Integrated throat nozzle hot end

tool

H1.5/H2.0/H2.5 hexagonal wrench

Scissors

¶ 1. Unload the filament

¶ 1.1 Unload the filament

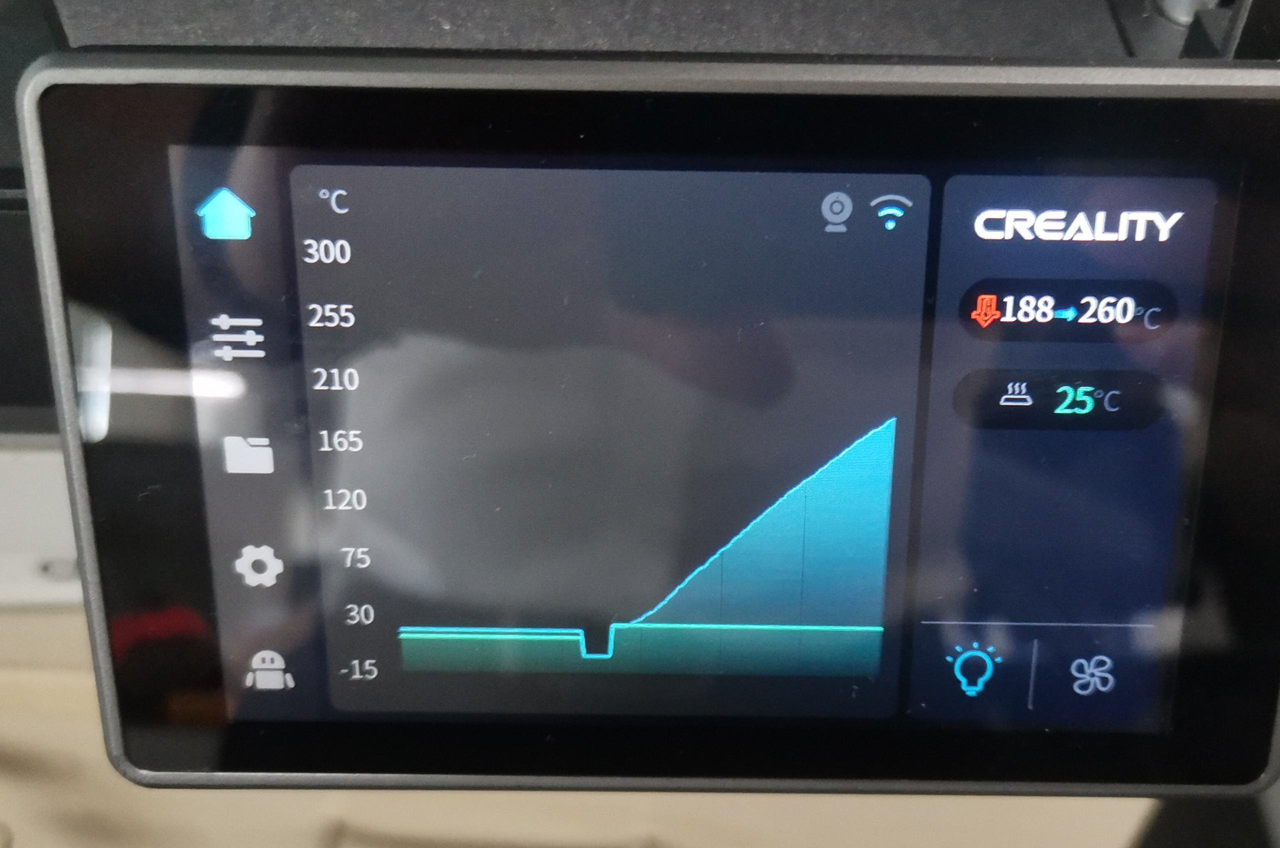

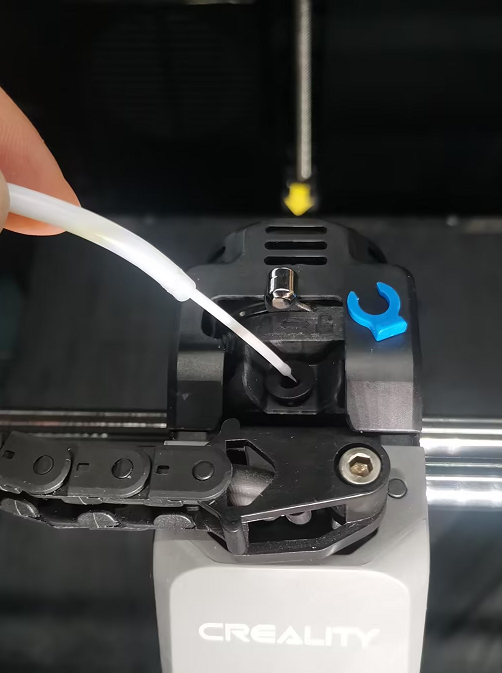

Set the nozzle temperature to 260°C, remove the blue clamp on the extruder, press the claw to pull out the Teflon tube, move the extruder to the unlocked state, and pull out the filament (the new extrusion clamp presses the white Pull out the Teflon tube from the pneumatic joint, turn the extruder to the unlocked state, and pull out the filament);

