¶ Analysis of Print Defects: Incomplete and Fractured Parts

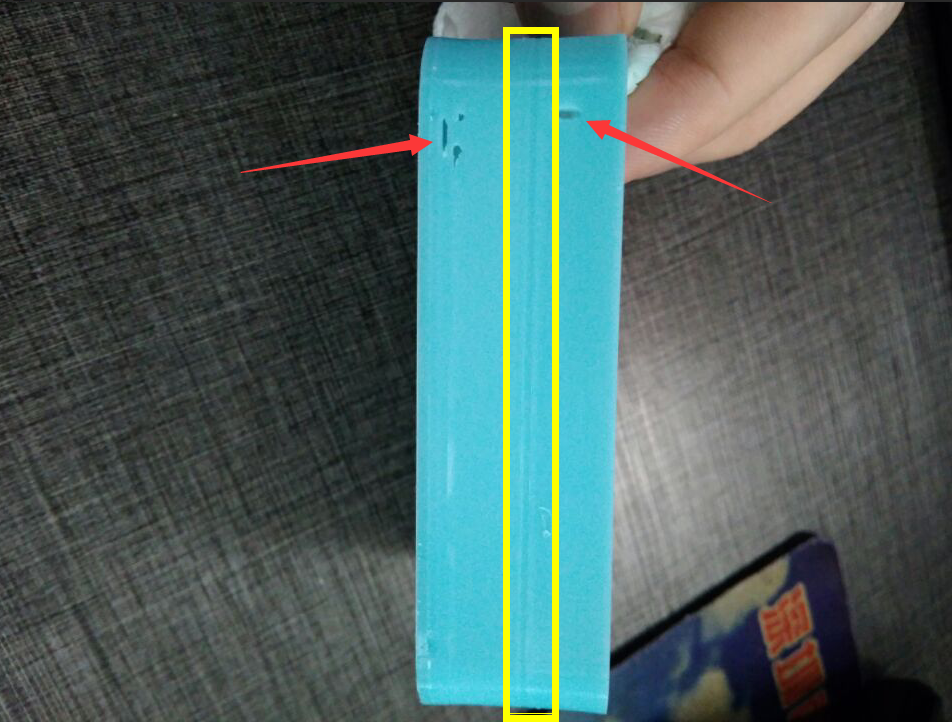

¶ As illustrated, the hole indicated by the red arrow is caused by the following factors:

- Impurities in the consumable material or on the build plate obstruct the forming area, leading to voids.

- The release film of the build plate or obstructions on the printer.

- The printing screen has dead pixels or is cracked.

