AI cannot completely replace manual work. It has certain limitations and cannot achieve 100% accuracy. We will continue to optimize the algorithm to improve detection accuracy.

K1 series AI detection adopts edge AI solution (local deployment on the machine). Advantages: real-time feedback, no network required

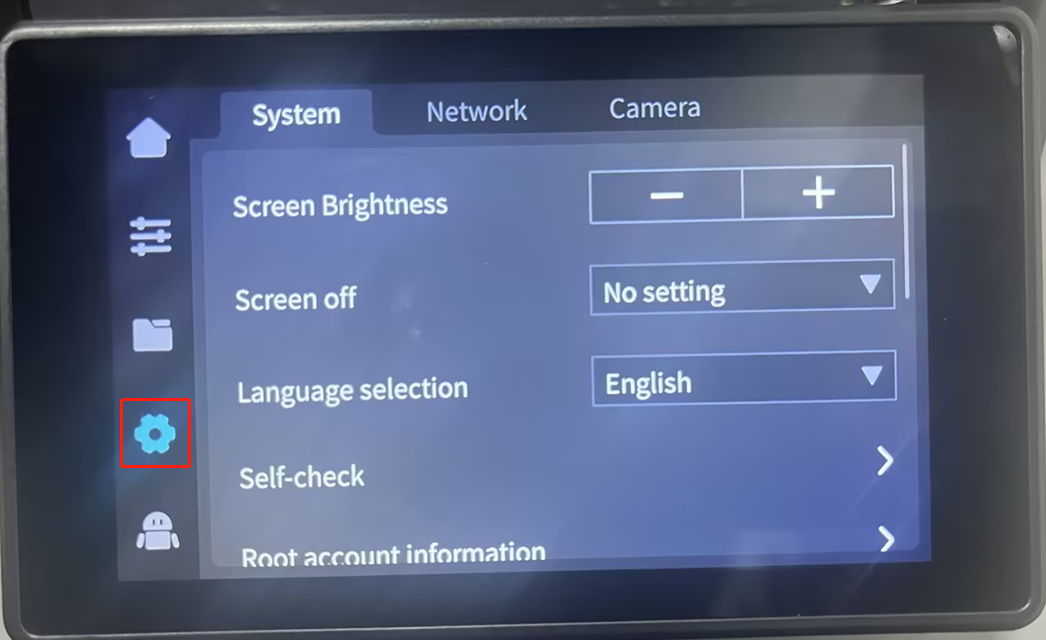

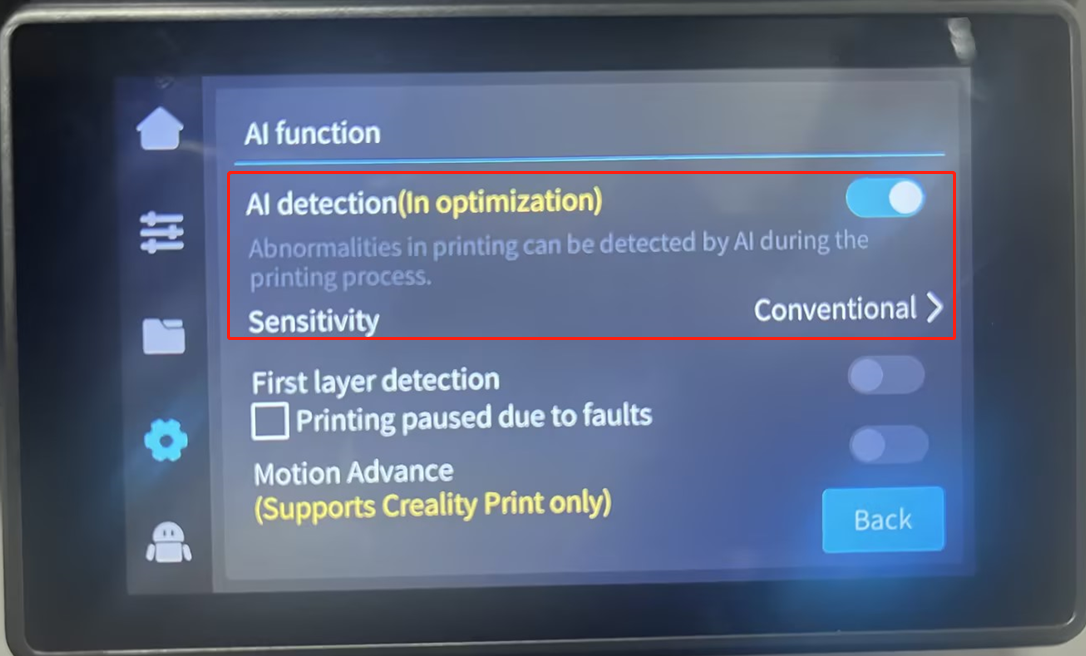

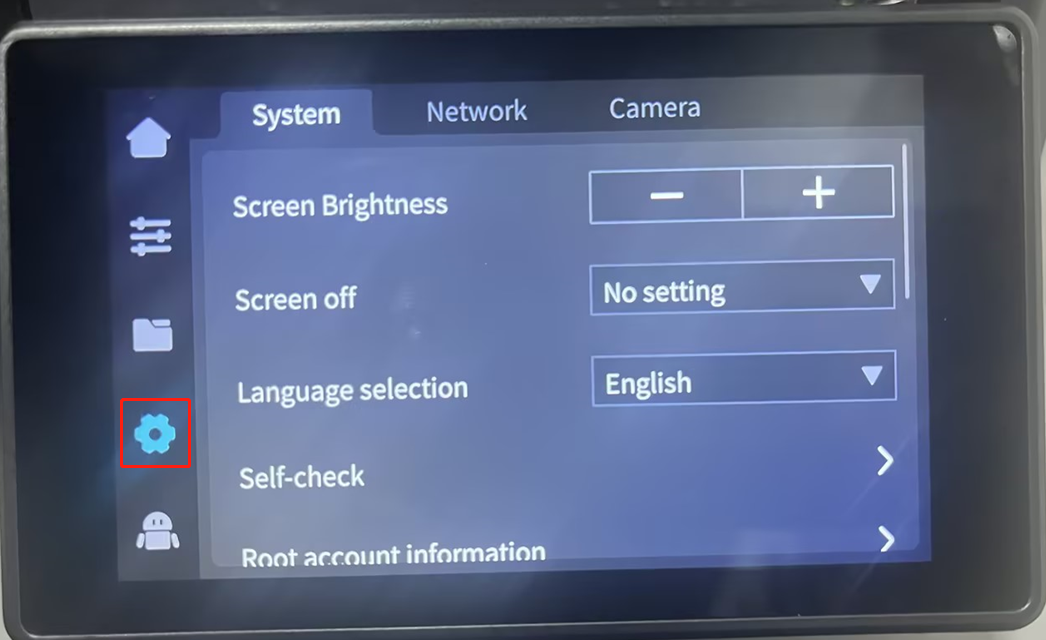

¶ 1. Where to turn on/off the AI function

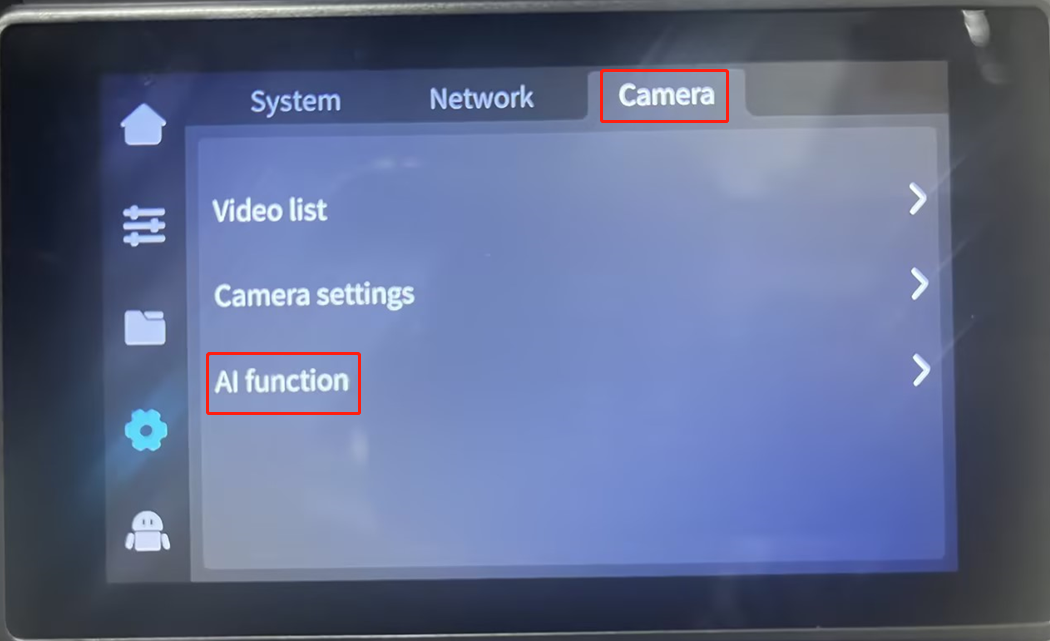

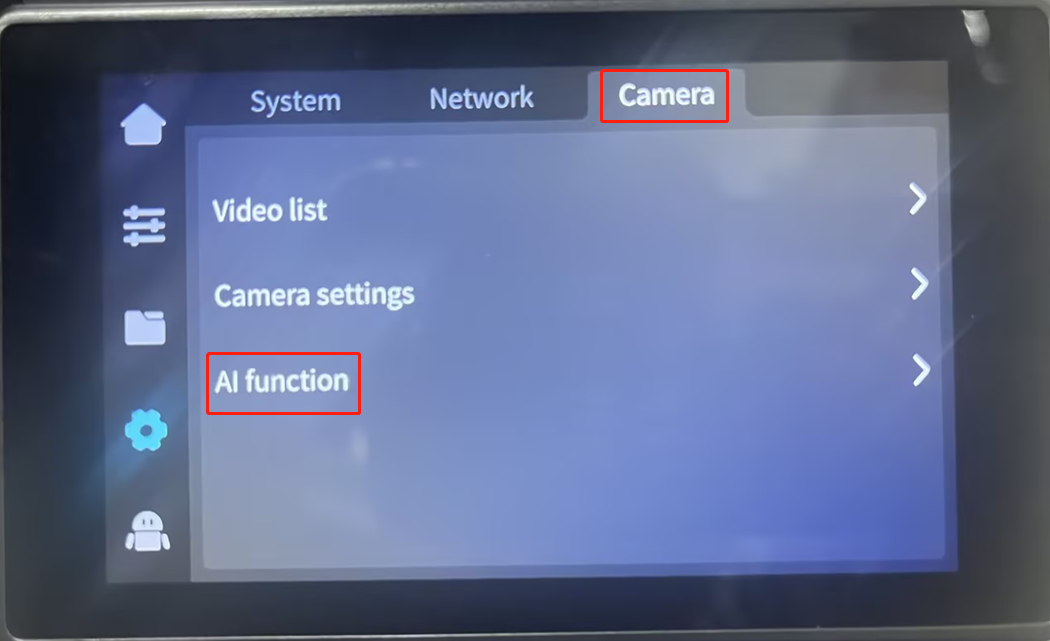

