¶ 1. Problem description

When printing the first layer, there is a localized scraping on printing platform or the localized first layer is too high, The first layer of the printed model behaves differently in various places.

¶ 2. Cause analysis

(1) Not leveled after updating firmware.

(2) Environmental disturbances during leveling process.

(3) Abnormal pulling of hot bed wiring during leveling process.

(4) There's a residual filament in the nozzle during leveling.

(5) The strain gauge is damaged.

(6) The printing platform board is severely damaged.

(7) Possible problems with the Z-axis assembly, such as lead screw movement/loose screws, etc.

(8) The platform board was severely deformed during assembly, with an error of more than 5mm.

¶ 3. Troubleshooting and solutions

Before proceeding with the following steps, clean the platform plate and clean the nozzle.

¶ 3.1 Re-leveling

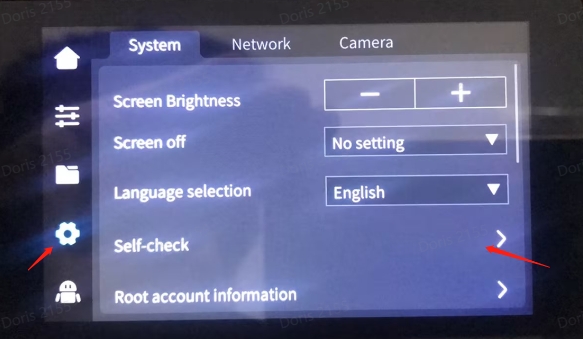

①: When the machine is idle, click Settings - Machine Self-Test.

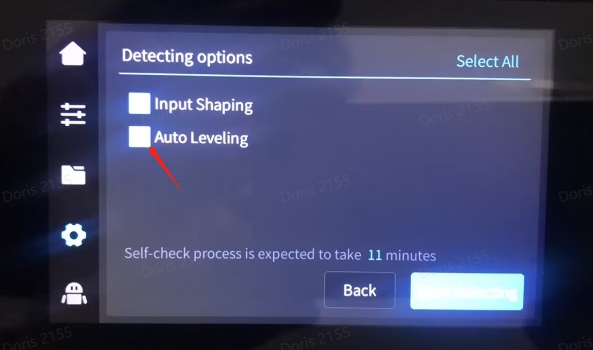

②: Select Auto-leveling and click Start detection.

Tips: Environmental interference should be avoided during the leveling process。 Place the printer in a sturdy environment, and avoid touching the printer or disturbing it in any way during the leveling process.

