¶ 1. How to Scan Black/Reflective/Transparent Objects

How to Scan Black/Reflective/Transparent Objects

In daily scanning, we often encounter objects with challenging materials such as deep black (light-absorbing), reflective (light-reflecting), and transparent (light-refracting). These materials make it difficult for scanners to capture accurate model data. Below are solutions for each type:

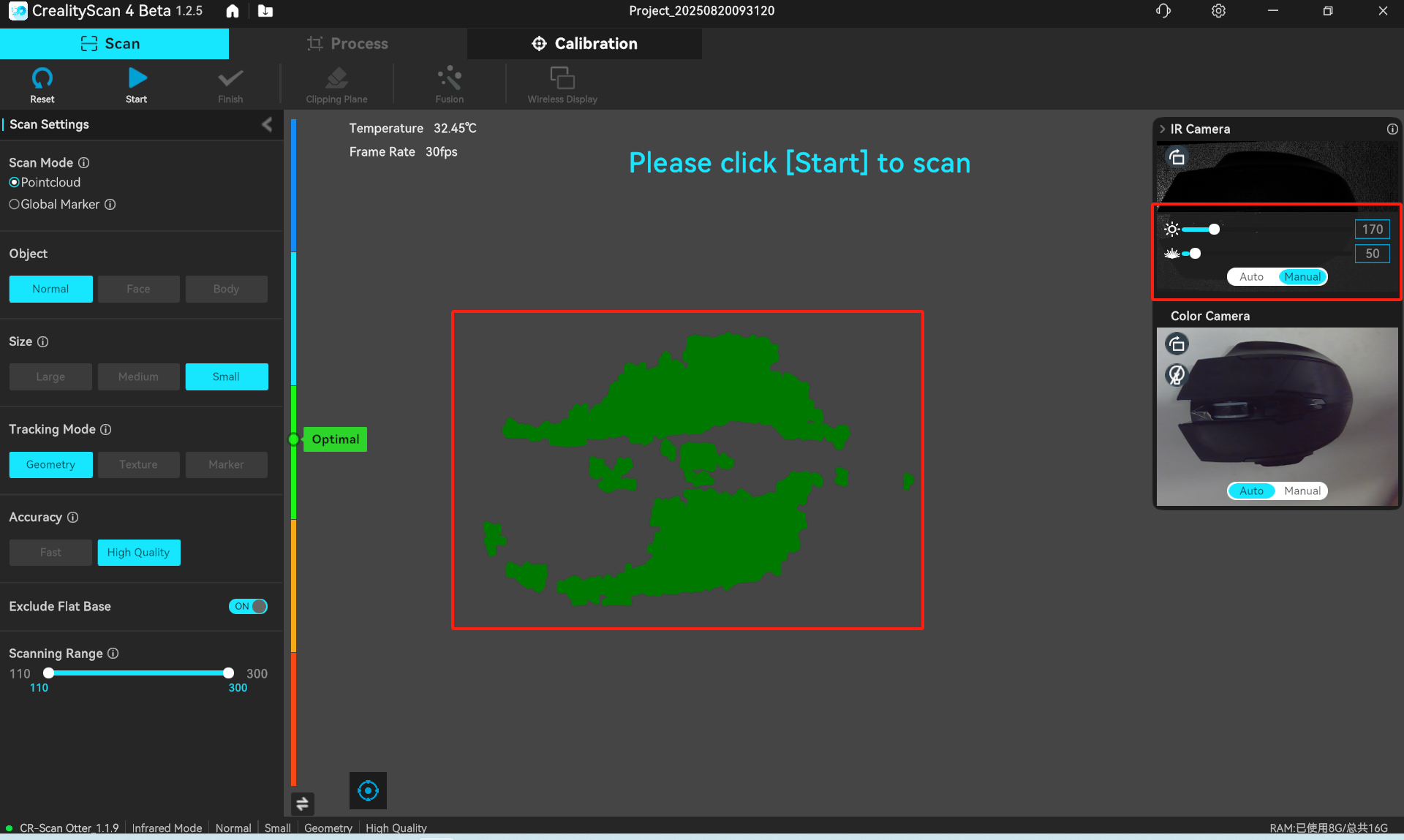

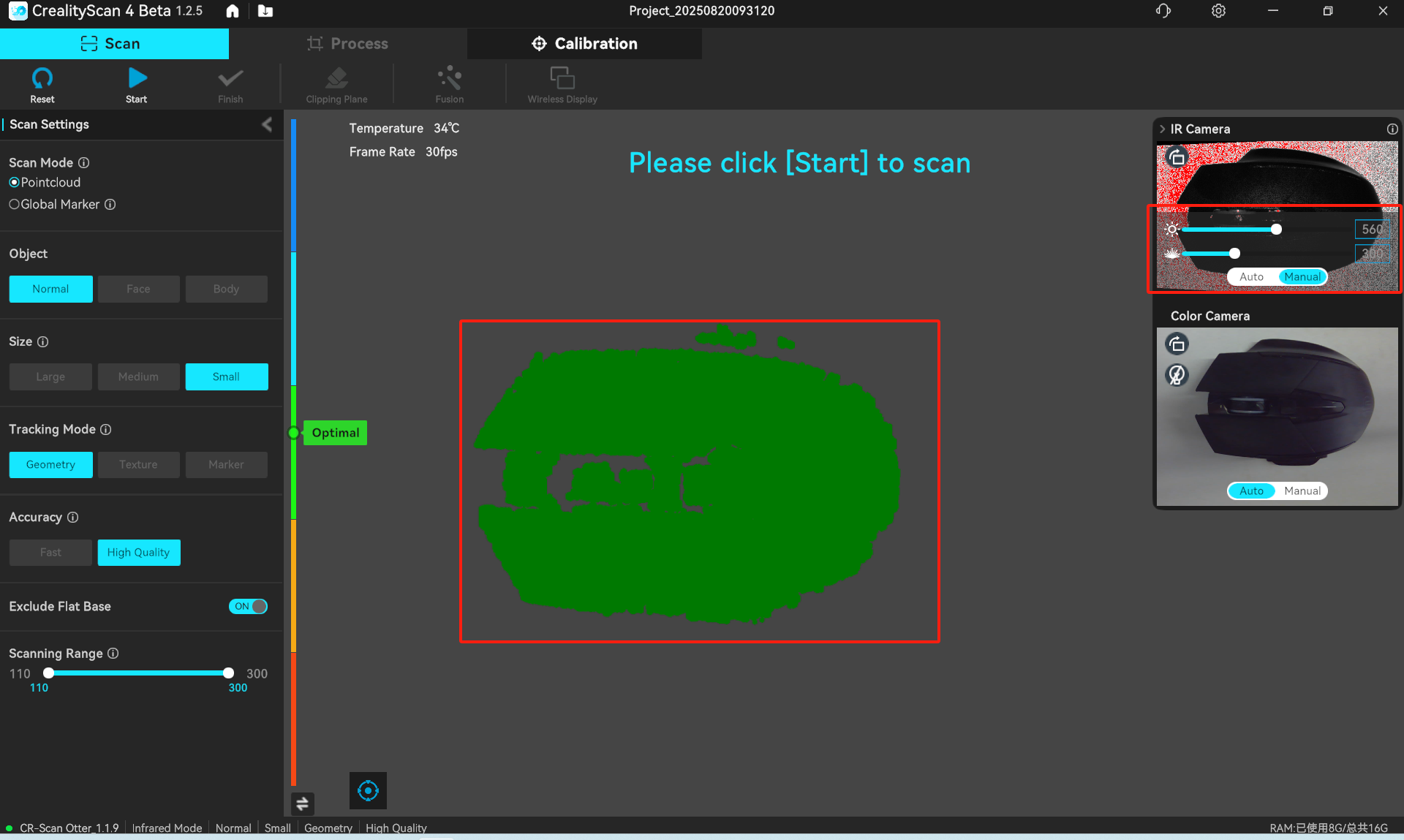

- Scanning Black Objects (e.g., Black Mouse)