¶ 1.2 Power off, or set the nozzle temperature to 0°C

¶ 2. Dismantle AI LIDAR

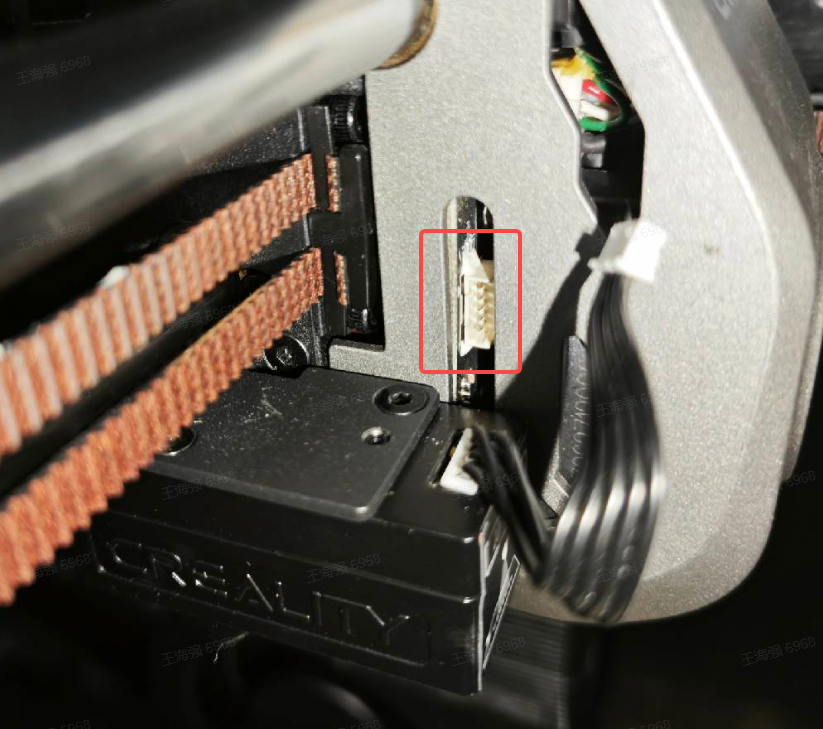

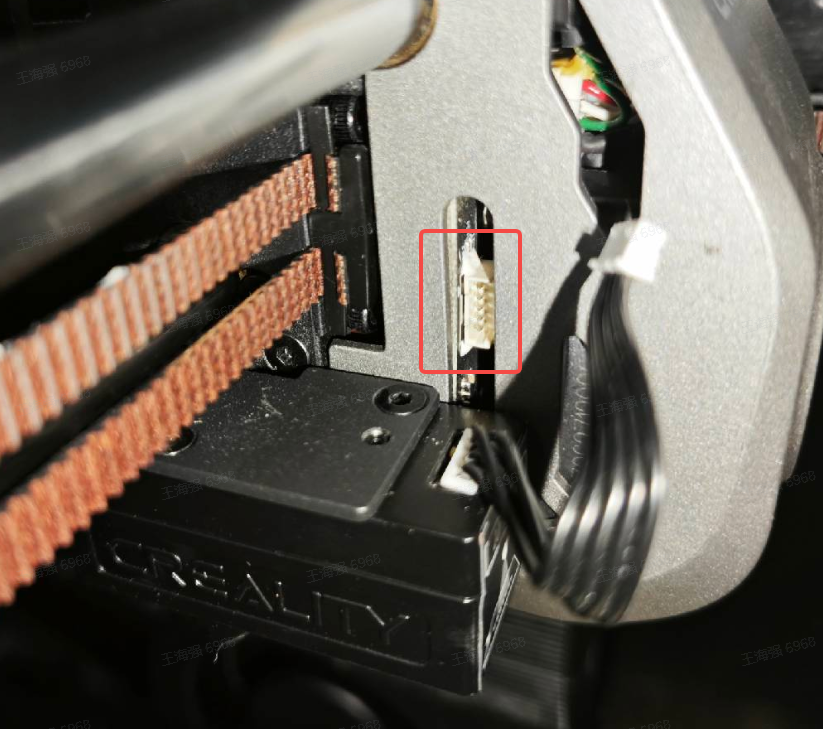

¶ 2.1 Unplug the AI LiDAR terminal

¶ 2.2 Remove the LIDAR fixing screws.

¶ 3. Remove the extruder front cover

- Tool: H2.0 Hex Wrench

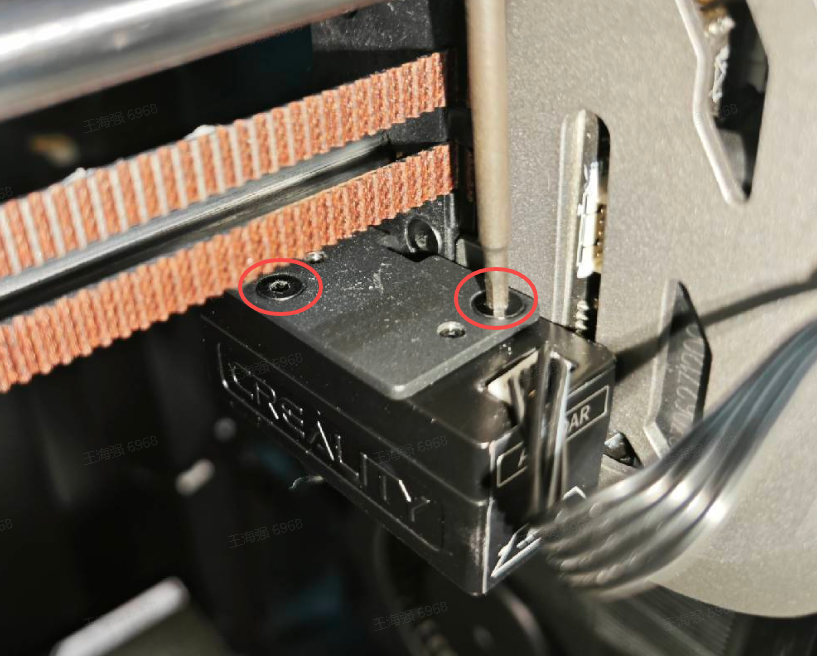

¶ 3.1 Remove the fixing screws on both sides of the extruder cover.