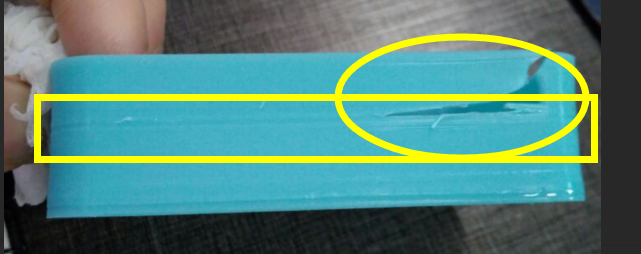

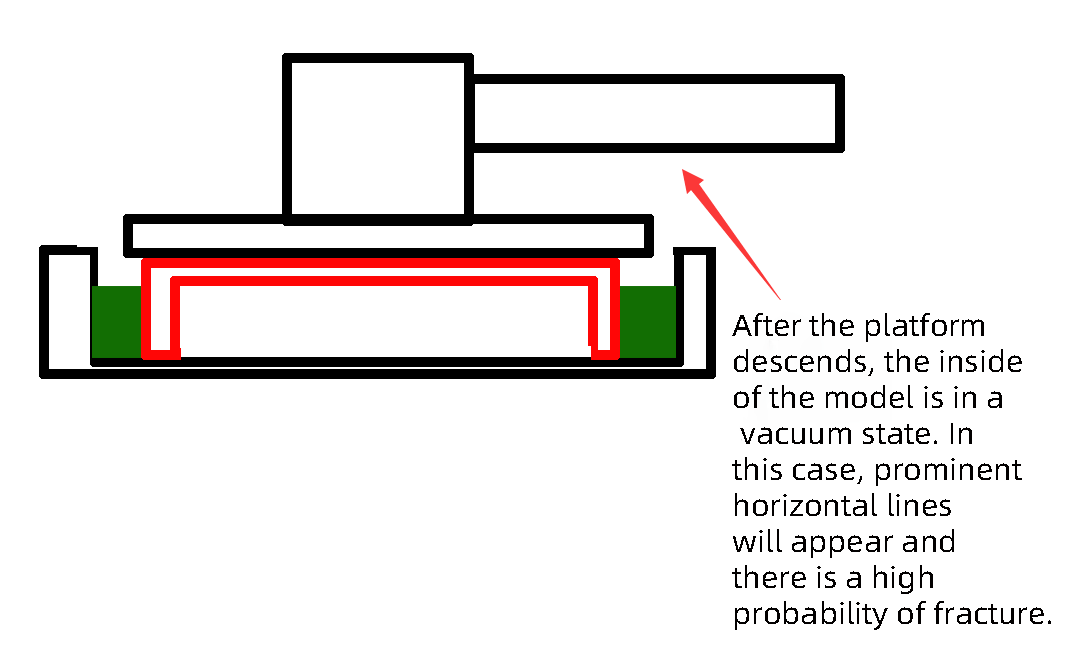

¶ In the yellow framed area, there is evident layering and signs of delamination analysis:

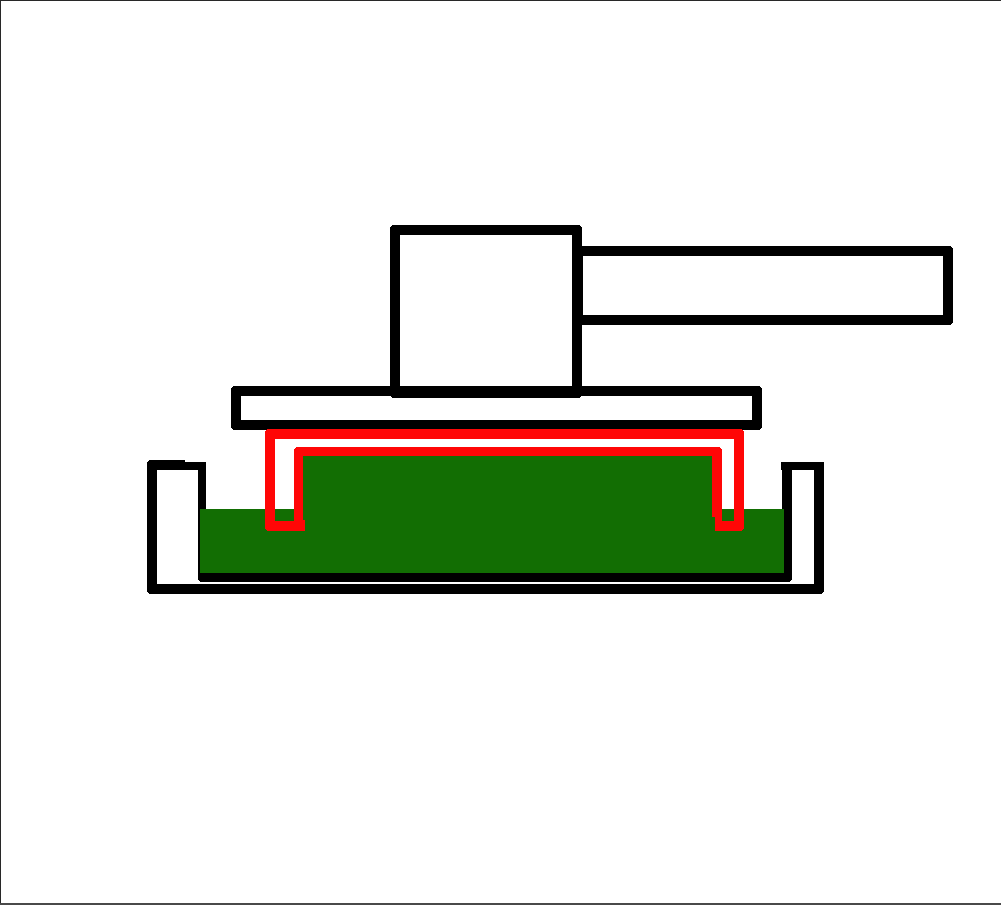

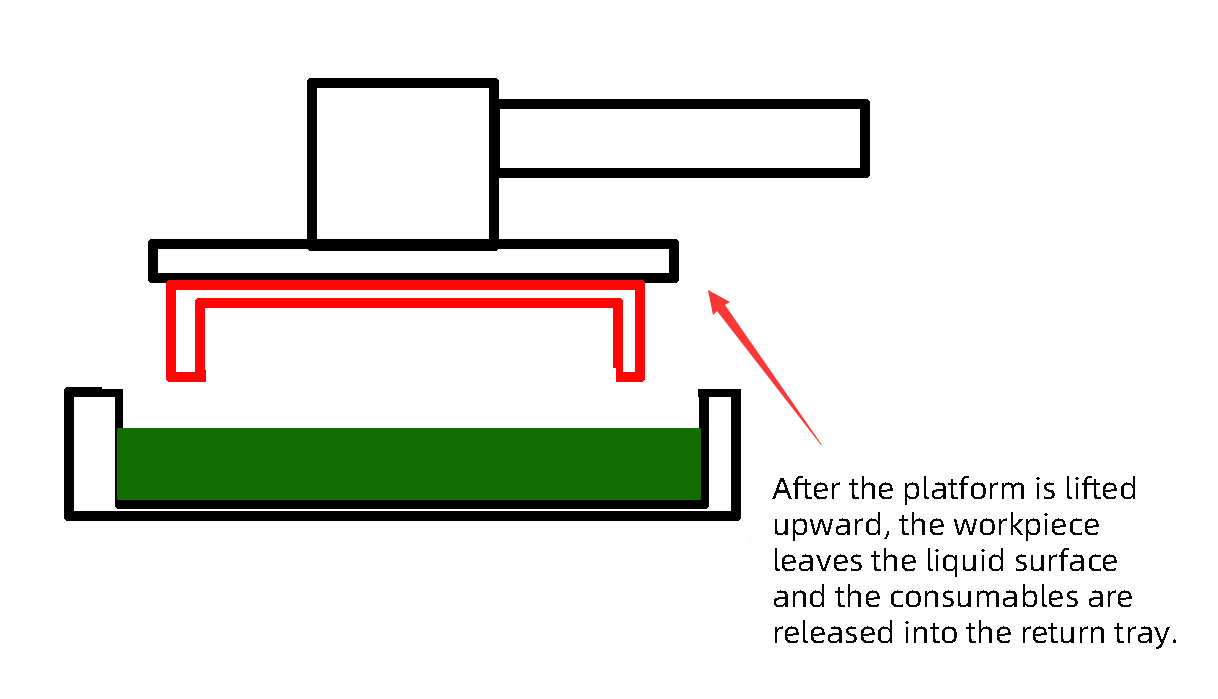

When printing the shell-like parts, under such printing conditions, it resembles a bowl filled with liquid being inverted and tapped on the liquid surface. The surrounding frame is in a vacuum state within the material and stores the material. When the part needs to be lifted from the liquid surface, it will release and merge with other materials. This inverted tapping printing method results in a vacuum state after the internal material is suddenly released when the part leaves the liquid surface, leading to issues with print lines and incomplete printing.

¶ Troubleshooting and solution

¶ Solutions to Red Arrow Hole Issues:

- First, inspect the 3D printer's display screen. Use the screen diagnostics to check if there are any dead pixels (black spots) or contaminants at the corresponding hole locations and clean the screen to ensure it's free from impurities and clear. 2. Filter and pour out the material from the resin vat and examine the FEP film for any obstructions or contaminants. After filtering the resin, check again for any obstructions or impurities.

- Clean the build plate with alcohol to ensure that there are no protrusions or remnants of previous prints on the build area.

¶ Solutions to Horizontal Lines and Breakages within the Yellow Circle:

- Change the orientation of the print object to avoid situations where vacuum suction occurs. For example, position it at an angle (recommended).

- Use third-party software to create a small hole in the model to release the vacuum pressure, such as with software like Magics or ChiTuBox.