We are excited to announce the official release of Creality Print 6.0! This update is designed to enhance user experience, offering smoother, more comprehensive, and more user-friendly features while significantly improving the quality of printed models.

¶ Enhanced Slicing Experience

¶ Significantly Improved Slicing Efficiency

Creality Print 6.0 has undergone software reconstruction and framework upgrades, greatly improving operating efficiency and resource utilization.

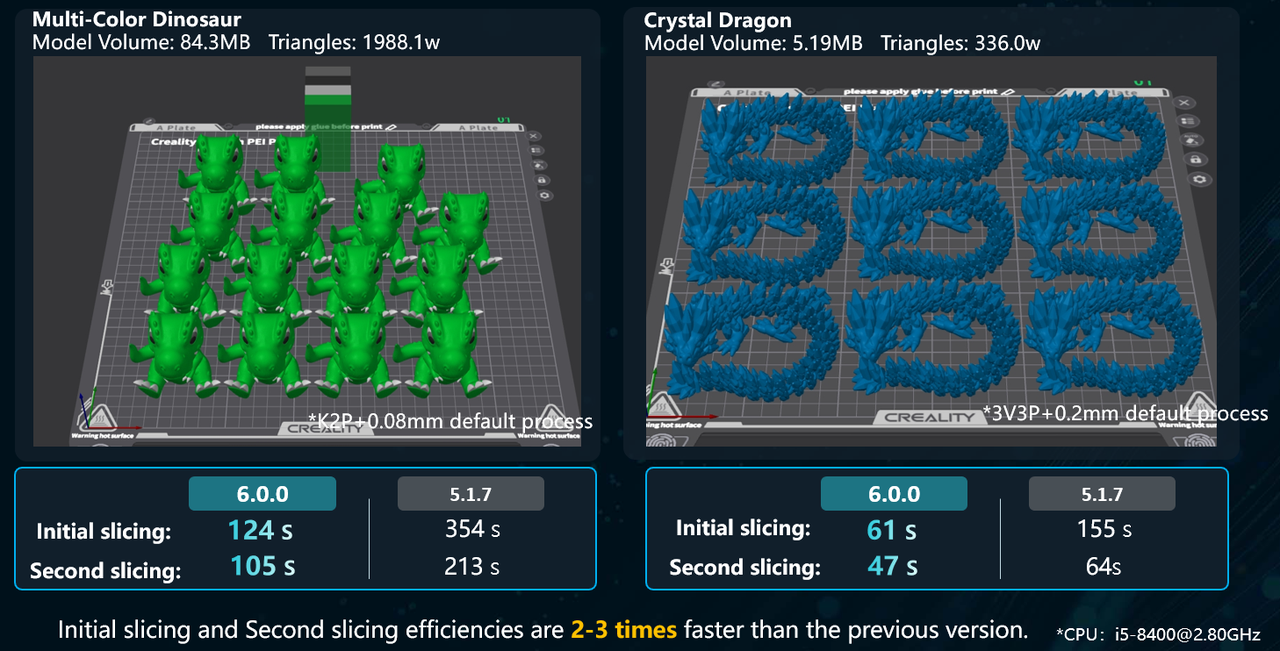

Testing shows that both initial and repeat slicing speeds have increased substantially compared to version 5.1.7. Initial slicing speeds are up by 10%-70%, while repeat slicing speeds are approximately 50% faster. The exact improvement depends on your computer configuration and model size.

For example, models like multi-color dinosaurs and crystal dragons now slice 2-3 times faster than in previous versions.

¶ Streamlined Workflow

Creality Print now enables users to complete the entire process of model acquisition, slicing, and printing in one platform, eliminating the need for frequent switching. A new “My Downloads” section has also been added, allowing users to easily view and manage all downloaded models and print configurations, significantly improving workflow efficiency.

¶ Comprehensive Management

¶ Manage All Machines in One Place

Over 100 new third-party printer models have been added, along with optimized corresponding filament and process parameters. Users can now select the desired printer, filament, and process for “one-click printing.”

Additionally, the newly added Fluidd connection allows users to manage all their printers through one interface, reducing the hassle of switching between different programs.

