¶ Basic Principle: The drier the filament, the higher the print quality.

When filament is exposed to air, it absorbs moisture, leading to dampness. This phenomenon is called hygroscopicity. The degree of moisture absorption is closely related to the type of filament and environmental conditions (such as temperature, humidity, and exposure time).

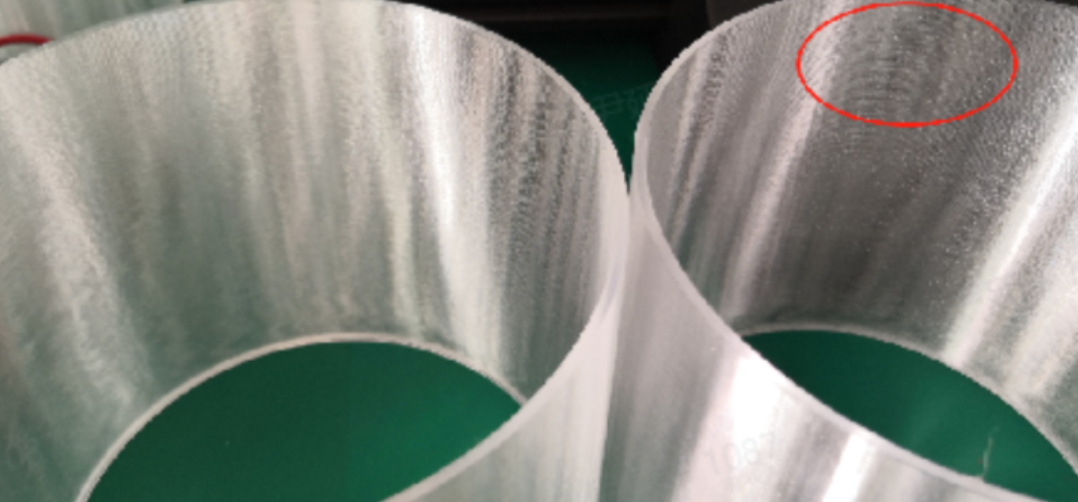

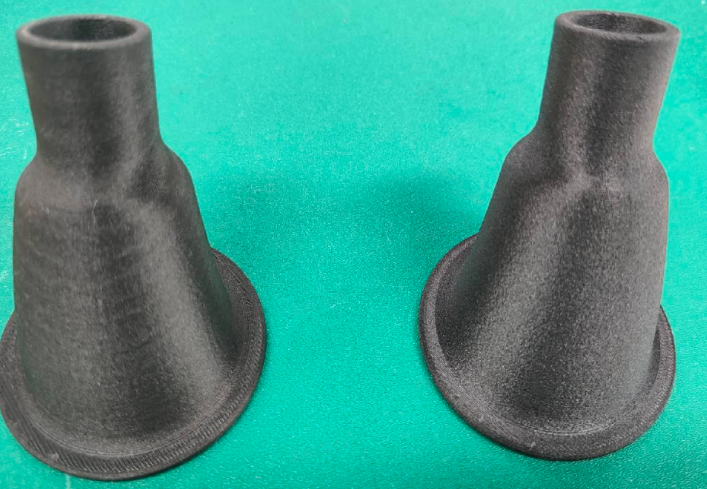

Once the filament becomes damp, during the heating process of printing, the moisture inside the nozzle turns into water vapor, causing increased fluidity of the filament. At this time, bubbles may appear on the surface of the extruded filament, leading to issues such as stringing, leakage, holes, bubbles, roughness, and color differences on the surface of the printed object. The strength of the printed parts will also decrease. Therefore, when filament dampness is detected, it is recommended to dry it immediately before printing.

For situations requiring high model strength and appearance quality, it is recommended to thoroughly dry the filament before printing and maintain its sealing and dryness protection during use.

¶ Pre-printing filament drying requirements

The recommended drying parameters for various filaments are as follows:

| Filament | Dry before Use | Dry in Use | Creality Filament Dryer | Blast Dryer | ||

| Drying Temp/℃ | Drying Time/h | Drying Temp/℃ | Drying Time/h | |||

| PLA、PLA-CF | Suggest | When the ambient humidity exceeds 50% Suggest | 55 | 8 - 12 | 50 - 60 | 8 |

| PETG | Suggest | When the ambient humidity exceeds 50% Suggest | 60 | 8 - 12 | 65 | 8 |

| ABS、ASA | Suggest | When the ambient humidity exceeds 50% Suggest | 65 | 8 - 12 | 70 - 80 | 8 |

| PC | Must | Must | / | / | 80 - 100 | 8 |

| TPU | Must | Must | 70 | 8 - 12 | 65 - 75 | 8 |

| PA、PA-CF | Must | Must | / | / | 80 - 90 | 8 - 12 |

| PAHT-CF/GF | Must | Must | / | / | 80 - 100 | 4 - 8 |

| PPA-CF | Must | Must | / | / | 100 -120 | 8 - 12 |

| PET-CF | Must | Must | / | / | 100 -120 | 8 |

| PPS、PPS-CF/GF | Must | Must | / | / | 130 -140 | 8 |

| PVA | Must | Must | 70 | 16 | 75 - 85 | 8 - 12 |

| BVOH | Must | Must | 65 | 8-16 | 60 | 6-16 |

| Support for PLA | Suggest | When the ambient humidity exceeds 50% Suggest | 60 | 8 - 12 | 60 - 70 | 6 - 8 |

| Support for PA | Must | Must | 70 | 16 | 75 - 85 | 8 - 12 |

Note: When drying, be aware that if the drying temperature exceeds the heat resistance of the tray, it may deform or melt.

¶ Filament drying during printing

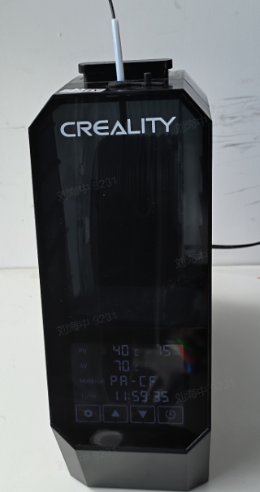

Moisture-sensitive filaments need to be kept dry during printing to prevent moisture absorption during the printing process, which affects the surface quality and strength of the printed object. As shown in the figure below, there are three drying methods available for users: ordinary non-heated drying box, (Creality) heatable drying box, and (Creality CFS) multi-color filament box.