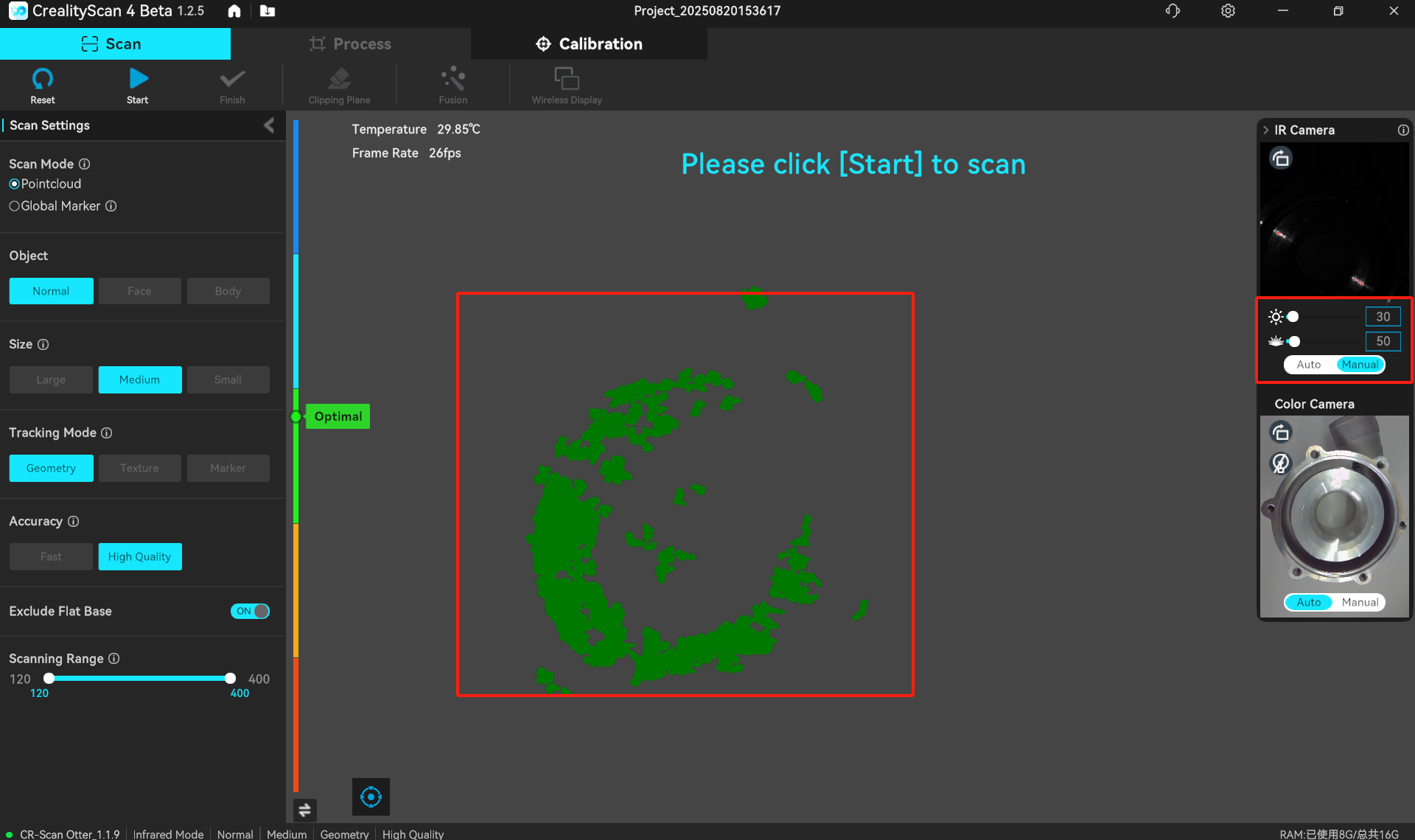

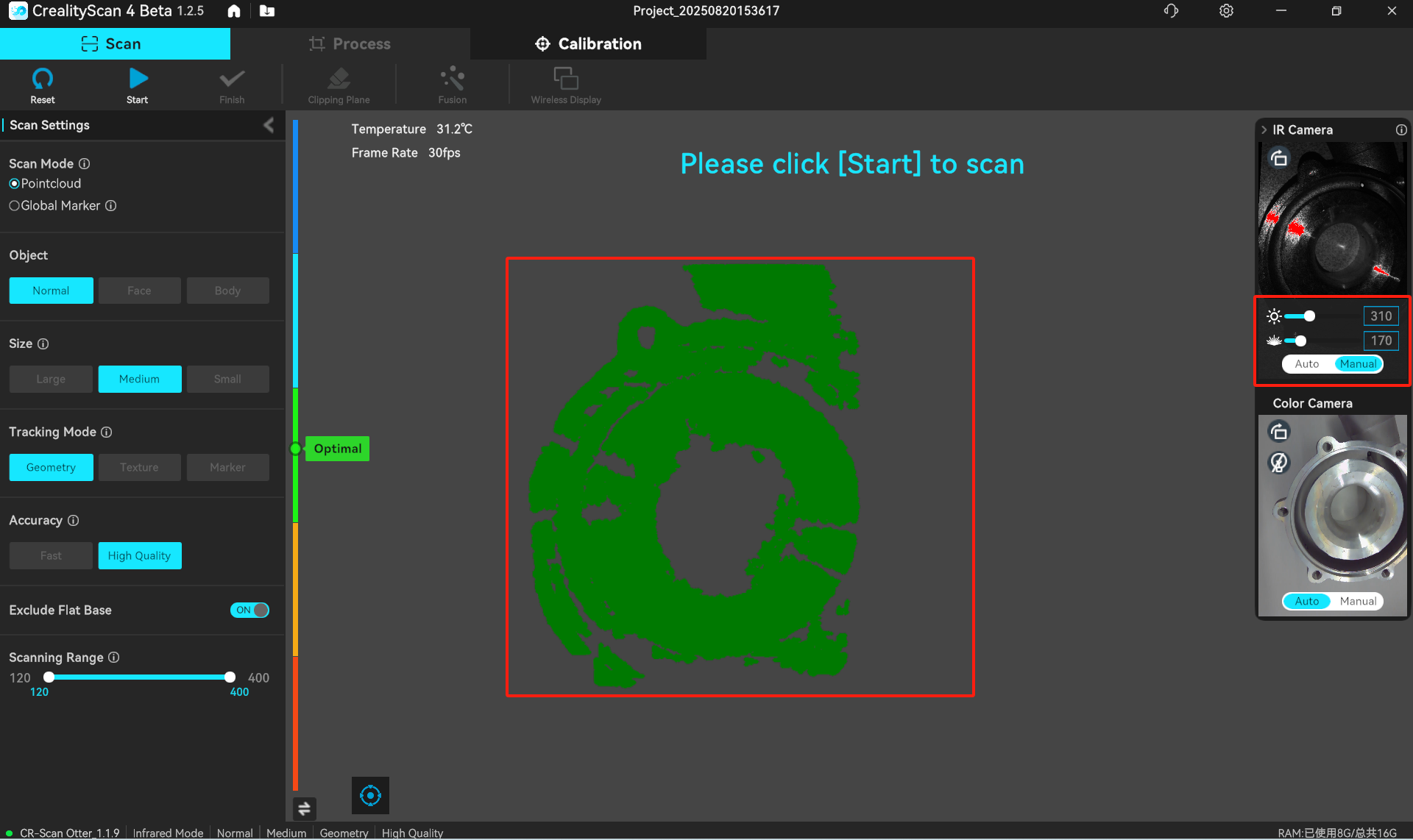

Infrared Mode:

Adjust the IR exposure until the previewed point cloud model is clear and complete.

Adjust the laser brightness until the laser lines in the preview are sharp and continuous.

