¶ 1. Phenomenon Description

The first printed layer shows partial scraping of the platform or partial height exceeding in some areas, leading to inconsistent appearances across different parts of the first layer model.

¶ 2. Cause Analysis

2.1 Unleveled after firmware upgrade

2.2 Environmental interference during leveling

2.3 Unusual pulling of heated bed wiring during leveling

2.4 Residual filament in the nozzle during leveling

2.5 Damaged strain gauge

2.6 Damaged printing platform

2.7 Z-axis component issues, such as lead screw backlash/screw loosening, etc.

2.8 Deformed the platform board's assembly with an error exceeding 5mm.

¶ 3. Troubleshooting and Solution

Before proceeding with the following steps, first clear the build plate and clean the nozzle.

¶ 3.1 Redo Leveling

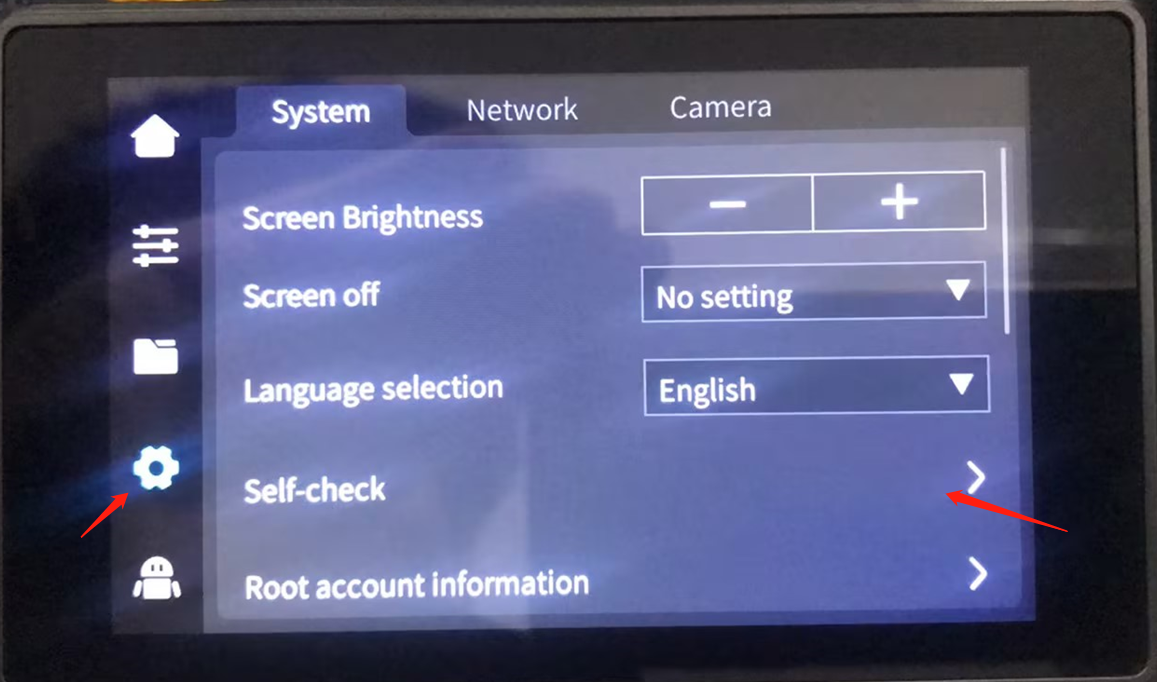

① Turn on printer,click 'Settings".click system "Self-check"

