¶ 1.Propeller Scanning:

¶ 1)Paste markers

Paste 3-4 markers on the propeller's cylindrical surface and place it on a turntable with markers.

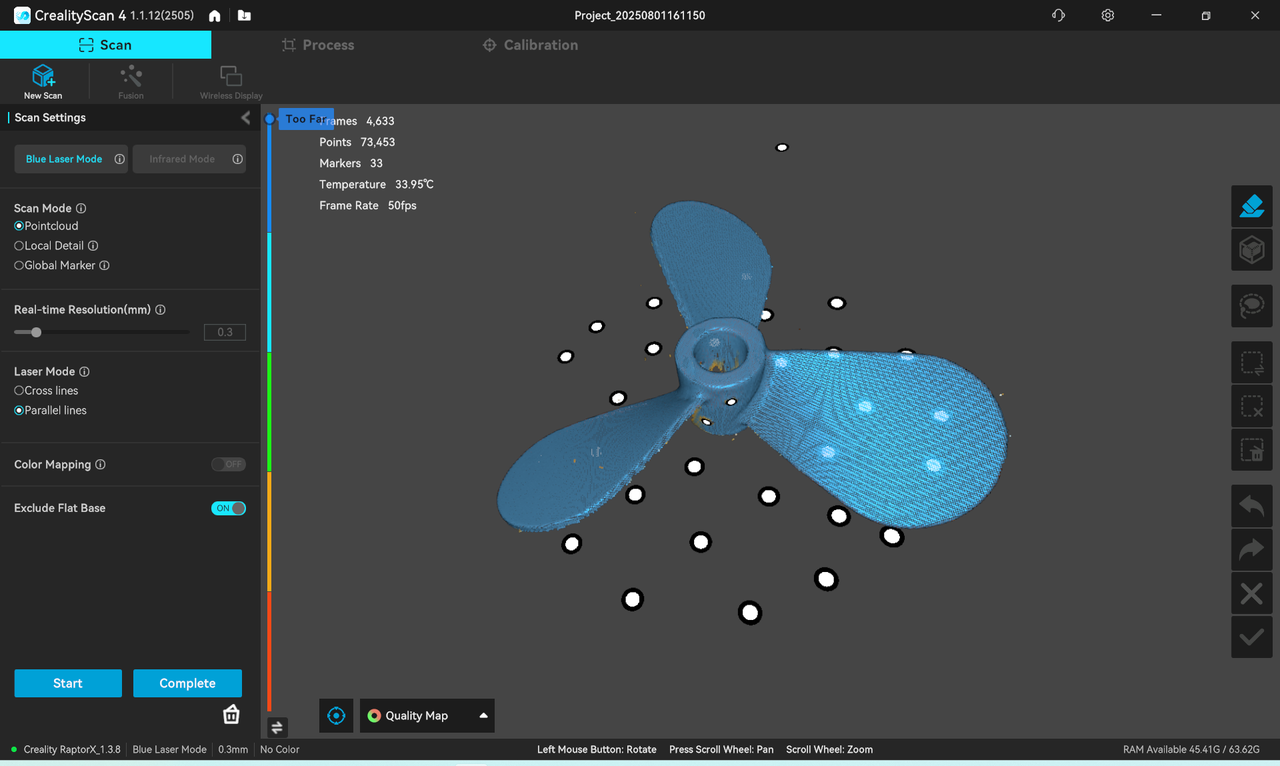

¶ 2)Scanning the front side

Open the CrealityScan software, select Blue Laser Mode, set resolution to 0.3mm, and scan the first side. Click "Complete" to complete scan1.