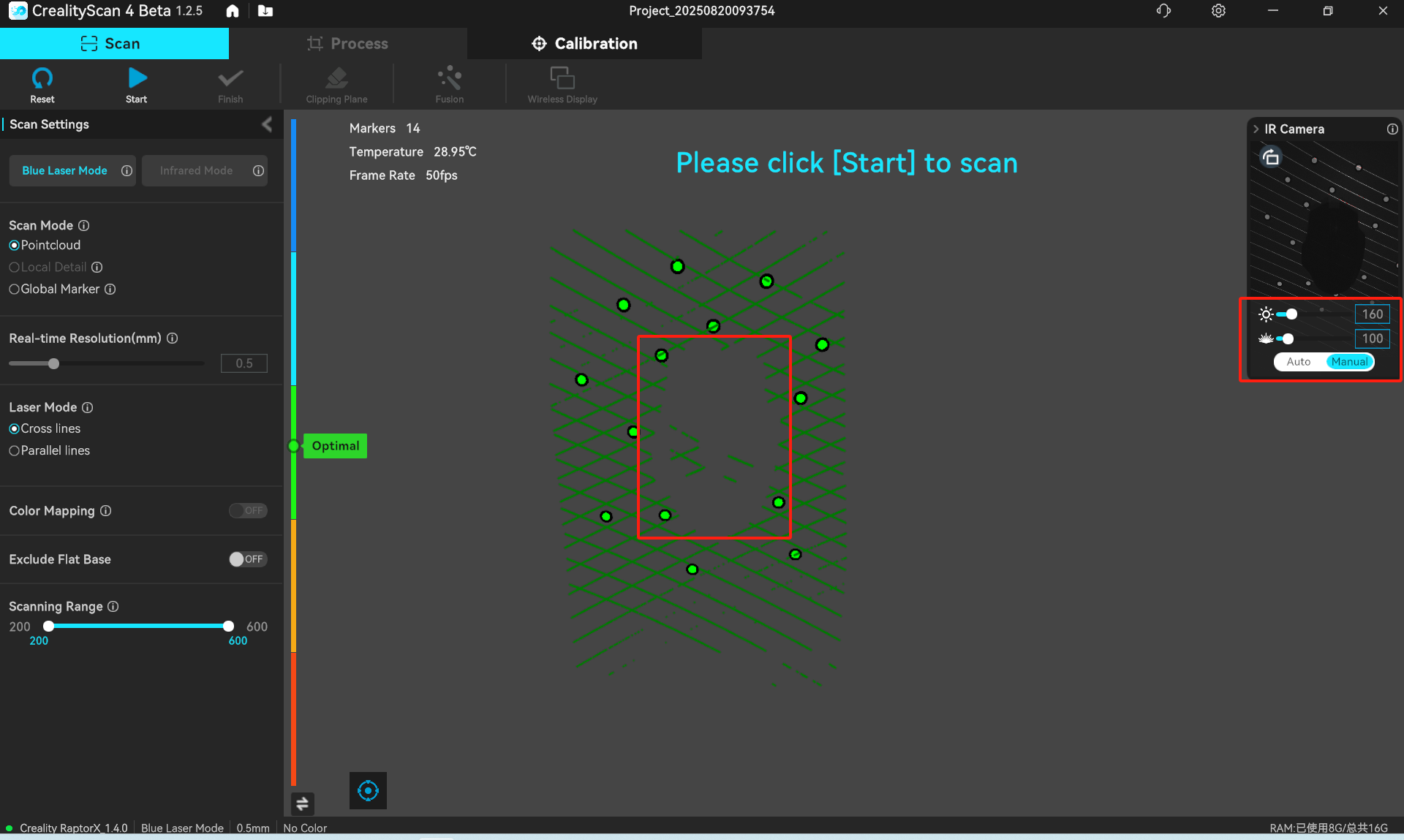

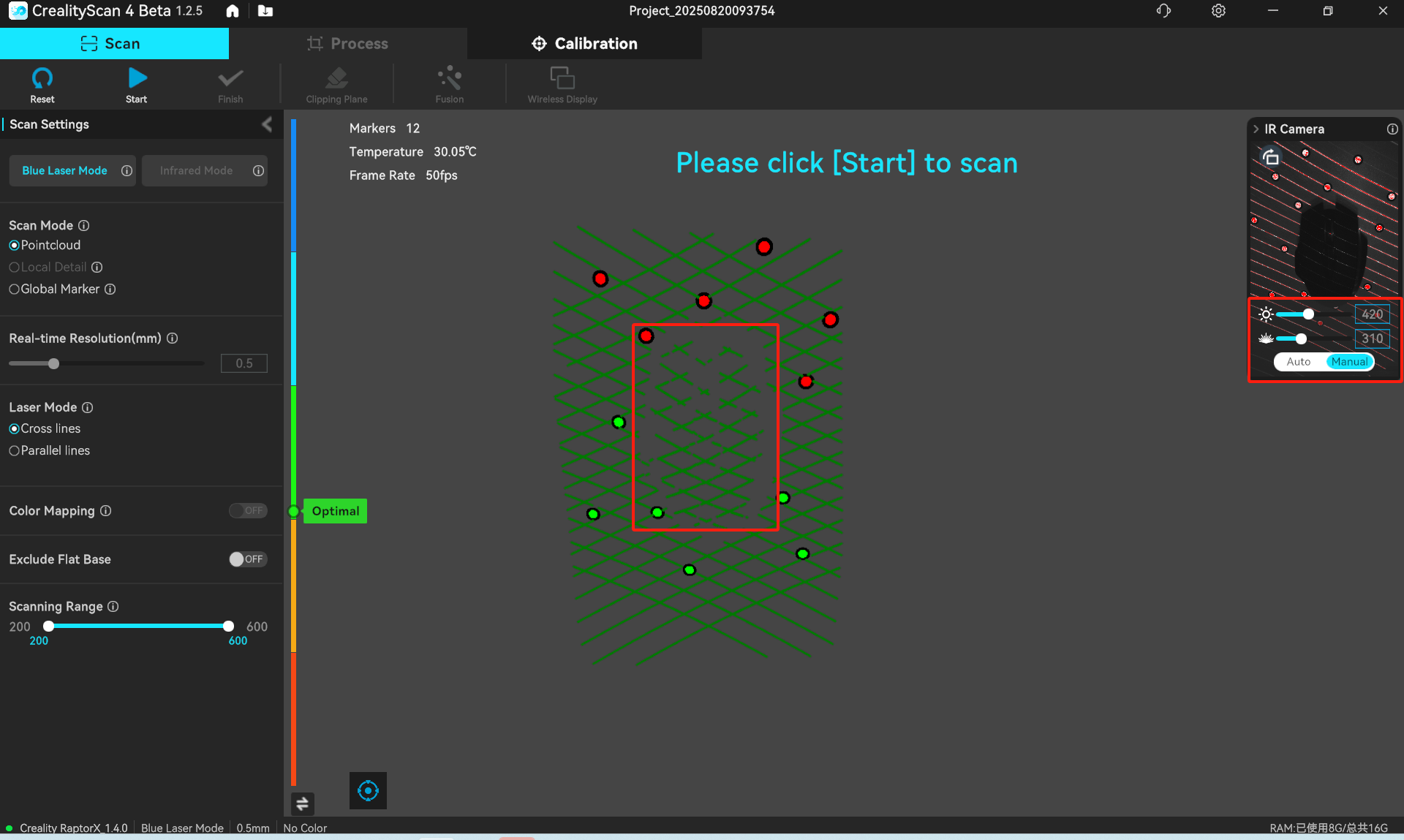

¶ 2.Scanning Reflective Objects (e.g., Metal Parts)

Infrared mode: try to adjust the IR exposure until the previewed point cloud model is clear and complete

In addition, you can adjust the scanning angle and try to scan reflective objects at different angles to minimize light reflection and reduce the impact of reflection

If the above methods cannot solve the problem, it is recommended to spray the object with powder (spray developer), which can effectively control light reflection after spraying.