¶ Clear Preset Relationships

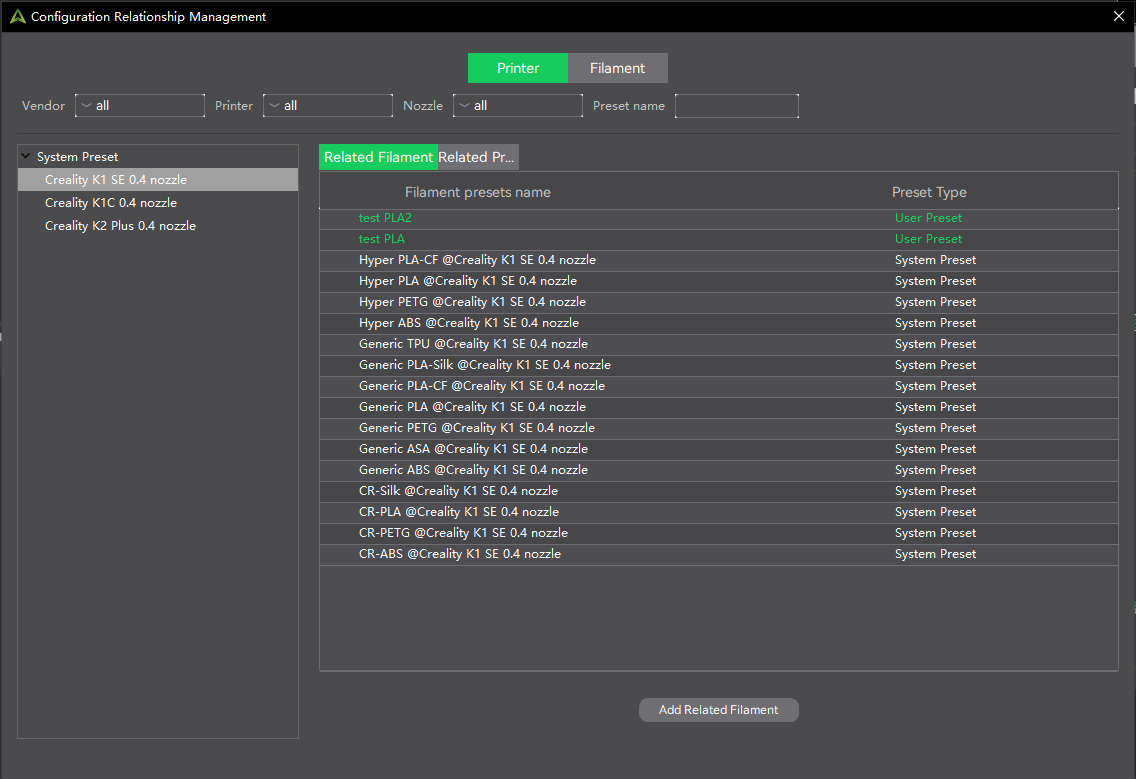

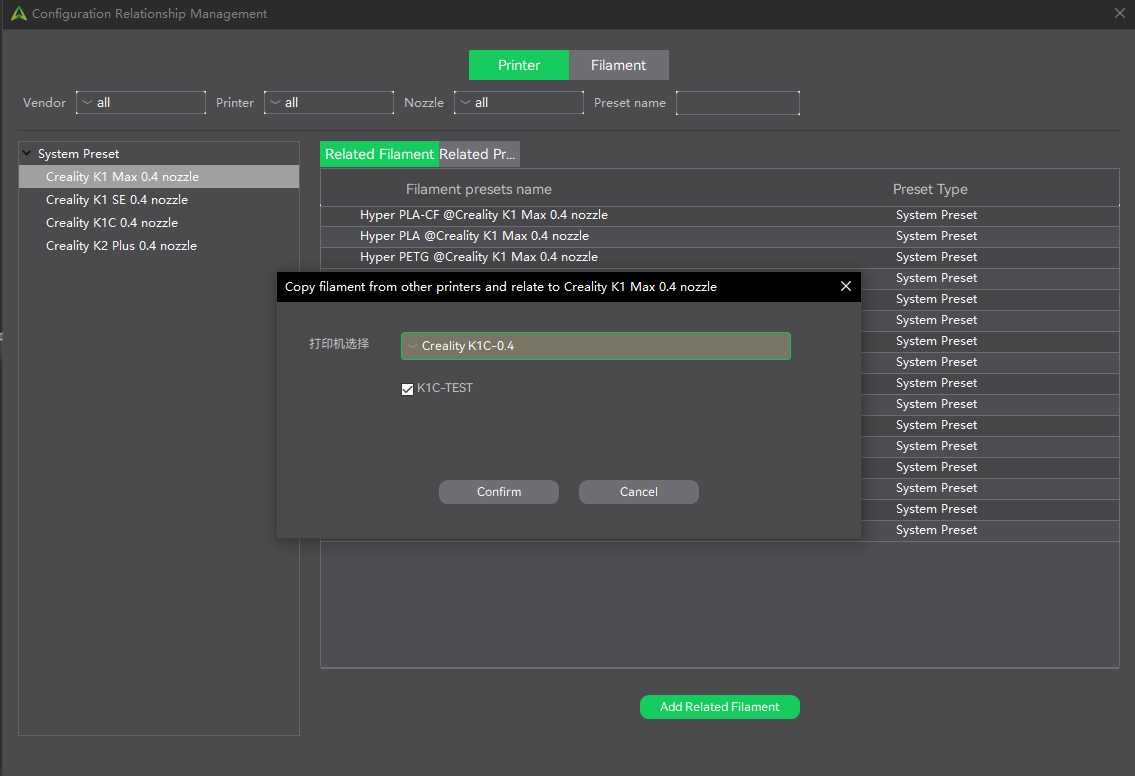

Users can now view and manage the relationships between their printer, filament, and process profiles in one place.

Previously, transferring optimized filament or process parameters between similar printer models required manual recording and reconfiguration—a tedious and error-prone process. The new “Add Related Filament” and “Add Related Process” features solve this issue, enabling users to quickly copy optimized settings from one printer to another, improving efficiency and reducing errors.

