¶ 1. X-axis Guide Rail Maintenance

The guide rail needs to be regularly checked for lubricant depletion, dust or filament debris accumulation, and requires periodic cleaning and lubrication.

¶ 1.1 When maintenance is needed

Check once a month for dust or debris accumulation.

¶ 1.2 How to maintain

Clean the guide rail surface with a lint-free cloth and apply a thin layer of metal anti-rust oil.

¶ 2. Y-axis Dual-core Optical Shaft Maintenance

The Y-axis dual-core optical shafts have been lubricated before leaving the factory. To prevent corrosion and extend service life, regular maintenance is recommended.

¶ 2.1 When maintenance is needed

Check and maintain once a month. If frequently printing with volatile materials like ABS or ASA, maintenance is recommended every 5 days.

¶ 2.2 How to maintain

Clean the optical shaft surface with a lint-free cloth and apply lubricating grease.

¶ 3. Z-axis Lead Screw Maintenance

Creality Hi has two lead screws on the left and right sides, responsible for the up and down movement of the hotend assembly. Regular cleaning and lubrication are required to ensure service life.

¶ 3.1 When maintenance is needed

Check and maintain every three months. If frequently printing with volatile materials like ABS or ASA, maintenance is recommended every 5 days.

¶ 3.2 How to maintain

Clean the optical shaft surface with a lint-free cloth and apply lubricating grease.

¶ 4. Belt Maintenance/Belt Tensioning

¶ 4.1 Belt Inspection

After continuous printing for over 336 hours (two weeks), the X-axis belt may fatigue, leading to difficulties in cutting the filament. Users need to manually tension the belt.

Check the belt tension and cleanliness weekly.

¶ 4.2 Belt Maintenance

If there is dirt or debris, wipe clean with a clean cloth and add an appropriate amount of lubricating oil.

¶ 4.3 Manual Belt Tensioning

¶ 4.3.1 X-axis synchronous belt tensioning.

Locate the X-axis belt tensioning screw on the back of the X-axis. Loosen the screw counterclockwise, and the internal spring in the X-axis will tighten the X-axis belt. Then tighten the screw clockwise to complete X-axis belt tensioning.

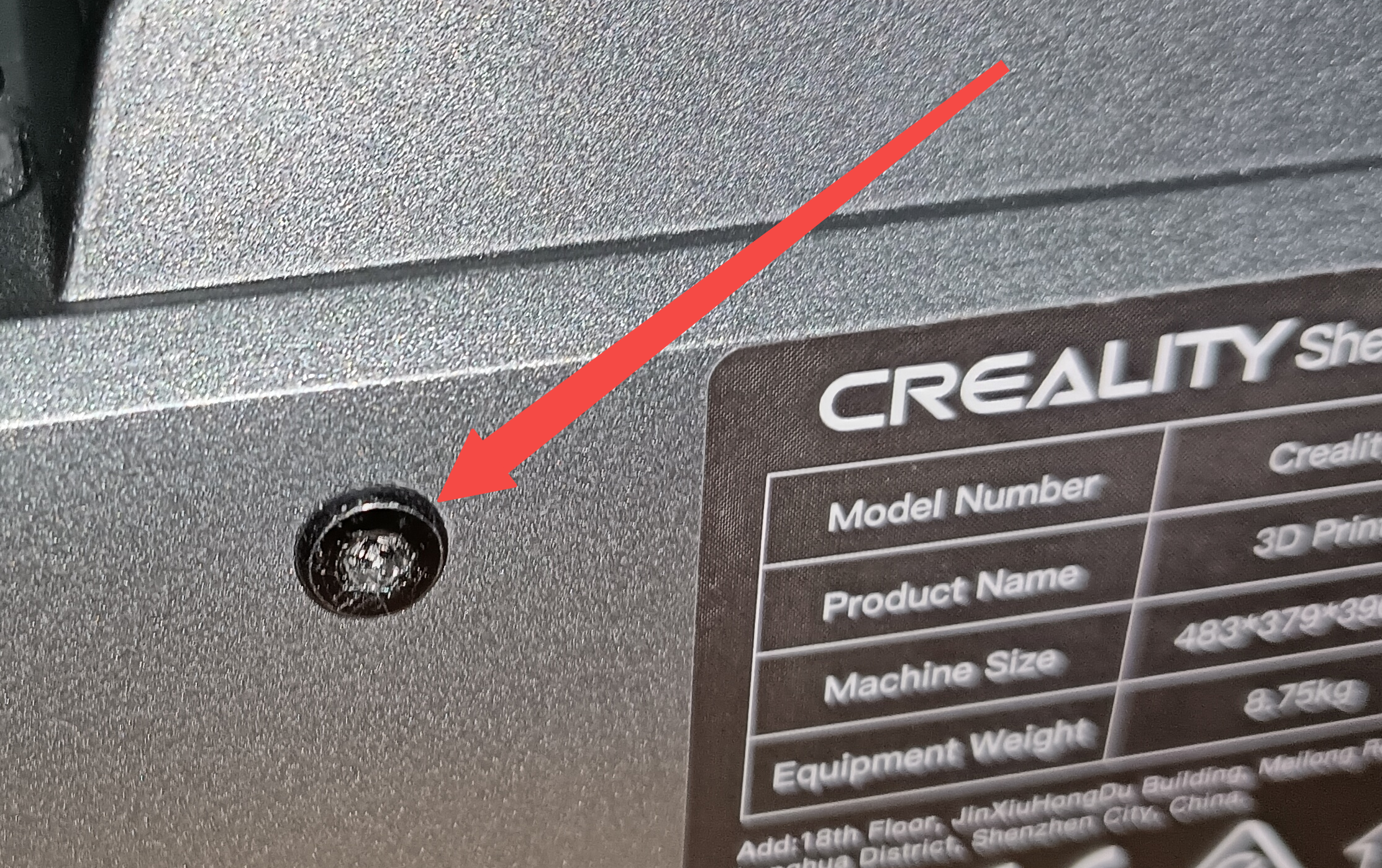

¶ 4.3.2 Y-axis synchronous belt tensioning.

Push the hot bed forward from the back of the machine. The two screws under the hot bed are the Y-axis belt tensioning block fixing screws. Turn counterclockwise to loosen these screws, but no need to remove them completely, just loosen them.

At the back of the machine base, this screw is the Y-axis belt tensioning screw. Turn this screw clockwise to tighten the belt. Then tighten the Y-axis belt tensioning block fixing screws.