Before powder spraying

After powder spraying

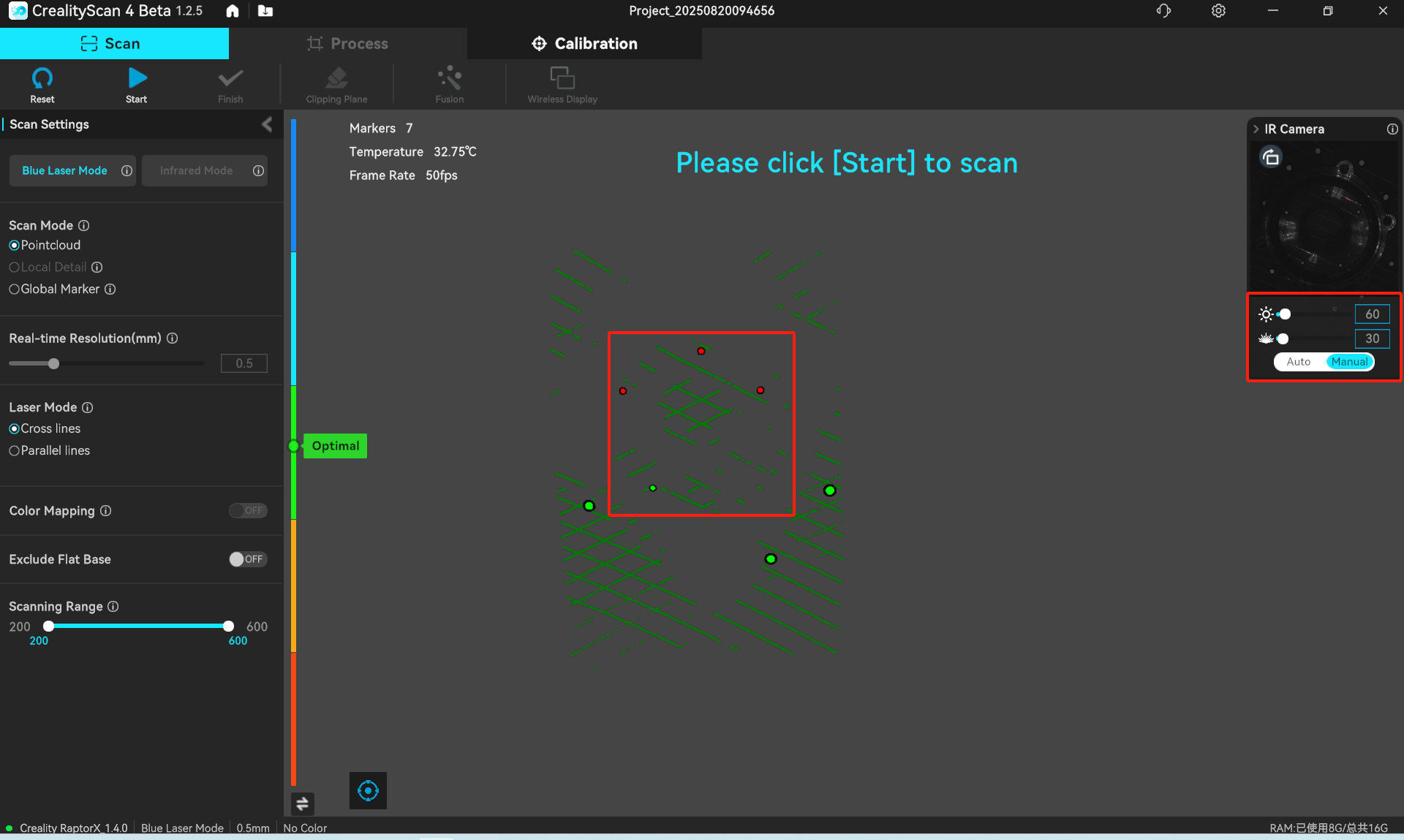

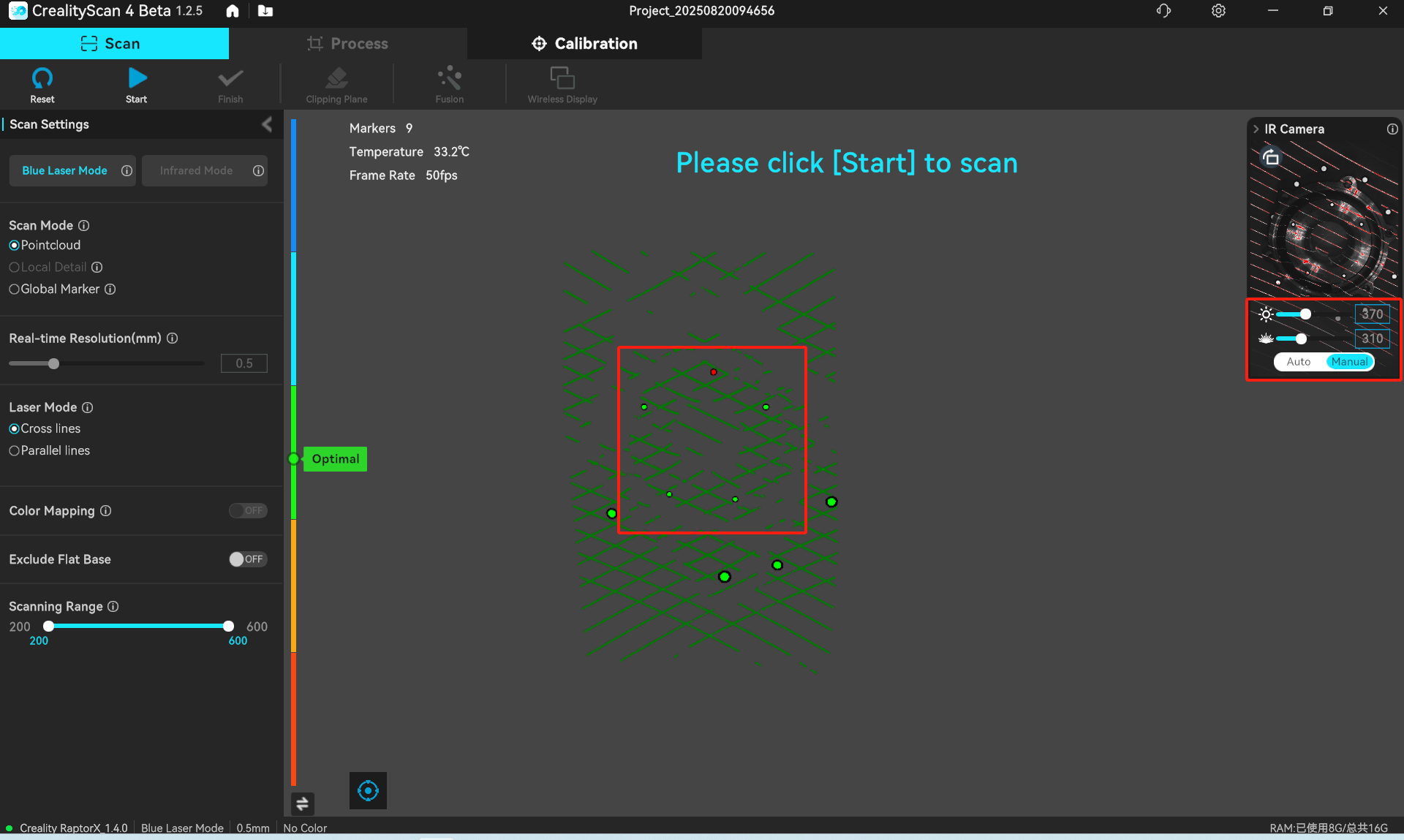

Laser mode: Adjust the laser brightness until the previewed laser lines are clear and continuous

¶ 3. Scanning method for transparent materials---Take transparent bottles as an example

Objects made of transparent materials must be sprayed with developer before scanning, because the light projected by the scanner will refract and penetrate on transparent objects, and the acquisition camera cannot capture it.

¶ Summary: When scanning these types of workpieces, if the scanning quality of the model is high, it is recommended to spray powder before scanning.

Steps for using developer: Take AESUB volatile developer as an example

- Clean the outer surface of the scanned part

- After fully shaking the developer, aim the nozzle at a distance of about 150mm-200mm from the scanned part, spray the surface evenly, and do not get too close or stop during the spraying process to prevent excessive spraying from causing sagging and affecting accuracy.

- Air dry for 2-3 minutes after spraying, and scan after the surface is dry.

- After scanning, the developer will automatically evaporate without residue.