¶ Exploded Diagram of Hotend Kit

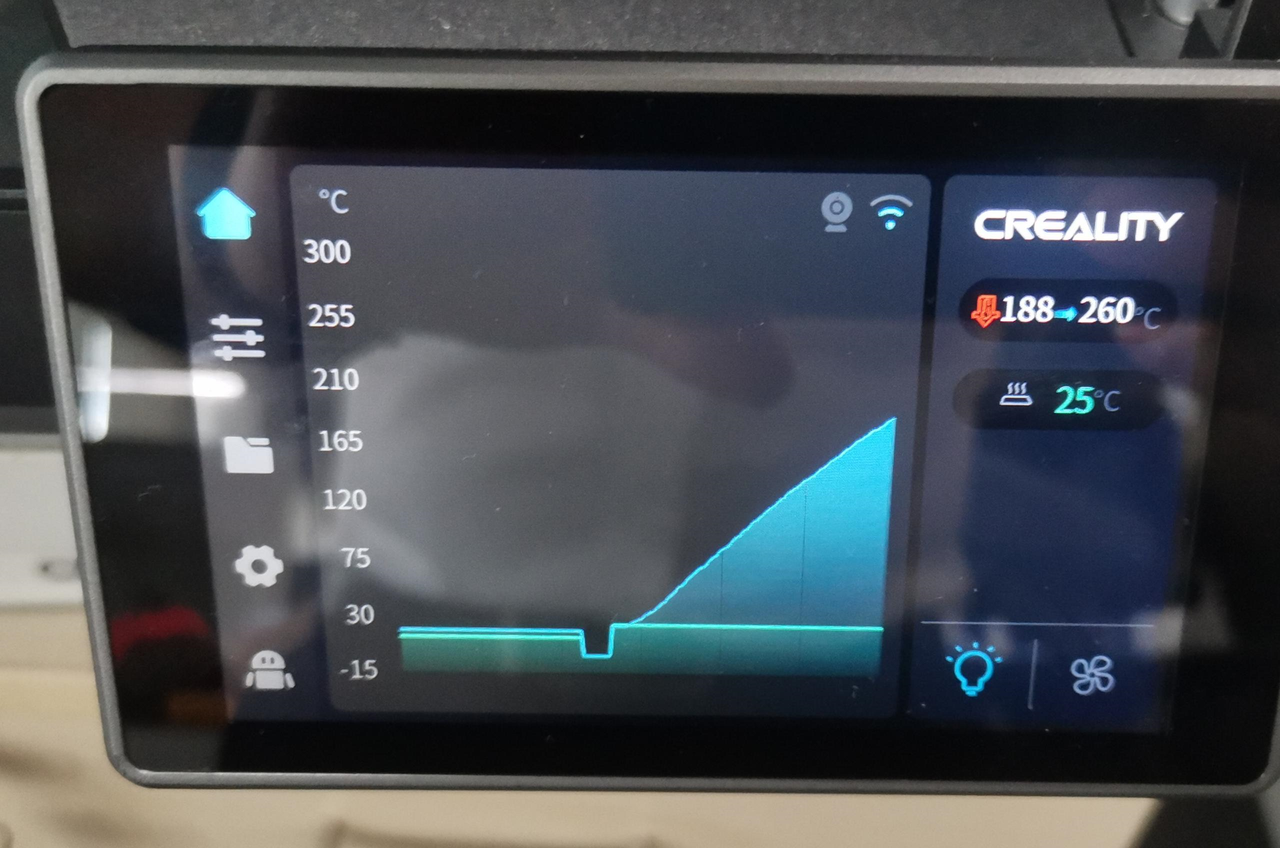

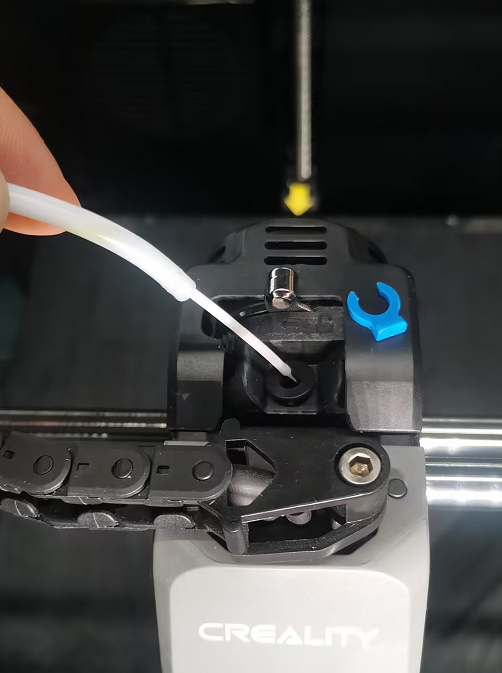

¶ 1. Remove the filament and power off the machine.

¶ 1.1 Set the nozzle temperature to 260°C, remove the blue clip on the extruder, press the latch to extract the PTFE tube, switch on the extruder kit, and remove the filament.

¶ 1.2 Power off or set the nozzle temperature to 0°C.