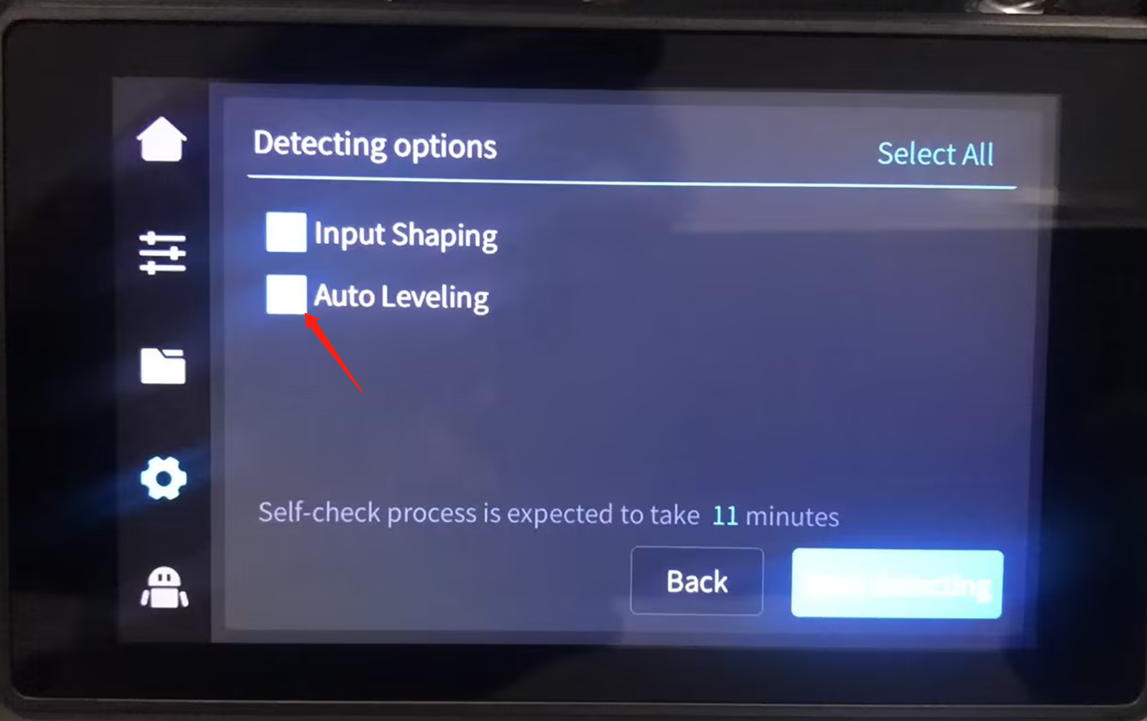

② Check Auto Leveling, click Start Detecting.

Tips: During the leveling process, environmental disturbances should be avoided. The 3D printer should be placed in a stable environment, and external vibration interference should be avoided during the leveling process.