- System Settings-Camera-AI Function

STEP1:Settings

STEP2:Camera-AI Function

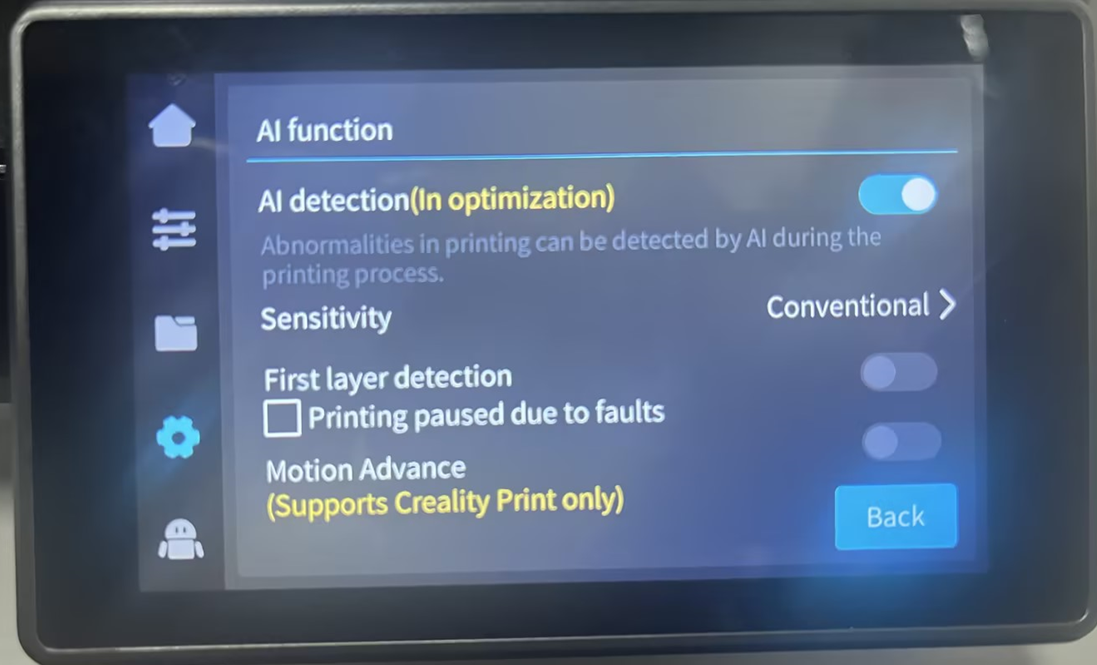

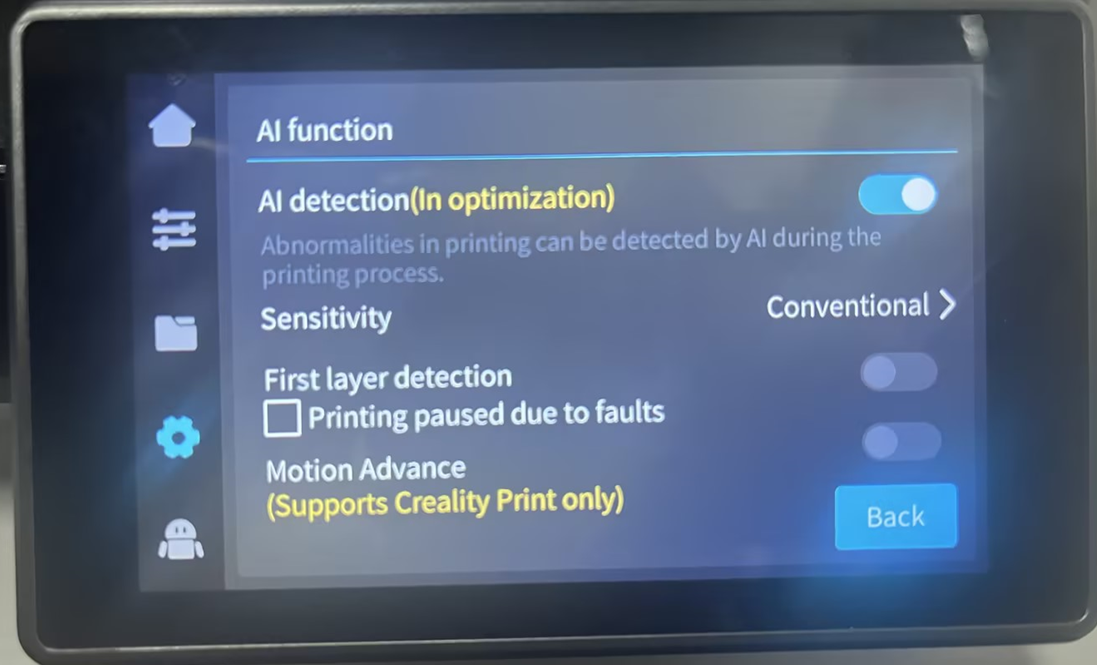

STEP3:AI related settings

In factory state, all AI calibrations are turned off by default and need to be turned on manually.