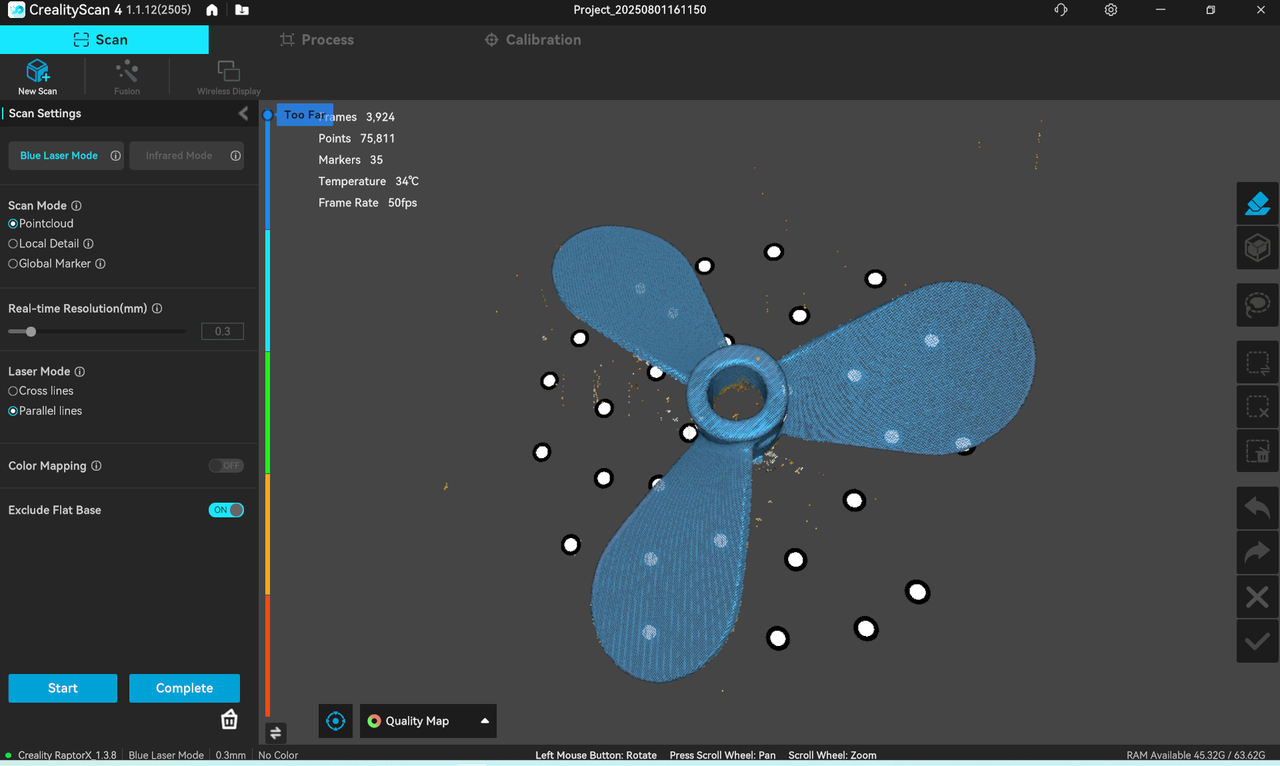

¶ 3)Scanning the back side

Click "New Scan" to scan the second side. Click "Complete" to complete scan2.

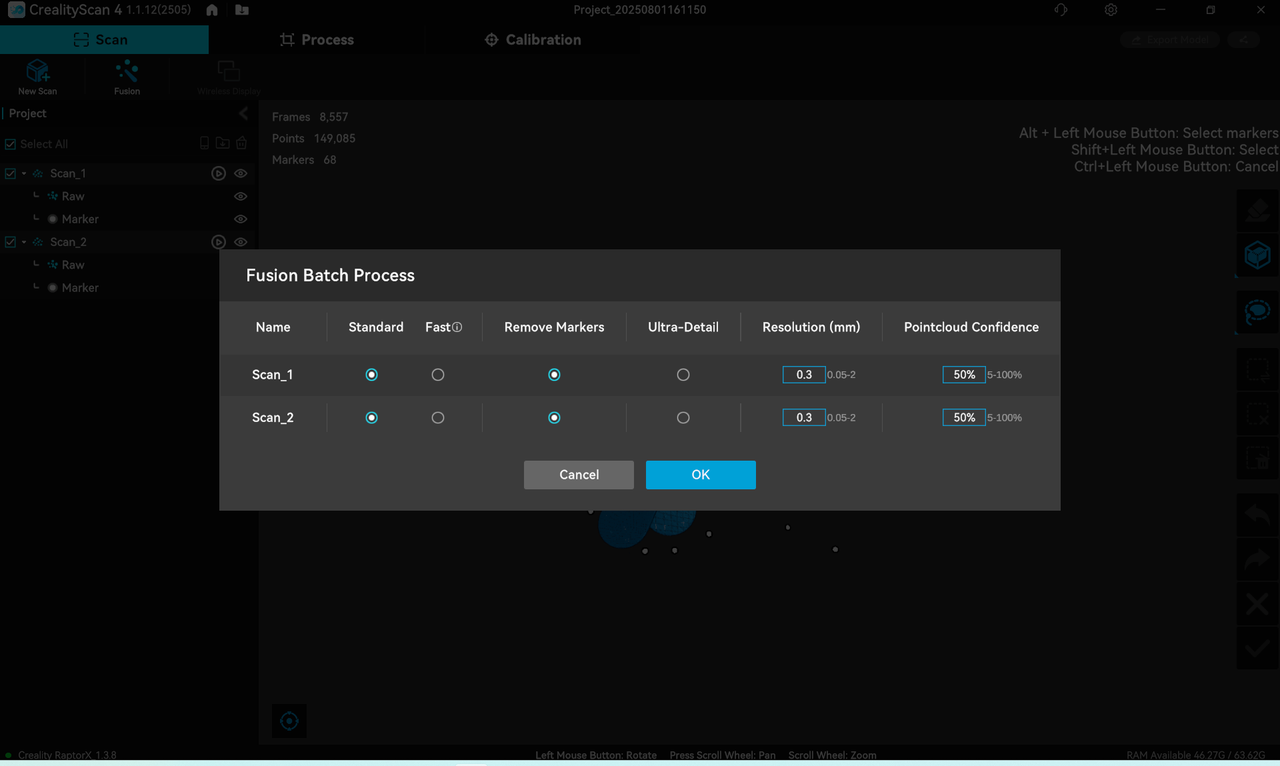

¶ 4)Fusion Batch Process

In the project list on the left, check scan1 and scan2, then click "Fusion" for Fusion Batch processing.