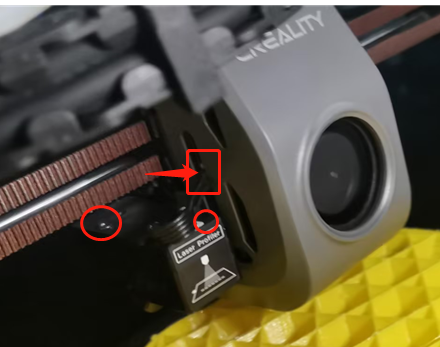

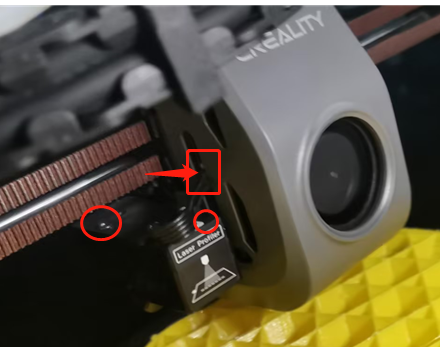

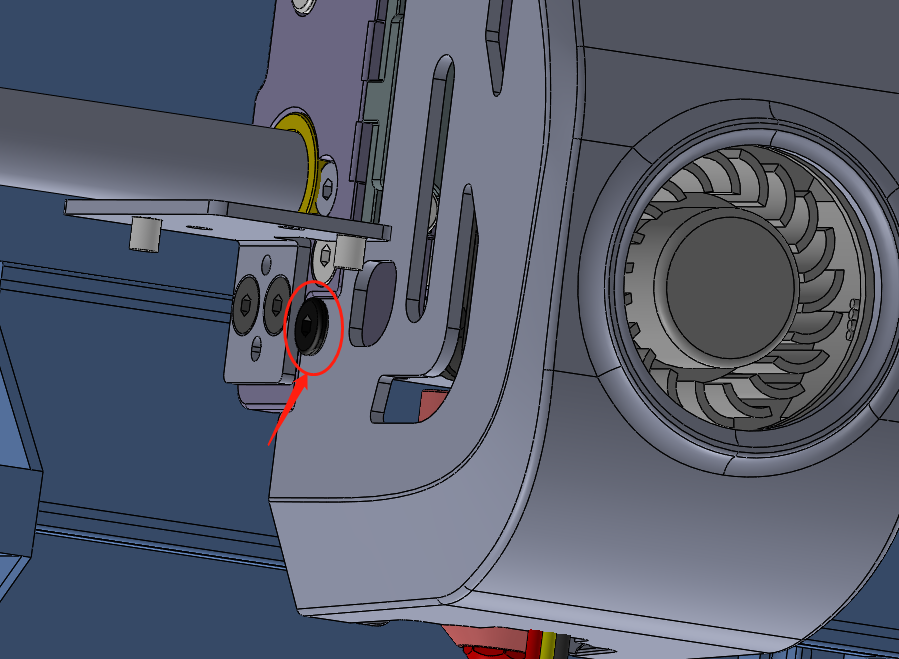

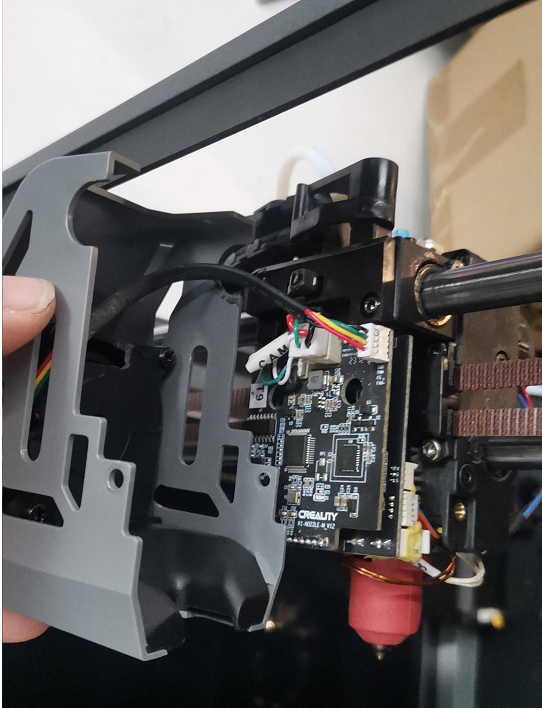

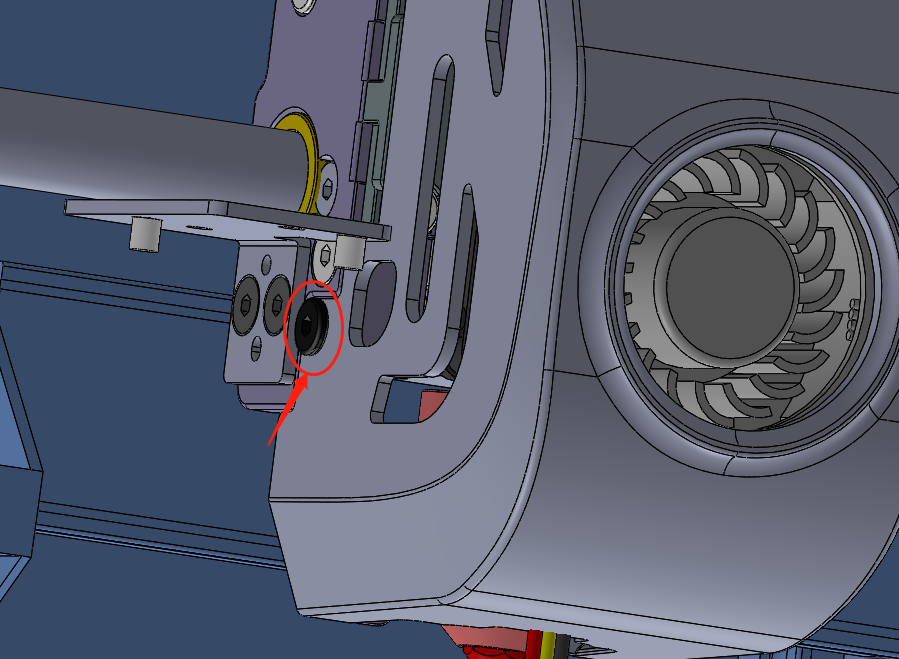

¶ 2. Disassemble the AI Lidar

Disconnect the transfer cable terminal on the left side of the nozzle sub-board and, use an Allen wrench to remove the two fixing screws above the AI Lidar.