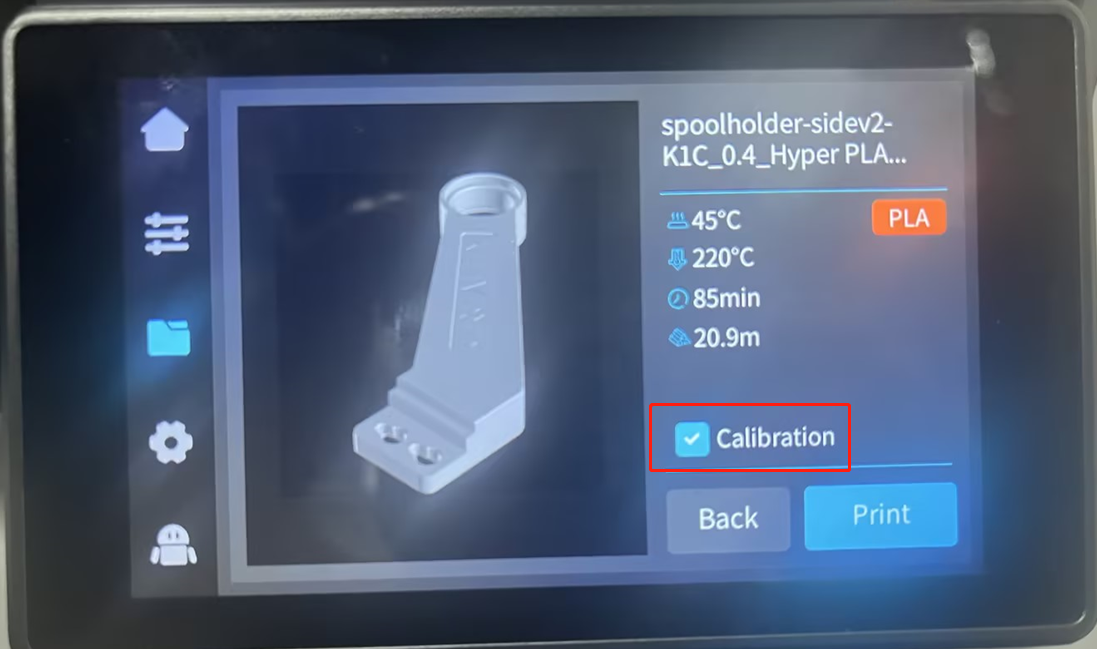

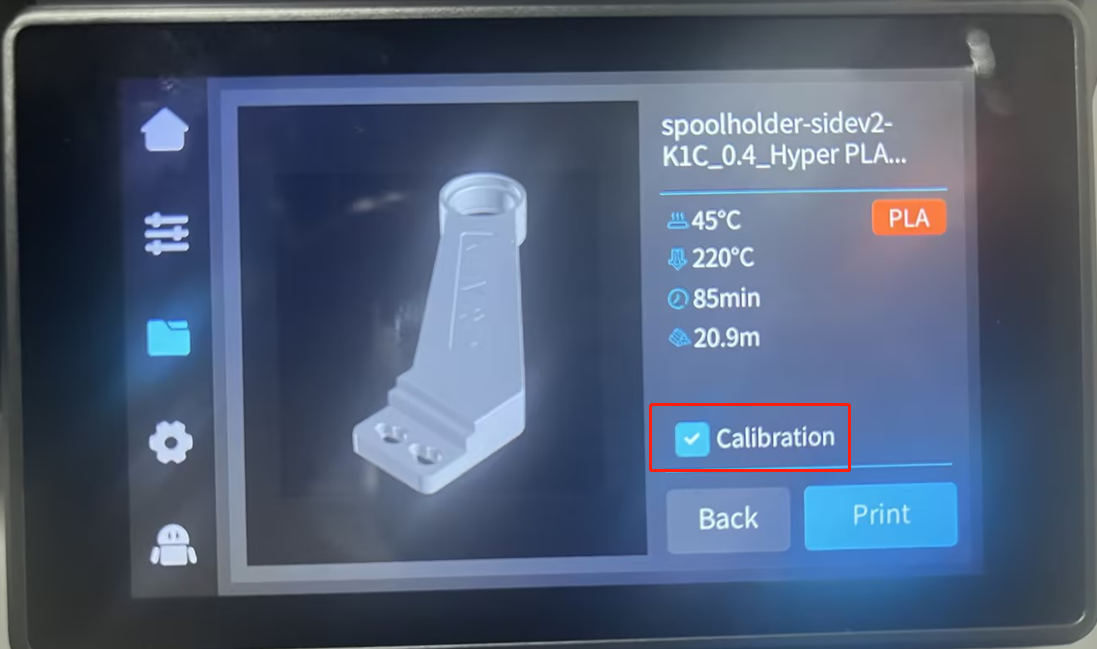

STEP4:Check Print Calibration

If unchecked, leveling/first layer detection/flow calibration will not be performed during printing.

¶ 2. What are the functions of AI functions?

¶ 2.1 AI detection (cavity camera)

Foreign object detection and pasta detection are both controlled by AI detection buttons

¶ 2.1.1 Platform board presence detection [K1Max]

Overview: When the platform plate is not placed before printing, click Print, and the camera detects that the printing platform plate is not placed, and a pop-up window will remind and the printing will be paused.

¶ 2.1.2 Platform foreign object detection

Overview: When there are items left on the platform, or the last printed model has not been removed, click to print the model, and the camera detects that there are items on the platform, and a pop-up window will remind the user and the printing will be paused (code 104)

¶ 2.1.2.1 Foreign body detection process

The camera monitors the presence of objects on the printing platform board.

- Click to print, foreign matter is detected, reminder and pause

- If there is a misdetection, just click to continue printing.

