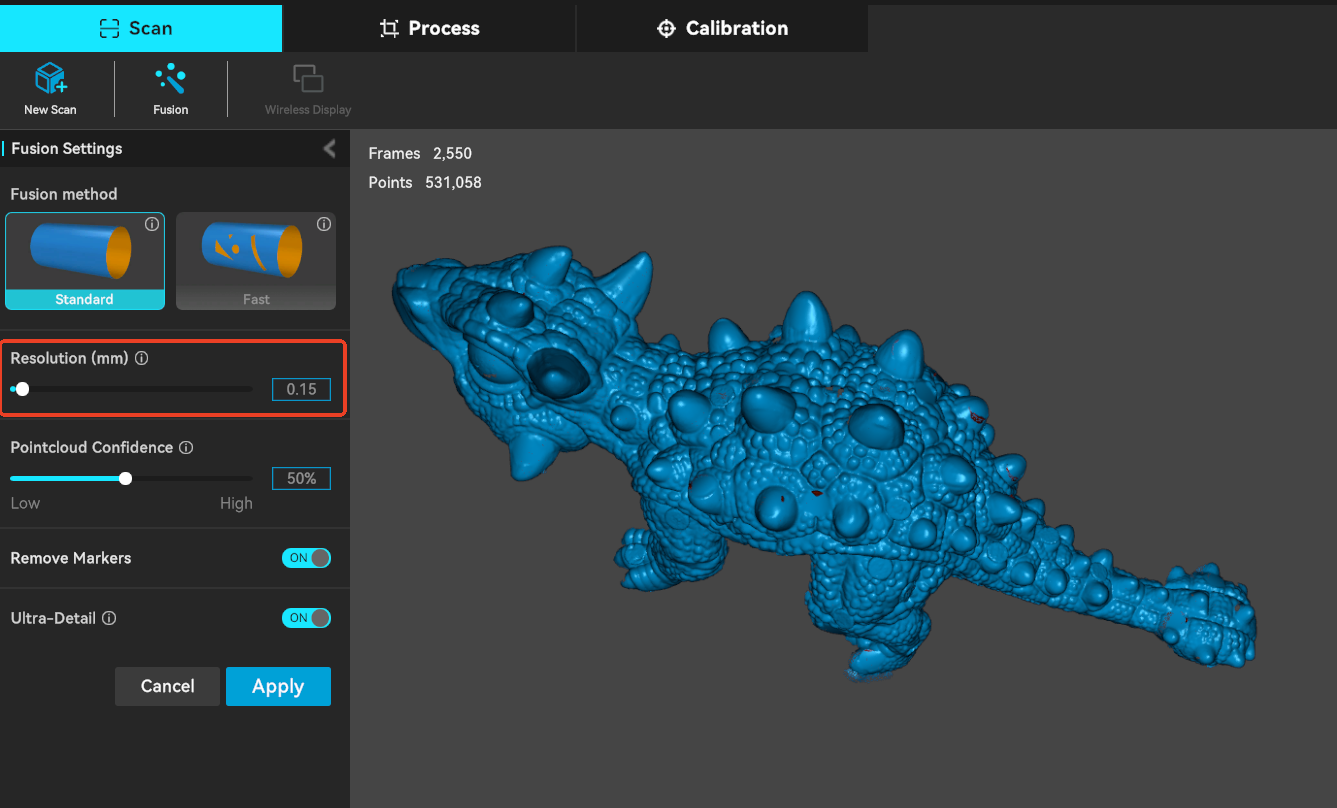

After the scanning, it is necessary to perform pointcloud fusion to fuse the scanned multiple frames of pointclouds (several hundred or even thousand frames) and obtain a higher quality pointcloud.

Resolution is one of the important parameters for this step. A smaller resolution setting will capture more details in the model but may require longer processing time. However, setting the resolution too small, such as 0.02mm, may result in missing parts of the model.

When dealing with smaller objects, such as those below 25cm, or when seeking better details, it is recommended to set the resolution to 0.1mm or 0.15mm. Using a resolution of 0.1mm, we can achieve sufficiently good detail for most objects.

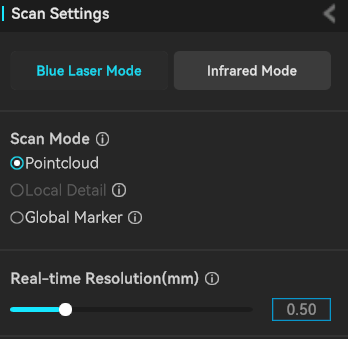

For laser scanning, the software requires users to set two resolutions: the resoluion in real-time scanning and the resolution in pointcloud fusion stage.

CrealityScan 4 offers two pointcloud fusion methods for laser line scanning: Standard and Fast. The Fast mode processes data more quickly and produces meshes with more accurate edges. The mesh obtained using the Standard mode tends to be more complete.

(1) Resolution in real-time scanning stage. The resolution primarily affects the quality of real-time scanning rendering and does not impact the final 3D model. The smaller the resolution, the finer the model rendered in real-time scanning, but it will consume more memory. For smaller objects, it’s recommended to set a smaller resolution. For instance, when scanning a 10cm part, you can set the resolution to 0.15mm. For larger objects, we suggest using a larger resolution for scanning. For example, when scanning a car door, you can set the dot pitch to 0.5mm.

For cross-line scanning, we recommend setting the resolution to above 0.2mm, as cross-line scanning is mainly used for medium to large objects.

If you use a large resolution for scanning, how can you achieve good detail? You can utilize the Local Detail Scanning function provided by the software. For example, first scan the entire object with a resolution of 0.5mm, then select the area where you need to enhance detail, and perform local detail scanning with a resolution of 0.1mm to obtain the geometric details of that area.

(2) Resolution in pointcloud fusion. It will directly impact the details of the final model. The smaller the point distance, the better the detail, but it requires more processing time and RAM. For most objects, a point distance of 0.1mm can achieve good detail. If a point distance of 0.02mm is used, the processing time and memory will increase sharply. For larger objects, it is recommended to use a larger point distance. For example, when scanning a car door, a resolution of 0.5mm can be used.

For cross-line scanning, we recommend setting the resolution to above 0.2mm, as cross-line scanning is mainly used for medium to large objects.

Confidence: The larger this value, the more points can be retained. The smaller the value, the more points will be filtered out.

The CrealityScan software allows users to perform pointcloud fusion multiple times. For instance, if you are not satisfied with the current results, you can modify the parameters and re-run the pointcloud fusion step.