¶ Machine Cleaning

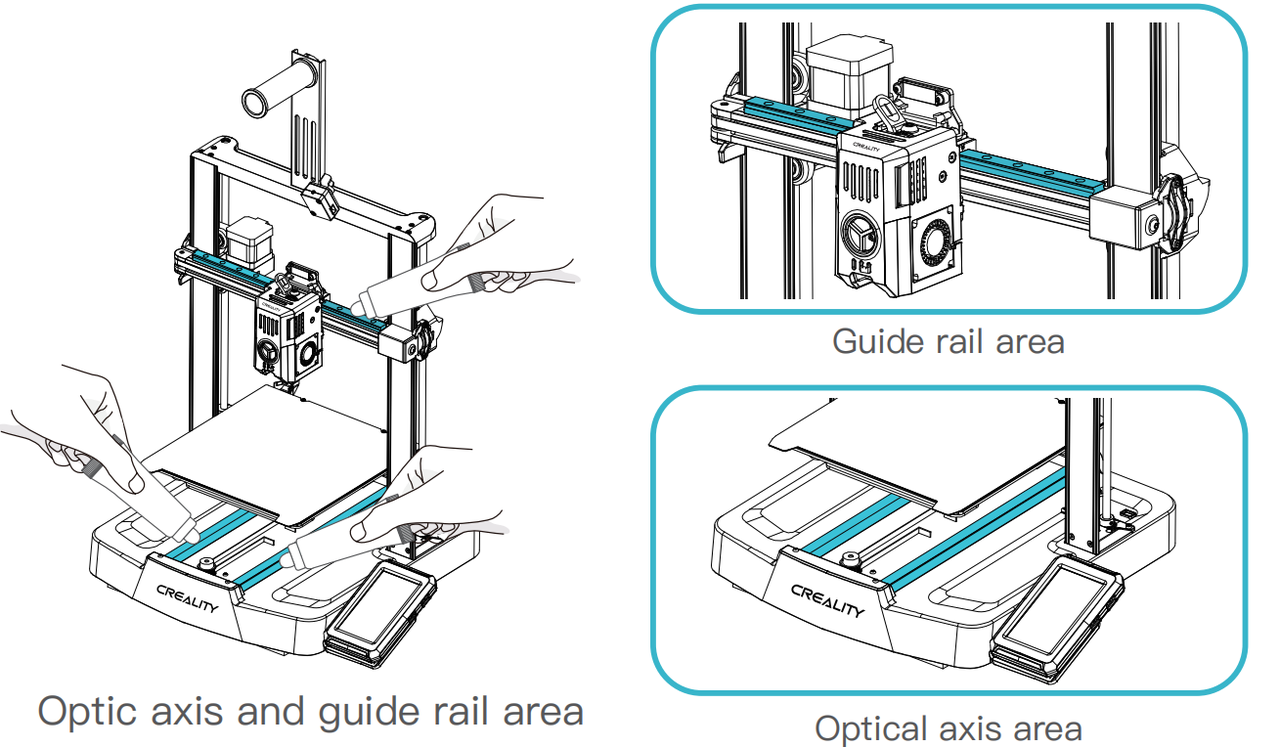

1.1 Clean the debris in the area under the platform near the optical axis before each print to prevent waste material from affecting the machine's movement.

¶ Hot-end Maintenance

2.1 Please replace the nozzle after every cumulative 500 hours of printing. (Note: Before replacing the nozzle, heat it up to 200 degrees Celsius. For detailed instructions, refer to the after-sales service video.)

Video Link: Replace Ender-3 V3 KE Nozzle

2.2 After each material change, please check if the extrusion is normal. If it is abnormal, check for nozzle clogs or jams.

2.3 Before each print, please check if there is any residual material on the nozzle. If present, heat the nozzle and remove the residue using a tool.