¶ 3.2 Remove the nozzle cover and disconnect the model fan terminal.

¶ 4. Disassembling the old hotend and heat sink.

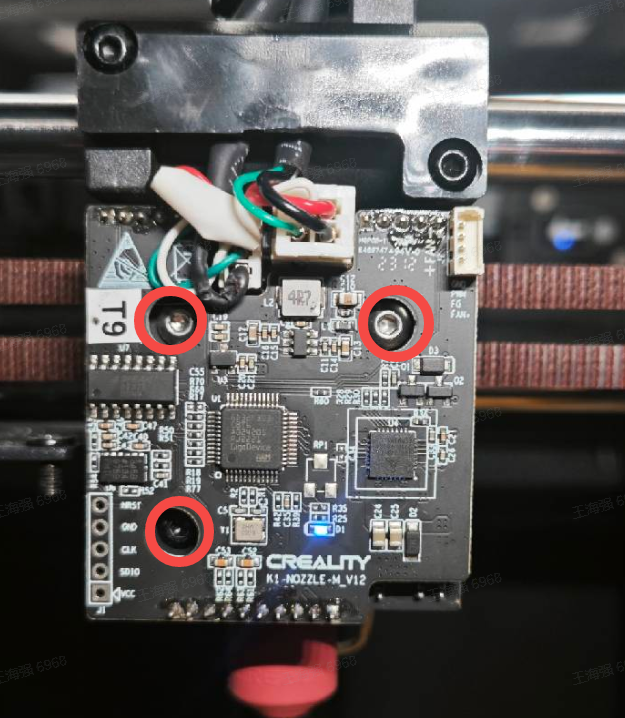

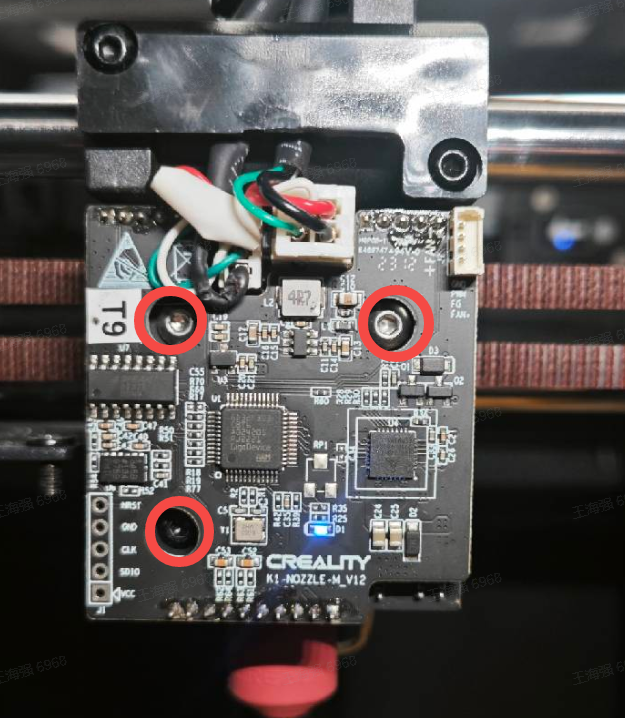

¶ 4.1 Remove the extruder front circuit board.

Use a H2.0 hex wrench to remove the three screws on the front.