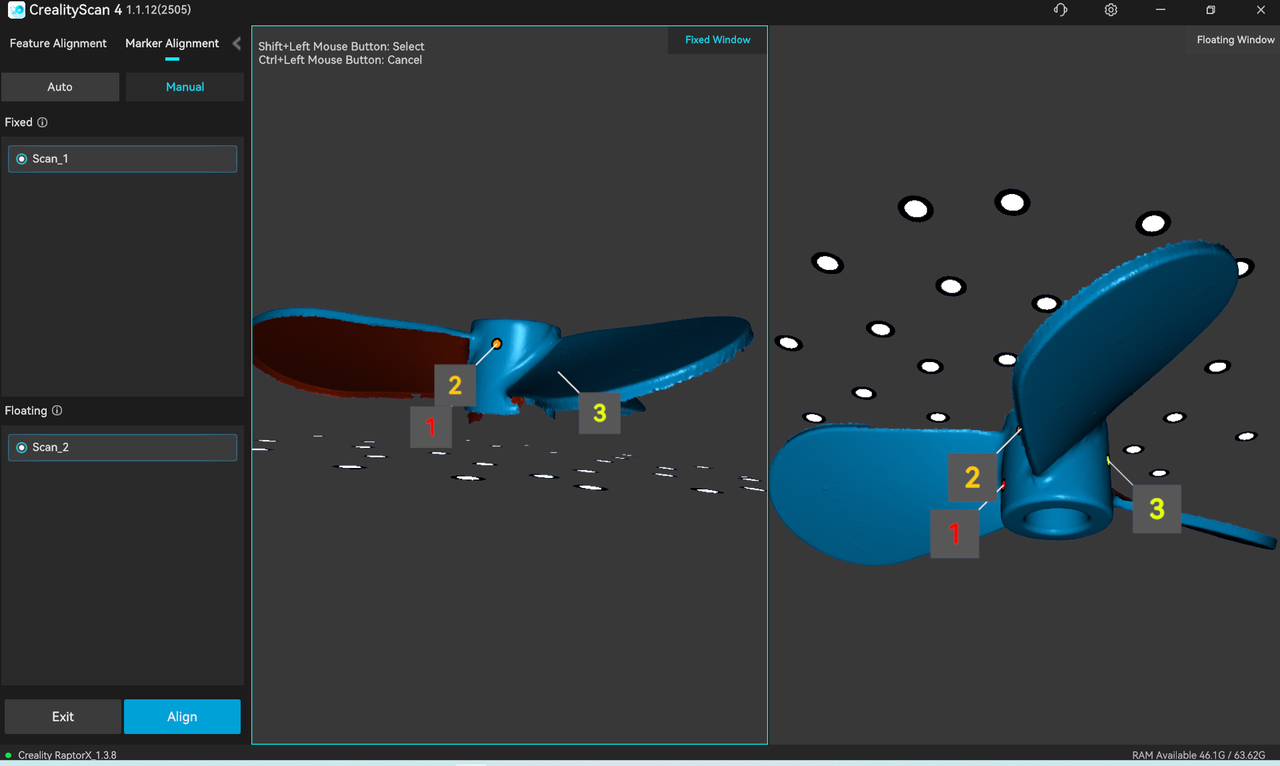

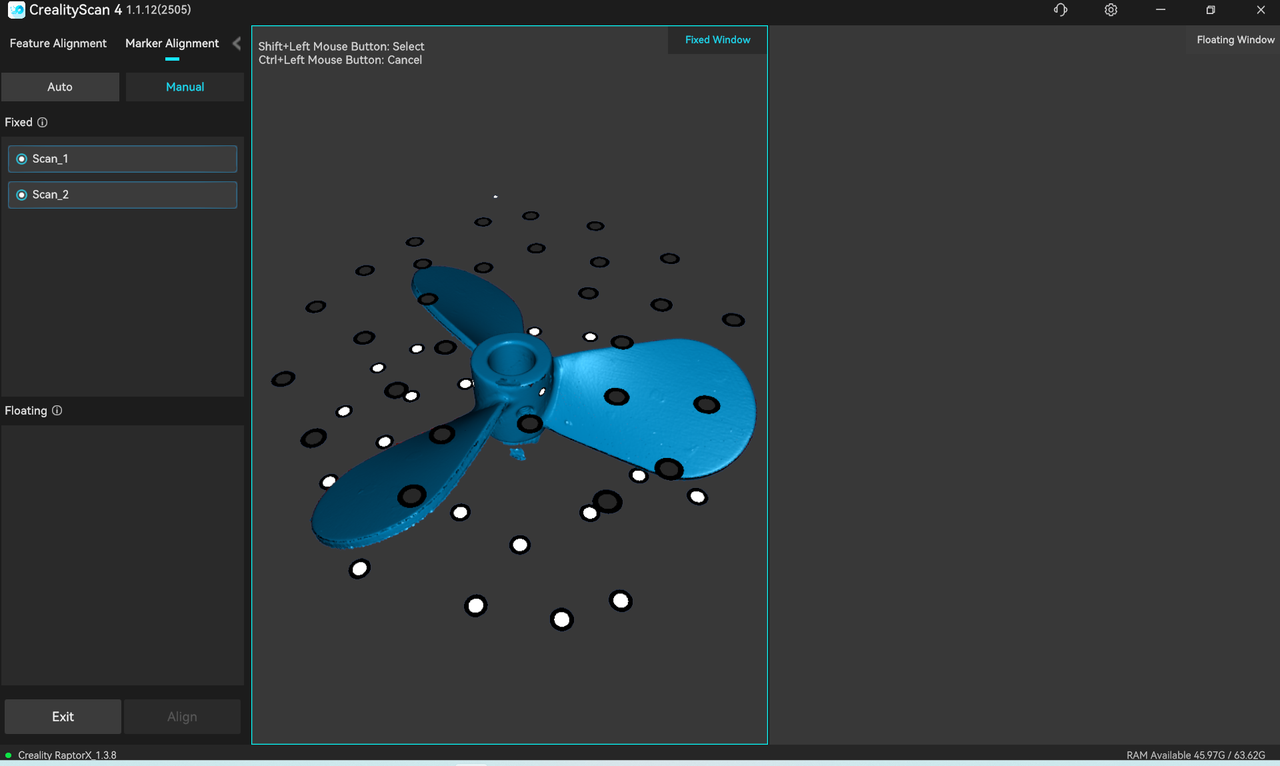

¶ 5) Alignment

After fusion, go to the "Process" module and click " Alignment". Use manual marker alignment mode, sequentially select markers on the front and the back of the cylindrical surfaces, and complete alignment.