2.4 In case of a nozzle clog, please refer to the instructional video for cleaning procedures.

Video Link: Clean Ender-3 V3 KE Nozzle and Heat Break

¶ Print Bed Maintenance

3.1 Before each print, inspect the bed surface for any residual materials, glue, etc. If present, clean the bed surface.

3.2 Before each bed leveling, first check if there are any residual materials or glue on the bed surface, and whether the bed is damaged. If the bed has damaged or residual materials, it may cause errors in leveling, leading to the model not adhering to the bed.

3.3 The print bed is a consumable item and may encounter adhesion issues with the model after prolonged use. It is recommended to apply solid adhesive or replace the build plate.

¶ Motion Structure Maintenance

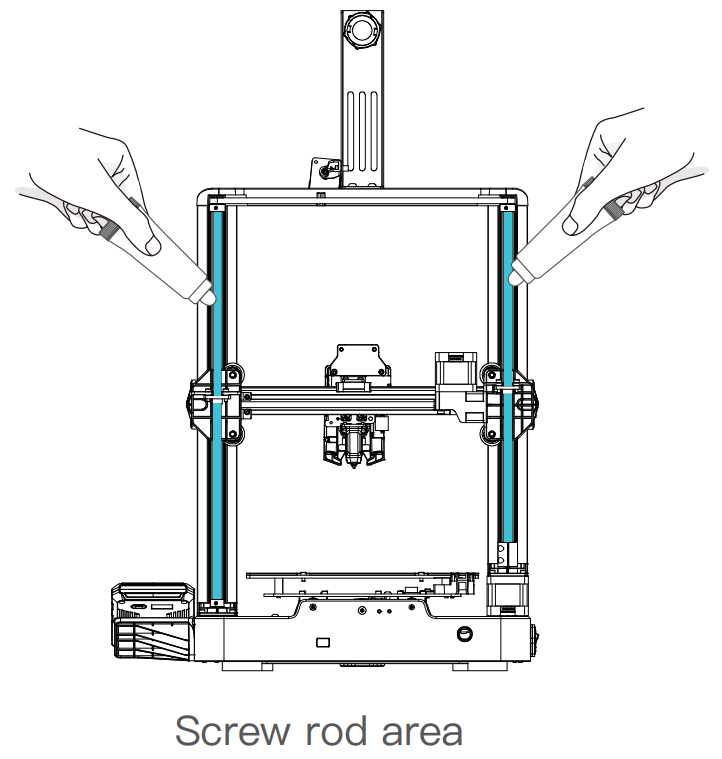

4.1 We recommend that users purchase lubricant and regularly (every 500 cumulative hours of printing time) lubricate the lead screws, optical axes, and guide rail areas.

¶ Equipment Self-Check

5.1 Please perform a self-check every 300 cumulative printing hours (automatic Z-axis homing + auto-leveling).

5.2 If a vibration compensation sensor has been purchased, also execute vibration pattern optimization operations.

Note: After each firmware update, it is necessary to re-perform the machine self-diagnosis and resonance tuning (unless it has not been purchased).

¶ Material Replacement

6.1 Material replacement of the same type follows the standard unloading-loading process.

6.2 Material Replacement for Different Materials: Preheat the nozzle to the target temperature of the current material - unload material, switch to the target material, preheat the nozzle to the higher of the two material's nozzle temperatures - load for 30 seconds until the residual material is completely extruded, then set the nozzle temperature to the current material's nozzle temperature to complete the process.

Example 1: Switching from PLA filament to ABS filament

First, preheat the nozzle to 220 degrees Celsius, retract the filament, remove the PLA filament, and replace it with ABS filament; then preheat the nozzle to 260 degrees Celsius, feed the filament for 30 seconds until the ABS filament extrudes normally.

Example 2: Switching from ABS filament to PLA filament

First, preheat the nozzle to 260 degrees Celsius, retract the filament, remove the ABS filament, and replace it with PLA filament; then maintain the nozzle at 260 degrees Celsius, feed the filament for 30 seconds until the PLA filament extrudes normally, and finally set the nozzle temperature to 220 degrees Celsius.