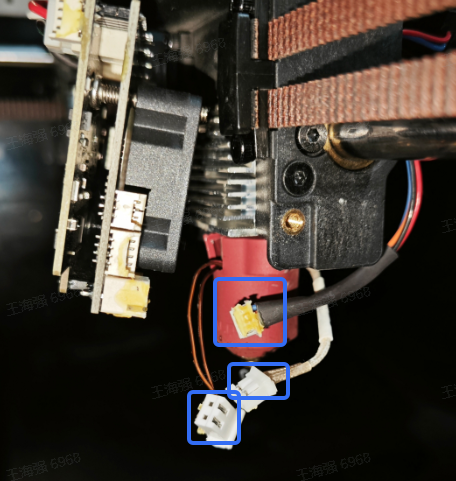

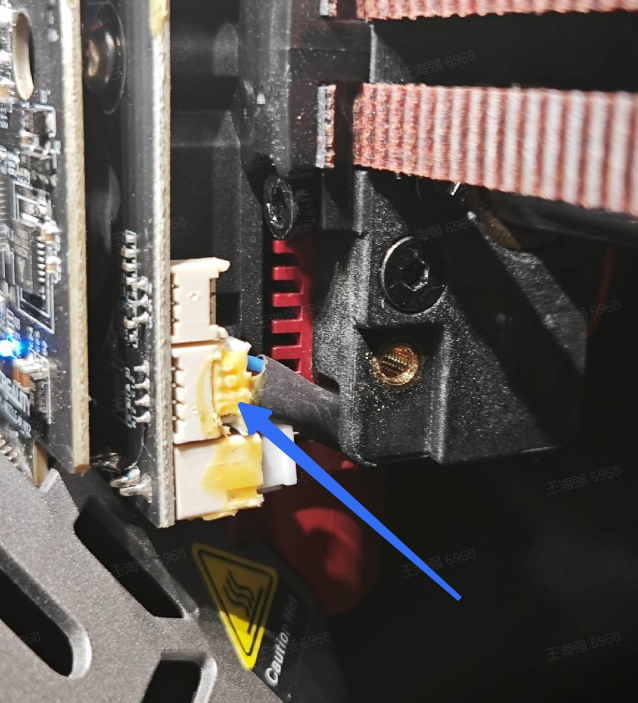

¶ 4.2 Remove the hot end terminal block

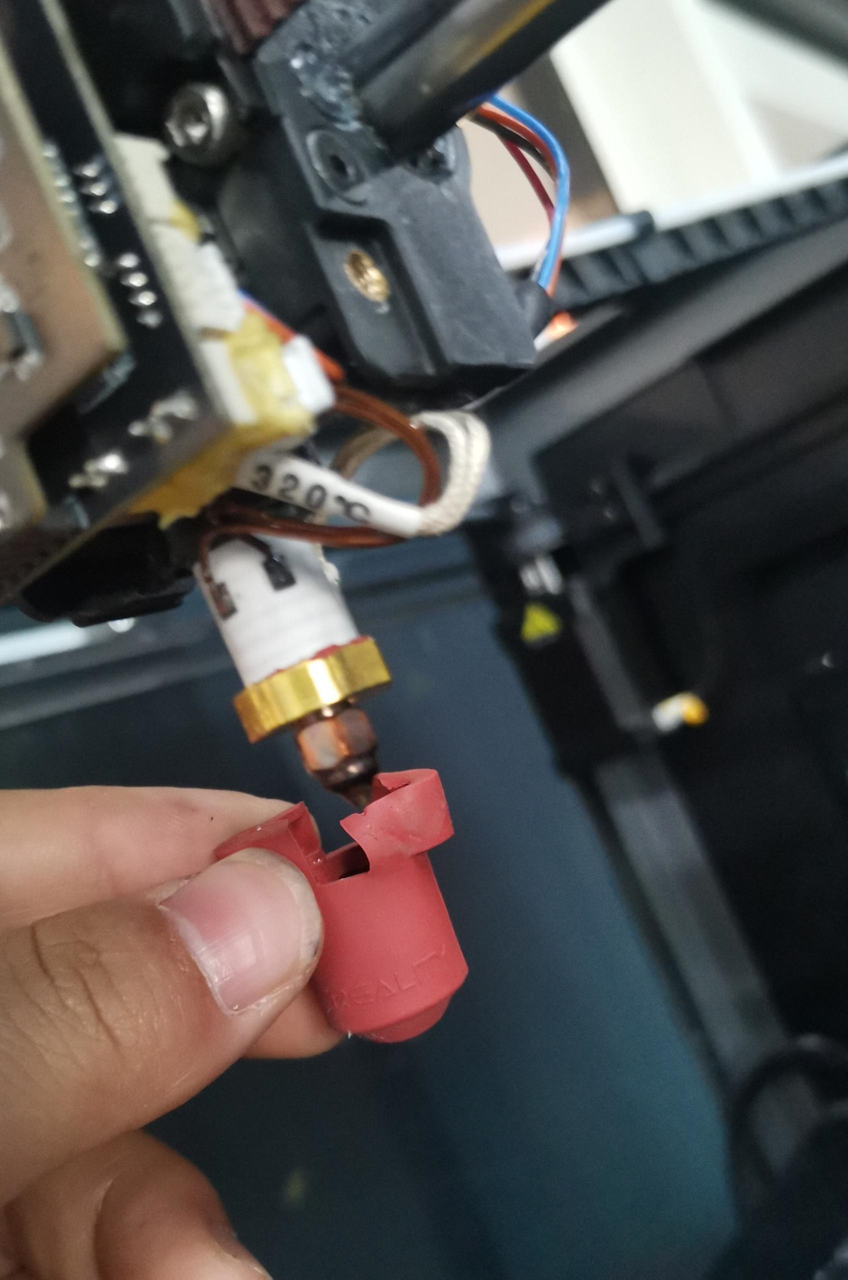

¶ 4.3 Remove the Hotend Silicone Sock

Operate after isotropic cooling to avoid burns