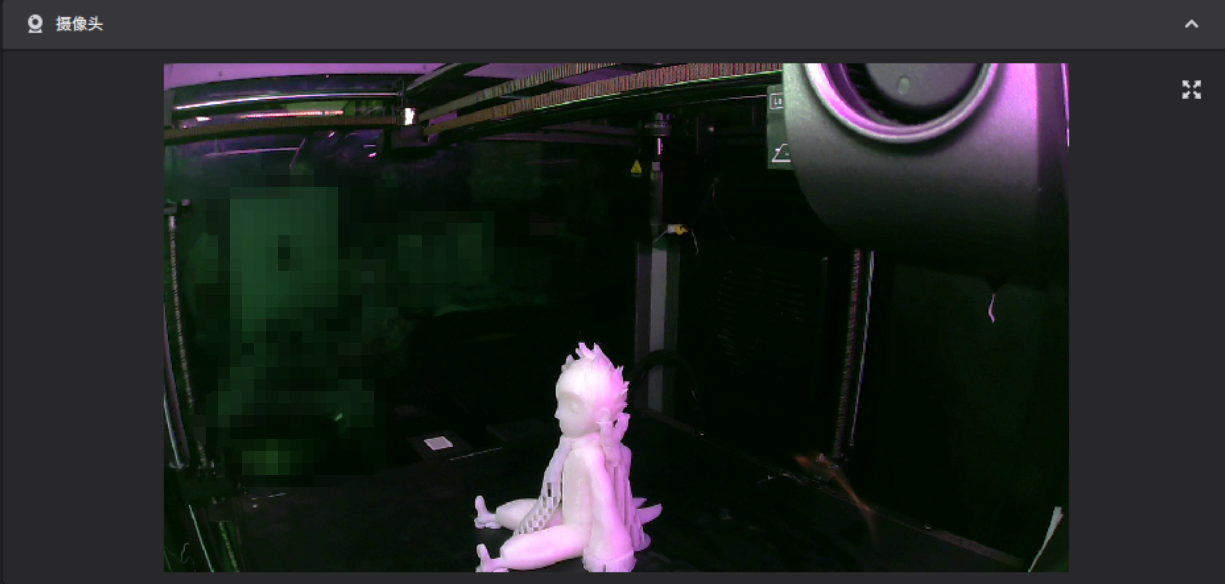

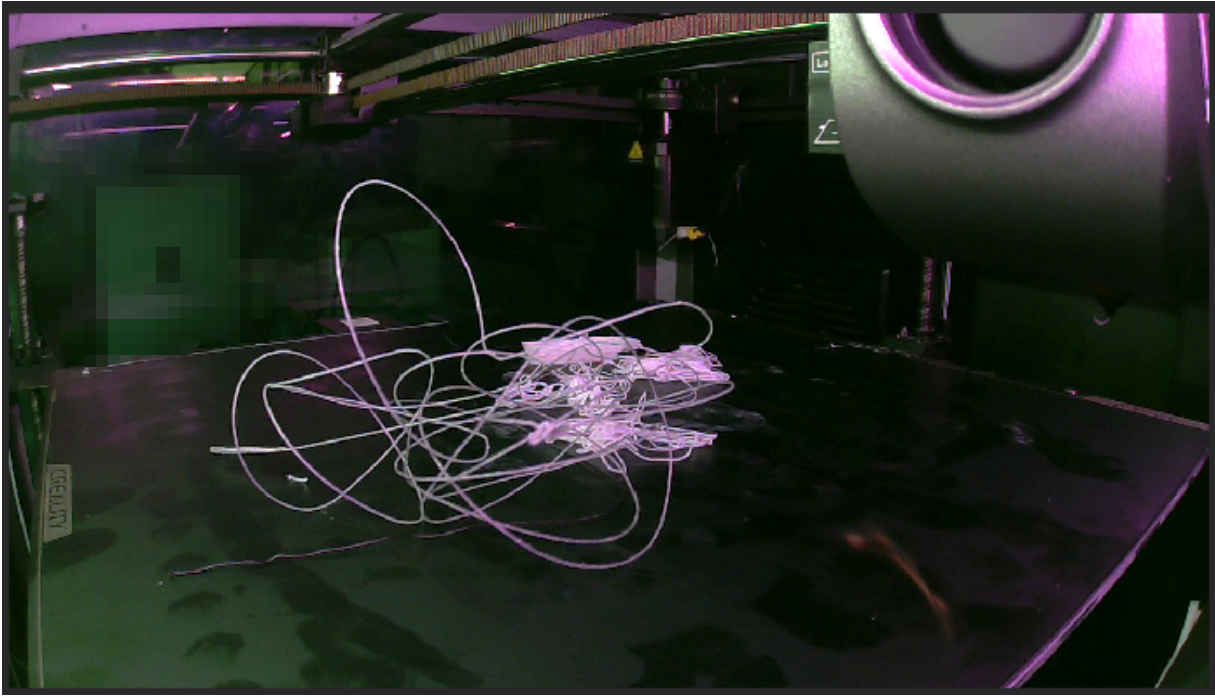

¶ 2.1.3 Pasta detection

-

Overview: When the model collapses during printing, or the Z-axis is abnormal, but there is no blockage, a pile of filaments will appear on the platform board. If the camera detects the presence of filaments, a window will pop up to report a print quality problem.

-

The pause function is not turned on by factory default to prevent misdetection and printing failure.

-

If false alarms occur frequently, you can turn off AI detection in System Settings-Camera-AI Function

-

Technologies used: deep learning neural networks, end-to-end target detection algorithm

¶ 2.1.3.1 Pasta detection process

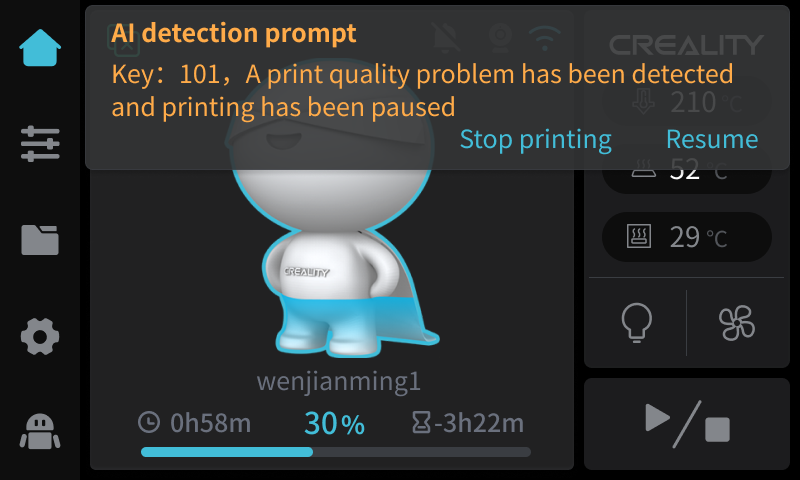

If a printing failure occurs during printing, a pop-up window will pop up on the screen/slice to report that a print quality problem has been detected (code 101), and printing will be suspended (you need to check the fault to pause printing)