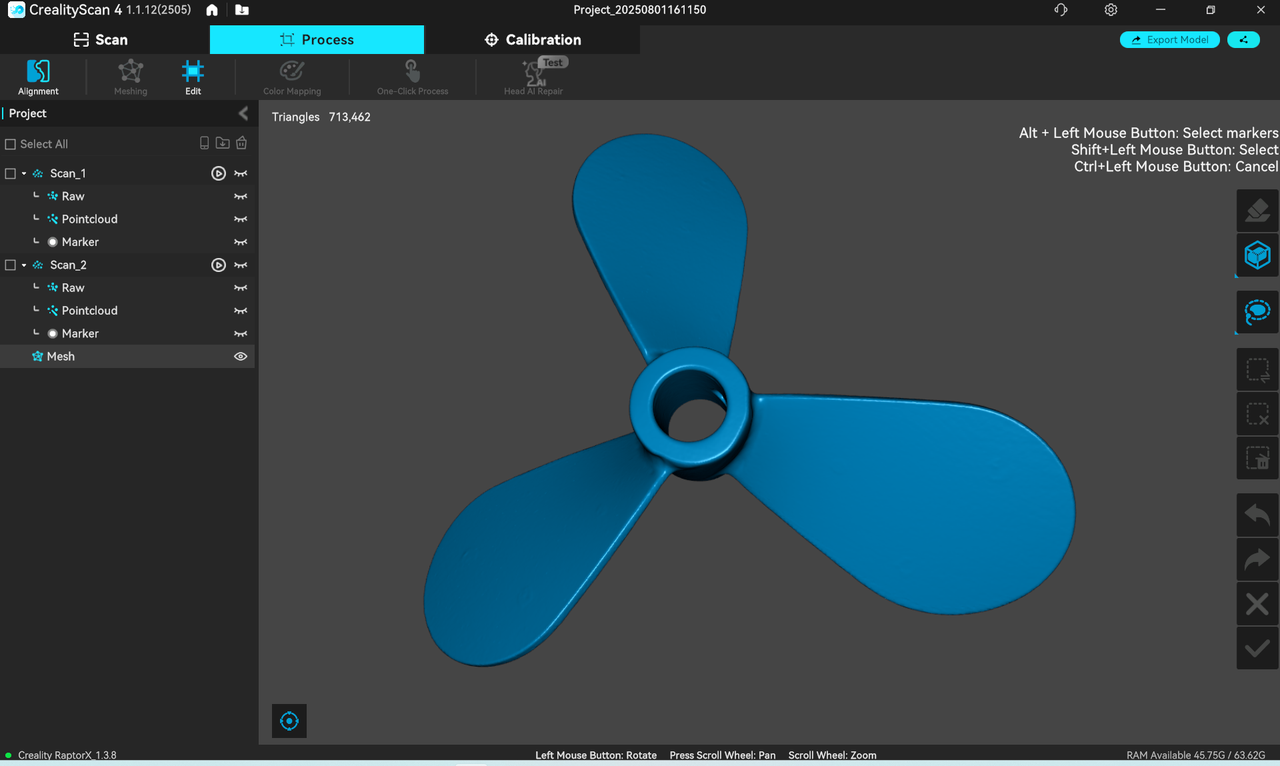

¶ 6) Meshing

Click "Meshing" to generate the surface model and finish the scanning job.

¶ 2. Propeller Reverse Modelling:

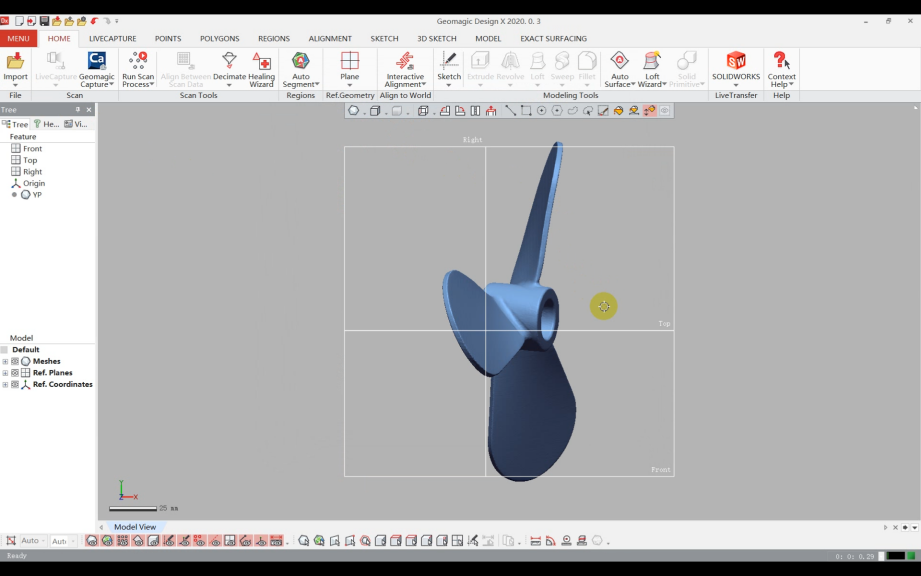

¶ (1)Import Data:

Import the "Propeller Data" into the reverse engineering software Geomagic Design X.