¶ Superior Print Quality

¶ Refined Print Quality

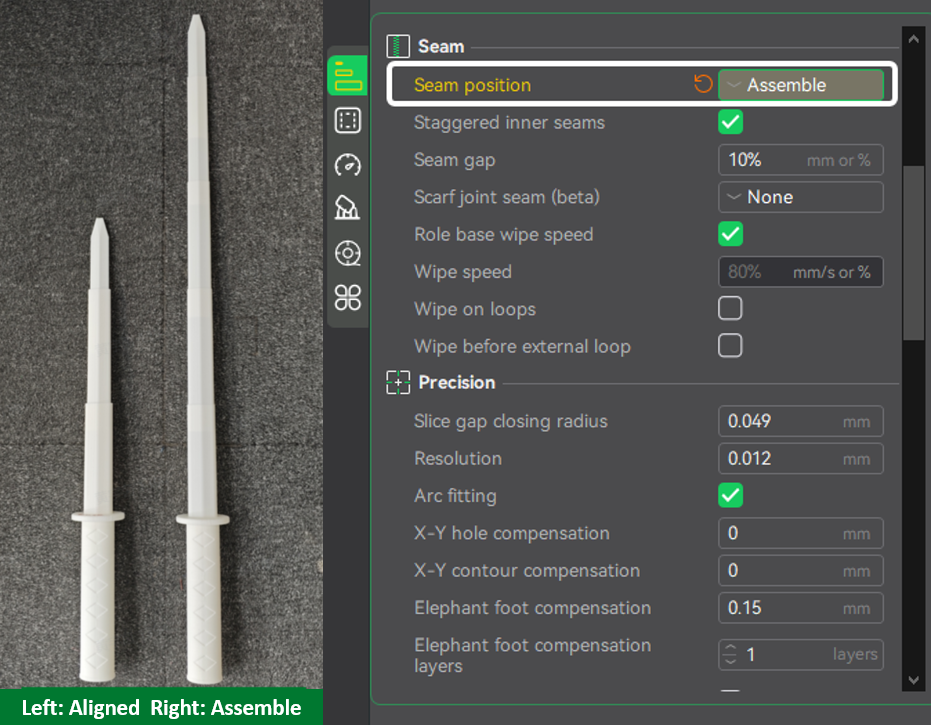

¶ Z-Seam assemble Mode

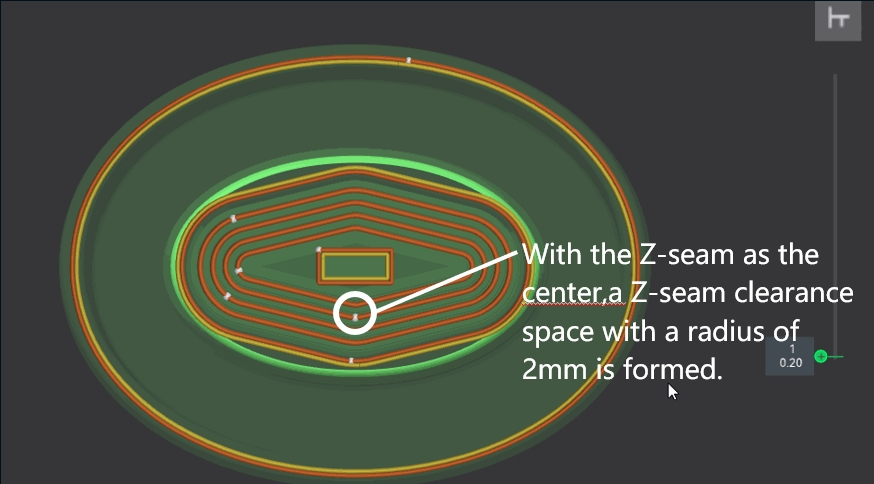

When making print in place (PIP) models like extendable swords, users often encountered issues with Z-seam adhesion, preventing smooth operation. To address this, the “Assemble” option has been introduced. Enabling this feature adds a clearance zone (2mm radius) around Z-seam points, preventing overlap and ensuring proper model functionality.