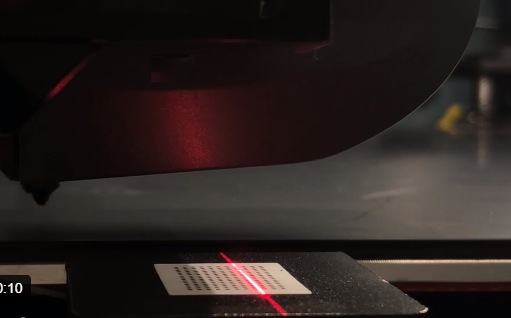

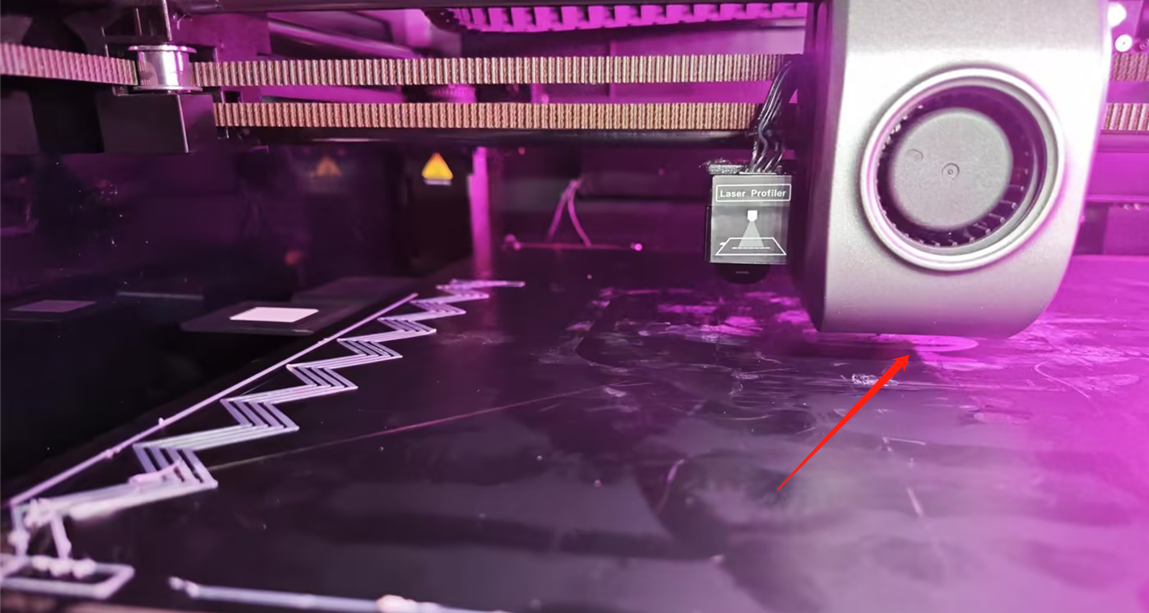

¶ 2.2 Flow calibration (AI lidar)

-

Overview: Flow calibration is to find out the best pressure advancement parameters of the current printing file, so as to obtain better printing quality. By printing the flow calibration pattern, using the laser to scan the pattern, the best pattern can be used to determine the best parameters.

-

Currently compatible with print files generated by CrealityPrint/Orcaslicer/Prusaslicer [gcode]

-

Turn on flow calibration

-

System Settings-Camera-AI Function

STEP1:Settings

STEP2:Camera-AI Function

STEP3:AI related settings

- Turn on flow calibration (mothion advance)

- If not turned on, flow calibration will not be performed

STEP4:Check Print Calibration during printing

If unchecked, flow calibration will not be performed.

If unchecked, leveling/first layer detection/flow calibration will not be performed during printing.

- Flow calibration process:

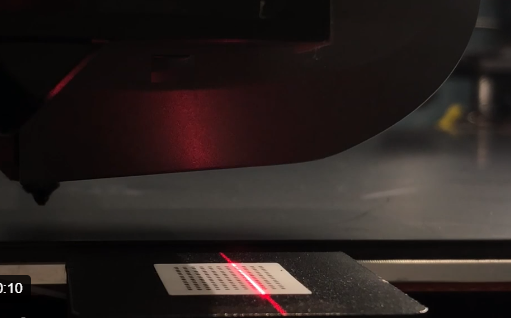

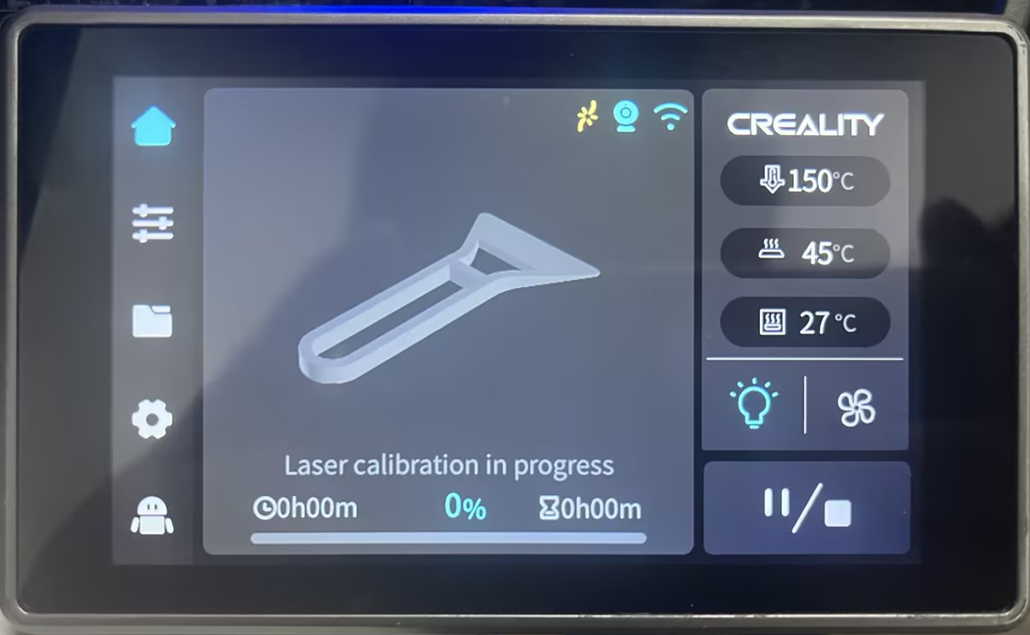

STEP1:Laser calibration (calibration laser)

