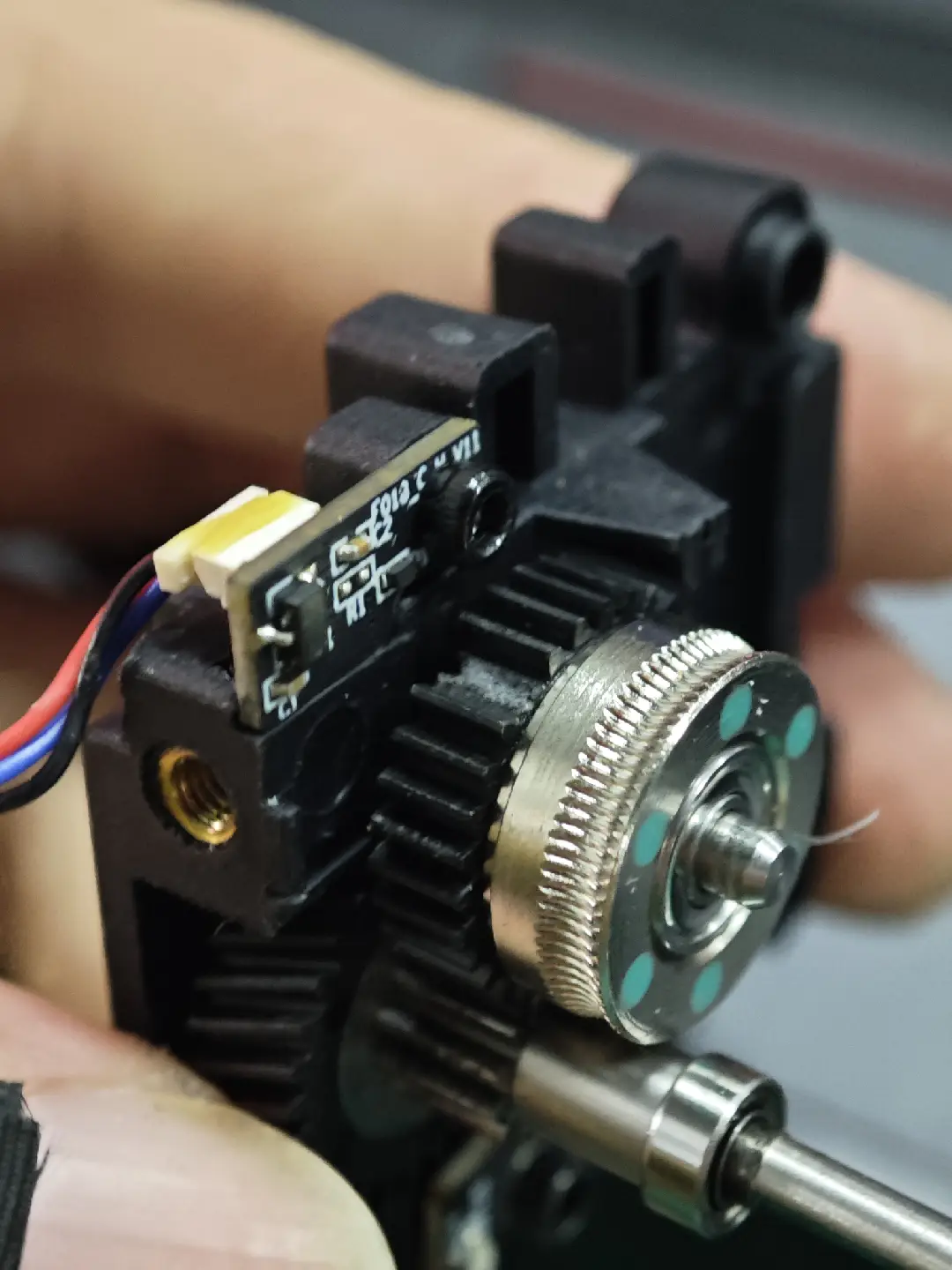

¶ 1. Extruder Gear Assembly

¶ 1.1 When maintenance is needed

Check the extruder or gears monthly for dust or filament debris, and clean them promptly.