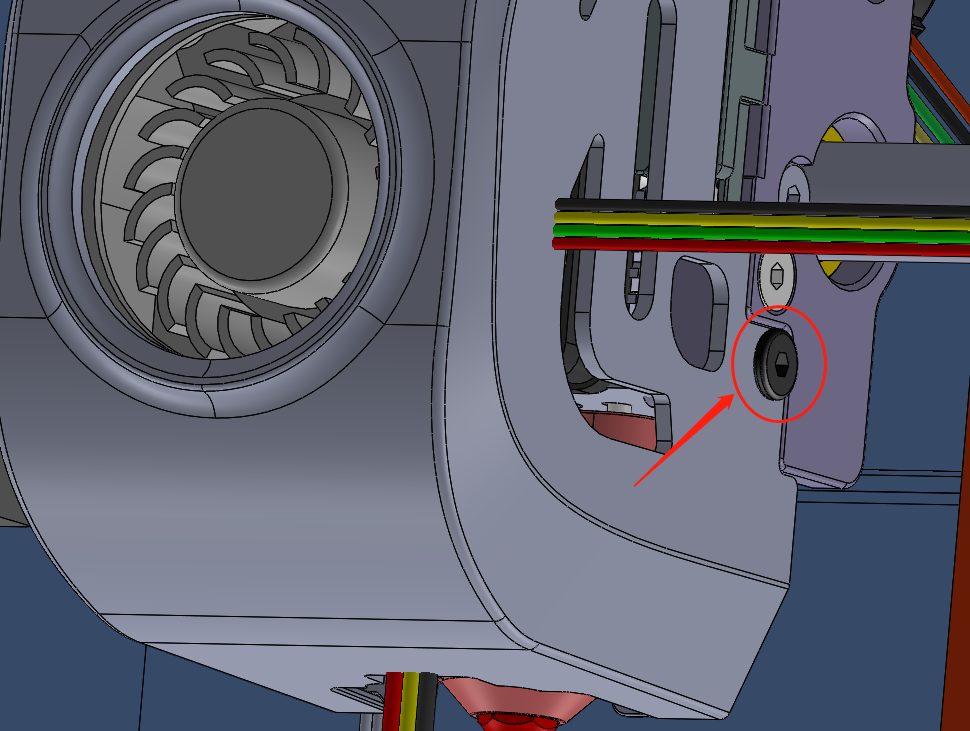

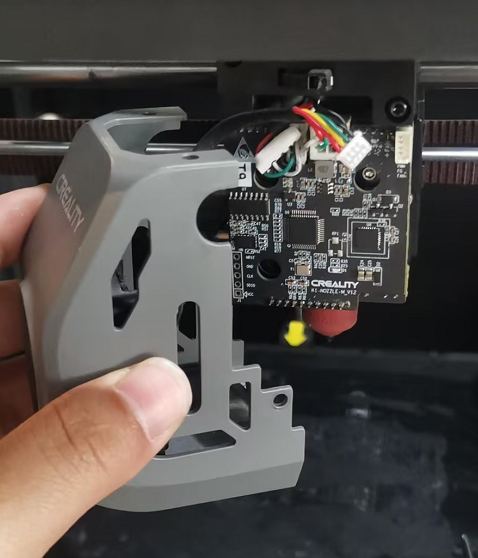

¶ 3. Disassemble the Fan Cover

¶ 3.1 Remove the fixing screws on both sides of the fan cover.

¶ 3.2 Take off the fan cover and unplug the cooling fan cable connector.

