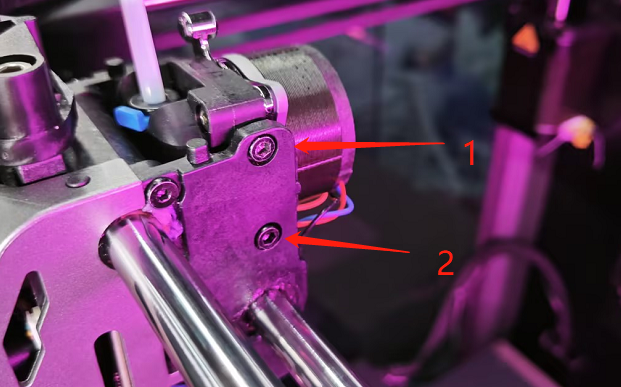

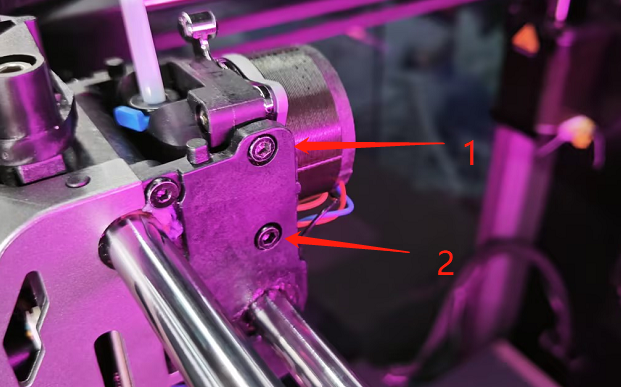

STEP3: Disassemble the three screws from the extrusion kit.

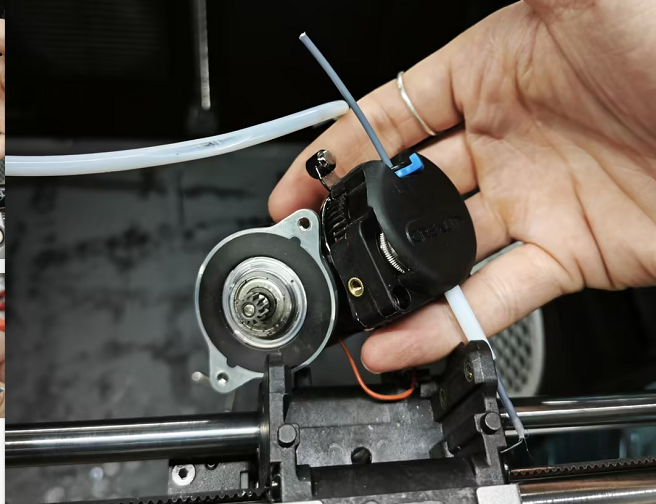

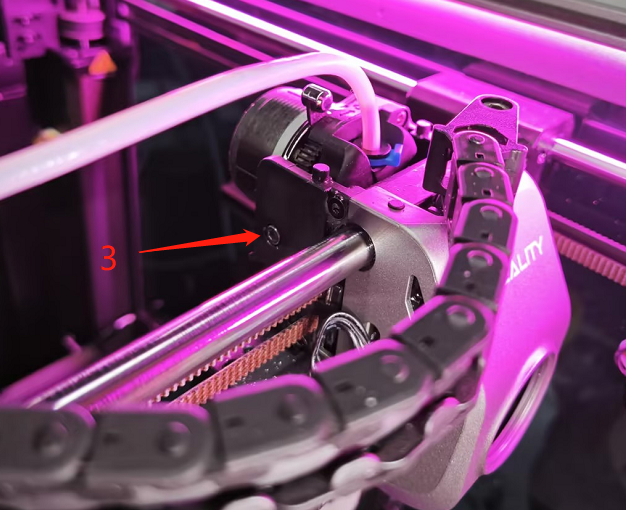

STEP4: Remove the extrusion assembly (avoid pulling on the stepper motor wires).

STEP5: Remove the two screws securing the extrusion kit front cover.

Important: Set the nozzle temperature to 0°C after removal.

STEP6: Separate the motor and the extrusion gear part, place the motor on the X-axis bracket temporarily.