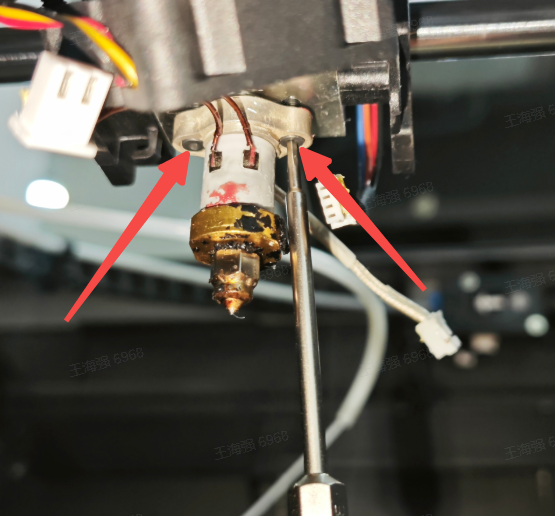

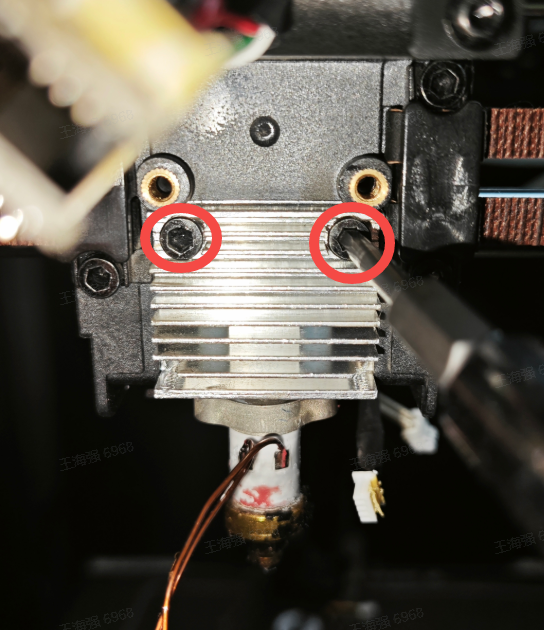

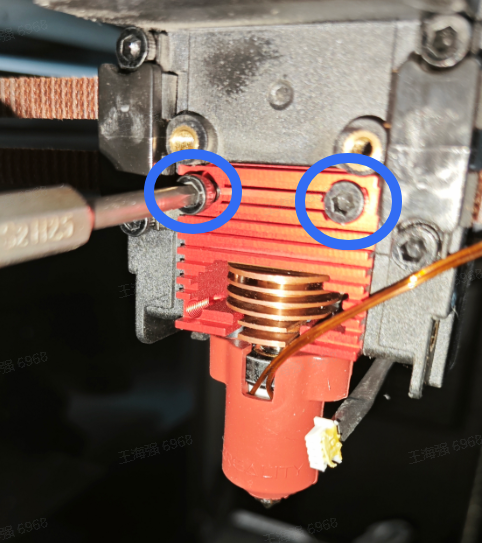

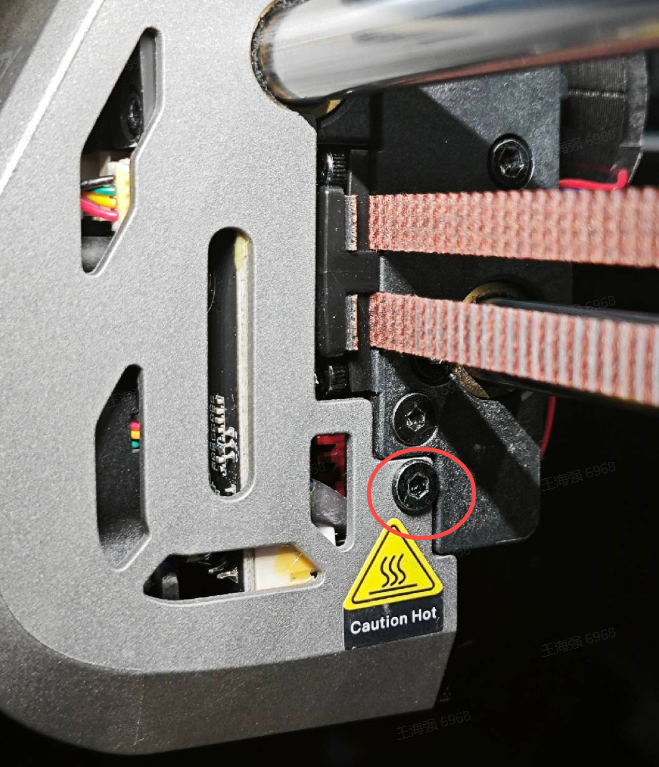

¶ 4.4 Remove the hotend retaining screws

Use an H2.0 hex key to remove the two cylindrical head screws securing the hot end.