If the extruder shows exception like clogging, abnormal noises, or severe filament grinding, investigate the cause immediately.

¶ 1.2 How to maintain

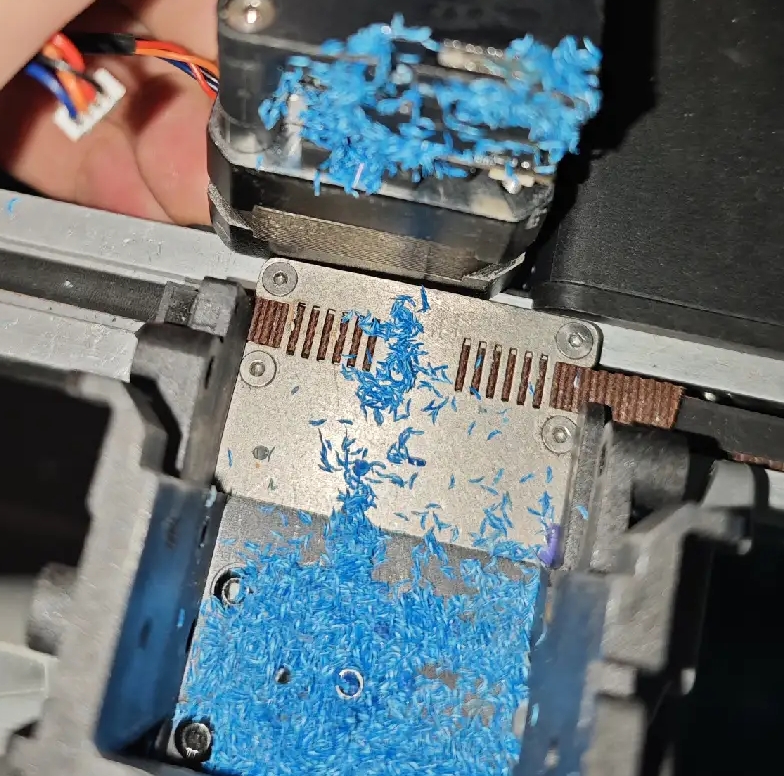

¶ 1.2.1 Cleaning the extruder gears

Refer to the after-sales video "Clearing Clogged Extruder ". Disassemble the extruder, use a brush or air blower to clean filament debris and other foreign objects from the gears.

Then reassemble the extruder.

¶ 1.2.2 Filament expansion, bending, or accumulation inside the extruder

Remove the extruder gear, cut the filament with diagonal pliers and pull it out.

Check if the three gears are damaged

After cleaning the filament inside the extruder, if the gears are undamaged, reinstall them.

For detailed procedures, please refer to the after-sales video tutorial "Clean the clogged Extruder".