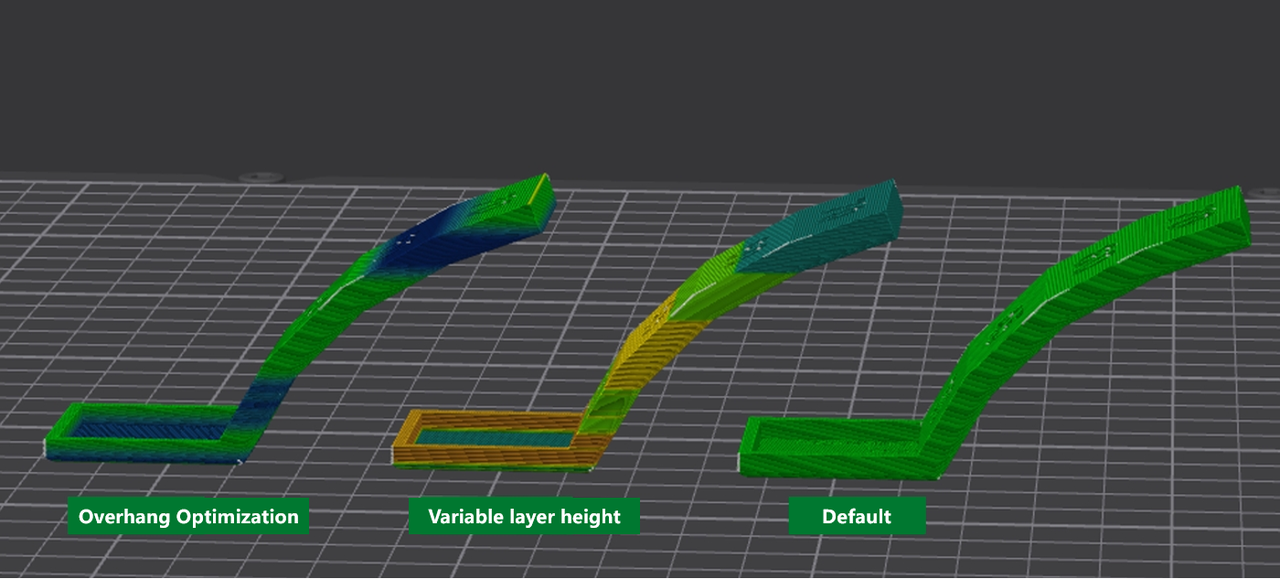

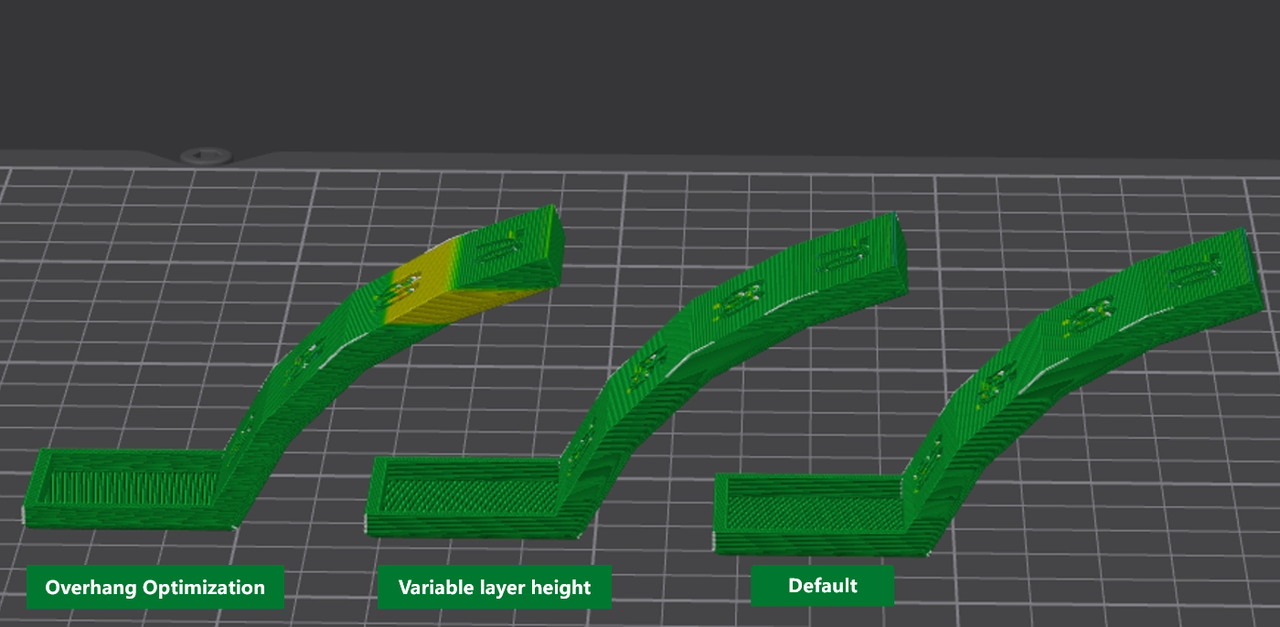

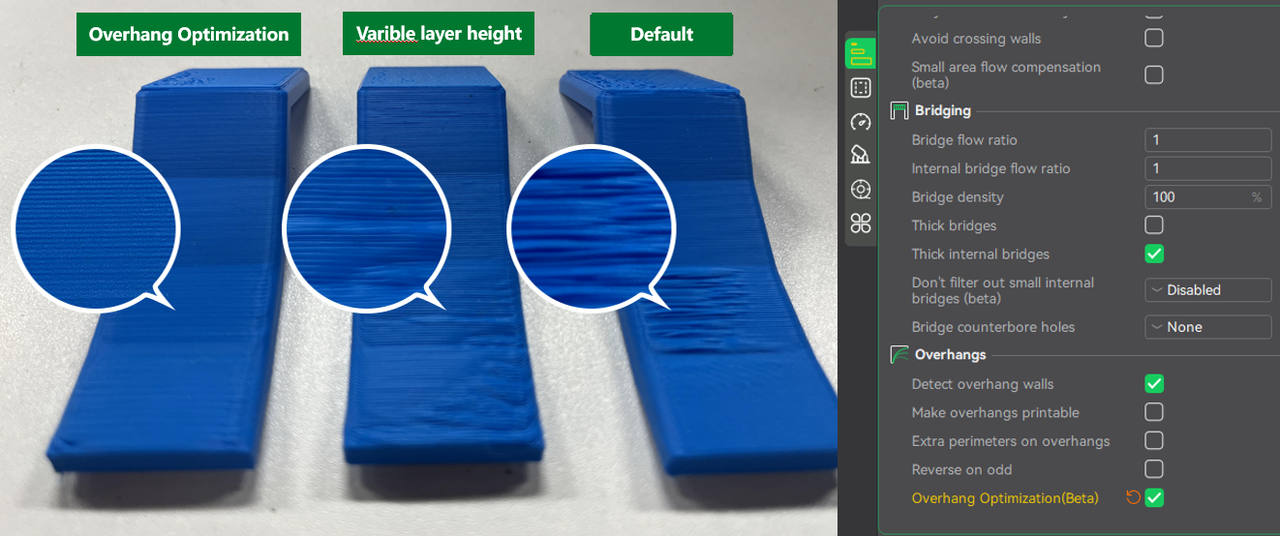

¶ Overhang Optimization (Beta)

A new “Overhang Optimization(Beta)” feature has been added, which automatically identifies overhang areas and adjusts layer height and line width for improved print quality. This feature is enabled with a single click, delivering optimal overhang performance.