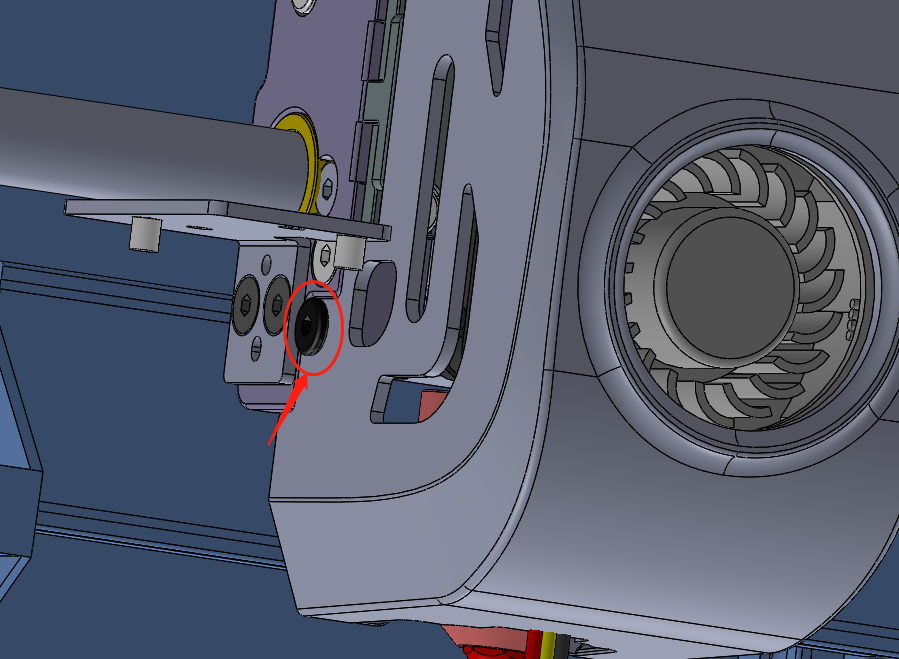

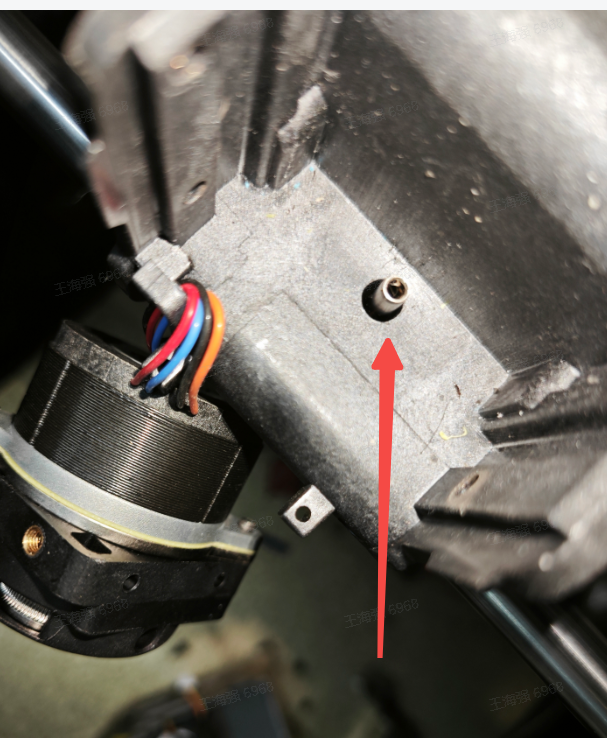

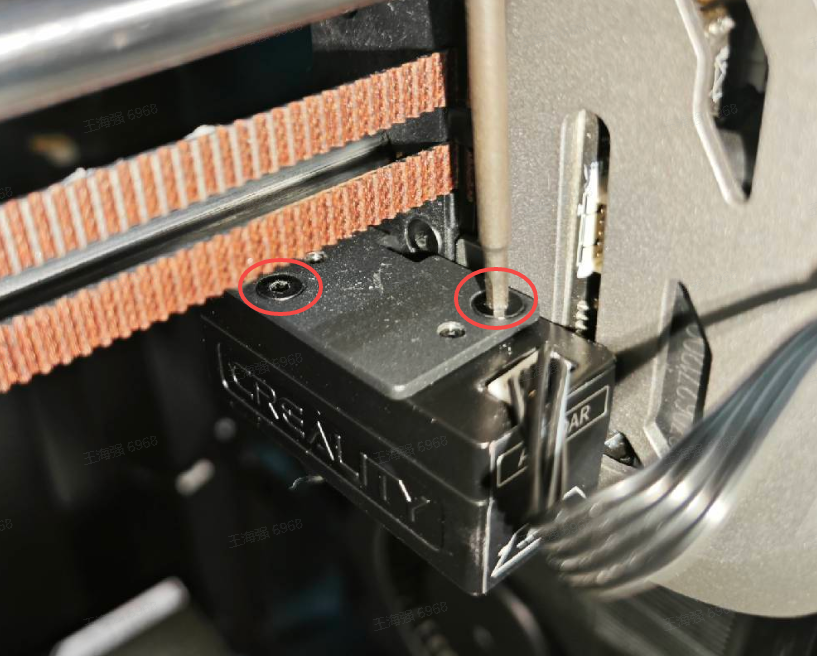

¶ 4.5 Remove the screws fixing the heatsink on both sides

Use an H2.0 hex key to remove the two screws on both sides.

¶ 4.6 Remove the front heatsink mounting screws

Use an H2.5 hex wrench to remove the two front screws.

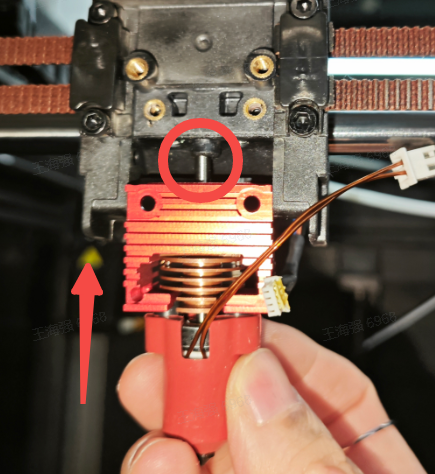

¶ 4.7 Remove the old hot end

Hold the heat sink block in your hand and use vertical force to completely remove the old hot end.