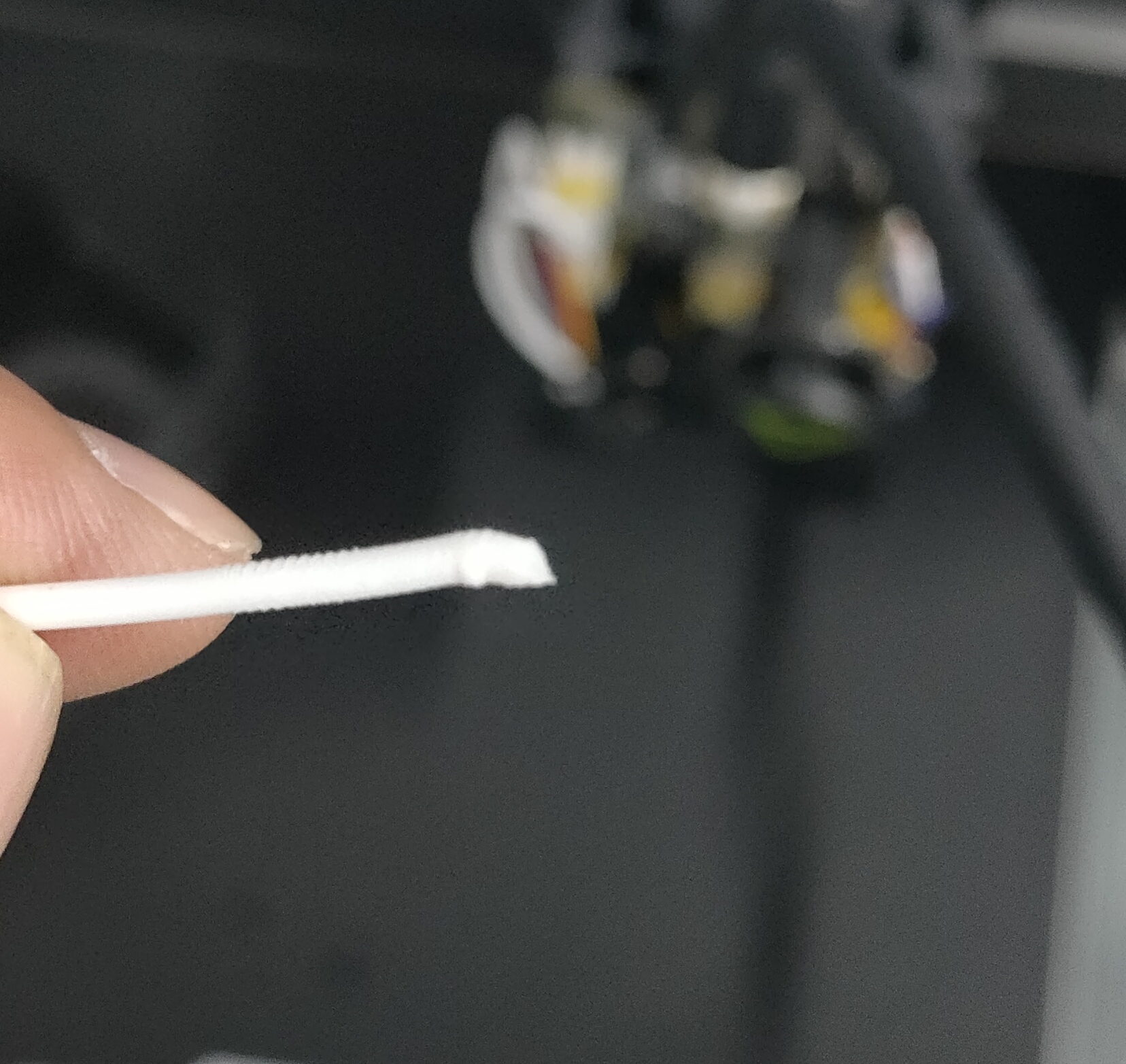

¶ 1.2.3 Clogged nozzle

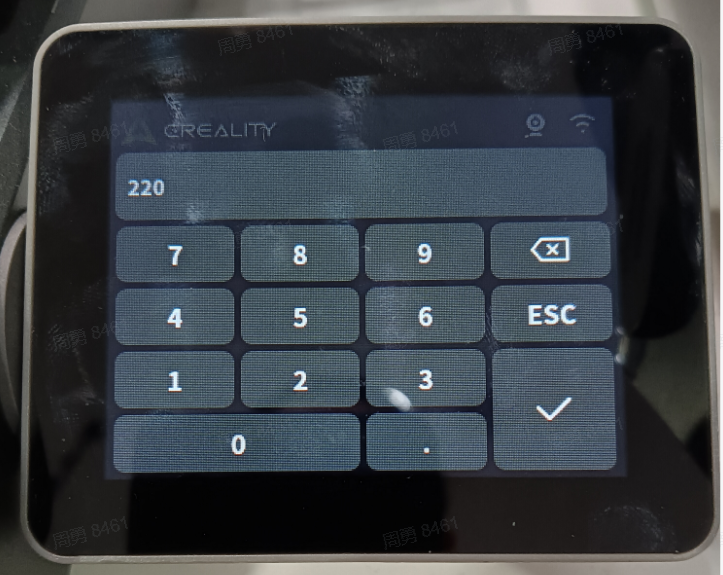

- On the screen, tap the nozzle temperature and heat it to the filament extrusion temperature