¶ 3.2 Check Leveling Data

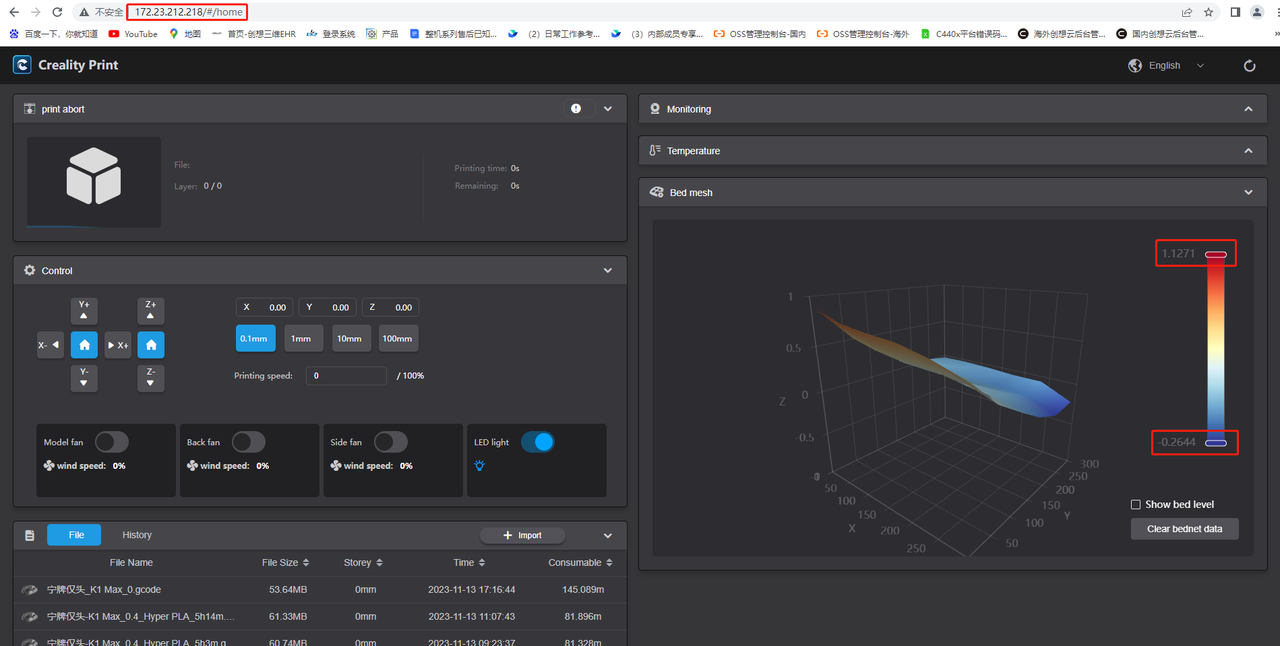

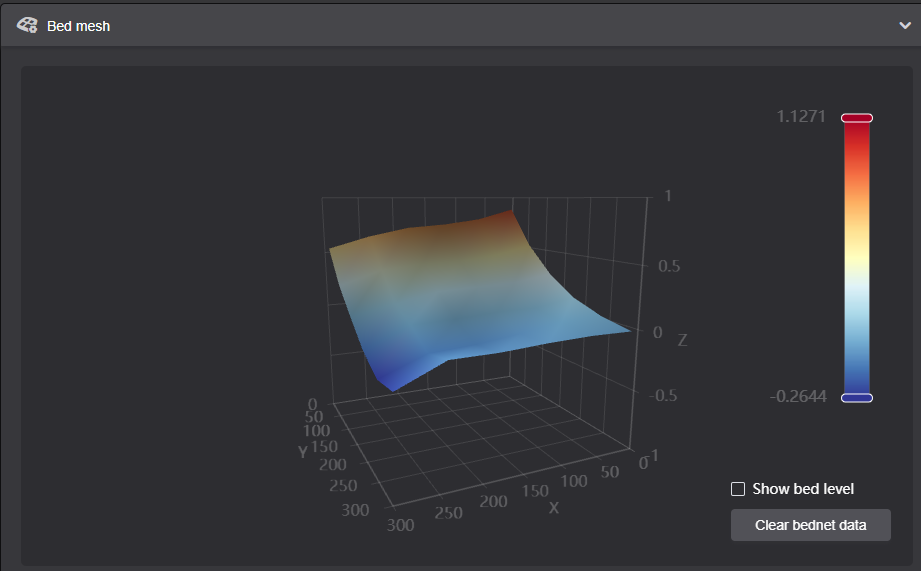

① The machine is connected to the network, enter the machine's IP address into the browser to access the web control interface, and check whether the leveling data is normal.

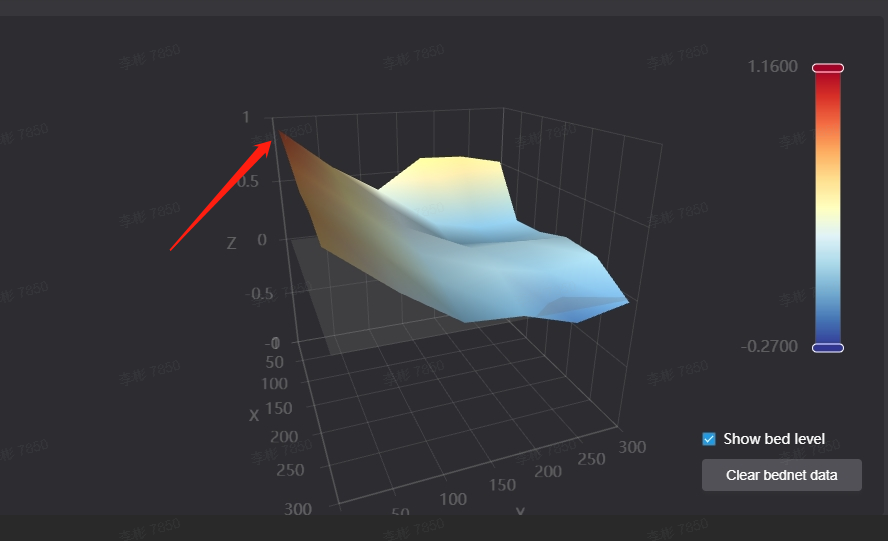

-

If the data trend is normal, but the absolute sum of the leveling differences is greater than 5mm, it is necessary to retighten the Z-axis.

-

If the data trend is abnormal,maybe the strain gauge is damaged, the strain gauge needs to be replaced.

The gap between the highest and the lowest is within the normal range if it is less than 3mm.

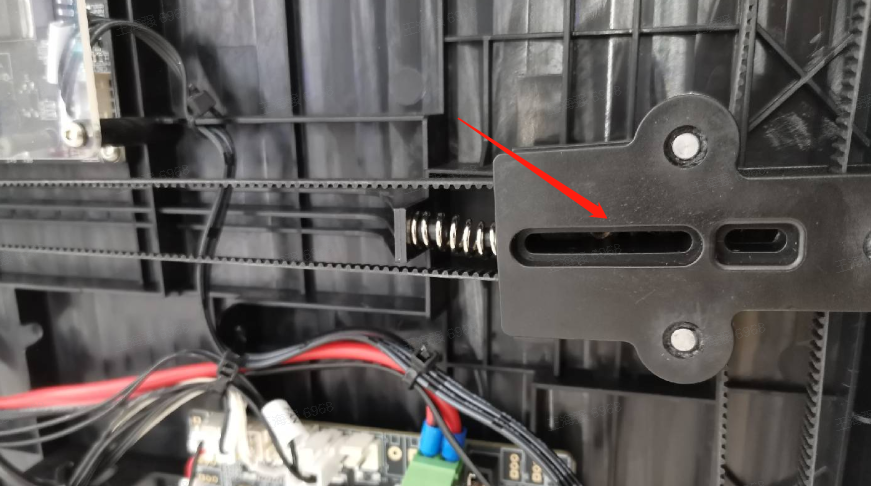

② Dismantle the machine base, inspect if the Z-axis assembly is functioning properly.

The absence of screws in the Z-axis tension block leads to abnormal leveling.