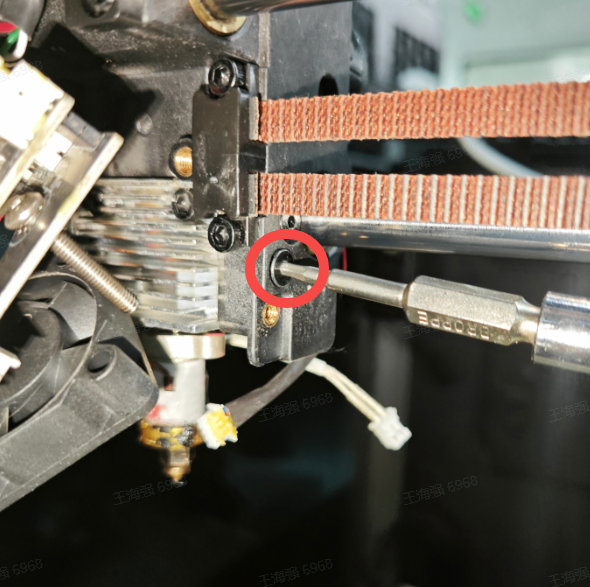

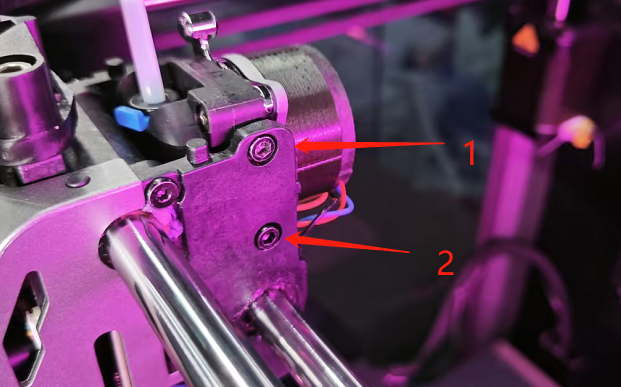

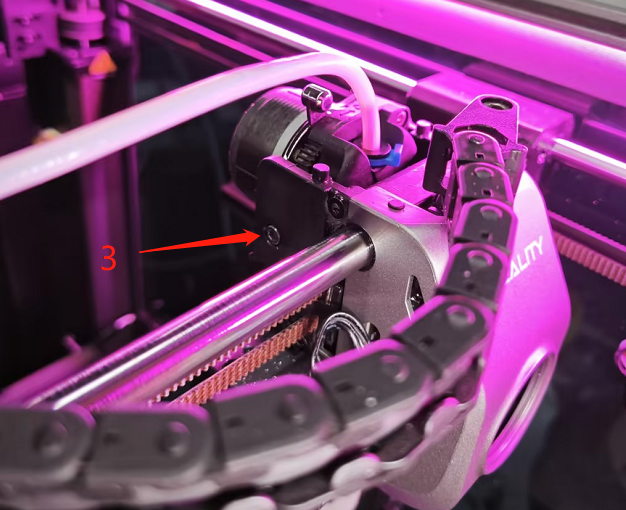

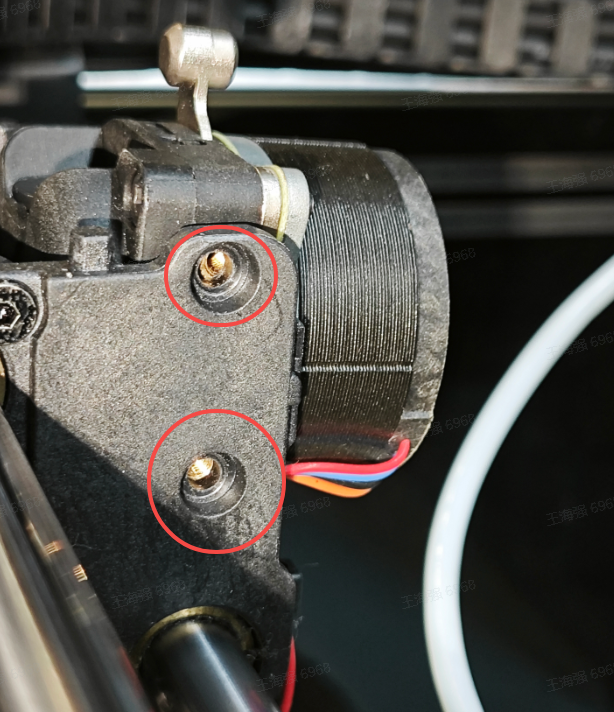

¶ 5. Disassemble the extruder

¶ 5.1 Disassemble the extruder

Use an H2.5 hex wrench to remove the three fixing screws on both sides of the extruder.