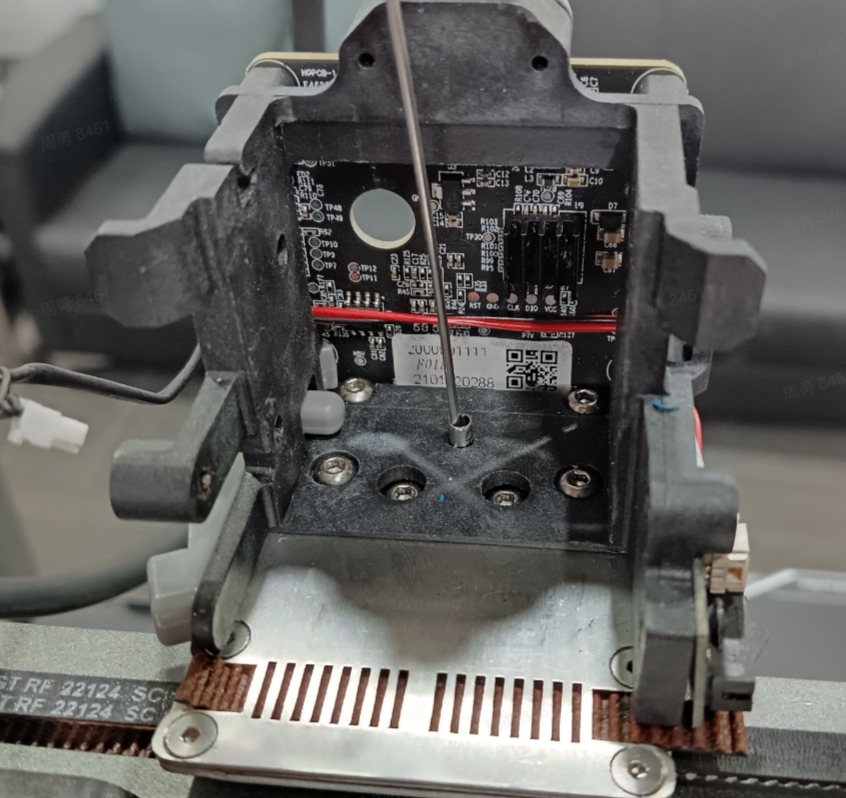

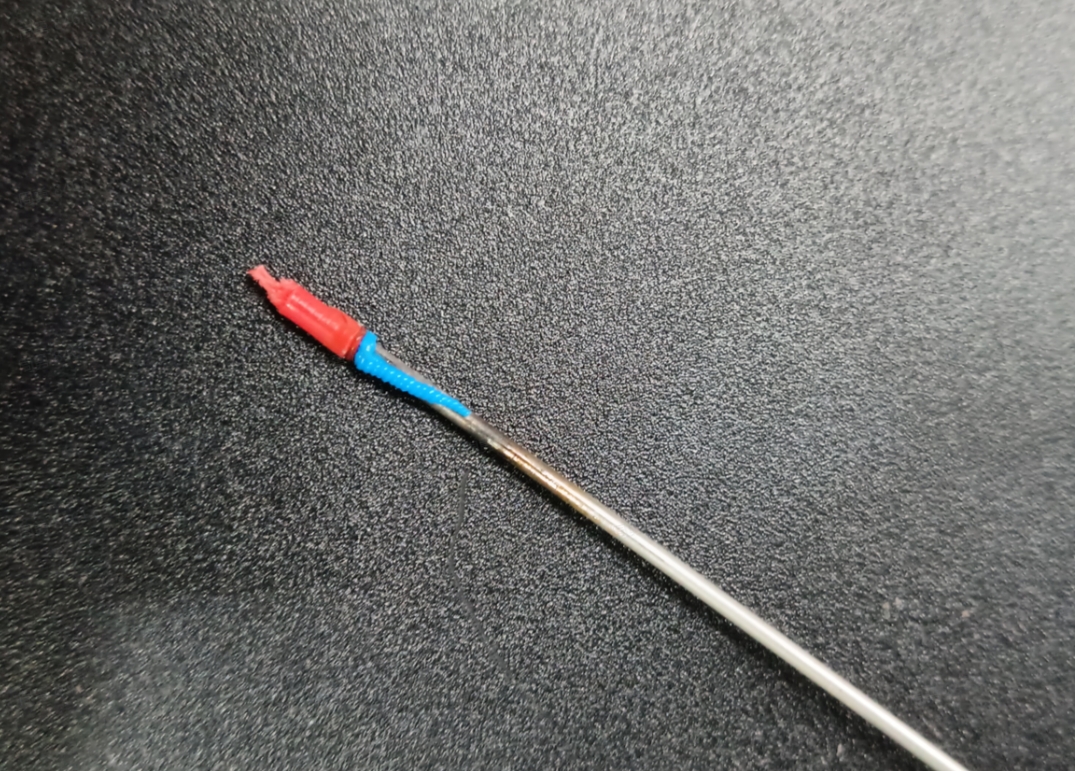

- Use a heating tool to heat the needle tip

- Insert the cleaning needle into the heat break, wait 30 seconds for the needle to cool

- After the needle cools, slowly pull it out, which can remove clogged filament from the pipe.

If the clog cannot be cleared after attempting this, replace the integrated nozzle. For detailed procedures, please refer to the tutorial "Replace the Hotend".