¶ Accurate Printing Targets

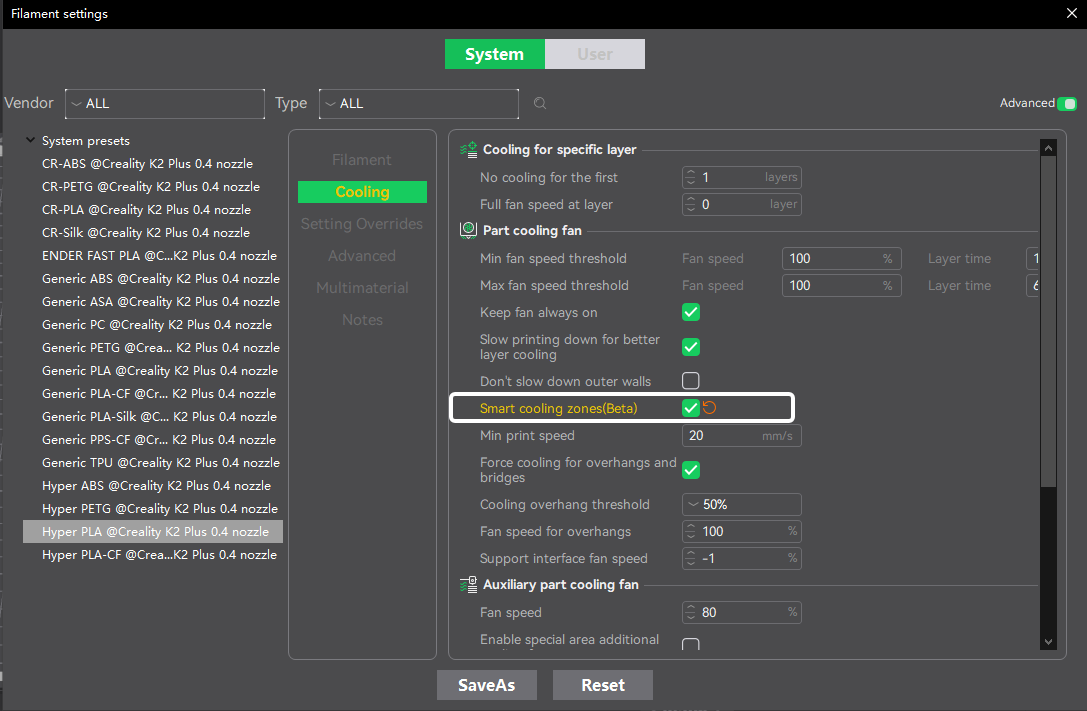

¶ Smart Cooling Zones(Beta)

This feature analyzes the geometry of a model and automatically disables cooling slowdowns for layers where it isn’t necessary, significantly reducing printing time while maintaining quality.