STEP2:Laser scanning calibration area

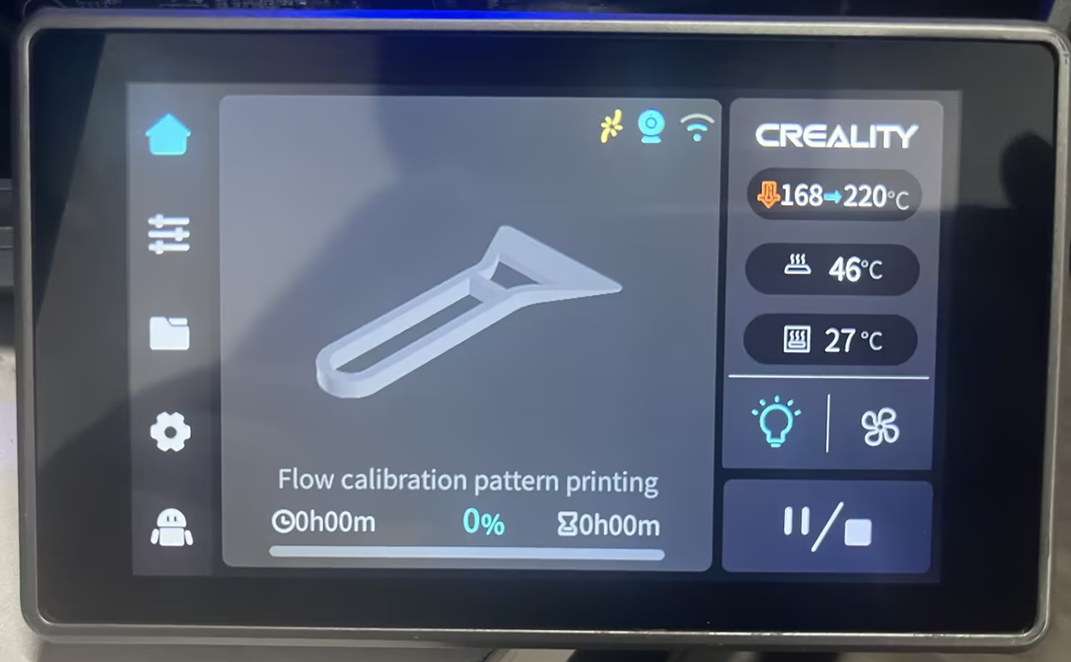

STEP3:Print flow calibration pattern

STEP4:Calculate and apply to current print file

¶ 2.2.1 Why perform flow calibration?

Let us first look at the situation where the pressure propulsion parameter (PA value) is set incorrectly

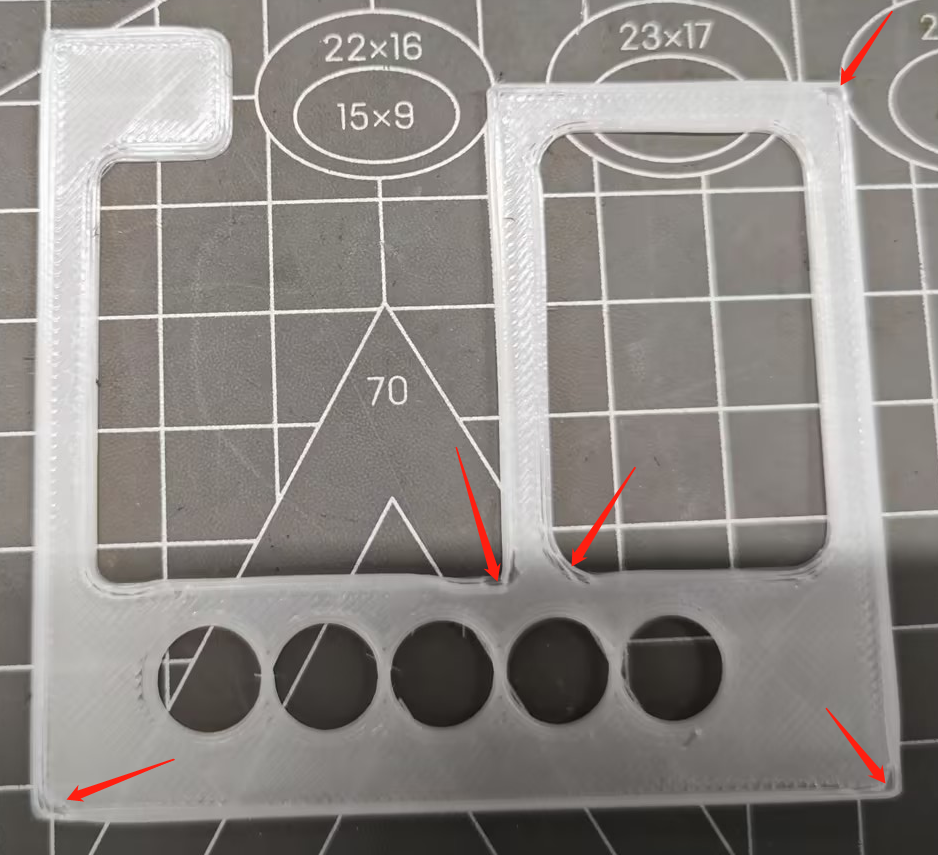

¶ 2.2.1.1 PA value is too large

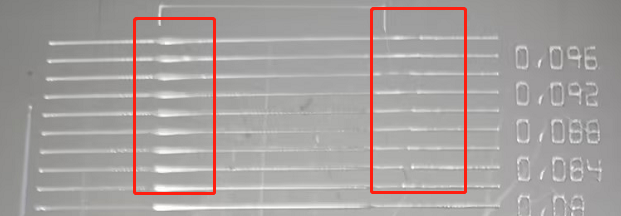

The test uses HyperPLA. The correct PA value is 0.04. It is set to 0.08 in the picture. There is insufficient material at the corner.