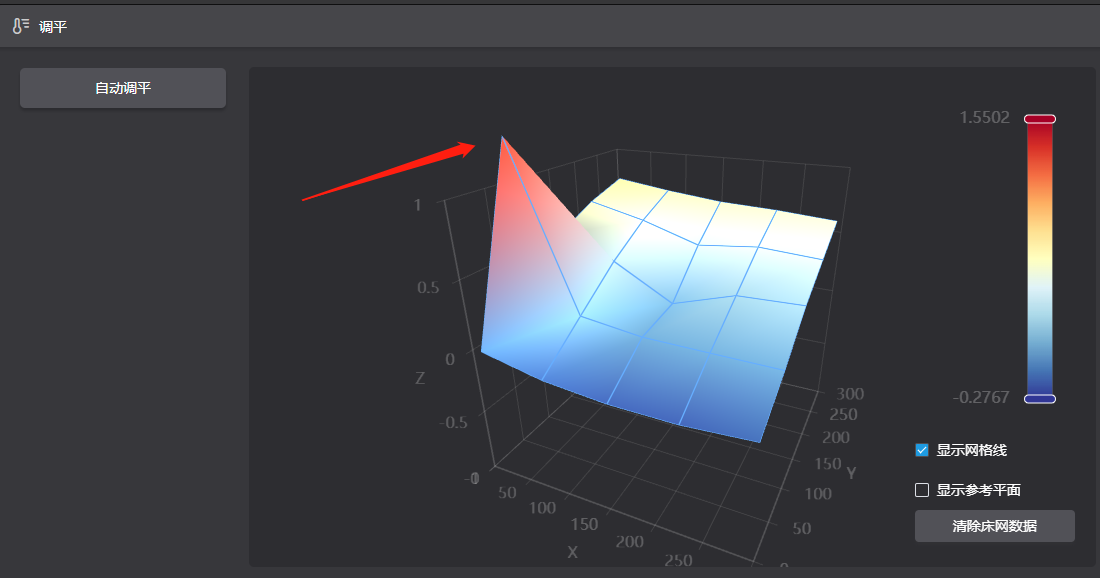

¶ 3.2 Check leveling data

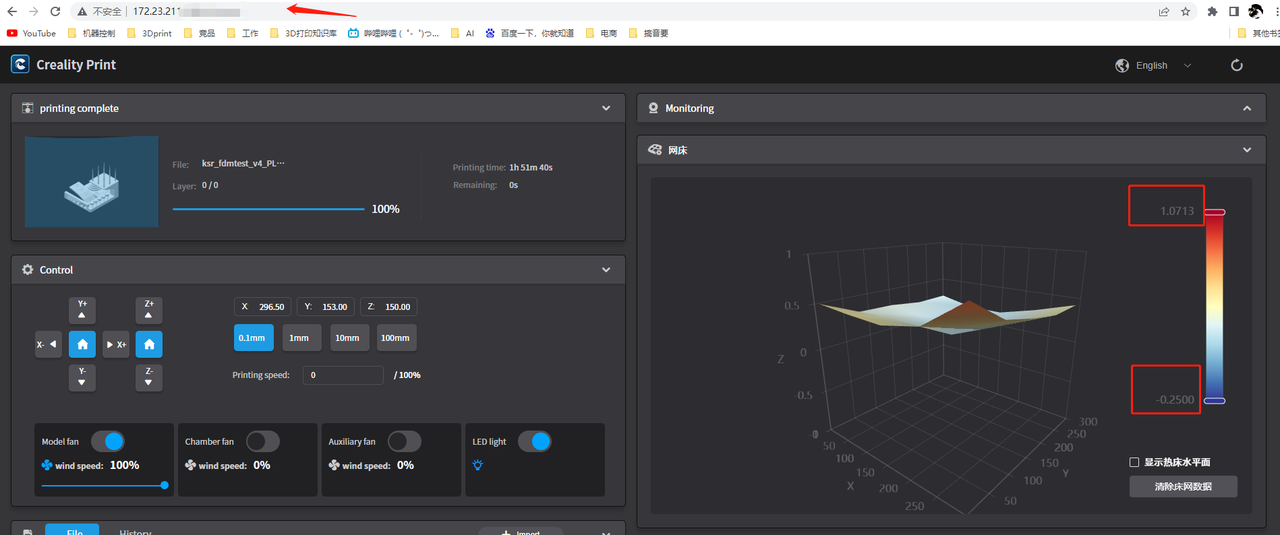

①: Connect the machine to the network, enter the machine IP Address in the browser to enter the web control terminal, and check whether the leveling data is normal.

If the data trend is normal and the absolute value of the leveling difference is greater than 5mm, the Z-axis needs to be re-tensioned.

If the data trend is abnormal and it is suspected that the strain gauge is damaged, the strain gauge needs to be replaced.

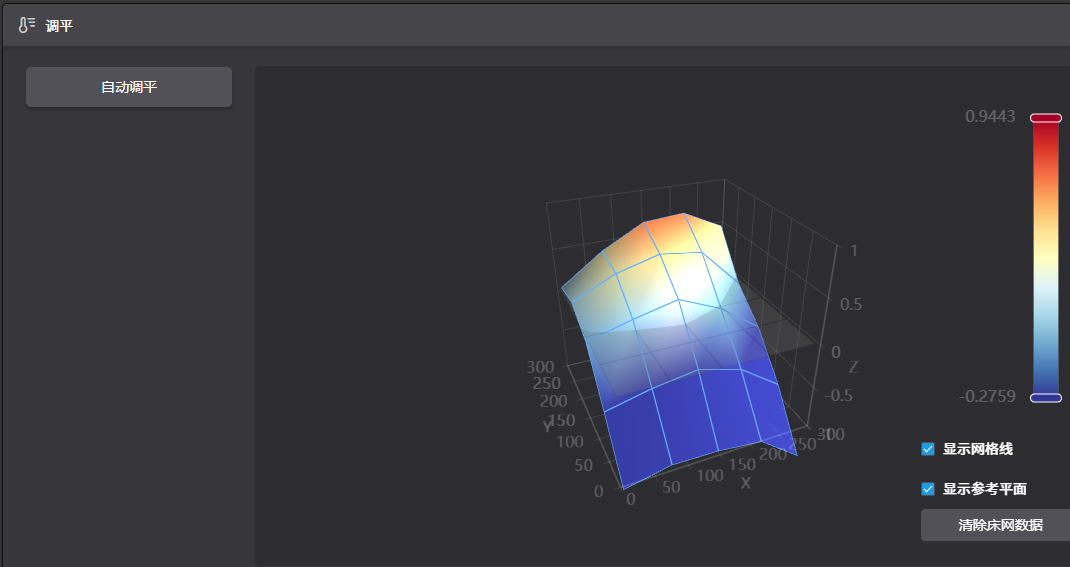

Data is normal

The difference between the highest and lowest is less than 3mm, which is within the normal range.

Hot bed 100 ℃, normal data

Single point data anomaly

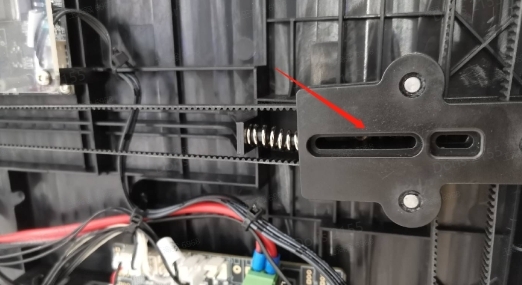

②: Disassemble the machine bottom shell and check whether the Z-axis component is normal.

For example, this Z-axis tensioning block lacks bolts, resulting in abnormal leveling