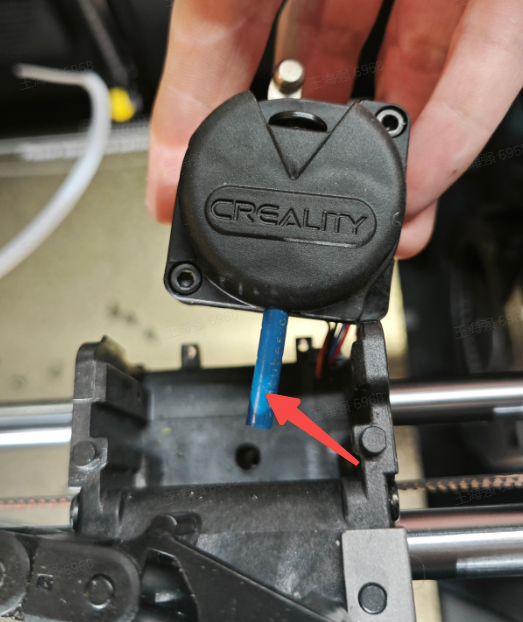

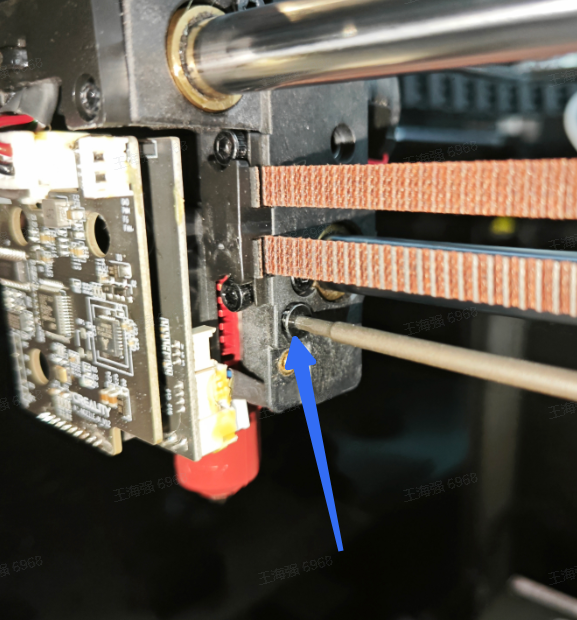

¶ 5.2 Remove the original blue Teflon tube

¶ 6. Install the new hot end

¶ 6.1 Install the new hot end

Align the throat hole position and install vertically

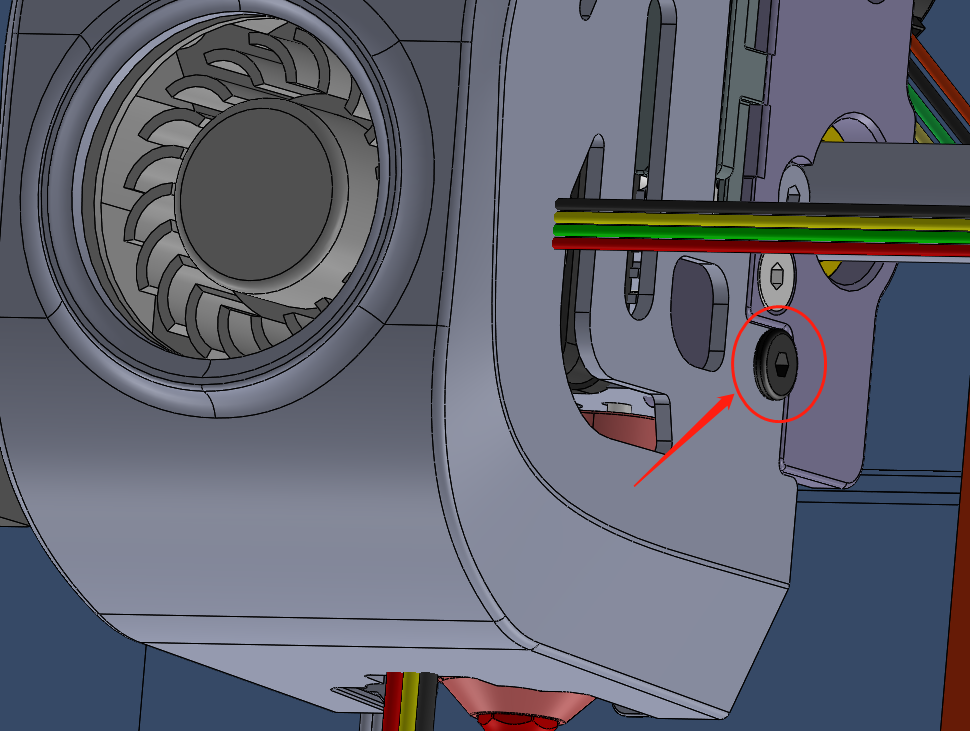

¶ 6.2 Tighten the fixing screws on the front of the heat sink

Use an H2.5 hex wrench to tighten the fixing screws on the front of the heat sink.

¶ 6.3 Tighten the screws on both sides of the heat sink

Use H2.0 hex wrench to tighten the screws on both sides of the heat sink

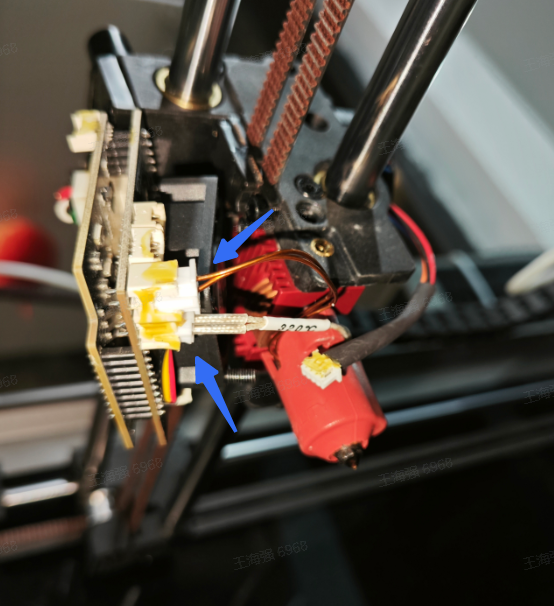

¶ 6.4 Plug in the hot end terminal

¶ 6.5 Install the front circuit board of the extruder

Use the H2.0 hex wrench to tighten the three screws. Be careful not to tighten the bottom screw too tightly to avoid damaging the circuit board.

¶ 6.6 Plug in the extruder terminals

¶ 7. Restoring the extruder

¶ 7.1 Check that there is no abnormality in the throat

¶ 7.2 Restore extruder

Use an H2.5 hex wrench to tighten the three fixing screws on both sides of the extruder.

¶ 8. Restore sprinkler head cover

¶ 8.1 Plug in the model fan terminals

¶ 8.2 Tighten the fixing screws on both sides

Use H2.0 hex wrench to tighten the fixing screws on both sides

¶ 9. Restoration lidar

¶ 9.1 Install AI lidar

Use the H2.0 hex wrench to install the radar

¶ 10. Plug in the AI lidar terminal