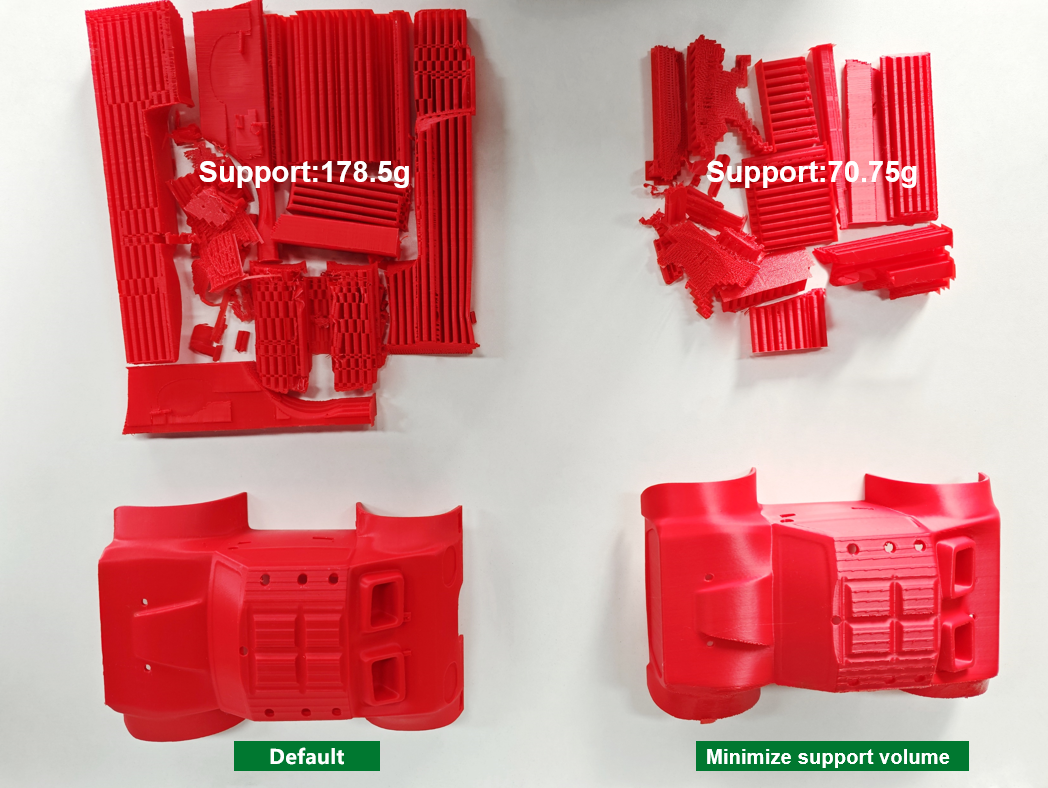

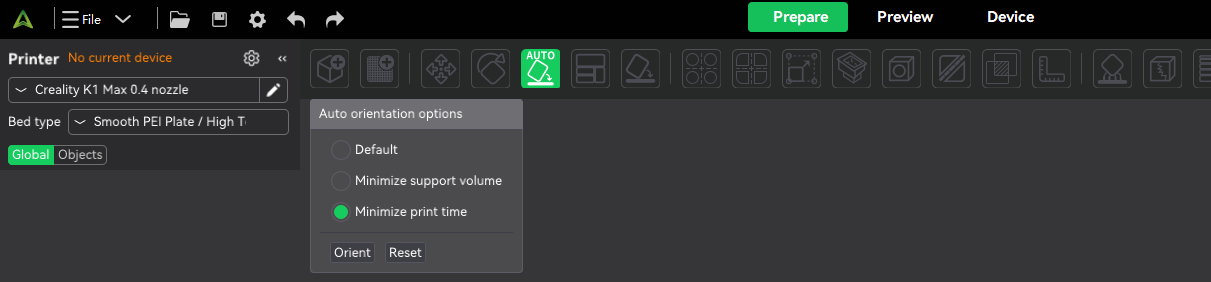

¶ Auto Orientation

Previously, users had to manually adjust model orientation to reduce print time or support usage, often with suboptimal results. The new Auto Orientation feature uses intelligent algorithms to optimize either print time or support volume with a single click.

- Minimize print time: For example, reduces print time by 24.1% compared to default settings.

- Minimize support volume: For example, reduces support volume by 60.36%.

¶ Stronger Printed Models

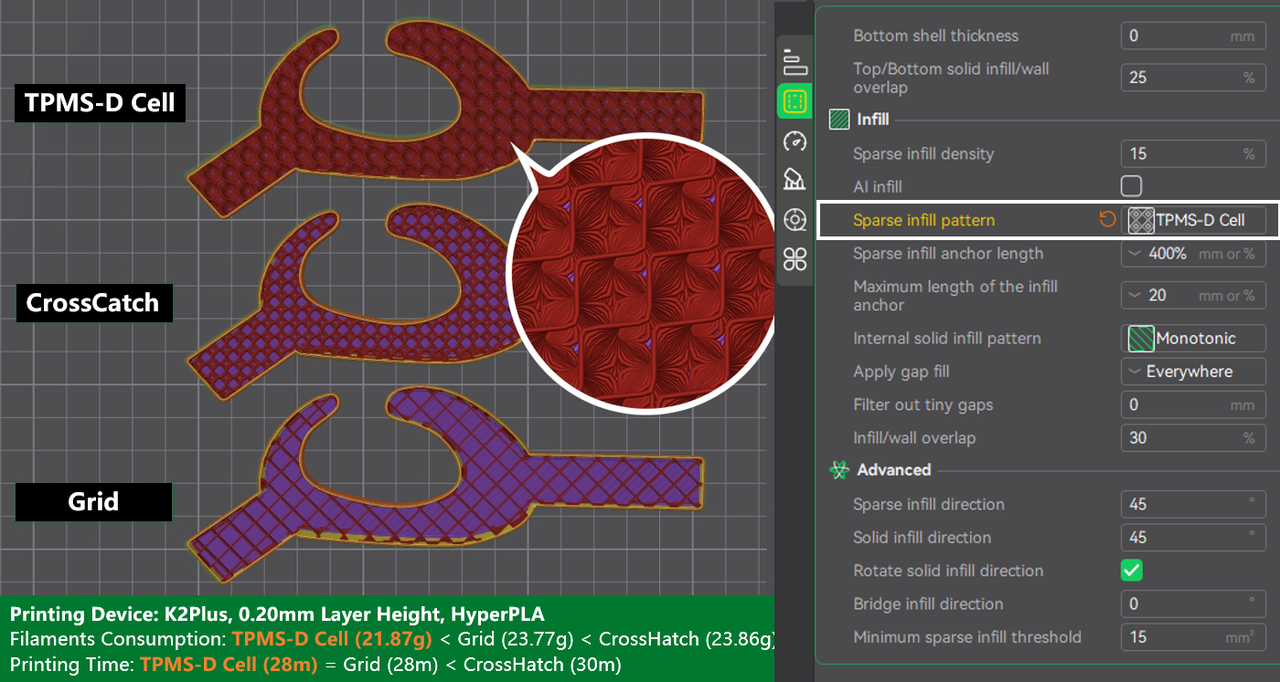

To address the challenges of balancing strength, print time, and filament usage, Creality Print introduces the TPMS-D Cell infill pattern.

Compared to traditional CrossCatch or Grid infill patterns, the TPMS-D cell provides tighter structures while consuming less filament and reducing print time, thanks to its advanced geometric design.

For example, this pattern reduces filament consumption and shortens print time compared to cross-layer infill.