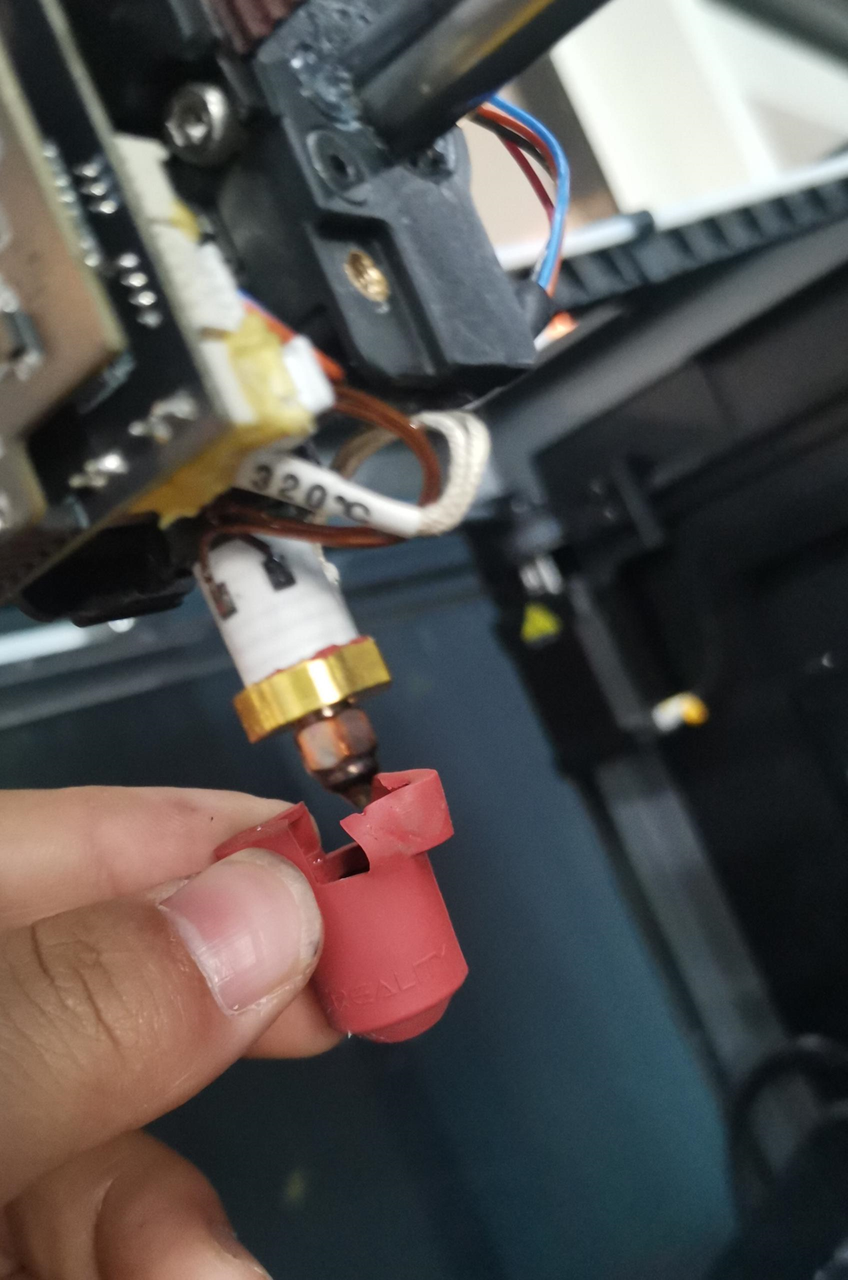

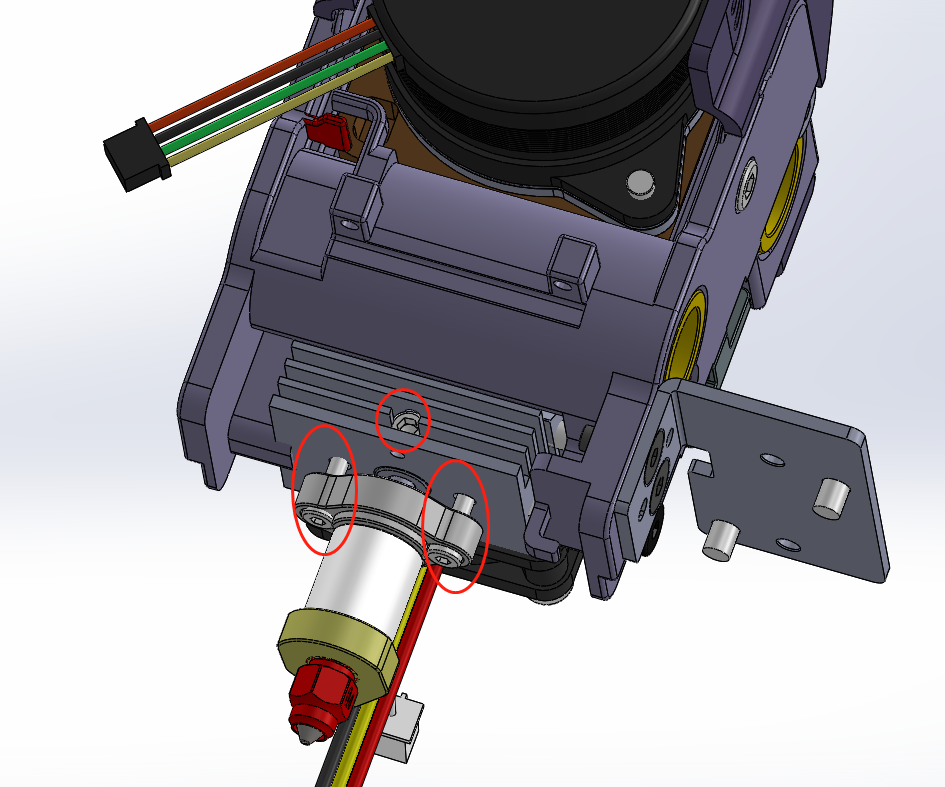

¶ 4. Disassemble the Hotend

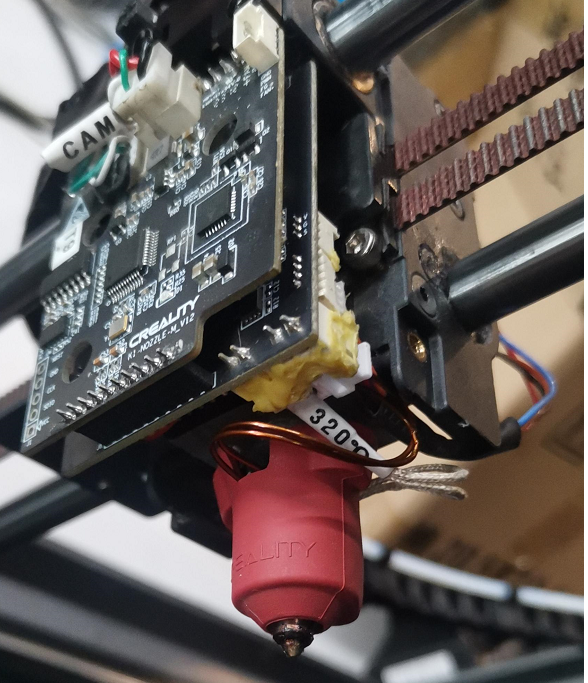

¶ 4.1 Cool the hotend temperature down to room temperature, remove the silicone sleeve surrounding the hotend.

¶ 4.2 Use an Allen wrench to disassemble the screw in the center of the heat sink and the two screws on the hotend.

¶ 4.3 Unplug the heater cable connectors and the thermistor cable behind the nozzle sub-board and remove the hotend.