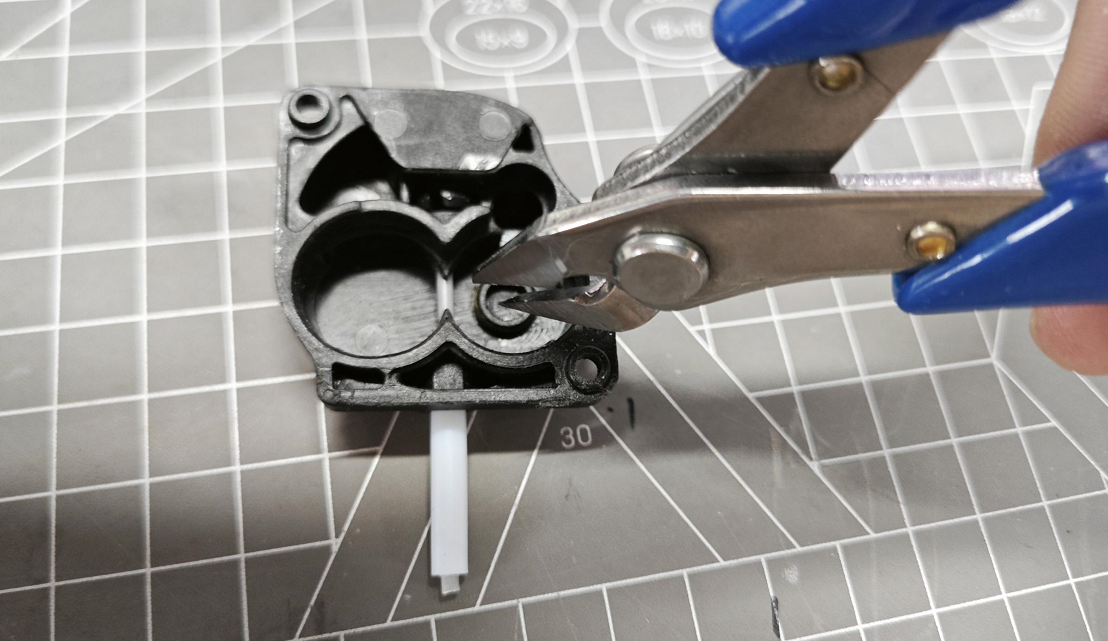

STEP7: Separate the extrusion gear assembly from the front cover (in case the filamentis jammed in the extrusion and cannot be removed). You can use tools like a spatula or pliers.

STEP8: Handle the jammed filament inside the front cover.

If the filamentis jammed inside the PTFE tube, you can use a probe or an L-shaped wrench to push the filamentout.

STEP9: Reassemble following the disassembly steps.

¶ 3.3.4 Clog Resolution

STEP1: Heat up the nozzle to the filament extrusion temperature.

STEP2: Unlock the extruder, remove the PTFE tube, and cut the filament.

STEP3: Disassemble the three screws from the extrusion kit.

STEP4: Remove the extrusion kit, and if there's a clog that prevents filament removal, and the filament is stuck, you cannot pull it out.

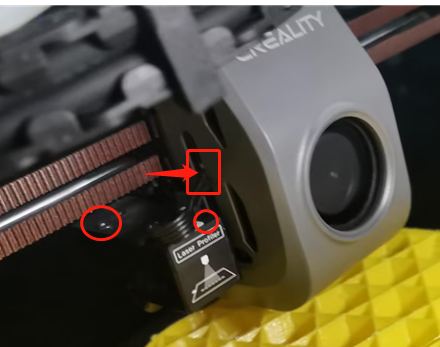

STEP5: Disassemble the AI laser Lidar and the front cover of the extrusion kit.

① Disconnect the transmission cable on the left side of the nozzle board and remove the two screws above the AI laser lidar and the screws on both sides of the nozzle cover by using a hex wrench.

② Remove the hotend cover and disconnect the model fan cable.

STEP6: Disassemble the hotend.

① Turn off the printer's power or set the nozzle temperature to 0°C before proceeding.

② Cool the hot end temperature to room temperature, remove the insulating sleeve that covers the hot end, and use a hex wrench to remove the top screw that secures the throat tube and the two cylindrical head screws that secure the hotend from the center of the heat sink.

③ Remove the connector for the heating element and the thermistor on the back of the nozzle board, and remove the hot end.

STEP7: Handle the clogged filament.

STEP8: Reassemble.