¶ (2)Coordinate Alignment:

1)Create alignment reference features.

2)Enter "Interactive Alignment" and perform a 321 alignment based on the workpiece structure, and complete alignment.

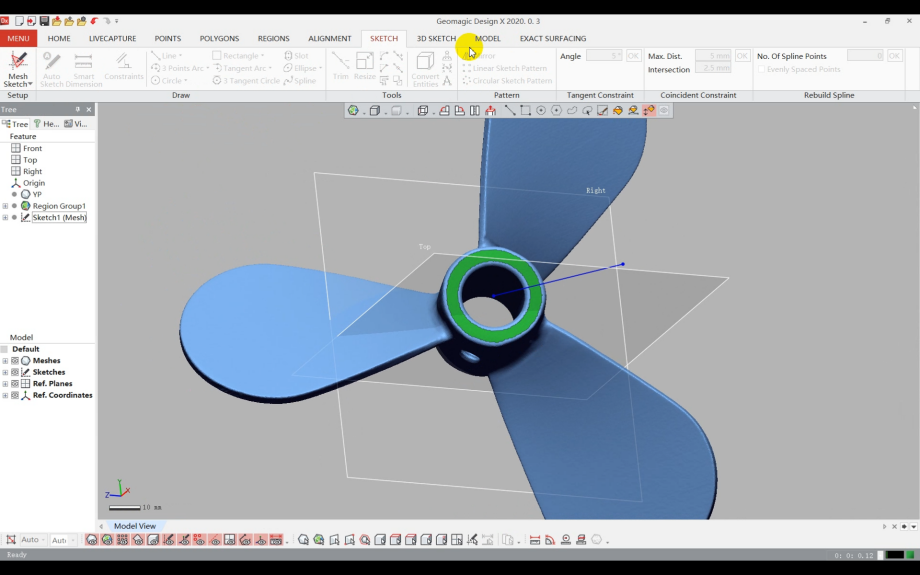

¶ (3)Blade Modeling:

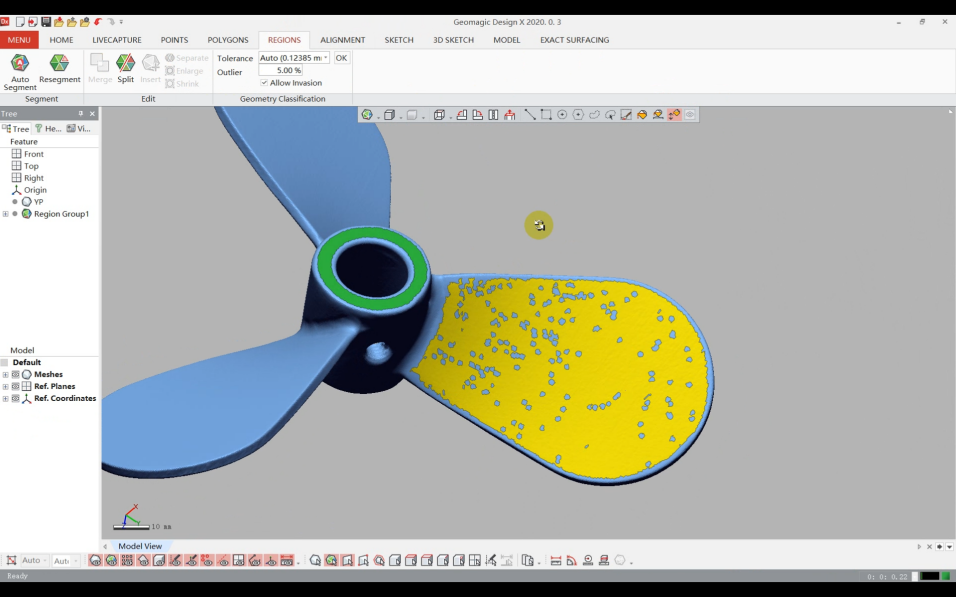

1)Divide one blade surface into a "Regions" in the software

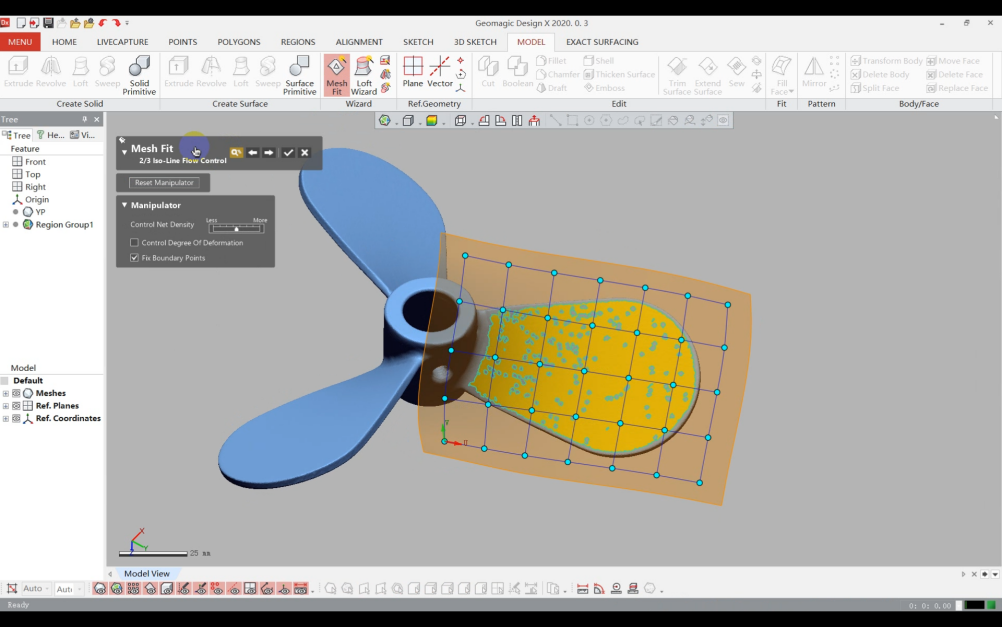

2)Use the "Mesh fit" tool to create the curved surface.

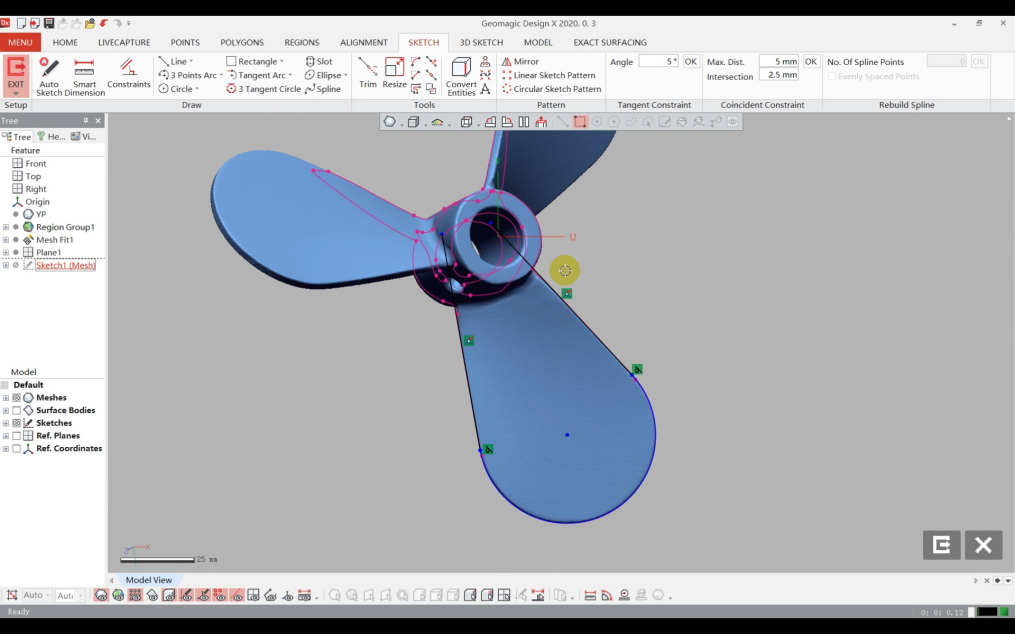

3)Create a sketch plane, enter "Sketch" with this plane, and redraw the blade contour using sketch lines.

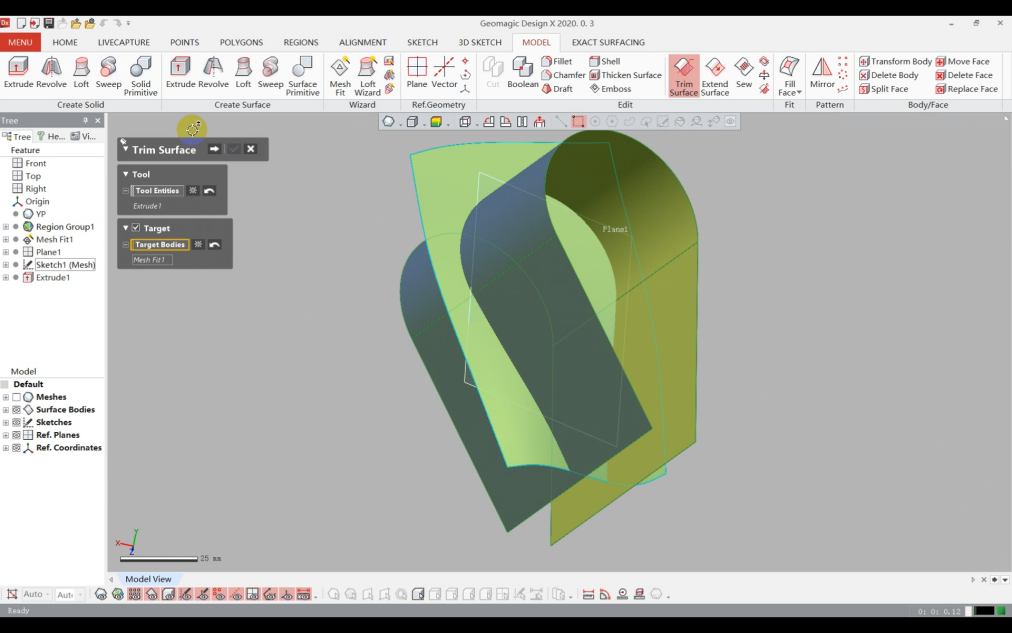

4)Extrude the surface and use it to trim excess areas.