¶ Enhanced User Experience

¶ Auto-Sync User Presets

Users can now enable the “Sync User Presets” option in Preferences. Once activated, all user-created presets are automatically synced to Creality Cloud. When switching devices, simply log in to your account and enable this option to retrieve all your presets.

Additionally, you can view synced presets in the “My Presets” section, complete with details like upload times and modified parameters for easy management and tracking.

¶ Slice and Print Anytime, Anywhere

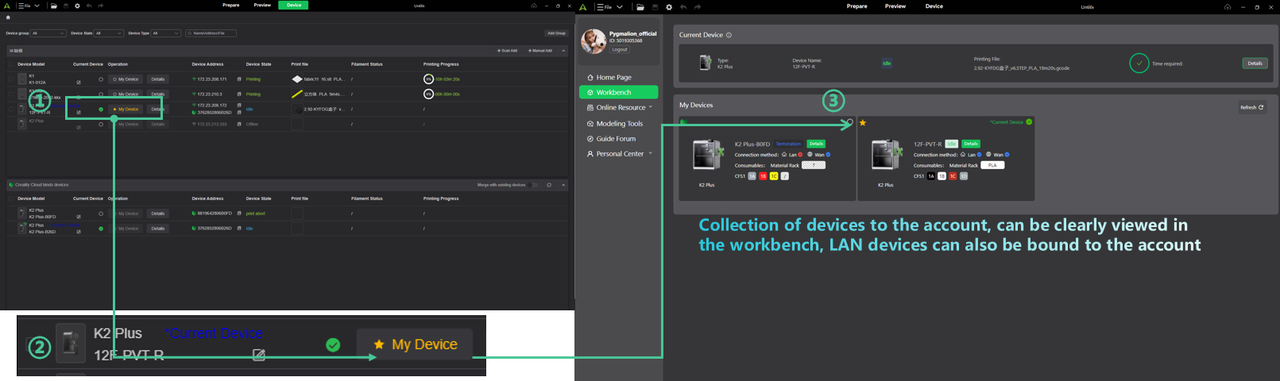

With the ability to manage local and remote devices in one user interface, users can enjoy stable LAN/Wifi printing at home and convenient Creality Cloud printing while on the go. With added remote monitoring, we're combining stability, flexibility and security.

¶ Easily Track Your Devices

Users can now mark their most-used devices as favorites, displaying them on the workbench for quick access. Favorite devices are synced across accounts, eliminating the hassle of switching computers.

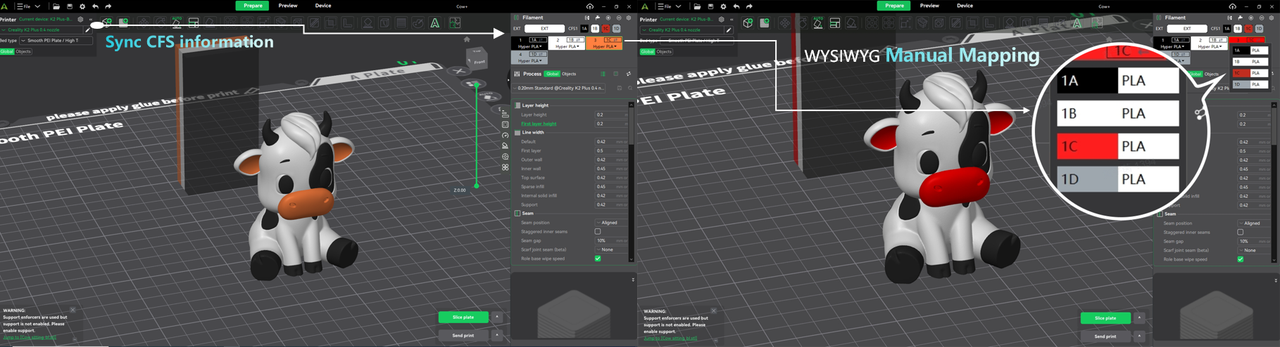

¶ Simplified Multi-Color Printing

Previously, filament colors and types were automatically mapped to models, often overriding original colors. The new Manual Mapping feature allows users to manually assign or modify model colors when using multi-color printers.

¶ Other Updates

Additional new features include:

- Embedded Community: Added badge customization, tutorial guides, and optimized online resources and personal center content.

- Custom Presets: Added user mode switching, printer/nozzle creation, and filament creation, with an improved interface for editing printer and filament presets.

- Print Quality Improvements: Added parameters for overhang area size, support distance priority selection, hybrid tree-cross supports, monotonic support contact patterns, surface ironing, travel lift angles, and ignore internal colors.