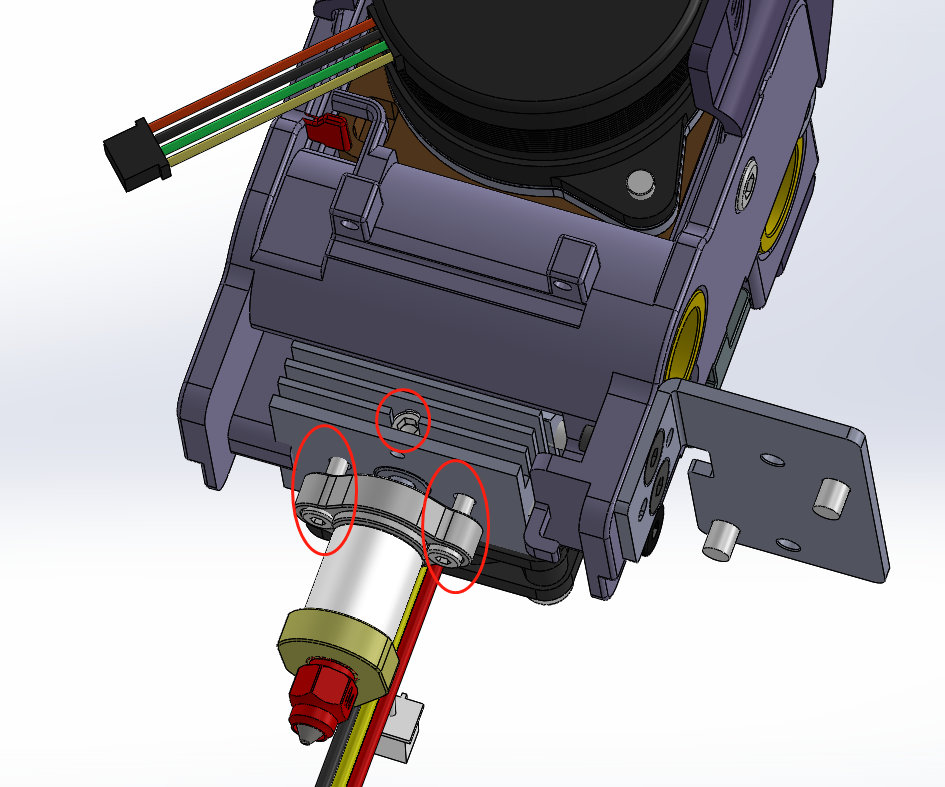

¶ 5. Install a New Hotend

¶ 5.1 Add appropriate thermal grease to the upper end of the throat tube, and insert the throat tube into the mounting hole of the heat sink.

¶ 5.2 Turn the heating tube wire towards the front of the machine, then insert the connectors of the heating tube wire and thermistor into the corresponding terminal ports on the sub-board.

¶ 5.3 Secure the hotend by tightening the hotend fixing screws and the upper screw of the throat tube. During the tightening process, ensure that the hotend is installed vertically, and that the mounting screws on both sides of the hotend bracket are equal in force.

¶ 5.4 Align the silicone sleeve with the nozzle and slide it over the hotend, ensuring that the silicone sleeve completely covers the hotend.

¶ 6. Reassemble the Extruder fan cover

Pick up the fan cover, insert the model cooling fan connector into the corresponding terminal port on the front of the nozzle sub-board, fasten the fan cover, and tighten the two screws on the left and right sides of the fan cover.

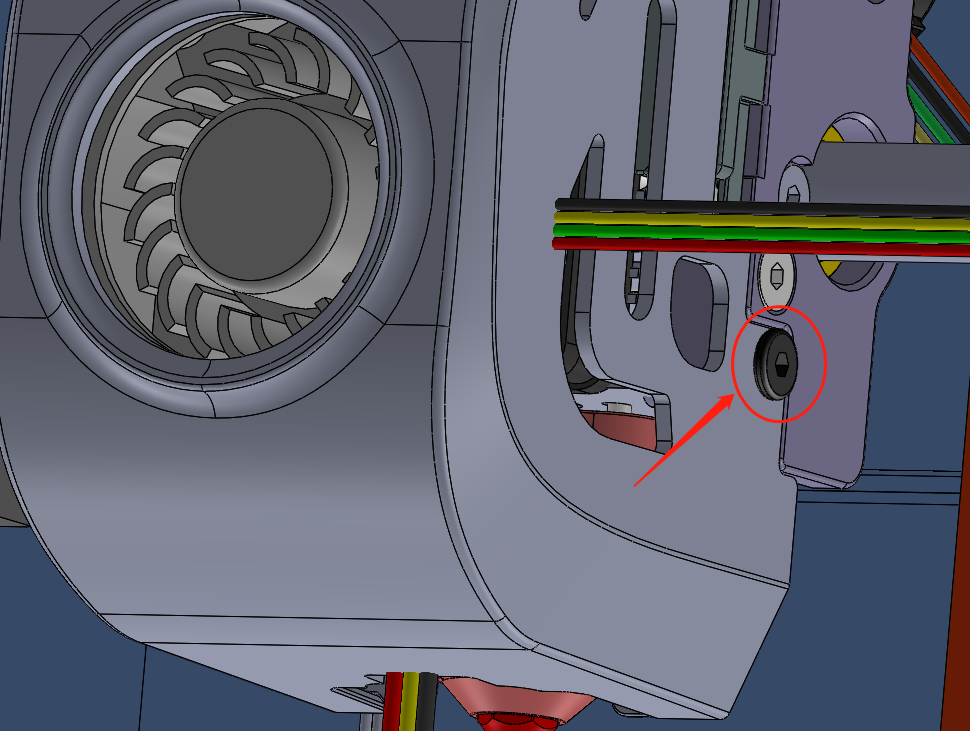

¶ 7. Reassemble the AI Lidar

Insert the connectors for the AI Lidar connection cable into the corresponding mounting port on the nozzle sub-board, then insert the alignment posts at the top of the module into the alignment holes on the mounting bracket and secure them with the two screws.