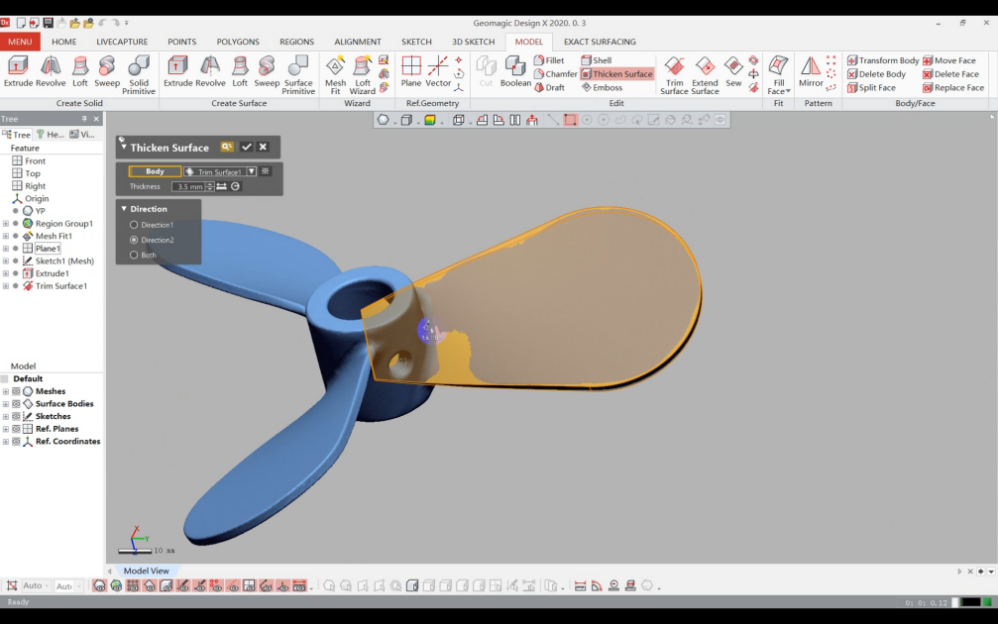

5)Thicken the blade surface based on its actual thickness

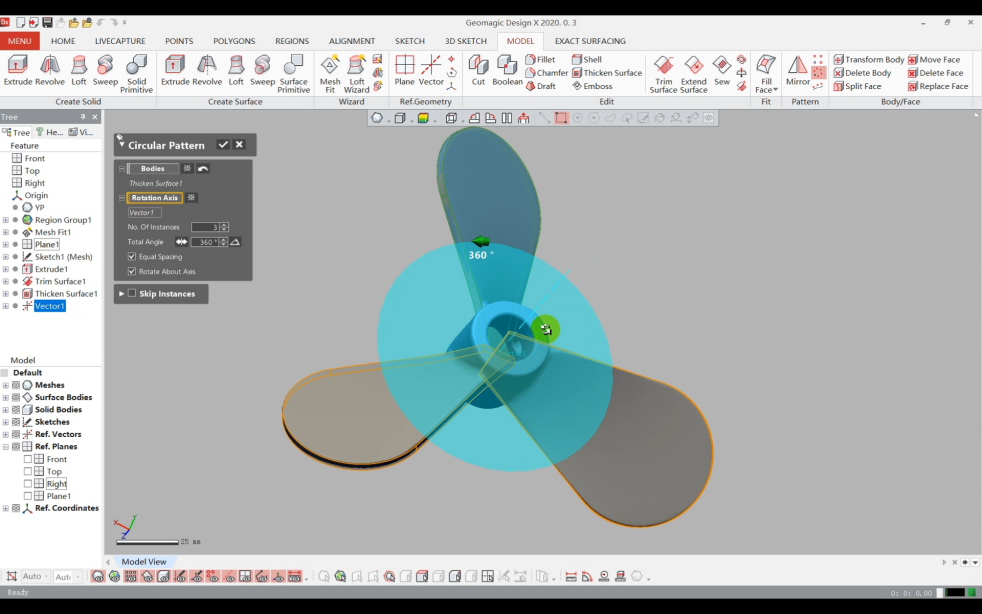

6)Array the blades, complete the solid modeling.

¶ (4)Hub Modeling:

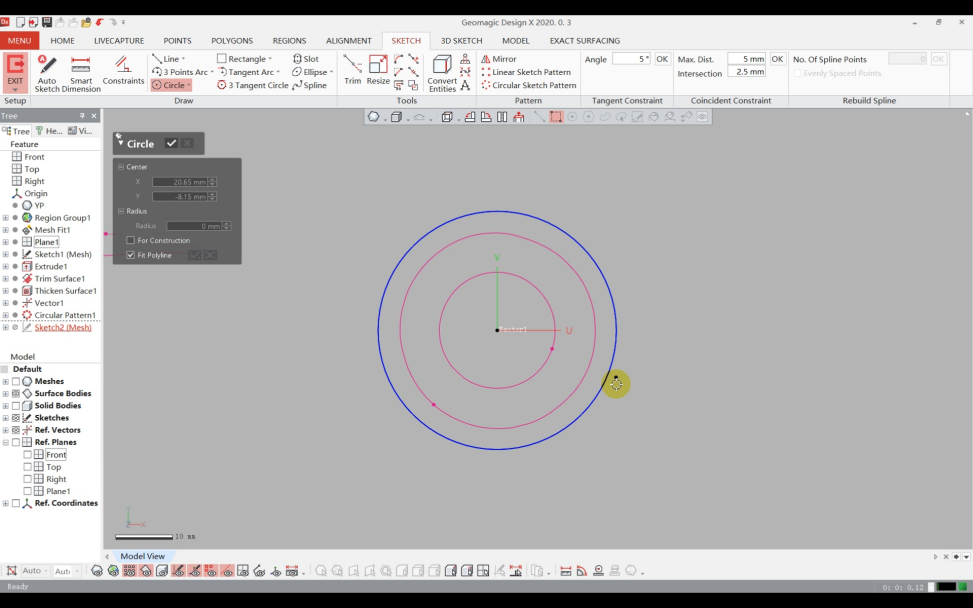

1)Use "Sketch" to draw the hub’s cross-sectional sketch.

2)Extrude the hub sketch into a solid and merge it with the blades.

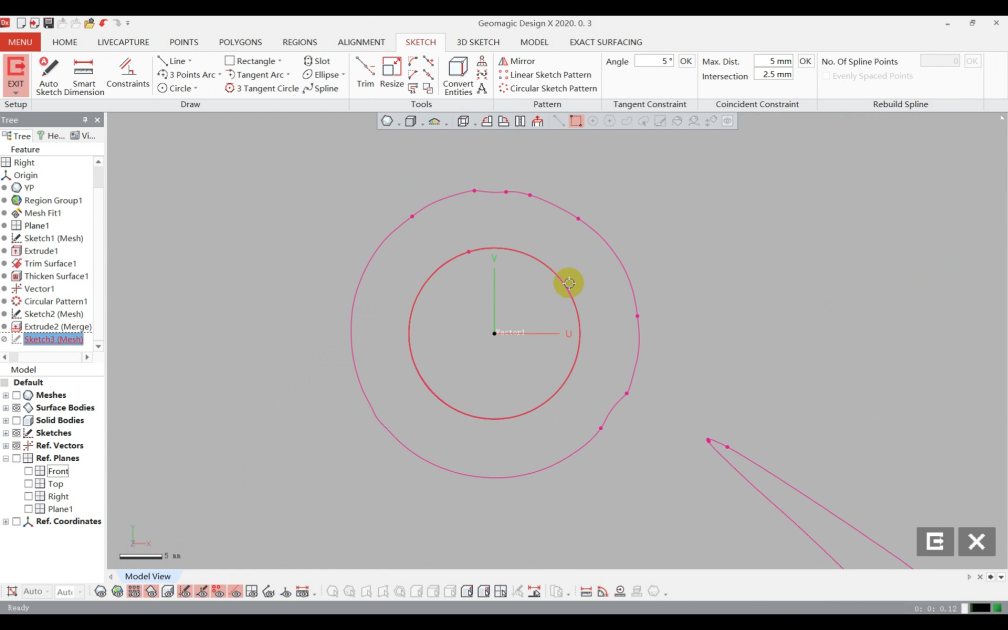

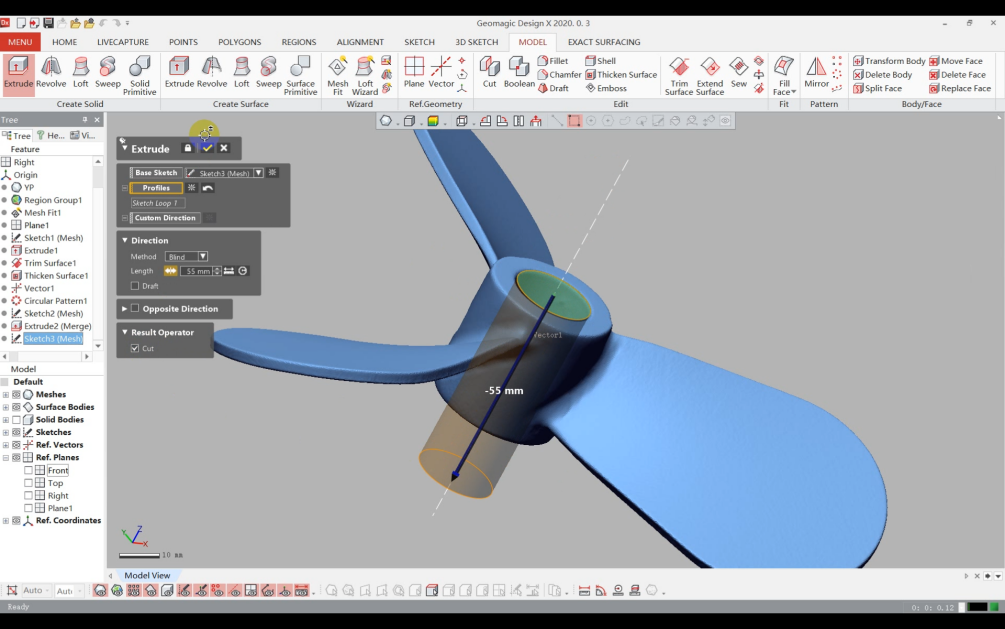

3) Use "Sketch" to draw the hub’s through-hole sketch.

4)Extrude the sketch and cut out the through-hole.

¶ (5)Fillet Edges:

Add fillets to edges as needed.

(6) Reverse Modeling Completed.