As shown in the figure, the PA value in the PA test pattern is too large, which will lead to excessive extrusion at the beginning and lack of material at the end of extrusion.

¶ 2.2.1.2 PA value is too small

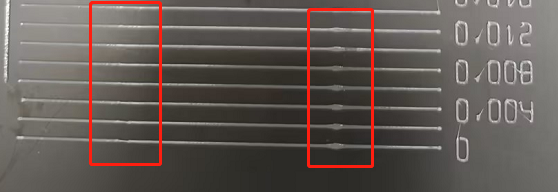

The test uses HyperPLA. The correct PA value is 0.04. It is set to 0 in the picture. The defect is manifested as excessive protrusion of the corners.

As shown in the figure, the PA value in the calibration pattern is too small, which will result in too little extrusion at the beginning and too much extrusion at the end.

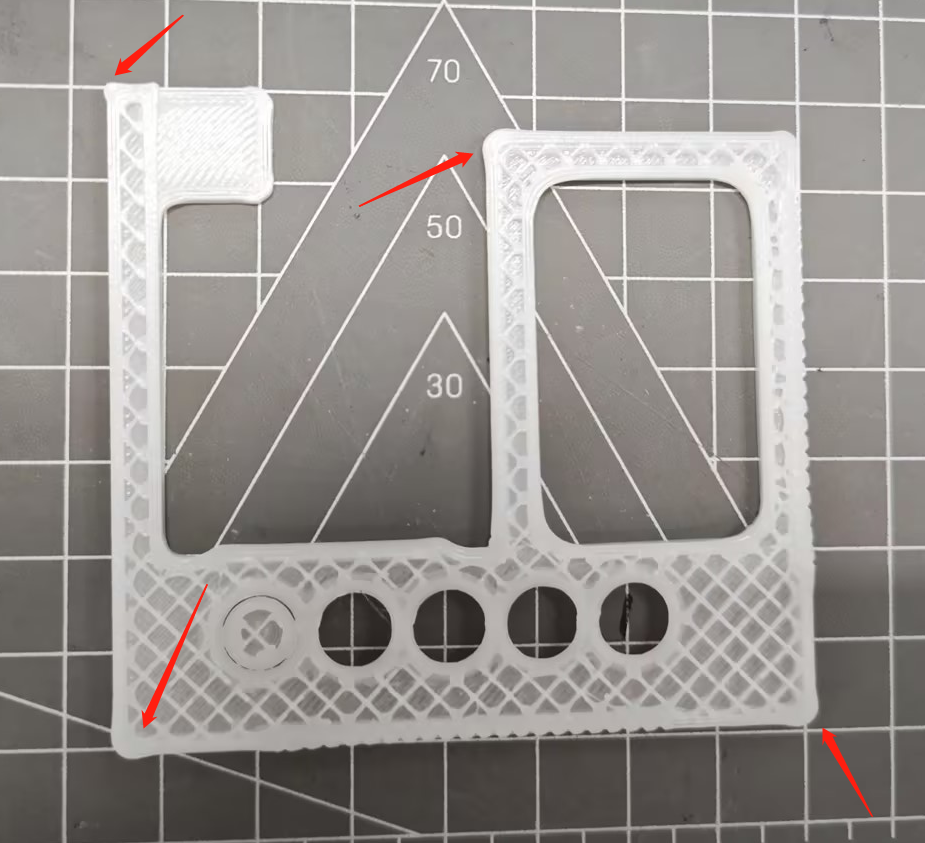

¶ 2.3 First layer detection (AI lidar function)

Overview: When this function is turned on, the lidar will scan the first layer of printing. If the model is missing or the model is warped, a pop-up window will report printing quality problems.

¶ 2.3.1 First-level detection process

STEP1:Laser calibration (calibration laser)

STEP2:Laser scanning of first floor area

STEP3:Print first layer

STEP4:Laser scanning first floor

¶ 3. What are the limitations of AI detection and calibration?

3.1 Foreign objects and platform board detection: can identify most situations (such as the printing platform board is not placed, there are models or large debris on the platform board), the influence of ambient light or special colors may not be detected, and temporary detection outside the camera range If the glue on the platform plate is not enough, it may cause false detection;

3.2 Pasta detection: It can identify most situations, and there are requirements for the color of consumables and ambient light; some environments adapt well, but in some environments recognition may cause misdetection problems;

3.3 First layer detection: low sensitivity, the first layer is slightly missing, and slight warping cannot be detected;

3.4 Flow calibration: Compatible with CrealityPirnt4.3 or above and Orcaslicer slices; can calibrate harder consumables such as PLA/ABS, but cannot calibrate TPU/PA or Carbon fiber materials at the moment

3.5 Fault pause: Since there are different misdetection situations in the above different environments, you can decide whether to turn it on or off according to your own machine environment, or set the sensitivity to a low level.

¶ 4. What upgrades will AI have in the future?

-

Air-Printing detection: When the model appears to be empty-printing, it can be automatically paused.

-

Warpage detection: When the model has warping, it can automatically pause