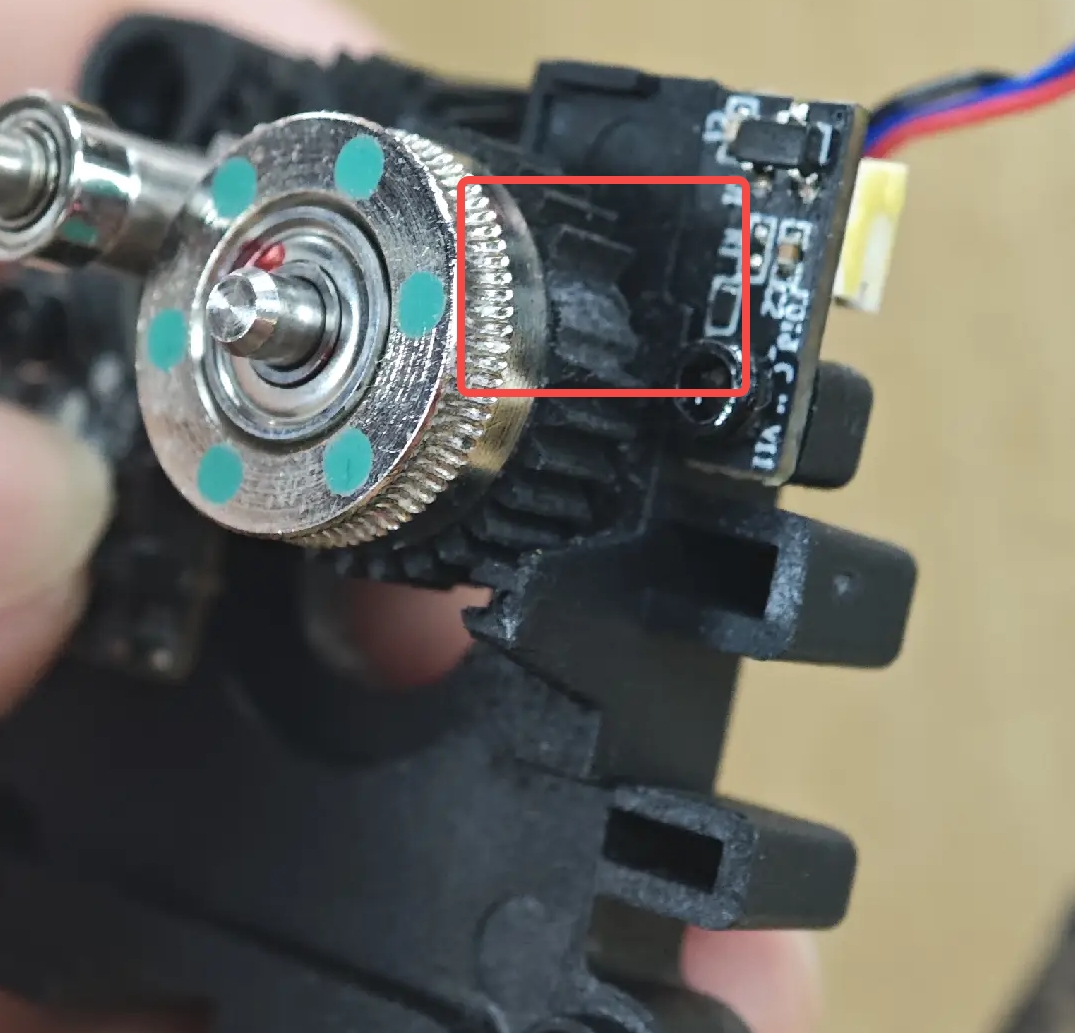

¶ 2. Integrated Material Break Detection Module

¶ 2.1 When maintenance is needed

When filament is extruded to the extruder, the blue light of the filament break detection should turn on, and turn off when there's no filament. If abnormal, check promptly to avoid affecting normal printing.

¶ 2.2 How to maintain

2.2.1. Check if filament from an external spool holder was left inserted after last use, while trying to print with CFS this time; if so, retract the filament first, then connect the CFS's PTFE tube before printing with CFS.

2.2.2. If it's not filament from an external spool holder, there might be broken filament remnants inside the extruder.

2.2.3. False triggering of filament break detection. Check if the detection light is blue when no filament is inserted (normally, it should light up blue when filament is detected, and be off when there's no filament), indicating a triggered state.

A. Check if there's residual filament or other debris in the feeding tube.

B. Check if the buckle at the material break detection port is broken, causing poor contact.

¶ 3. Filament Cutter Maintenance

Creality Hi uses the cutter to cut filament during each filament change, print pause, or print stop; after frequent cutting, the cutter may become less sharp, eventually failing to cut filament, so regular inspection and replacement of the cutter is necessary.

¶ 3.1 When maintenance is needed

For PLA/ABS/PETG/PC and other filaments, check once after printing 5 rolls

For fiber-reinforced filaments, if frequent cutting still occurs during printing, check immediately after printing 1 spool

¶ 3.2 How to maintain

Following the cutter replacement procedure, remove the cutter for inspection, replace if worn.

¶ 3.3 Replacing with a new cutter

If filament still can't be cut after recalibration, directly replace with a new cutter, recalibrate the cutter, then print and monitor subsequent cutting performance.

¶ 4. Input Shaping

Creality Hi's Input Shaping feature includes filament cutter position calibration and shape compensation; as belts gradually stretch with long-term use, print quality may deteriorate and the filament cutter position may change, so regular running of the input shaping function is necessary.

¶ 4.1 When maintenance is needed

Run once a month.

¶ 4.2 How to maintain

Ensure no filament is in the extruder, as it will affect cutter position calibration and cause failure.

Tap on the screen: Settings - Device Self-Check - Check Input Shaping - Tap Calibrate.